Freemelt AB: Open source technology to explore the potential of Electron Beam Powder Bed Fusion

A new wave of AM machine manufacturers focused on Electron Beam Powder Bed Fusion (PBF-EB) is looking to capitalise on what is perceived as a process with significant untapped market potential. One of the most prominent of these newcomers is Freemelt AB, a developer of open-source machines designed to help broaden the PBF-EB material portfolio and application areas. As Metal AM magazine’s Emily-Jo Hopson-VandenBos reports, co-founders Ulric Ljungblad and Ulf Ackelid have no doubt as to the opportunities ahead. [First published in Metal AM Vol. 6 No. 2, Summer 2020 | 10 minute read | View on Issuu | Download PDF]

Sweden is famed for many fine things; summerhouses, long summer evenings, plenty of crayfish, and, of course, electron beam-based Additive Manufacturing. The city of Göteborg has for decades been at the heart of all things related to Electron Beam Powder Bed Fusion (PBF-EB). The founders of Freemelt AB, Ulric Ljungblad and Ulf Ackelid, are a key part of this story, together accumulating more than twenty years of service at PBF-EB pioneer Arcam AB, now part of GE Additive. During this period, they are credited as the inventors of more than 30% of all the patents assigned to the company.

As is often the way with such innovative technologies, clusters of companies are formed as employees leave the first company and start their own firms, perhaps leveraging niche opportunities, focusing on materials development or even exploiting the technology as end-users. With PBF-EB such a cluster failed to materialise and as a result, the wider growth of PBF-EB applications stalled.

This changed in 2017 with the foundation of Freemelt AB. The company now numbers seventeen employees and launched its first PBF-EB machine, the Freemelt ONE, in early 2019. In September 2019, in a funding round led by Swedish venture capital fund Industrifonden, the company raised €1.4 million for its development, to grow its team and expand its offering to the metal AM machine market. This same venture capital fund was, of course, an early investor in Arcam AB.

Commenting on the mission behind Freemelt’s establishment, Ulf Ackelid, Senior Scientist, explained that its co-founders shared the opinion that PBF-EB had not yet realised its full potential. “It was lagging behind laser PBF systems in market acceptance, yet our belief was that there was so much more that the technology could offer. Our objective in founding the company was to facilitate the development of new applications and new materials for PBF-EB through an open source platform. Our plan is to take electron beam technology for AM to the next level.”

But why did PBF-EB lag so far behind PBF-LB? According to Ackelid, there are multiple historical and commercial reasons. Early PBF-EB efforts were limited to mainly one material class, titanium alloys, and geared toward just two high-end market segments: aerospace and medical. This early focus is understandable, as these markets had the greatest practical chance of success. It also enabled product development goals that fitted within the resources available at the time for a technology initially deemed complex and sensitive, in part because of its vacuum requirement. “Because of the perceived complexity of the technology, Arcam remained the sole PBF-EB equipment manufacturer on the market for a long time,” he explained.

Over the years, PBF-EB has matured into a robust and reliable technology, but the available material portfolio is still extremely limited when compared to Laser Beam Powder Bed Fusion (PBF-LB). “With new players entering the PBF-EB field, including Freemelt and others, we expect to see a boost in new materials as well as productivity. The unexplored potential of PBF-EB is huge.”

Freemelt ONE: An enabler for the advancement of PBF-EB

As a PBF-EB specialist, Freemelt has since its foundation pursued its mission to first introduce a small, open source material development system to the market, and to grow the organisation in order to be able to deliver even more powerful PBF-EB technologies for future industrial systems. “Our experience taught us that the key to success with AM in general, and PBF-EB in particular, is the development of viable applications with a good business case,” stated Ulric Ljungblad, Freemelt’s CEO.

“We also know that developing new applications is a time-consuming and detail-driven pursuit. To achieve that, one first needs a platform that is open and on which you can try new materials and innovative beam scanning strategies. There are thousands of metal alloys out there and, without a broad community having the possibility of experimenting with them, AM processes using them might never be developed. Material development in PBF-EB is the single biggest hurdle limiting the broader adoption of the process,” he added.

