Hot Isostatic Pressing: Improving quality and performance in AM parts production

Hot Isostatic Pressing (HIP) has been used for a number of decades as a method to consolidate metal powders and metal matrix composites to produce fully dense components, to eliminate porosity in sintered parts, to produce metal-clad parts through diffusion bonding, and to eliminate defects in castings. HIP is now also playing an important role in assuring and increasing the quality of critical components produced by powder-based Additive Manufacturing. In the following article Magnus Ahlfors and Johan Hjärne describe the HIP process and its influence on the microstructure and properties of AM Ti-6Al-4V alloys. [First published in Metal AM Vol. 1 No. 4, Winter 2015 | 40 minute read | View on Issuu | Download PDF]

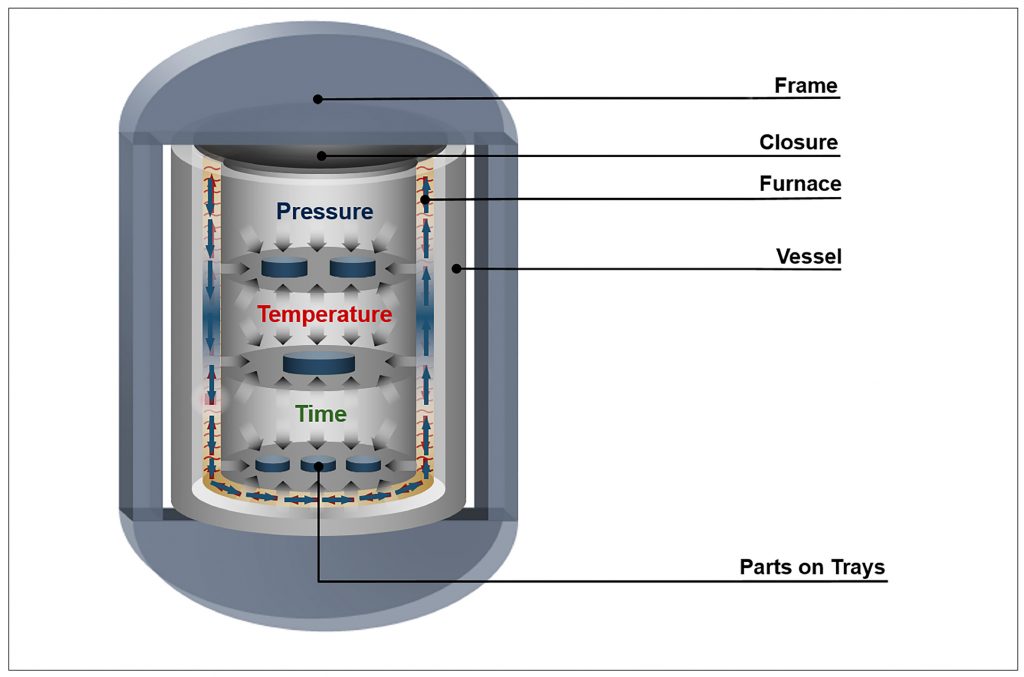

Hot Isostatic Pressing is a process which is used to consolidate metal powder or to eliminate defects in solids such as pores, voids and internal cracks, thus densifying the material to 100% of the theoretical density. When loose metal powders are consolidated by HIP, or when previously densified parts having surface connected porosity need to be fully densified, the HIP cycle must be done in gas tight capsules made from sheet metal or glass. Previously densified parts not having surface connected porosity, such as products with a gas tight surface, can be HIPed without the need for encapsulation. The process includes high temperature and a high isostatic gas pressure, meaning that the pressure acts on all surfaces of the component in all directions leading to densification. The mechanisms for densification during HIP are plastic deformation, creep and diffusion. Initially, plastic deformation is the dominant driving mechanism since the applied external pressure is higher than the yield strength of the material at the HIP temperature, thus making the voids in the material collapse. After the initial plastic deformation, creep and diffusion contributes to densification. These mechanisms not only collapse and close the pores, but totally eliminate them to create a material free of defects. The process has been successfully used for a number of decades to both manufacture and densify critical components for sectors such as aerospace, medical implants, power generation and oil and gas exploration. In Fig. 1 a schematic picture of a HIP process is presented.

