Metal Additive Manufacturing magazine

Your source for metal Additive Manufacturing and 3D printing

GE Additive rebrands as Colibrium Additive, retires Concept Laser and Arcam branding

April 26, 2024

GE Additive has officially relaunched as Colibrium Additive – a GE Aerospace company. As part of the transition, it was also announced that both ...»

Linde and NASA partner on GRX-810 alloy powder for Additive Manufacturing

April 25, 2024

Linde Advanced Material Technologies Inc. and the National Aeronautics and Space Administration (NASA) have announced the licensing agreement for t...»

AMEXCI looks to large-scale Additive Manufacturing with additional Nikon SLM Solutions machines

April 25, 2024

AMEXCI, located in Karlskoga, Sweden, and Nikon SLM Solutions AG, based in Lübeck, Germany, have announced a significant expansion of their partne...»

AMGTA releases preliminary research on sustainability of powder and wire additive feedstock

April 25, 2024

The Additive Manufacturer Green Trade Association (AMGTA), a global advocacy group focused on promoting sustainable Additive Manufacturing industry...»

| View all news |

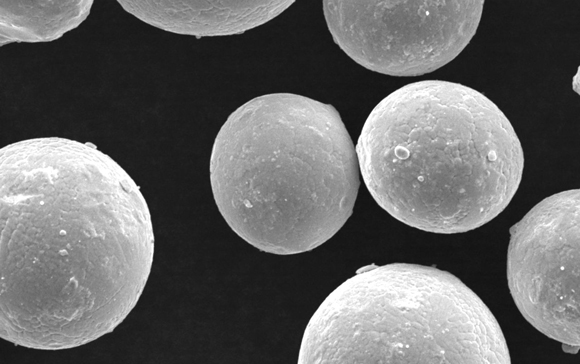

Metal powders in Additive Manufacturing: An exploration of sustainable production, usage and recycling

Sustainability has risen to the top of the global manufacturing agenda. Whilst metal AM has long been considered a green technology because of its net-shape capabilities, it is far from being a process absent of environmental impact.

Here, Martin McMahon explores how global efforts are being made to improve this through the use of more sustainable metal powders, combined with a greater focus on powder reuse and recycling. Inextricably linked to this are, of course, economic gains and, in terms of supply chain, national security benefits.

| Download PDF |

Inside Wayland Additive: How innovation in electron beam PBF is opening new markets for AM

UK-based Wayland Additive is convinced that, when it comes to metal Additive Manufacturing, Electron Beam Powder Bed Fusion (PBF-EB) has a bright future ahead. Whilst laser-based PBF is the most widely commercialised AM technology, it has inherent limitations that electron beam-based innovations such as Wayland’s NeuBeam process promise to overcome.

Rachel Park reports on how the technology could open up the AM market by enabling users of the Calibur3 machine to rapidly develop and commercialise a wider range of industrial materials.

| Download PDF |

Metal AM: True metal Additive Manufacturing insight

At Metal AM, we cut out the hype, kill the buzzwords and clarify metal Additive Manufacturing / 3D printing technologies and industry trends. Since launching in 2015, we’ve worked to provide a platform for the sharing of experiences from the heart of the AM industry, helping to push the technology and its users towards success.

Metal AM magazine is your go-to authority to keep track of the fast-evolving metal Additive Manufacturing landscape. Offering quarterly issues, daily news and a twice-weekly newsletter, we help you to stay informed as the industry grows.

And it’s not just about keeping up to date: As AM technology evolves, we want our readers to truly understand it. That’s why we provide transparency and reliable information that empowers our readers to navigate this complex industry and make better, more informed decisions.

| Get the newsletter |

Download Metal AM magazine