In-depth insight into metal Additive Manufacturing / 3D printing

At Metal AM magazine, our mission for each issue is to present in-depth articles that provide unique perspectives on the rapidly evolving world of metal Additive Manufacturing. Here, selected articles from past issues find a new lease of life in an easy-to-access format designed to attract an ever wider audience to content that we believe stands the test of time. For the latest articles and industry news in the current issue of Metal AM magazine, click here.

Browse articles by topic

Featured articles

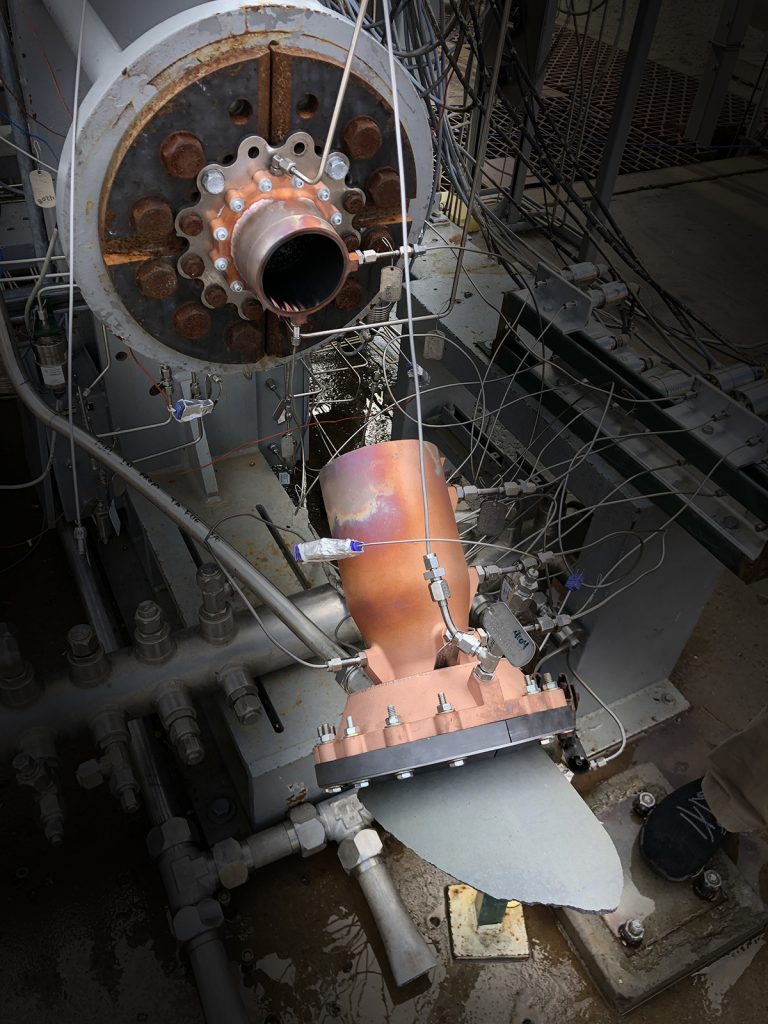

Separation anxiety: Lessons learned at NASA from a developmental rocket engine failure

So much is discovered when it just all goes wrong. From a ‘design-fail-fix’ perspective, it’s expected that developmental components may be pushed to destruction. With rocket engines that operate near the limits of their performance, however, the need to understand the causes of a failure is critical. In the competitive commercial space business there’s a clear advantage not to disclose knowledge gained from such incidents. Thankfully, NASA can share what others cannot. Go to article…

Scalmalloy is too expensive and design optimisation only makes sense in aerospace. True or false?

Additive Manufacturing is not a cheap process and this can give rise to the temptations to select a material on price alone and view advanced topology optimisation as a luxury. Here, Jon Meyer and John Barnes demonstrate that the unique capabilities of AM mean that basing material choice on cost without considering the impact of material performance can limit the competitiveness and potential of an application. Go to article…

Metal AM in automotive: How the Czinger 21C is redefining next-generation car manufacturing

The Czinger 21C hypercar is a ‘tour de force’ of metal Additive Manufacturing. Behind the headlines about the car’s record-breaking performance, however, is a far more important story: the development of the Divergent Adaptive Production System (DAPS), a complete software/hardware solution designed to replace traditional vehicle manufacturing. Jeff Kerns reports for Metal AM magazine. Go to article…