There are three main parameters in a HIP cycle which determine the densification. These are temperature, pressure and hold time. HIP temperatures are often in the range of 70 to 90% of the solidus temperature of the material being processed and the pressure used is usually in the range of 100-200 MPa, mostly with argon as the pressure medium. The hold time is somewhat dependent on the thickness of the components being processed since there is a longer temperature delay in the core of large parts depending on the thermal conductivity of the material. For a specific material, there can be several different HIP cycles which will generate 100% density but in different ways, since all three parameters affect the densification process. For example, a cycle with relatively low temperature, low pressure, but long hold time can generate the same results as a cycle with relatively high temperature, high pressure and short hold time in terms of densification. Heating rate and cooling rate, the latter in particular, are other parameters that need to be defined for the HIP cycle. Heating and cooling rate will not affect the densification of the material, but can be very important for the final microstructure and thus the mechanical properties of the material being processed.

Hot Isostatic Pressing for metal Additive Manufacturing

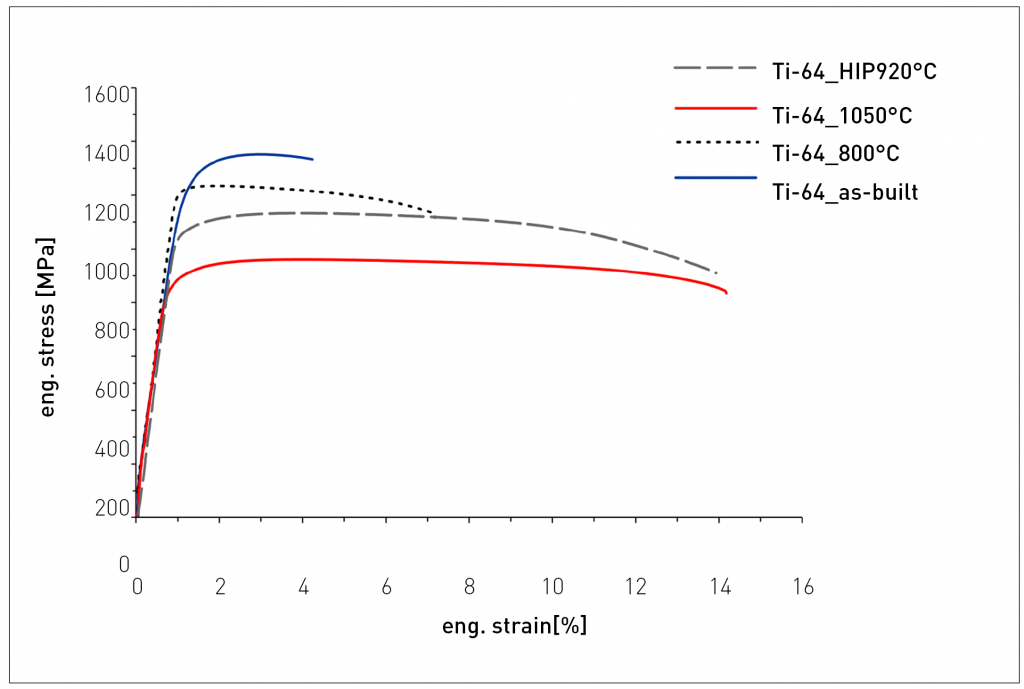

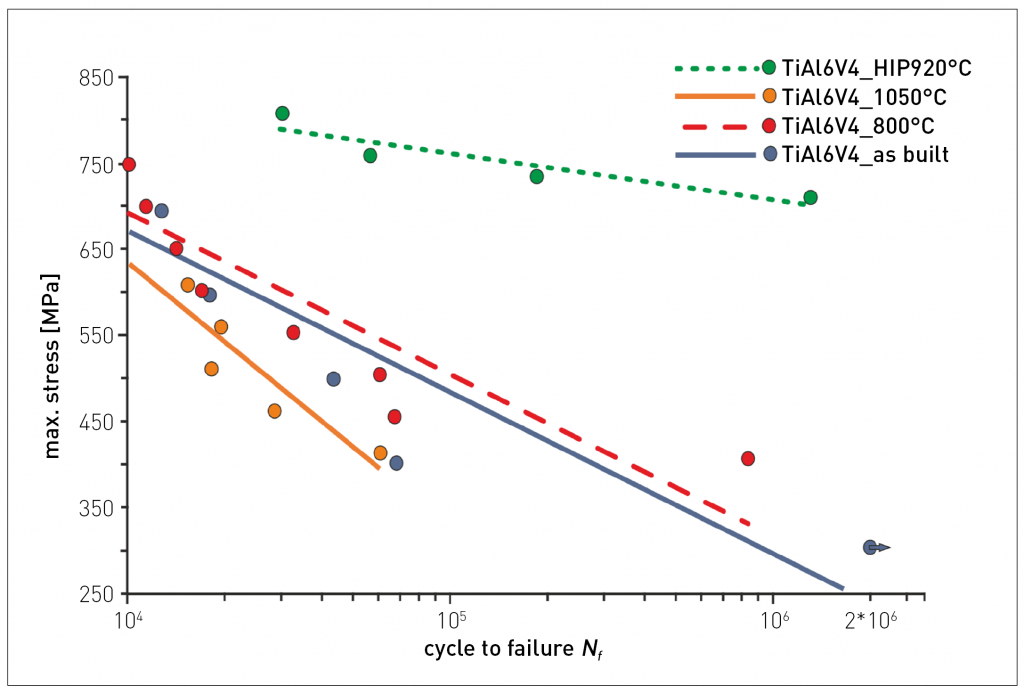

Even though the relative density of powder based AM material often is very high, there can be no guarantee against defects in the material such as pores and internal cracks. The defect types, size and occurrence are determined by the powder and printing parameters. These defects influence the mechanical properties of the material in a negative way, especially the fatigue behaviour. By the use of HIP for AM materials, these defects can be eliminated and the material will have a 100% relative density. The most pronounced benefit of removing printing defects by HIP is that the fatigue properties can be improved since the stress concentrations from the defects are eliminated. As reported by Stefan Leuders [1], the fatigue properties of SLM Ti-6Al-4V were shown to be improved compared to as-printed material and solution