MAMC2018: Vienna hosts ASMET’s third Metal Additive Manufacturing Conference

The third Metal Additive Manufacturing Conference (MAMC2018), organised by the Austrian Society for Metallurgy and Materials (ASMET) and voestalpine, took place in Vienna, Austria, from November 21–23, 2018. The event, which attracted an international audience, covered a broad range of metal AM technologies and considered the technical challenges that need to be overcome to make the industry more economically competitive with conventional manufacturing. Prof Dr Bruno Buchmayr, Dr Bruno Hribernik, Dipl-Ing Gerhard Panzl and Prof Dr Jürgen Stampfl review the event for Metal AM magazine. [First published in Metal AM Vol. 5 No. 1, Spring 2019 | 15 minute read | View on Issuu | Download PDF]

The third Metal Additive Manufacturing Conference (MAMC2018), organised by the Austrian Society for Metallurgy and Materials (ASMET), Leoben, Austria, and voestalpine, Linz, Austria, saw more than 220 international participants meet in Vienna, Austria, from November 21–23, 2018, to discuss current topics relating to metal AM. The event’s growth, up from 150 participants at MAMC2014, clearly reflects the growing interest in this field. The MAMC2018 conference programme saw forty-six oral presentations given on topics relating to recent developments in materials, processes, applications and business in the metal Additive Manufacturing industry. In addition, a co-located exhibition showcased many of the most recent industrial developments in the field.

The worldwide market for AM-related products and services has seen significant growth in the past year, with overall revenues growing to $7.5 billion according to The Wohlers Report. Of specific interest is the significant increase in the number of metal AM machines sold. As reported by Wohlers, sales grew from 980 machines in 2016 to over 1,750 systems in 2017. Since such systems are typically used in industrial settings, this increase is an encouraging sign of the industrial uptake of the technology.

The continued development of AM within the Austrian market was demonstrated in the first plenary talk at MAMC2018. In their talk, ‘Challenges of Additive Manufacturing in High Performance Markets,’ Stefan Seidel, Managing Director, Pankl Racing Systems, and Dr Michael Rotpart, member of the management board of voestalpine Böhler Edelstahl, gave an insight into the integration of AM in an industrial setting. Pankl and voestalpine both see significant benefits in the use of metal AM for high-value added products in fields like aerospace, mechanical engineering and energy.

The companies are currently involved in a cooperation based out of the Pankl Additive Manufacturing Competence Center (PAMCC) in Kapfenberg, Austria, which looks to develop the complete value chain and push the limits of Additive Manufacturing in order to establish the technology as an effective production method within the challenging fields of aerospace and high-performance automotive. The speakers brought up critical issues for these fields which need to be targeted if AM is to become a reliable and widely-used industrial production solution, such as the requirement for ‘zero failure tolerance’ in critical applications.

Metal AM process developments

Optimising existing processes

A number of metal AM processes were covered during the conference, with the widest-used being Laser Powder Bed Fusion (L-PBF). Prof Bruno Buchmayr, formerly Head of the Chair of Metal Forming at Montanuniversität Leoben, presented the ‘Results and conclusions on metallic materials made by AM within the Austrian leader project “addmanu”.’ The project, sponsored by The Austrian Research Promotion Agency (FFG), ran over a period of three years from 2015–2018 and involved more than twenty research partners. It incorporated aspects of the design, processing and applications of additively manufactured metal, polymer, ceramic and hybrid material components.

Focusing on metal AM, Buchmayr presented the project’s conclusions on new powder materials, hybrids, topology optimisation, joints between dissimilar materials, the fabrication of small channels and surface modifications using AM. Regarding potential application fields, demonstrator examples were shown for mechanical engineering, injection moulding tools, lightweight automotive components, nozzles for aerospace technology and composites with special properties produced for satellites. Those materials evaluated by the project are now being commercialised by voestalpine Böhler Edelstahl, and the project team was also said to have demonstrated that high-performance metals, such as hybrid systems with high thermal conductivity, can be processed by L-PBF.

