Advances in aerospace applications: MTU produces Airbus A320neo borescope bosses with Additive Manufacturing

Additive Manufacturing technology is rapidly making gains in the aerospace sector, particularly in the field of aero engine construction. Munich-based MTU Aero Engines is the first company to use this technology for the serial production of borescope bosses used in the new PurePower® PW1100G-JM engine from Pratt & Whitney and fitted to the Airbus A320neo aircraft. In this report Metal AM magazine reviews the development of the technology at MTU and the close collaboration with EOS that helped to ensure the success of the project. [First published in Metal AM Vol. 1 No. 2, Summer 2015 | 10 minute read | View on Issuu | Download PDF]

When it comes to new technologies, the aerospace sector is one of the most innovative yet cautious industries in the world. New materials and technologies that are suitable for series production have an important role to play, with the primary drivers being cost, weight and function. Because of this, both aerospace manufacturers and suppliers have been testing the performance capabilities of metal Additive Manufacturing (AM) processes for many years.

Whilst Additive Manufacturing was originally used in the manufacture of prototypes, thanks to its many advantages the technology has since established itself as a staple in series production. The advantages associated with metal AM include increased design freedom as well the ability to use a wide range of raw materials that are extremely difficult to process using conventional technologies.

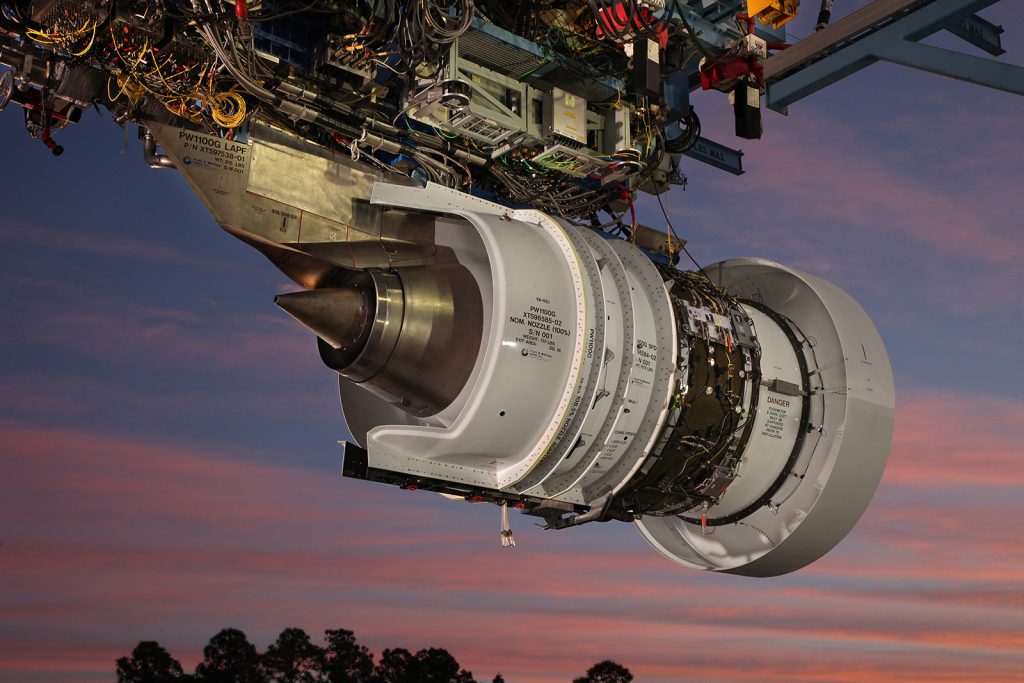

With its A320neo (new engine option), a new short and medium haul aircraft, Airbus’ key objective was to offer global airlines a significant reduction in fuel consumption. Achieving this goal required, above all, much more efficient engines. Airbus selected the award-winning Pratt & Whitney geared turbofanTM engine as the launch engine on the A320neo aircraft family (Fig. 1). The ultra-efficient PurePower PW1100G-JM engine, described by Pratt & Whitney as the greenest engine option on the A320neo, delivers double-digit improvements in fuel efficiency, reduces noise by 50% and cuts CO2 and NOX emissions (Fig. 2).