annealed material with a large increase in fatigue life and also a decrease in the fatigue slope, see Fig. 2. This is an important factor for components in highly demanding applications such as aerospace components and medical implants. One thing to note from the investigation performed by Leuders is that the yield strength actually decreases for the annealed and HIP processed SLM Ti-6Al-4V compared with the as-printed material, but instead a much improved ductility is generated, see Fig. 3. This change in properties is explained by the fine microstructure in the as-printed SLM material, which is generated by the very high cooling rates in the printing process of several thousand degrees per second and delivers a high yield strength in the as-printed condition. When post heat treatments with more conventional cooling rates such as HIP and annealing are added, the microstructure is coarsened resulting in a lower yield strength, but ductility is improved as a result of the removal of any porosity.

As previously mentioned, a prerequisite for AM parts to be HIPed without encapsulation is for the parts to have a gas tight surface so that the pressure medium will not penetrate the material. For some powder processes, this is a challenge. Conventional press and sinter Powder Metallurgy parts, for example, have to be sintered to a very high density to enable capsule-free HIP processing. However, for AM processes, the surface will always be gas tight due to the relatively high density achieved during manufacturing, which enables capsule-free HIP processing of AM parts as-printed.

The HIP treatment of Additive Manufacturing material will eliminate all defects, independent of the number of defects in the material prior to HIP, as long as the requirement of a gas tight surface is fulfilled. This means that it does not matter whether the material includes 0.2% or 2% porosity as-printed, since the HIP process will eliminate all the defects. This makes it possible to speed up the printing process by printing “lower quality” material with more defects since the as-HIPed material will be the same independent of the as-printed porosity levels. This enables time and cost savings in the printing process by printing the components faster.

