Rapid.Tech 2015: Germany’s conference and exhibition on AM targets an international audience

The Rapid.Tech Conference and Exhibition was first held in Erfurt, Germany, eleven years ago and since then this annual event has attracted ever more visitors. Originally a German language event, the organisers have in recent years worked hard to increase its international appeal and this year the conference was held both in German and English with simultaneous translation. Dr Georg Schlieper reports for Metal Additive Manufacturing magazine. [First published in Metal AM Vol. 1 No. 2, Summer 2015 | 10 minute read | View on Issuu | Download PDF]

The Rapid.Tech 2015 Conference and Exhibition took place from June 10–11. The technical conference included 79 oral presentations and the event as a whole attracted almost 4,000 visitors from fifteen countries, many of whom are active in research and development. The combination of a technical conference and exhibition is considered by the organisers to be rather unique in this industry as opposed to the larger trade exhibitions.

Rapid.Tech provided a comprehensive overview of the present status of metal Additive Manufacturing in Europe and the diversity of its products. Within the exhibition, a wide variety of metal AM products was on display demonstrating the design possibilities and range of applications. Figs. 2-5 show a number of impressive examples. Besides the high number of equipment manufacturers and research institutions, many AM service providers promoted their expertise to interested visitors.

Selective Laser Melting (SLM) is today by far the most widely used technology for metal AM, followed by Electron Beam Melting (EBM). Other emerging technologies such as inkjet printing are further behind on the route to full commercialisation. At the start of the conference, five keynote presentations under the headline Vision 3D, with two of them covering metal components, highlighted the future of Additive Manufacturing.

The event was held in conjunction with FabCon 3.D, an exhibition for start-ups and semi-professional users of 3D printers with a focus on non-metallic materials. Since the focus of this magazine is on Additive Manufacturing with metals, this report does not cover the non-metal side of the conference and exhibition.

Aerospace applications

Peter Sander, Manager, Emerging Technologies & Concepts at Airbus, Hamburg, gave a lecture about the present status and future expectations for Additive Manufacturing in the aerospace industry. Sander reported that the Airbus A350 today contains 80 “flying AM parts”. While most of these components are non-metallic lightweight structures, he stated that a trend towards metal components is noticeable.

Sander said that the Ti6Al4V cabin bracket shown in Fig. 6 was the first metal AM component in an Airbus aircraft. It had been designed as a bionic structure, reducing as much material and weight as possible and leaving material only where it is needed for strength. He stated that metal AM allows Airbus to achieve a 30% weight reduction over the carbon fibre reinforced composite (CFC) structures which are currently widely used in aircraft.

Sander also announced that Airbus Operations plans to produce more than 30 tons of AM parts by 2018 and he made clear that Airbus is a key driving force behind the industrialisation of AM technology. His focus was very much on titanium components for aircraft and he expected that the productivity of Additive Manufacturing would increase by a factor of 100 in the near future. However, no definite time scale was given. If this optimistic appraisal should come true, it would mean a fundamental structural change in the industries manufacturing titanium aircraft components.

Jewellery made by AM

The jewellery and watchmaking industries are showing a growing interest in the Additive Manufacturing of precious metals, as was outlined in the keynote presentation by Frank Cooper, Birmingham City University School of Jewellery, UK. It is obvious that the potential for saving material through AM is particularly attractive for high value precious metals. The students of the School of Jewellery explored the design options offered by AM with great excitement and creativity and Cooper demonstrated new solutions for 18 carat gold jewellery manufactured at his institute. Some examples are given in Fig. 7. Watchcases can be designed with unique features that offer protection against product piracy, as shown in Fig. 8.

AM in medical technology

Medical technology was a main focus of the technical conference, with five sessions and fourteen presentations reflecting the high standard of recent applications and ongoing research. Topics ranged from surgical instruments, endoprosthetic implants and vascular stents through to innovative biodegradable materials.

The advantages of AM for customised endoprosthetic implants were demonstrated by Maximilian Munsch of Implantcast GmbH, Buxtehude, Germany, with an impressive example as shown in Fig. 9. The custom-made component for partial hip replacement is made from Ti6Al4V by EBM. The part’s length is 120 mm and the central section has a diameter of 56 mm. The surface with its EPORE® structure is specifically designed for fast and permanent osseointegration.