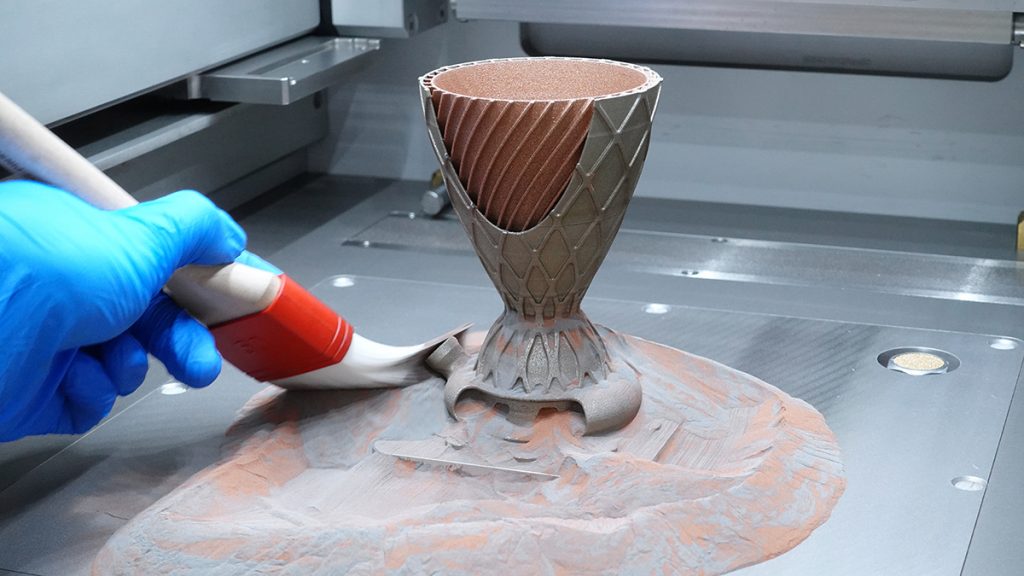

Multi-material metal parts by Powder Bed Fusion: New application opportunities

One novel capability of PBF-LB/M which has yet to be fully explored is the production of multi-material metal parts, which would offer huge new potential for designers in many industries. Prof Dr-Ing Christian Seidel looks at methods and solutions for the AM of parts consisting of two arbitrarily distributed metal alloys and presents use cases with the potential for series production by multi-material PBF-LB/M in the near future. Go to article…

Special focus:

Sinter-based metal AM resources

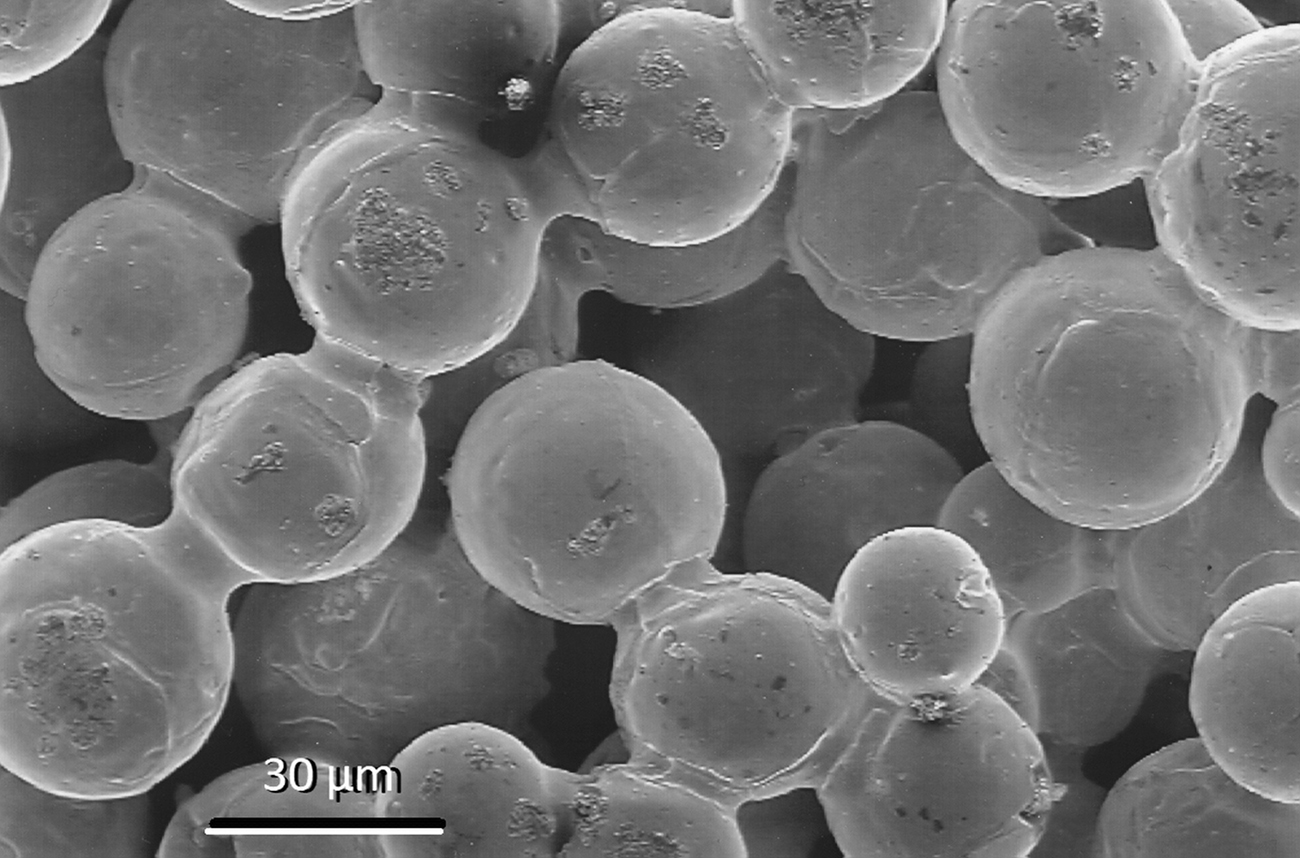

Thinking about metal Binder Jetting or FFF? Here is (almost) everything you need to know about sintering

With the arrival of high-volume metal Binder Jet systems and a growing interest in metal Fused Filament Fabrication, the AM industry is set for a new phase of growth. The ability to use this new generation of systems for the production of ‘green’ parts is, however, only half of the story. The sintering of these parts to create large quantities of finished product to a consistent quality requires both an investment in furnaces that can cost in excess of $1 million each, and a thorough understanding of sintering. In this article, Prof Randall German, the leading authority on the science of sintering, outlines the process and its core challenges. Go to article >>