Since the pores in as-printed powder based AM material are homogeneously distributed throughout the material, the shrinkage generated during HIP will be homogeneous in all directions over the volume, and corresponding to the amount of porosity removed. Thus, no distortion of the net shape AM parts is to be expected during HIP, however a relief of the residual stresses in the material introduced during the AM process will occur.

Hot Isostatic Pressing equipment suitable for Additive Manufacturing

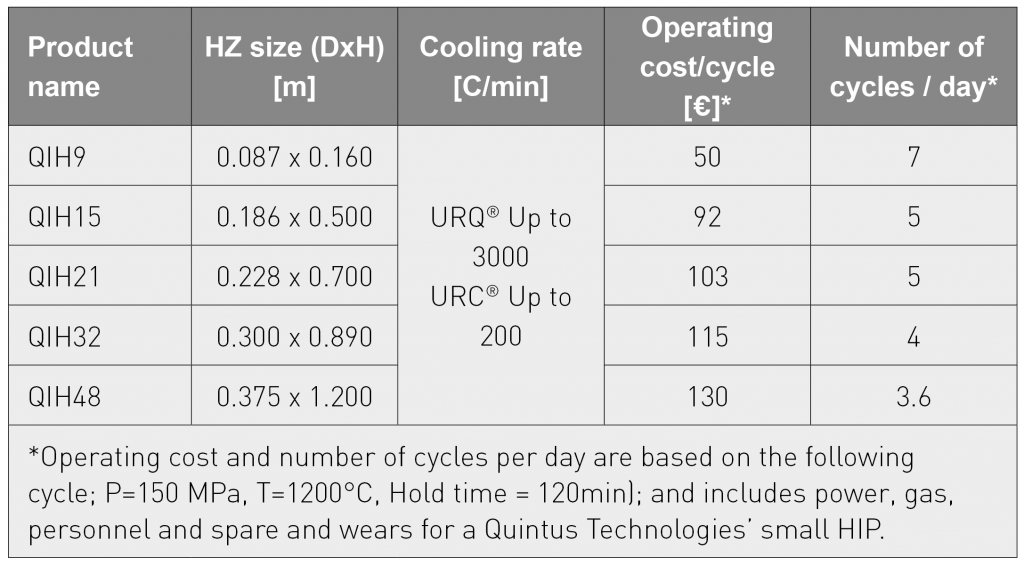

Quintus Technologies is the world’s largest manufacturer of HIP systems and has delivered state of the art HIP systems worldwide for the last fifty years. During recent years, Quintus has developed a series of HIP systems perfectly matched to the requirements of the Additive Manufacturing industry (Fig. 4). This small HIP series has a varying furnace diameters of 0.186 to 0.375 m and furnace height of 0.5 m to 1.2 m. These presses are modularised, meaning that customers can choose what pressure level, temperature range and cooling rate they want for their specific process. All units are delivered fully tested as plug and play units.

This series of small HIP systems, with Quintus Technologies’ patented Uniform Rapid Cooling (URC®) or Uniform Rapid Quenching (URQ®) furnaces, can provide extremely fast cooling rates of up to 3000°C/min, high productivity and robustness, and even combine HIP and heat treatment in the same cycle. The required cooling rates for heat treating Ti, TiAl and CoCr alloys can almost always be achieved with the URC® furnace, which is standard for all Quintus Technologies’ HIP systems. These systems can easily cool the full workload in a small HIP with cooling rates up to 200°C/min (Table 1) and, in addition, the URC® technology ensures that all areas of the workload are cooled uniformly, minimising thermal distortion and non-uniform grain growth. For additively manufactured medical implants and aerospace components, HIP is now standard practice and, for these applications, it is becoming more and more common to include the heat treatment directly in the HIP cycle. Should even higher cooling rates be needed, URQ® furnaces could also be offered to achieve cooling rates as high as 3000°C/min.

Most often it is advantageous to in-source HIPing, not only to reduce cost but also to control and optimise the HIP parameters for best results. Other benefits would be reduced stock levels and shortened delivery times. Table 1 shows what the approximate operational cost will be per cycle for the different sizes in the Quintus technologies’ small HIP series.