The low-pressure turbine for the PW1100G-JM geared turbofan (GTF) engine is the first turbine ever to come equipped with borescope bosses produced by AM (Fig. 3).

The application of metal AM at MTU

MTU Aero Engines, based in Munich, is Germany’s leading aero engine manufacturer. The company, which has around 9000 employees worldwide and annual sales of €3.9 billion, is a primary supplier to Pratt & Whitney and played a key role in Airbus reaching its objectives.

MTU began looking into options to use metal Additive Manufacturing around ten years ago, describing the benefits as “too compelling to ignore.” The company has taken a strategic step-by-step approach towards the technology’s use. “About ten years ago, we began with the manufacture of tools and development components,” stated Dr Karl-Heinz Dusel, Director of Rapid Technologies at MTU. “In order to optimise capacity utilisation and implement our phased plan, we went in search of further areas where we could apply the technology” [1]. The principal challenge consisted of cost and safety considerations on the one hand, and the pursuit of strategic innovation on the other.

Metal Additive Manufacturing processes allow complex components that are extremely difficult, if not impossible, to manufacture using conventional methods to be produced with minimal amounts of material. The technology opens the door to entirely new designs, appreciably cuts development, production and lead times and brings down production costs. “Additive Manufacturing is particularly suitable for producing parts in materials that are difficult to machine, as, for example, nickel alloys,” stated Dusel.

MTU started off making tools and development parts with a simple geometry. In a second phase, parts were produced by metal Additive Manufacturing as substitutes for existing ones, such as spray nozzles and grinding wheels for use on the shop floor. At around the same time, work on the engine borescope bosses began to pick up speed [2].

“At the beginning of the second phase we started to produce raw components, which replaced existing parts. The borescope bosses for the low-pressure turbines of the A320neo-GTFs fell into this category,” explained Dusel.

