EOS GmbH: Transforming companies into AM champions with Additive Minds

EOS GmbH, based in Krailling, near Munich, has long been recognised as a leader in powder bed Additive Manufacturing technologies for both metals and plastics. The launch of its Additive Minds training and consultancy service, however, represents a significant expansion of the support that the company can offer to those entering the industry. Nick Williams talks to EOS’s Güngör Kara, Director of Global Application & Consulting, on the evolution of the metal AM industry and the changing approach that customers are taking to implement the technology. [First published in Metal AM Vol. 3 No. 1, Spring 2017 | 15 minute read | View on Issuu | Download PDF]

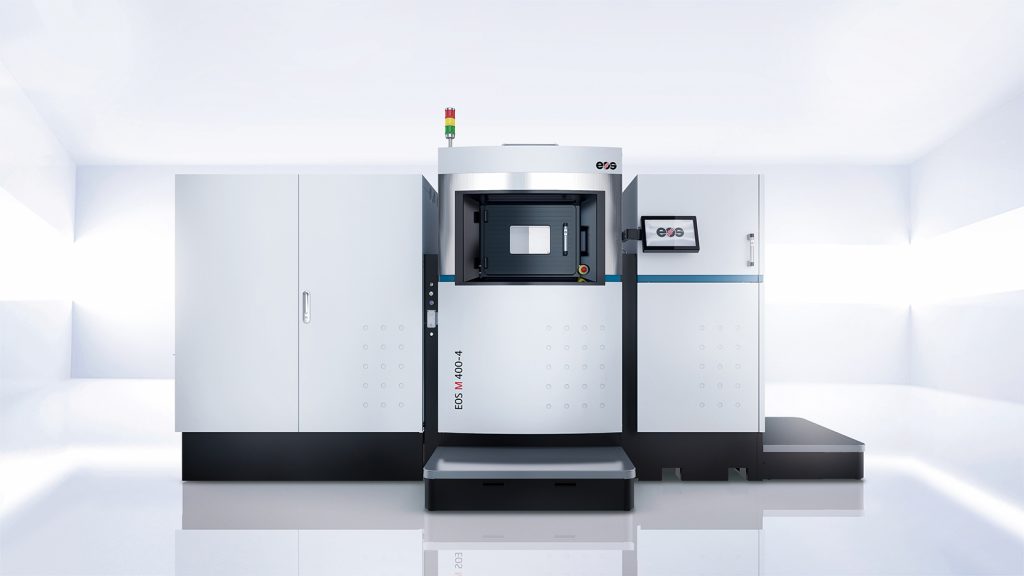

When Metal Additive Manufacturing magazine visited EOS GmbH’s headquarters in Krailling last summer, the site was busy with the construction of a third large administrative building. The main technology and customer centre that the company inaugurated in 2014 represented a substantial expansion at the firm’s headquarters, however this latest phase of development has resulted in the creation of a much larger, vibrant and modern campus dedicated to AM. Set in an attractive rural environment, the campus is less than half an hour from Munich’s city centre. The company’s workforce has also continued to grow and in January this year the milestone of 1000 employees worldwide was reached, doubling that of just three years ago. New production facilities are also planned and the company’s regional offices are also expanding.

It has, however, not only been the company’s physical infrastructure and employee count that has expanded to keep up with industry demand. With the announcement of its Additive Minds offering in late 2016, the company is seeking to position itself as a leading supplier for AM training, application development, consulting and technology implementation.

Additive Minds is led by EOS’s Güngör Kara, Director of Global Application & Consulting. Following the announcement about the new Additive Minds service at Formnext 2016, Metal AM magazine met with Kara, where discussions focused on the new venture’s roots and objectives. This article picks up on a number of themes that were highlighted in those discussions. What is clear is that the Additive Minds concept is a timely expansion of the support that EOS has always offered to its customers in their development and implementation of AM.

The Additive Minds approach to supporting AM development

Additive Minds has been structured to offer a wide range of support options for those looking to make the move into metal AM. These options range from straightforward employee training through to comprehensive application development support and complete facility planning. The Additive Minds service is based around three core areas that can support company’s move into metal AM; Consulting, Innovation Centres and its Customer Academy.

Explaining the evolution of the Additive Minds concept, Kara stated, “Initially, we expanded our conventional sales and support offerings through consulting as it became clear that many of our customers still needed a significant level of educational support. This support often went far beyond the basic training we were initially offering and as this service grew it became clear that we needed to give it an identity of its own, so Additive Minds was born. With our training and customer specific consulting we can now support customers at all stages of the AM learning curve. We can enable and support all the necessary steps to develop an application, from an initial introduction to AM technology to supporting application redesigns, application-specific parameter development, operational qualification and in-process quality observance via our MeltPool monitoring tool.”

Additive Minds Innovation Centre

With its Additive Minds Innovation Centre, EOS has significantly extended its range of services in the area of AM support and has created what it calls a ‘central hub of innovation’. Companies can send a team of engineers and technicians to EOS where experts from Additive Minds oversee their education and development for a period of six to eighteen months. During this time, there is the potential to develop new applications through to a production stage. At the end of this phase, a team will have the capability to immediately continue production in their own company, thus gaining a huge time advantage.