New Hot Isostatic Pressing process developments for Additive Manufacturing

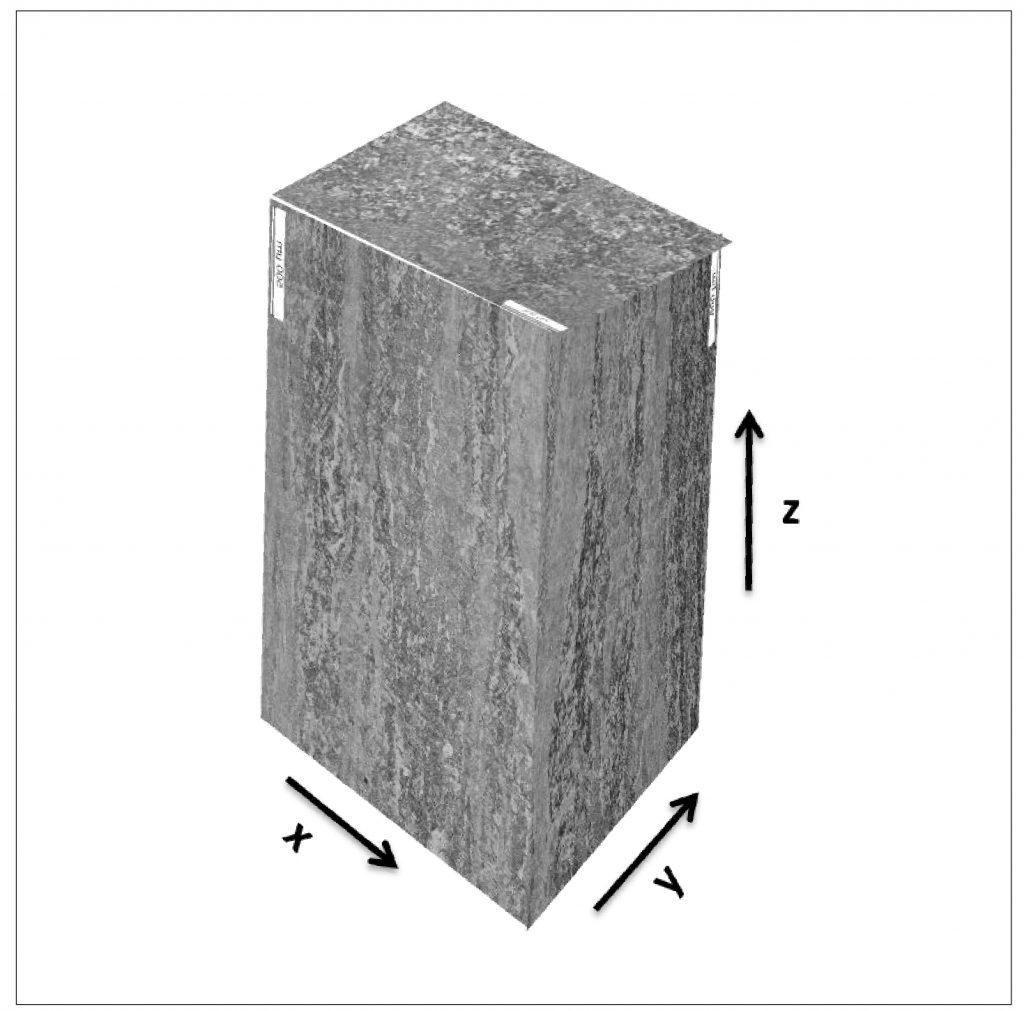

Powder bed, layer by layer, manufacturing processes have directional solidification and cooling in the build direction due to the nature of printing. The directional solidification and cooling make the grains grow in the building direction through the layers resulting in a columnar microstructure. This columnar microstructure gives the as-printed material anisotropic mechanical properties, where the properties in the building direction (z) can be quite different from the properties in the plane perpendicular to the building direction (x, y). A typical as-printed microstructure of EBM Ti-6Al-4V is shown in Fig. 5 where the build direction is indicated with an arrow and the columnar grain structure is evident [2].