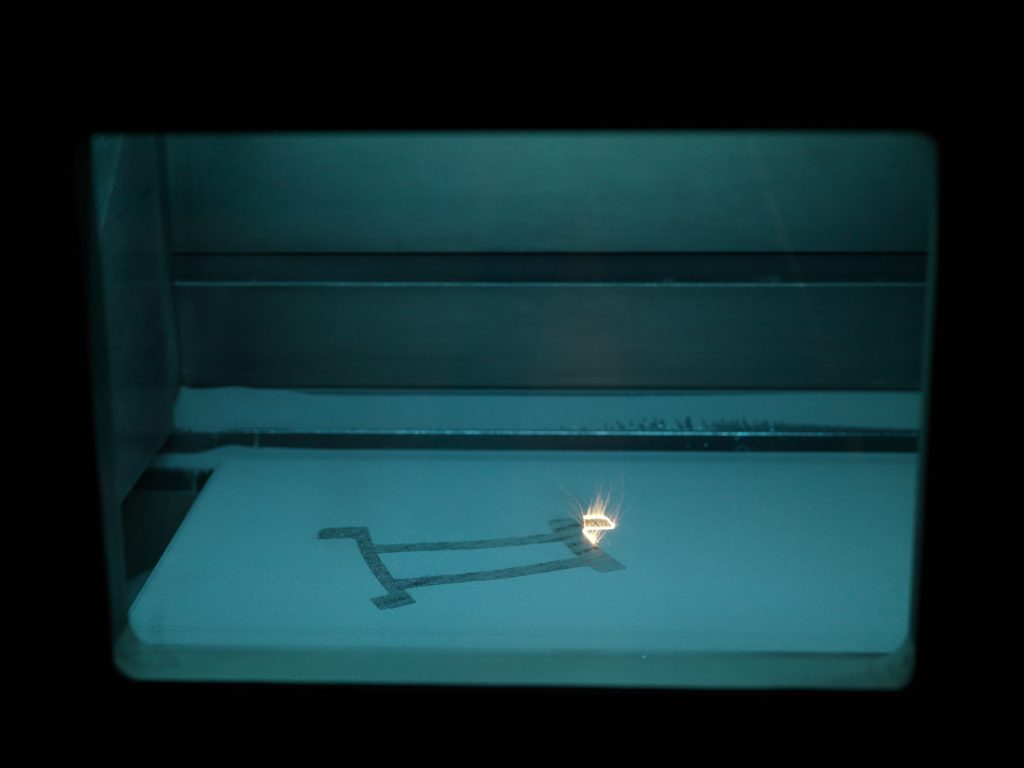

MTU currently uses seven laser sintering machines from EOS, also based in Munich (Fig. 4). “EOS technology is characterised by its virtually unlimited design freedom and the significantly shortened development, production and delivery times. In addition, development and production costs are drastically reduced. Components of lighter weight and greater complexity can be made a reality and production requires less material and minimal tools,” stated Dusel.

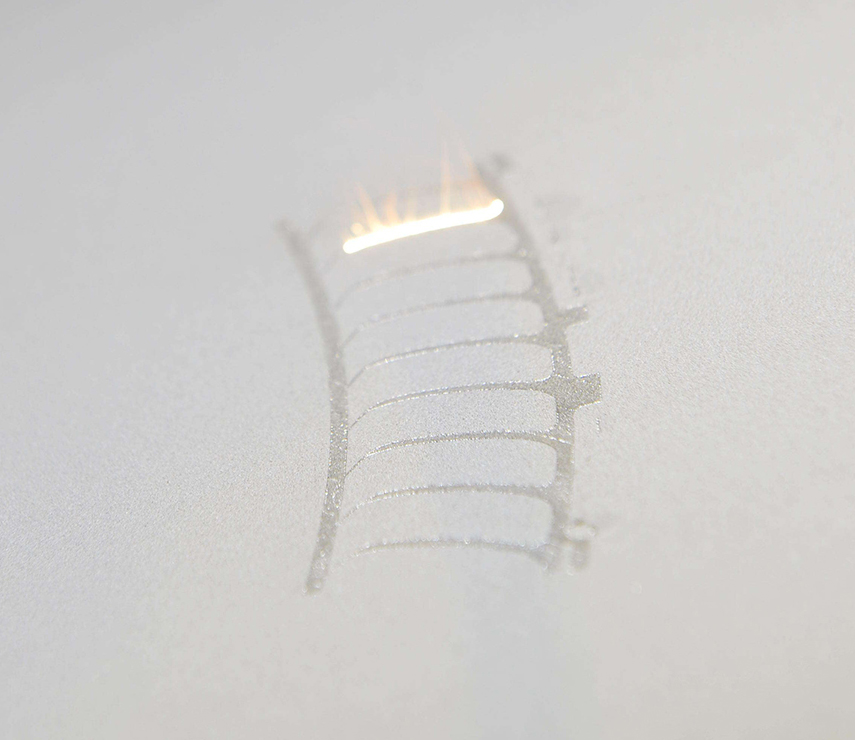

The Additive Manufacturing of borescope bosses

Borescope bosses are small add-on components that allow technicians to check the condition of turbine blades inside the engine using endoscopes. The parts are riveted to the turbine housing to create an opening for the endoscope, which in the aerospace sector is termed a borescope. In the past, the borescope bosses were cast, or milled from a solid, but the low-pressure turbines for the A320neo’s geared turbofan are the first turbines to be serially equipped with borescope bosses produced by Additive Manufacturing.

The key characteristics of the nickel-based alloy used in this application are heat resistance and durability. This high-quality material achieves the highest results demanded by the component, but it is very difficult to machine. Fortunately a problem such as this is easily overcome with Additive Manufacturing. MTU is also a producer of raw materials and the company was able to develop a new process chain, which has been approved and integrated into the manufacturing system.

Series production of the borescope bosses has now begun. Sixteen parts per job are required, totalling up to 2,000 parts per year. The savings in percentage terms, compared to previously established processes, are expected to be in double figures and quality is already at a very high level. The borescope bosses are manufactured using the EOS laser sintering machines installed at MTU. EOS is working with MTU to further optimise the finishing for the component, especially the smooth surfaces, with the aim of achieving perfection in the structural mechanics.