In a talk titled ‘Digital photonic production along the lines of Industry 4.0,’ Prof Dr Reinhart Poprawe, Fraunhofer Institute for Laser Technology (ILT), Aachen, Germany, pointed to the importance of throughput, process control and cost-effectiveness for the further development of the field, stating that processes such as Laser Metal Deposition (LMD) and multi-beam L-PBF will play an important role in this context. In addition, Poprawe noted the importance of material innovations for the further development of metal AM (Fig. 2).

Richard Görgl, Joanneum Research, Niklasdorf, Austria, focused on ‘LMD as a complementary technology to Selective Laser Melting (SLM).’ Because LMD is, in principle, a welding process, it was stated that parts manufactured using the technology have high hardness, density, Young’s modulus, etc. Görgl looked at the technology’s applications and capabilities in laser cladding, repairing and reshaping and Additive Manufacturing, comparing the strengths and limitations of the technology against those of L-PBF for component production.

Fused Filament Fabrication (FFF) was addressed by Dr Christian Kukla, from Montanuniversität Leoben’s Industrial Liaison Department, in his presentation ‘Material extrusion with filaments for the production of metal parts and feedstock.’ FFF can be used to shape parts with feedstocks similar to those used in Powder Injection Moulding (PIM), resulting in the production of green parts which must be debound and sintered. The use of filaments imposes a strict set of requirements on the feedstock, such as the flexibility to be spooled, stiffness to avoid buckling and a constant diameter to ensure a consistent mass flow. However, it also enables the use of a wide range of metal powders, which are already available in the market, and employs the already established and standardised process of sintering, resulting in a homogeneous microstructure. During his presentation, Kukla offered his insight into the available powders, feedstocks, equipment and respective processing parameters for FFF, along with a number of examples of part shrinkage rates, densities, surface quality and other mechanical properties.

Developing new processes

Looking at the development of new processes, Dr Michael Kitzmantel of RHP-Technology GmbH, Seibersdorf, Austria, introduced ‘XL multi-material AM using an economic blown powder process,’ in which a plasma transferred arc system is used as a heat source in combination with powder feeding for the production of parts. Kitzmantel offered examples of how the technology can be used to manufacture parts from different materials, such as titanium alloys, iron-based alloys and nickel-based alloys, and the capability of the technology to produce multi-material components and gradient structures when two powder feeders are used simultaneously.

Gerald Mitteramskogler, Lithoz GmbH, Vienna, Austria, presented the first results achieved with a new process known as Lithography-based Metal Manufacturing (LMM), in which a photopolymer filled with metallic particles is selectively cured with a light engine based on digital light processing (Figs. 3-4). In his paper, ‘Lithography-based Additive Manufacturing of functional metal components,’ Mitteramskogler compared LMM to Metal Injection Moulding (MIM), in that both technologies require debinding and sintering in the green state and achieve similar relative densities (up to 98.5%). Mitteramskogler stated that LMM enables the production of highly complex parts in 316L, to good geometrical accuracy and with a very low surface roughness, resulting in mechanical properties comparable to conventionally manufactured 316L.

Post-processing of AM parts

Methods for post-processing and quality assurance were also discussed in detail during the conference. In a paper titled ‘Surface engineering for parts made by Additive Manufacturing’, Markus Hatzenbichler, Fotec, Vienna, offered insight into the surface engineering of stainless steel and titanium parts produced by L-PBF and Electron Beam Melting (EBM), demonstrating that surface properties such as roughness can have a significant influence on the mechanical properties of a part, especially when parts are loaded dynamically.

For the L-PBF process, AlSi10Mg, SS316L and Ti64 powder were used on an EOS M280 machine and, for the EBM process, only Ti64 powder was used on an Arcam Q20 machine. In general, the ‘as-built’ surface roughness of AM parts is rather high compared to conventional milled parts and, due to the powder bed process, semi-molten particles are always attached on the side surface. In this project, various (abrasive or coating) surface treatment technologies like shot peening, (electro-)chemical polishing or anodisation were applied and analysed in order to make a proposal for the most promising surface finishing scenarios, consisting of different treatments.

Lowering the surface roughness was not the only important aim; other issues, such as the geometry of the sample, surface quality in terms of particles and cracks or similar roughness on the top and side surfaces, have to be considered in space applications. To determine the impact of the chosen surface finishing scenarios, SEM images of the surfaces were taken and mechanical properties such as tensile strength and fatigue of the ‘as-built’ and surface treated parts were measured and compared. Furthermore, the stress corrosion cracking behaviour was analysed.