The columnar microstructure and anisotropic properties of as-printed powder bed deposition material can be a great drawback in many applications. In order to increase the potential applications that can benefit from the complex geometries made possible by powder bed deposition, it is of interest to develop a post printing treatment that can break down the coarse columnar microstructure of as-printed material into a more refined and equiaxed microstructure. A study of potential post treatments for generating equiaxed microstructures of AM material has been performed by Oak Ridge National laboratory in Oak Ridge, Tennessee, USA, and Quintus Technologies in Västerås, Sweden [3].

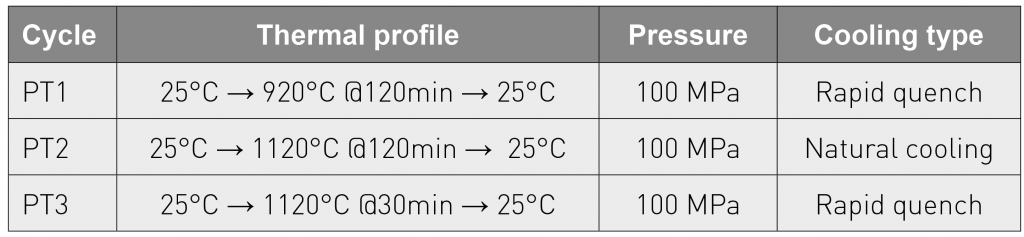

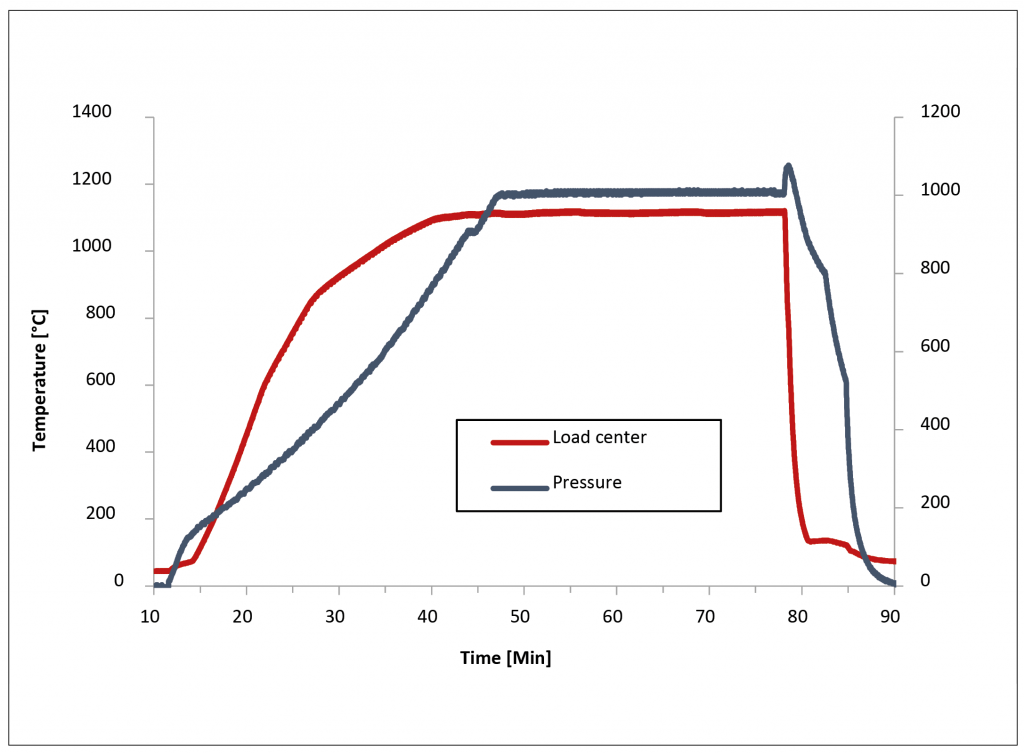

In this study, three different post printing treatments for EBM Ti-6Al-4V were investigated to see if the columnar grain structure of as-printed material can be broken down into a more equiaxed grain structure. The first post treatment investigated was the standard HIP cycle for EBM Ti-6Al-4V, recommended by Arcam AB, with a temperature of 920°C, a pressure of 100 MPa, a two hour hold time and rapid cooling. The second post treatment was a similar HIP cycle, but with a HIP temperature above the β-transus temperature and with slow natural cooling. The third post treatment was a HIP cycle with a temperature far above the β-transus, relatively short hold time and rapid quenching. In Table 2 and Fig. 6, the thermal and pressure profiles of the post treatments are presented.

PT1 and PT3 were performed in the QIH9 URQ® (Uniform Rapid Quenching) system at Quintus Technologies in Västerås, Sweden and PT2 was performed in a QIH9 URC® at Quintus Technologies in Columbus, Ohio, USA.

The material used in this study was alloy Ti-6Al-4V fabricated with an Arcam Q10 Electron Beam Melting system at the ORNL Manufacturing Demonstration Facility. Standard EBM Ti-6Al-4V printing parameters were used, with the powder layers deposited at 50 µm. The samples used in the study were cylinders and prismatic bars.