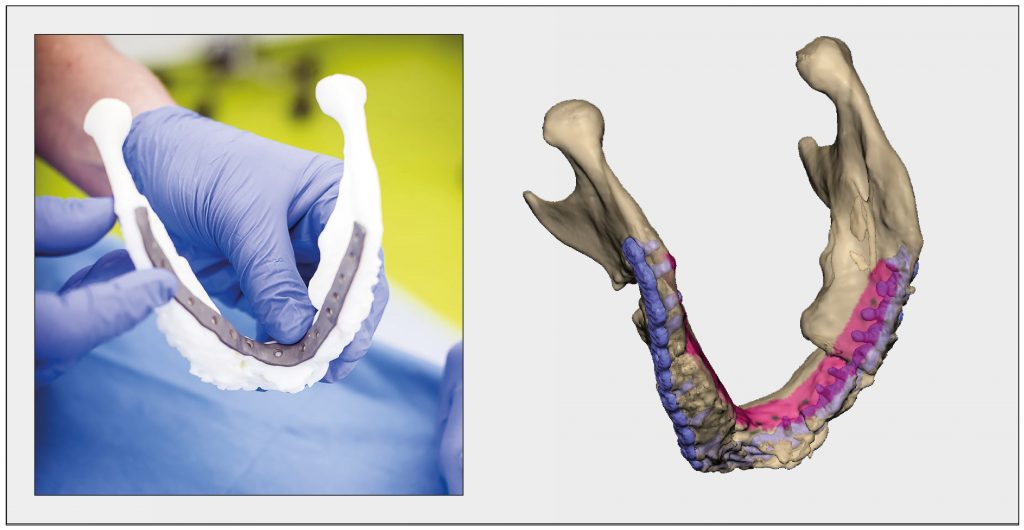

Advances in complex maxillofacial surgery were presented by Florian Thieringer, University Clinic Basel, Switzerland. Starting from a data set which had been generated by computer tomography or magnetic resonance imaging of the patient’s bone that undergoes surgery – a jaw for example – a virtual 3D model is created and 3D printed in polymer. The model is then used to precisely adapt a titanium plate for osteosynthesis and produce it by SLM. Fig. 10 shows the jaw model and the Ti plate (left) and a virtual simulation of the jaw with the Ti plate in place fixing a fracture (right).

This method is, of course, not restricted to maxillofacial surgery, but can be used for a wide range of surgeries. In medical technology, 3D imaging and 3D software is increasingly used for the simulation of surgical interventions.

Dental technology was notably under-represented at this year’s Rapid.Tech exhibition. This was due, stated the organisers, to the proximity to the International Dental Show (IDS) in Cologne, which has a far greater significance for the industry. The technical conference also widely omitted the subject of dental technology.

Software development

3D design software will soon be part of our everyday lives and Adrian Lannin, Microsoft Corporation, USA, announced that the Windows 10 operating system will include a platform that allows users to design in 3D and connect a 3D printer directly to a PC as a plug-and-play device. This underlines the importance that the world’s leading software provider for personal computers attributes to AM technology. A new file format, 3MF, has been developed that substantially reduces the size of data files for 3D printing. Lannin assured the audience that the new Windows 10 software would also be compatible with other 3D printer software.

Software developers work hard to improve the user friendliness of 3D design software and Florian Coigny of Mimedis AG, Basel, Switzerland, presented innovative design software for medical implants with improved user guidance and integrated manufacturing guidelines. He stated that the new software is easy to use and intuitive, allowing surgeons to become the designers of their own individual implant solutions, no longer having to rely on design engineers to transfer their ideas into a 3D design.

Tool making industry

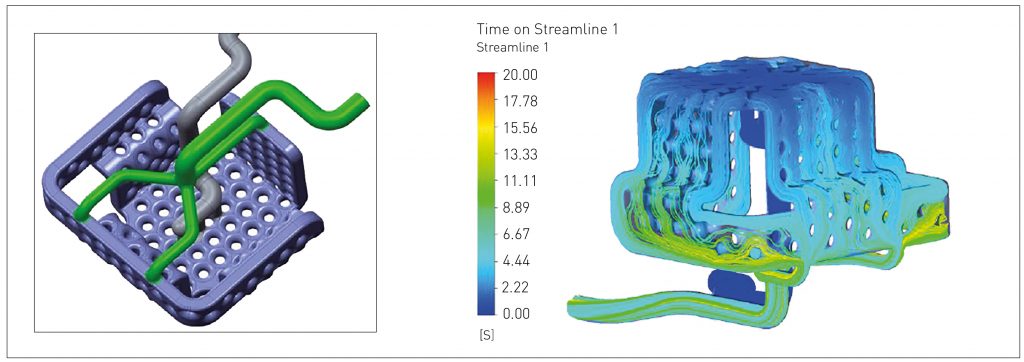

The tool making industry is increasingly using SLM for repairs, prototyping and advanced tools with integrated cooling channels. Intelligently designed cooling channels in tools used for die casting and injection moulding can help to reduce cycle times and improve temperature distribution in the tool dramatically. This can reduce the distortion of products due to thermal effects and improve overall quality.

Mathias Gebauer, Fraunhofer Institute for Machine Tools and Forming Technology (IWU), Chemnitz, Germany, reported on the development of inserts for an injection moulding tool by Additive Manufacturing with internal cooling channels as shown in Fig. 11. In addition to the cooling channels, the inserts featured areas with intentional porosity for improved venting of the cavity.

AM research

The number of research groups that are working in the field of metal Additive Manufacturing is rapidly growing and it is hard to keep track with the development. The Fraunhofer-Gesellschaft, a major institution for applied research in Germany, has formed an alliance between several of its institutes in order to cooperate on different areas of AM research. The Fraunhofer-Gesellschaft also held its own expert forum with a number of presentations.