Developments in metallurgy for AM

To be successful in their application, metal AM parts must possess comparable mechanical and technological properties to conventionally fabricated components. Achieving these properties involves the whole process chain, from powder production to post-processing. A number of the presentations given at MAMC2018 addressed these topics, from powder production and characterisation to process optimisation and control, as well as the development of new alloys.

Speaking on ‘The application of powder rheology for AM powders’, Gerhard Panzl, Montanuiversität Leoben, looked at the impact of feedstock properties on L-PBF process control and part quality and the important role played by powder rheology in understanding the behaviour of new and recycled metal powders. Since the costs of powder materials are a significant factor in the economic viability of AM components, powder recycling strategies are an important opportunity to enhance the economic efficiency of the process. However, recycling strategies can have a considerable influence on the characteristics and behaviour of metal powders. In his talk, Panzl investigated the use of powder rheology methods including the pressure drop method, weighted cohesion strength measurements and tensile strength measurements to predict the behaviour of metal powders in powder bed-based AM processes.

It is widely accepted that steel grades with high hardness levels are difficult to process in powder bed-based fabrication technologies. Fengchen Xia and Liang Wu, voestalpine Additive Manufacturing Center, Düsseldorf, Germany, and Jasmin Saewe, Fraunhofer ILT, Aachen, Germany, each offered insights into their work with high-grade tool steels and the possibility to create crack-free samples. In his talk, ‘On the formation of process-induced defects in H13 processed by laser beam melting’, Xia addressed the potential of H13 in AM due to its high thermo-fatigue and crack resistance. By presenting a detailed discussion on the processing conditions which can lead to pores, cracks and lack of fusion in L-PBF-processed H13, and theoretical models on the effect and optimisation strategies derived from an understanding of these conditions, Xia hoped to contribute to the development of effective guidelines for the robust processing of H13 by AM.

In his presentation, ‘Laser beam melting of H13 tool steel’, Wu detailed a comprehensive parameter investigation by which appropriate laser parameters were identified for the L-PBF of H13. In addition, he presented an evaluation of the material’s microstructure under different heat treatment conditions, focusing in particular on phases and defects at all length scales, from macro to nanoscale, and the corresponding mechanical properties. Using simulations, the mutual relationship between chemical composition, process conditions, microstructural and mechanical properties was discussed and clarified. In the future, Wu stated that these experimentally confirmed parameters should be valid for the AM of components in H13 by L-PBF, and can be implemented for a simulation model allowing for the prediction of laser parameters for new combinations of alloys.

In Jasmin Saewe’s presentation, ‘Feasibility investigation for Laser Powder Bed Fusion of high-speed steel AISI M50 with base plate preheating system’, she sought to demonstrate that the L-PBF of dense, crack-free parts with a hardness over 60 HRC (as-built), from high speed steels (with a carbon content higher than 0.5 wt.-%) is possible. In addition, the influence of typical L-PBF process parameters – in particular, preheating temperature – on the microstructure of the part was evaluated. Jochen Giedenbacher, of the University of Applied Science Upper Austria, also discussed how preheating of the substrate plate or the build chamber influences the build job and the final component in his presentation, ‘Investigations on the microstructure and mechanical properties of gas atomised hot work tool steels manufactured by Selective Laser Melting using powder bed preheating.’