This goal resulted in the Freemelt ONE. The company’s intention for the future is to launch a scaled up production system fully prepared for AM factory integration, based on materials and processes developed on the machine. The Freemelt ONE is therefore tailored for materials research and development, but with a view to industrial production, and has a build envelope of 100 mm high x 100 mm in diameter. The machine’s vacuum chamber is equipped with thick steel walls having a high stiffness to prevent thermal distortion, and uses all-metal seals and differential pumping solutions to ensure an excellent vacuum quality. The linear motion of its recoater is actuated by a mechanism positioned outside the vacuum chamber; this offers increased durability, since it is not exposed to extreme process conditions and can be accessed and serviced easily (Fig. 3). The design and properties of the recoater blades and the overall design of the recoater can be further modified and optimised by the user, and the movement of the recoater and the powder feeding pistons can also be programmed without restrictions.

As it was destined for research environments, the Freemelt ONE was designed from its start to be versatile and user friendly. The machine’s frame structure does not have an outer shell, giving open access to all ports on the vacuum chamber. If needed, this frame can be modified easily to support third-party R&D equipment connected to the system. Further, there are two operating sides to separate powder handling from machine operation: the door side, where the operator loads powder into the vacuum chamber and removes built parts, and the viewport side, from which the operator observes and controls the PBF-EB process.

“Freemelt ONE has been tailored for material R&D right from the start, in software as well as in hardware,” explains Ackelid. The machine’s physical and software architecture enable virtually every parameter to be changed and experimented with, among them new powder compositions, particle size distributions, layer thicknesses, recoating sequences, beam power and speed, beam scanning patterns, spot melting, powder bed temperature, controlled melt pool cooling, and more.

The electron beam source is a diode-type source with a laser-heated cathode. The reported advantage of this source type is its consistent beam spot quality throughout the entire beam power range from 0–6 kW. Freemelt ONE thus allows users to operate the electron beam at very high beam currents while still maintaining a well-focused beam spot; essential to reach high build rates as well as extremely high build temperatures. At the high end of the beam power range, 6 kW, the machine offers fast processing and very high powder bed temperatures over 1200°C. This enables the hot processing of crack-sensitive materials and refractory metals.

Thanks to the machine’s small build tank and lean powder feeding, tests can be run with very small powder quantities, avoiding the need to work with large and expensive containers of powder. The machine’s small, 70-litre vacuum chamber and high-capacity pumps enable the chamber to pump down and cool relatively rapidly.

Freemelt ONE’s software is created ‘bottom-up’ in layers to ensure stability. A service interacts with specific hardware, abstracting it into an API: a controller implements sequences and functions that use one or several services; a build processor runs the actual build by executing a build file provided by the user, sending commands to controllers and services; a user interface provides information and receives commands for the build processors, controllers and services; and an arbiter prioritises between the different actions while a data share interface records and passes relevant data.

The electron beam in Freemelt ONE is controlled by complex magnetic fields created by many magnetic coils acting together. This is made possible by the company’s in-house developed Field Construct software, which leverages computing power rather than complex hardware. The result is faster positioning of the electron beam to the right place at the right time. An advanced trigger and data acquisition system is integrated with the beam control data path. This data acquisition system records high-rate sample data from sensors in Freemelt ONE where the trigger system is used to synchronise sampled data with the melt process.

The first Freemelt ONE was installed in March 2019 at Friedrich-Alexander-Universität, Erlangen-Nürnberg, Germany, and systems have since been delivered to several locations in Europe, the most recent in May 2020 to the Chair for Hybrid Additive Manufacturing at Ruhr-Universität Bochum, also in Germany.

The advantages and weaknesses of PBF-EB

Asked what he considered the main strengths of PBF-EB, Ljungblad explained, “The main advantage is the high beam power achievable with electron beams and vacuum processing. These unique features enable high-temperature processing that avoids the need for heat treatment of parts and support structures, in many cases.” Moreover, he explained that these features enable the processing of a wide range of high-value materials which it would be impossible to process by any other AM technology, including the competing PBF-LB.

These advantages, alongside the fast build rate made possible by high beam power and virtually instantaneous beam positioning, are key factors in the microstructure control, productivity and versatility of the technology. “We should not forget the metallurgy,” Ljungblad adds. “The purity of 3D printing in vacuum results in the highest quality material. Nobody can deny that a good vacuum is orders of magnitude cleaner than the most purified inert gas available.”