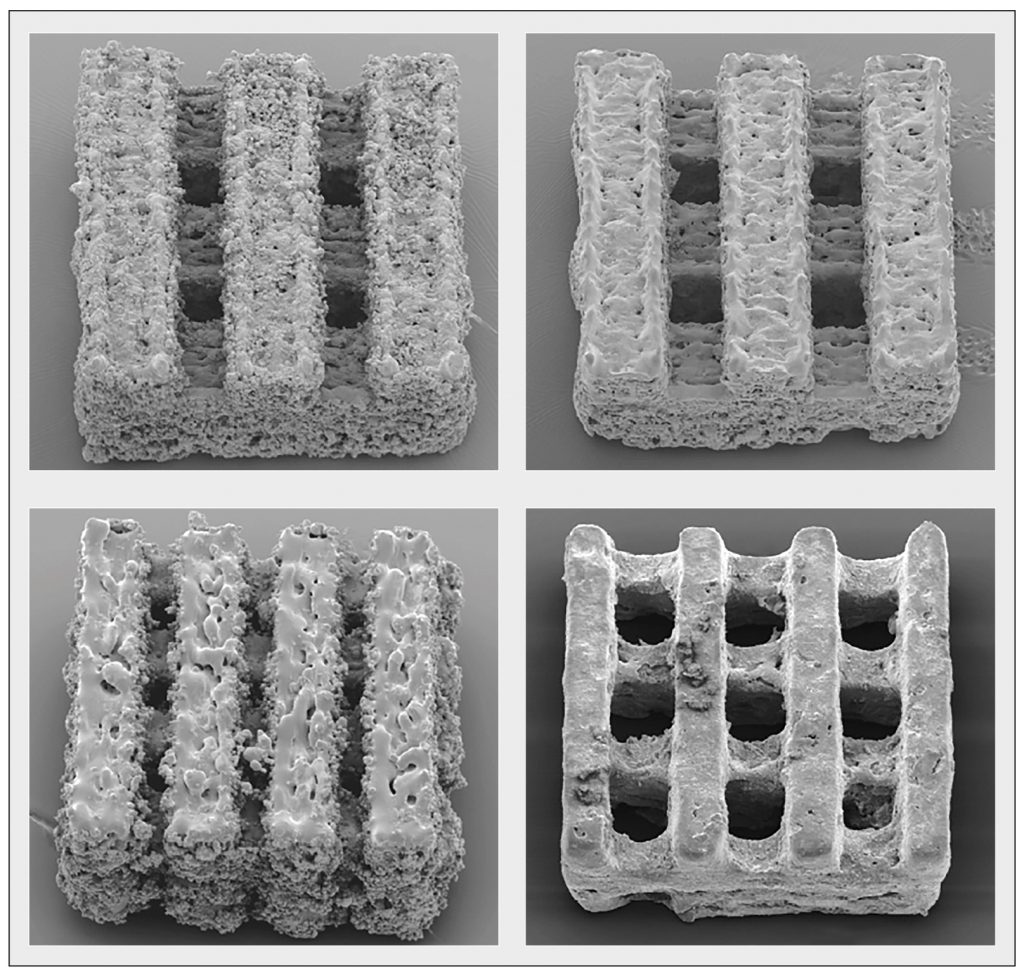

Numerous European universities have also created collaborative research centres for AM. Biodegradable metallic implants from magnesium alloys for applications in osteosynthesis are under development by working groups at the Laser Zentrum Hannover e.V. (LZH) and the University of Hannover. LZH’s Matthias Gieseke stated that the high oxygen affinity of magnesium and the formation of magnesium vapours during SLM are the main problems to be solved. The researchers worked with two alloys, MgCa0.8 (0.8% Ca, bal. Mg) and WE43 (4% Y, 2.25% Nd, 0.15% Zr, bal. Mg) and found a slight change in alloy composition due to Mg evaporation during SLM processing. With MgCa0.8 the open cavities of the scaffold were limited to a minimum of 600 µm. However, with WE43 it was possible to produce scaffolds with 400 µm cavities. Both alloys were subjected to a secondary treatment in aqueous nitric acid at room temperature to remove any adhering powder particles and create a smoother surface (Fig. 12). The author stated that the alloy WE43 could be processed more easily than MgCa0.8.

Outlook

Besides the many success stories that were reported during the conference, there were also critical remarks about the need for further development of AM technology and improvement to processing equipment. Productivity, it was stated, needs to be improved to make the technology attractive for more applications.

The change from one material to another is considered extremely tedious as cleaning a machine can in some cases take two to three days. The limited number of metal alloys that are currently available for 3D printing is another obstacle for further growth of the industry. In medical technology, approval by the US Food & Drug Administration (FDA) is essential. However, this is difficult to obtain and costly. Sophisticated process monitoring systems are also recognised as an essential way to secure higher quality standards.

Based on the success of this year’s event, the organisers have announced that Rapid.Tech 2016 will last for three days, taking place in Erfurt from June 21-23.

Author

Dr Georg Schlieper

Gammatec Engineering GmbH

Mermbacher Strasse 28

D-42477 Radevormwald

Germany

Tel: +49 2191 6889274

Email: [email protected]