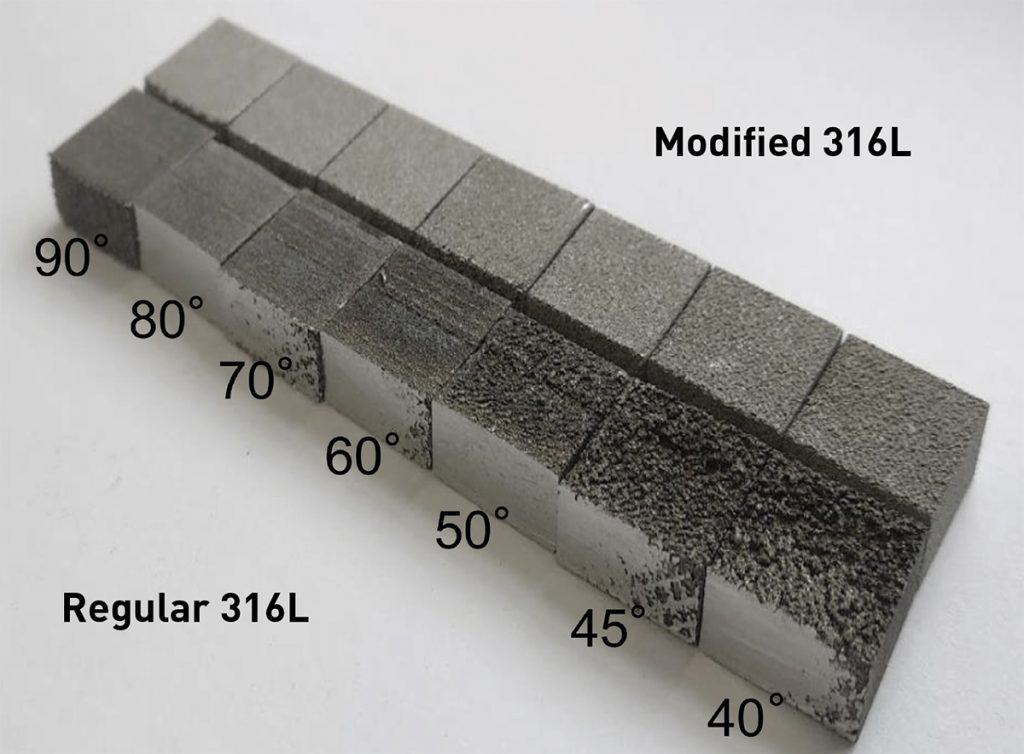

Looking to more familiar materials, Vincent Vignal, Laboratoir Interdisciplinaire Carnot de Bourgogne; Alex Lanzutti and Francesco Andreatta, University of Udine; Mateusz Skalon, Technische Universität Graz; and Quentin Portella, ICD-LASMIS/University of Technology of Troyes, looked at optimisation procedures which can help to extend the fields of application of 316L stainless steel. Vignal investigated the microstructure, passivity and corrosion behaviour of the material when manufactured by L-PBF, while Lanzutti looked at the high-temperature tribological behaviour of L-PBF-processed 316L parts. Andreatta investigated the material’s corrosion behaviour, comparing AISI 316L stainless steel produced by AM against wrought AISI 316L, finding that the AM material presents a dual phase microstructure, as well as the presence of small defects, which affect its corrosion behaviour. Skalon presented a paper on the influence of increasing inclination angle on the surface quality of the downskin of cubic samples produced by L-PBF in 316L (Fig. 5). A balling phenomenon was quantified and compared using the roughness test, and was found to be dependent on the inclination angle.

Besides the research and optimisation of known materials presented throughout the conference, a number of presentations looked at the development of new alloys. Horst Zunko, voestalpine Böhler Edelstahl, Kapfenberg, Austria, gave insight on the development strategy for advanced maraging steels, investigating the typical powder characteristics and microstructure of a number of materials in this category, and Michael Görtler, Joanneum Research, Graz, Austria, discussed the manufacturing of NdFeB permanent magnetic alloys by L-PBF, which could enable cost-efficient batch production of powerful magnets with customisable stray field distributions and enhanced functionalities, such as cooling channels for applications in high-temperature environments.