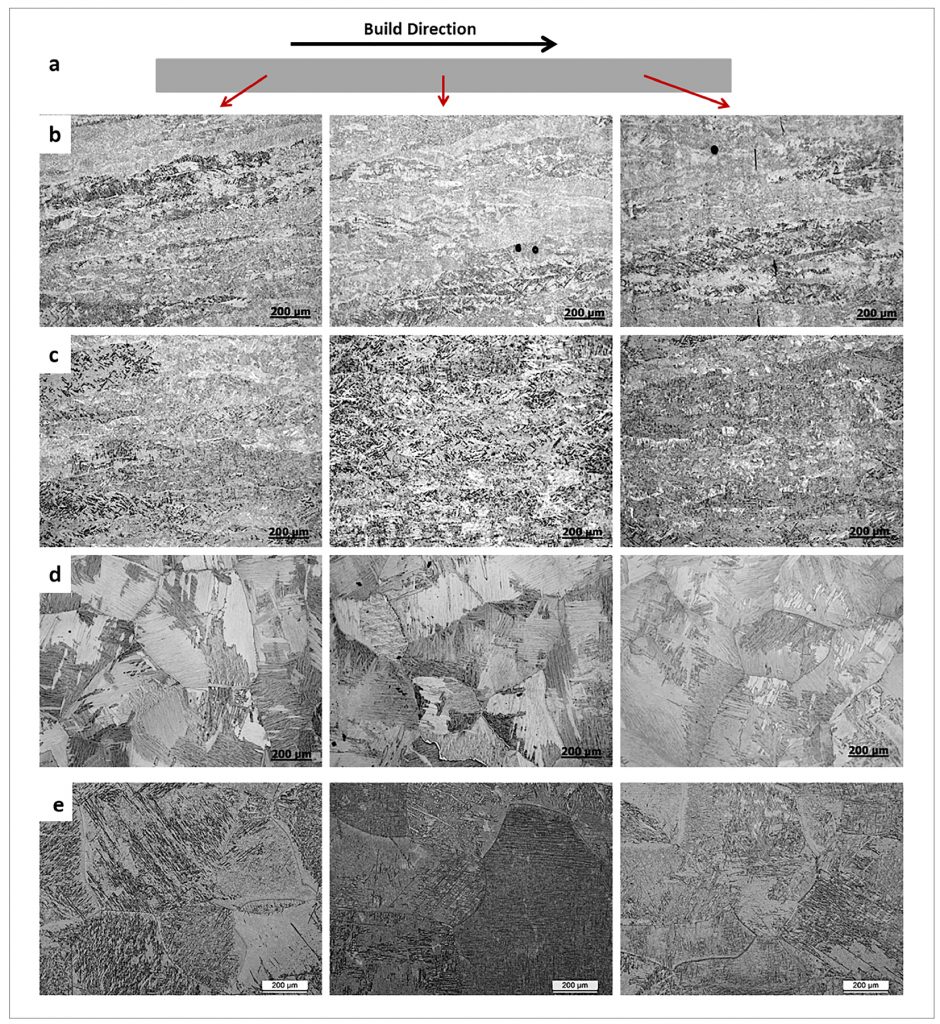

The resulting microstructures of the study are shown in Fig. 7 where (b) shows the as-printed material, (c) shows the PT1 standard HIP treated material, (d) shows the PT2 HIP treated material above the β-transus followed by slow cooling, and (e) shows the PT3 HIP treated material above the β-transus followed by rapid cooling. Fig. 7 (a) shows the build direction and the position in the sample where the micrographs were taken from. The black dots in Fig. 7 (b) are pores from the printing process and, in (c), (d) and (e), there are no black dots since the HIP process has eliminated the porosity.

The material treated with PT1 still shows a columnar grain structure similar to the as printed microstructure, showing no improvement for the aim of the study. On the other hand, the materials treated with PT2 and PT3 show a significant difference from the as-printed material resulting in a homogeneous microstructure with fully equiaxed grains. However, the slow cooling rate involved in the PT2 treatment (approx. 85°C/min) resulted in large α colonies. Such a colony microstructure has a negative impact on fatigue behaviour. For PT3, which had the same HIP temperature and pressure as PT2 but a much faster cooling rate after the hold time, the material shows the same equiaxed grain structure but with very fine α precipitates that are distributed more as a basket-weave microstructure rather than a large colony microstructure.

The observation that the microstructure can be changed from columnar to equiaxed beta grains via Hot Isostatic Pressing above the β-transus temperature of the alloy indicates a potential internal stress in the as-fabricated samples that is large enough to possibly cause recrystallization and grain growth of the beta grains. Other potential mechanisms could be that, on heating above the β-transus, the entire existing grain boundary α dissolves, allowing for free migration of the β grains and this may result in abnormal grain growth. Studies are currently underway to understand the mechanism of this transformation and fine-tune the HIP parameters to attain the equiaxed microstructure. In-depth EBSD analysis will be carried out to understand the origin of the equiaxed microstructure on HIPing of samples above the β-transus compared to a normal HIP cycle.