EOS stated that cost advantages of its technology were a decisive factor both in the successful serial production of the component and in the development stages.

MTU & EOS: A strategic partnership for quality control in Metal AM

The entire manufacturing process for the borescope bosses is underpinned by a quality control system specifically developed by MTU. Online monitoring captures each individual production step and layer. In addition, new quality assurance procedures have been introduced such as optical tomography. The German Federal Aviation Authority even certified the EOS machines.

As previously reported in Metal AM magazine (Vol. 1 No. 1, p. 9), EOS and MTU have closely cooperated on improving quality assurance for metal engine components produced using Additive Manufacturing. The two companies signed a framework agreement earlier in the year for the joint strategic development of their technology [3].

The first result of these joint endeavours is the Optical Tomography (OT) developed by MTU, a powerful complement to the modular EOS monitoring portfolio. In addition to several sensors that monitor the general system status, the camera-based OT technology controls the exposure process and melting characteristics of the material at all times to ensure the optimum coating and exposure quality.

Dr Adrian Keppler, Head of Sales and Marketing (CMO) at EOS, stated at the time of the announcement, “MTU and EOS have been working intensively for several years and this collaboration is now about to develop into an even closer, partner-based technological cooperation, centred on the above quality assurance tool. The OT solution enables us to perform an even more holistic quality control of the metal Additive Manufacturing process – layer by layer and part by part. A very large proportion of the quality control process that previously took place downstream can now be performed during the manufacturing process, with a considerable saving in quality assurance costs. This also allows us to satisfy a central customer requirement in the area of serial production.”

“By employing the quality assurance system developed by us for use in serial production, EOS is backing an industrially proven solution for its Direct Metal Laser Sintering (DMLS) process. It has proven itself in practical testing and we now intend to make it available to other customers too,” stated Thomas Dautl, Head of Production Technologies at MTU.

MTU has been amassing its experience over several years by deploying the system on EOS machines. Not only does this ensure comprehensive transparency, but it also provides a quality analysis method for the entire manufacturing process and supports its full documentation. Dautl stated that, in this way, EOS and MTU are jointly furthering the qualified use of Additive Manufacturing in aerospace engineering while also reducing costs. “The monitoring solution represents a value enhancement not only for the EOS technology, but also for each and every customer.”

Quality assurance is especially important in serial production because it is vital for ensuring repeatable high component quality and for continually reducing the quality control costs of components made using the technology, which ultimately serves to reduce unit costs. The system settings and process parameters are constantly monitored in the ongoing manufacturing process to ensure that system and manufacturing process conditions are ideal for maximum component quality.

Looking to the future

MTU sees significant opportunities for the manufacture of further series components for aero engine manufacture, including bearing housings and turbine blades, both of which need to meet the highest demands in terms of safety and reliability. MTU’s aim, it is stated, is that a significant proportion of components should be manufactured using industrial 3D printing within fifteen years.

Commenting on the development of the metal AM borescope bosses when the application was first announced in May 2014, Dr Rainer Martens, MTU Aero Engines’ Chief Operating Officer, stated, “With this move, MTU has reaffirmed its leadership in delivering innovation; for we are using one of the most advanced technologies there is to produce parts for one of the most advanced engines in the world, the geared turbofan.”

What is clear is that the aerospace sector shows little sign of slowing down, with growth supported in particular by the Asian and Middle East markets. During the 2015 Paris Air Show alone, Airbus reports that it won $57 billion worth of business for a total of 421 aircraft. The deals comprise firm orders for 124 aircraft worth $16.3 billion and commitments for 297 aircraft worth $40.7 billion. The A320neo aircraft accounted for 323 of the above, taking total orders and commitments for the A320neo family beyond 4,000 since launch in December 2010.

References

[1] “Aerospace: MTU manufactures Engine Components for the Airbus A320neo with EOS Technology,” Case Study as published on www.eos.info

[2] “Trailblazing technology: MTU Aero Engines produces parts by additive manufacturing,” Press Release, March 13, 2014, www.mtu.de

[3] “EOS and MTU: strategic partnership for quality control in metal-based additive manufacturing,” Press Release, January 20, 2015,

www.mtu.de