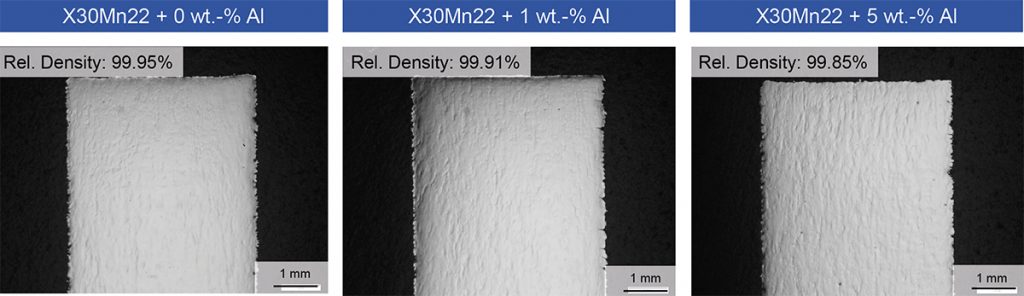

Drawing on the proven success of the L-PBF as a suitable production technology for medical implants, Maximilian Voshage provided information on the development of biodegradable implants made of pure zinc, detailed later in this report. Simon Ewald, RWTH Aachen University, demonstrated that for Advanced High Strength Steels (AHSS), where the powder composition was influenced by dry mixing of alloying elements to a base alloy, it is possible to adjust the stacking fault energy (SFE) for tailored mechanical properties when producing parts by L-PBF, overcoming some of the shortcomings related to conventional processing of high-manganese steels (Fig. 6).

Applications, design and business models for AM

Industrial

From an industrial perspective, the suitability of an application for Additive Manufacturing is highly dependent on the economic and/or technical benefits offered by the technology in comparison to traditional manufacturing. Nader Asnafi, of Örebro University, presented ‘3D metal printing from an industrial perspective – product design, production and business models.’ This paper summarised the current position of metal AM, as well as different types of generative design concepts such as form synthesis, topology optimisation and lattice and surface optimisation. The use of AM for both low- and high-volume part production was also addressed, with a particular focus on the use of L-PBF to produce tools and dies for the engineering, automotive and furniture industries at high volumes, reducing product lead times and costs significantly.

Biomedical

In his paper titled ‘Additive Manufacturing for digital dentistry’, Jurgen Stampfl, TU Wien, compared metals, ceramics and polymers with regard to their relevance in the expanding field of digital dentistry. Applications such as orthodontics, restorative dentistry and implants, where personalised and highly aesthetic parts are demanded, are one of the key driving factors behind the uptake of AM in biomedical applications. This presentation focused in particular on the processing and characterisation of the relevant materials and provided a comparison of the most relevant AM technologies (stereolithography, L-PBF and inkjet printing) in terms of the quality and mechanical properties of the produced parts, mechanical properties of the finished parts, throughput and cost-per-part.

Innovations in material development are another driver behind the suitability of metal AM for biomedical applications and, in a presentation titled ‘Formation quality, mechanical properties and processing behaviour of pure zinc (Zn) metal parts produced by laser based manufacturing for biodegradable implants,’ Maximilian Voshage, RWTH Aachen, presented recent results achieved using biodegradable metals (zinc alloys) for metal additively manufactured medical implants.

According to Voshage, recent studies have shown that Zn-based metals exhibit potential for biodegradable medical implants due to the beneficial combination of biocompatibility, biodegradation rate and mechanical properties. However, only a few recent reports are available on the Additive Manufacturing of Zn and each shows that either the obtained density is too low, or the process window is quite narrow due to excessive evaporation.

Voshage’s paper aimed to clarify the effect of processing parameters on densification during the Laser Powder Bed Fusion (L-PBF) of pure Zn and the method by which a high density can be obtained in a reasonable process window. The final average values of hardness, elastic modulus, yield strength, ultimate strength and elongation in the pure zinc AM part were measured as 42 HV, 23 GPa, 114 MPa, 140 MPa and 10.1% respectively, with density over 99.9%.