Conclusions and outlook

Hot Isostatic pressing is an effective process to eliminate defects in powder based additively manufactured parts, generating 100% dense material with improved fatigue properties and ductility. The fast cooling possibilities with URC® and URQ®, provided by Quintus Technologies’ HIP units opens up new possibilities of thermal treatment of AM material under pressure. One example of new post treatments, made possible with URQ® HIP, is the above β-transus HIP cycle under high pressure of EBM Ti-6Al-4V followed by rapid quenching, which was shown to completely break down the columnar grain structure in the material to a homogeneous and equiaxed grain structure. The URC® and URQ® HIP units are capable of generating varying cooling rates that allow the tailoring of the microstructure according to the property requirements. Research between Quintus Technologies and Oak Ridge National Laboratory is aiming towards fine-tuning the HIP parameters for optimum properties and understanding the mechanism of the involved phase transformations.

Contact

Quintus Technologies AB

Quintusvägen 2, B343

SE 721 66 Västerås, Sweden

Tel: +46 (0)21 32 70 00

Email: [email protected]

Oak Ridge National Laboratory

Oak Ridge, TN 37831

Tel: +1 865-576-8401

E-mail: [email protected]

[ipmd_banner type="1" orderby="rand"]References

[1] On the mechanical performance of structures manufactured by Selective Laser Melting: Damage initiation and propagation, Stefan Leuders, University of Paderborn, Germany, as presented at AMPM2014, MPIF, USA

[2] H. Galaragga, D. Lados, R.Dehoff, M. Kirka, Unpublished ongoing research.

[3] Understanding the Role of Hot Isostatic Pressing Parameters on the Microstructural Evolution of Ti-6Al-4V and Inconel 718 Fabricated by Electron Beam Melting, William H. Peter et al