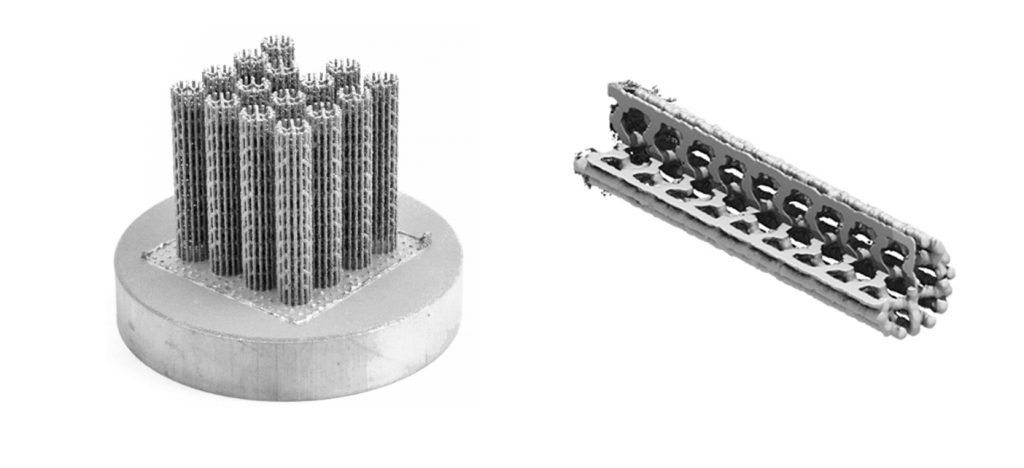

In terms of PBF-EB’s weaknesses, Ljungblad believes that many of the perceived weaknesses are in fact, misconceptions. “Avoiding them is just a question of resources and development,” he noted. For example, Freemelt believes that the surface finish of PBF-EB parts could be greatly improved if processes were developed to that end. As an example, Fig. 6 shows two geometries in 316L stainless steel, one built with 15–53 µm powder and 30 µm layers (left) and one built with 53–150 µm powder and 100 µm layers. Both builds ran smoothly without smoke events or other issues. As can be expected, the fine powder and thinner layers give a notably better surface finish. “That is the point of its open system: to facilitate this type of process development” he stated.

In addition, Ljungblad believes the powder cake removal process can be engineered to a higher level of performance and is not an obstacle for PBF-EB either technically or commercially. “On the contrary,” he explained, “the powder cake resulting from PBF-EB processing is a prerequisite for several of the advantages of PBF-EB we have mentioned. Powder removal from internal structures, especially narrow cooling channels, is challenging for any Powder Bed Fusion technology, especially using hot processing, but here we also see new solutions evolving.”

Looking ahead to the potential of PBF-EB

On the future of PBF-EB Additive Manufacturing, Ljungblad believes the segment is headed into a new phase of growth that will propel it toward greater acceptance and broader application. “GE Additive/Arcam has done an excellent job of laying the foundations of the electron beam AM segment, now more companies are being attracted into the field,” he stated. “We believe that all of the system manufacturers, including GE Additive, will benefit from better knowledge and increased competition with more players, since the potential market is still mainly unaddressed.”

In order to widen their knowledge of PBF-EB technology and its markets, Ackelid encourages those companies and institutions wishing to explore the potential of PBF-EB to start with the Electron Beam Additive Manufacturing (EBAM) conference, an international, biennial conference. EBAM2020, originally set for March but postponed due to the coronavirus (COVID-19), is now planned for October 5–7 this year in Erlangen, Germany. “EBAM covers the latest developments and applications of PBF-EB,” he explained. “It is a primary vehicle for educating the scientific and business communities on the potential of electron beam AM.”

The overall benefits of increased education, understanding and acceptance of PBF-EB will be seen by all companies with a stake in this technology, said Ljungblad. “The rising tide will lift all boats. We are proud to be a leader and innovator in this fast-growing market, which we believe will help broaden the use of AM processes for sustainable manufacturing, for the benefit of system providers and our customers.” As for those who are unsure why open source matters so much in application and technology development, Ackelid stated, “Put yourself in the driver’s seat; select your own powder, process it the way you want and investigate, discover and innovate. Go where you want to go!”

Contacts

Ulric Ljungblad, CEO

Ulf Ackelid, Senior Scientist

Freemelt AB

Bergfotsgatan 5A

431 35 Mölndal

Sweden

[email protected]

www.freemelt.com

EBAM2020

For more information on the Electron Beam Additive Manufacturing (EBAM) conference (EBAM2020), visit