Design for lightweighting

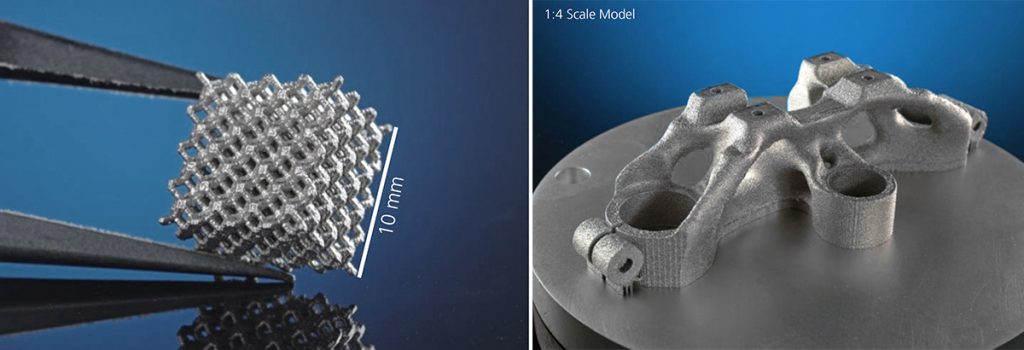

Another key application area in which AM offers a considerable advantage is in the lightweighting of components and structures. In his presentation, ‘Additive Manufacturing of microlattice structures at the resolution limit of the Selective Laser Melting process,’ Michael Görtler, Joanneum Research, discussed the possibilities and limitations for the fabrication of microlattice structures for lightweight applications. The production of parts with integrated lattice structures is one of the key methods by which lightweight parts can be produced, and can also significantly enhance the functional properties of a part, for example by encouraging bone ingrowth in medical implants.

Depending on the required load bearing efficiency and desired stiffness, the production of very thin struts and small unit cells can be necessary. However, microlattices with defined strut diameters below 300 µm cannot be produced by industrial L-PBF machines by default. To manufacture very thin microlattice structures, parameter studies have to be performed in advance and design rules must be followed.

Görtler presented the preliminary stages of microlattice fabrication on a commercial EOS M280 L-PBF machine and described the manufacturability of lattice strut elements for varying inclination angles and diameters. In the study, CAD rules were given based on the identified limits of the technology, enabling the manufacture of L-PBF compatible lattices with optimised parameters. Görtler and his team then compared the relative densities of the fabricated lattice structures against the CAD data and measured the mechanical properties of the structures using compression tests.

Conclusion

When compared to MAMC2014 and 2016, it is clear from the content of the technical programme in 2018 that significant progress has been made by the AM industry with regard to materials, the overall understanding of the AM process and the exploitation of new application areas using the technology’s unique capabilities. While the majority of AM processes remain less economical than conventional production methods, and might struggle to compete in high-volume industrial manufacturing, for lightweight, highly-designed applications such as those in the aerospace and space sectors, there can be a clear argument for the use of metal AM, which offers outstanding solutions for lightweight constructions with design features that would not be achievable by conventional manufacturing.

Furthermore, a growing recognition of the full process chain can be seen across the conference programme, with a number of presentations focusing on multiple points across the Additive Manufacturing process chain, from the initial material development to the final stages of post-processing. As the industry develops its ability to optimise and control the AM process at every step, it becomes possible to meet ever more challenging design criteria, such as strict requirements on the surface quality of parts for space flight. With such capabilities frequently exceeding those achievable by conventional manufacturing methods, AM continues to strengthen its position to exploit new and diverse applications.

The development of new, economical technologies such as those discussed during MAMC2018 also offers a route by which metal AM can become economically competitive with conventional manufacturing. While such technologies are not yet commercially available, it can be expected that the lower cost, and thus lower barrier to entry, will increase metal Additive Manufacturing adoption rates in a wider industrial context.

Authors

Prof Dr Bruno Buchmayr

Prof Dr Buchmayr is retired from the Chair for metal forming at Montanuniversität Leoben, Austria

Tel: +43 3842 402 5600

[email protected]

DI Dr Bruno Hribernik

Dr Hribernik is Executive Member of the Managing Board at ASMET – The Austrian Society for Metallurgy and Materials, Leoben

Tel: +43 3842 402 2294

[email protected]

Dipl-Ing Gerhard Panzl

Dipl.-Ing. Panzl is a PhD student at the Montanuniversität Leoben, Austria

Tel: +43 3842 402 5615

[email protected]

Prof Dr Jürgen Stampfl

Prof Dr Jürgen Stampfl is professor for materials and Additive Manufacturing at the Institute for Materials Science and Technology at TU Vienna, Austria

Tel: +43 1 58801 30862

[email protected]

Proceedings

Details of the presentations can found in the conference proceedings, which can be ordered from the ASMET secretariat ([email protected]).

MAMC2019

ASMET will hold the fourth Metal Additive Manufacturing Conference (MAMC2019) in Örebro, Sweden, from November 25–27, 2019.