“Developing applications for serial production can be a challenging task for a company that is new to the technology. Therefore, large organisations are now taking advantage of going through this development journey with an industry partner who not only supports but also enables them towards AM serial production,” stated Kara. “This is what we do with our Additive Minds Innovation Centre. Jointly with the customer, we initiate the development process by finding the right application for production using AM technology. Once identified, we then develop this application jointly with the customer’s engineers. As a result of this collaborative approach they have learned enough to enable them to develop further AM applications by themselves afterwards. This type of process normally happens either in our Innovation Centre at our headquarters in Krailling, in different regional EOS Innovation Labs around the globe, or on a customer site as a private Centre of Excellence.”

Additive Minds Consulting

The Additive Minds consulting service addresses each customer’s individual requirements. The range of topics on offer covers the complete cycle, from technology fundamentals, component choice for AM production, design and AM-compatible engineering to production scaling and validation.

“If an even more holistic approach is needed, we can accompany customers with a dedicated team of Additive Minds Consultants through the development of serial applications to starting serial production within one continuous project. This is the approach taken by our Innovation Centre team,” explained Kara.

Additive Minds Academy

The Additive Minds Academy additionally offers a range of AM training courses and workshops that can range from two days to six months. These courses cover all aspects of AM technology, from part screening and selection through to parameter editing, lattice structures and melt pool monitoring.

EOS has developed its own training programme in collaboration with the University of Wolverhampton and the SRH Hochschule Berlin. Through this, participants can qualify as an AM Application Engineer within six months through intensive learning modules and practical training. The first participants began their course in February 2017. “Educating and training AM Application Engineers can also be challenging as customers currently very often go through a ‘trial and error’ learning curve that is very time consuming and ties up resources. Because of this, we introduced our training programme, helping to prepare our customers for the next steps in introducing AM in their organisation and enabling them to tap the full potential of this disruptive technology,” stated Kara.

Speeding up the development cycle

Those who have already gone through the process of developing an AM application in-house for the first time will recognise that the length of the development cycle can be critical to the success or failure of a project. Budgets and patience are limited in all organisations and managing expectations, be they at board level or R&D level, is vital. A timescale of two years is often given in the industry in order to develop an application in-house for series production. Commenting on the typical timeline that a company should expect for a project to reach series production at a new in-house facility, Kara stated, “Our experience shows that customers who work with Additive Minds Innovation Centres can enter AM-based serial production within a timeframe of six to eighteen months.”

“The biggest initial misconception we see among newcomers to our technology is in relation to the complexity of building up the knowledge and experience that is necessary to succeed in AM. Today, there is still a low number of engineers in the market who can develop AM applications. Therefore, knowledge must be built up and scaled internally in every organisation. We see a lack of AM knowledge – and not taking seriously how important this is – as one of the key factors that contributes to the failure of ventures into AM. Investing into AM education and enablement is crucial as it will help the customer to better understand what they didn’t know before. Customers will get a better understanding of what AM can offer in general, as well as to their business. At the same time, they will also get a better feeling of what hurdles their organisation might have to overcome on the way to success,” stated Kara. “It is unsurprising that a customer needs to observe both sides of the coin to be successful. With every innovation that a company introduces, it will be entering new and unknown fields that will challenge the mindset of what was previously clear and certain. Once a customer understands the beauty of this innovative technology, we invite them to share the passion that we at EOS have for its possibilities.”

“In the past, a lot of effort went into helping customers who had achieved a certain level of expertise in AM by themselves, but had then hit obstacles that were simply beyond their capabilities. The inevitable result was that many of these early entrants lost momentum in their projects because of the complexity of the challenges that faced them. Now, by placing an emphasis on support from a very early stage, we can help to rapidly increase a company’s knowledge through a variety of routes and make them aware at a very first stage of their journey not only what is possible, but what the restrictions are too,” added Kara.

“We have seen inflated expectations guide decision processes. It goes without saying this will lead to disillusionment over the process of introducing AM to a business. However, once the reality of AM is clearer for your organisation, once your people are trained and educated, the application is defined and the AM strategy clear, the first successes will come – celebrate them! We have a growing number of customers that already entered a phase where they have become truly successful with their decision to make a strategic investment into AM,” stated Kara.

Companies introducing AM have to act in a very agile way to adapt to this new and disruptive technology. If they do not, they are more likely to fail. “Business models based on AM also need to be disruptive to make the use of AM a true and sustainable success story. In total, organisations constantly need to innovate – in the case of AM this will require an openness to disruptive change – but which will pay back in the end.”

Audi and Additive Minds

EOS recently announced a development partnership with Germany’s Audi AG, one of the leading manufacturers of premium automobiles, to support the carmaker in the holistic implementation of industrial Additive Manufacturing technology and the development of a corresponding Additive Manufacturing centre in Ingolstadt. “The aim is to not only supply Audi with the right additive systems and processes, but to also support them during applications development, when building up internal AM knowledge and training their engineers to become in-house AM experts,” commented Kara.

Audi has recognised the potential of Additive Manufacturing in the automotive industry for some time and now actively promotes the use of the technology within its business. The company’s toolmaking and casting technical centres play a leading role in these activities thanks to the advantages of conformal cooling, for example. AM is, however, also being applied to equipment and prototype manufacturing at Audi, as well as for motorsport applications.

Jörg Spindler, Head of Toolmaking at Audi, explained, “We have set up our own competence centre for 3D printing in order to gain experience with the materials and the process and to further develop them for series production. A close cooperation with AM solution providers such as EOS, who can support innovation in technology development, is essential for these aims. With this technology we are able to integrate internal structures and functions in tools that we have not been able to create so far with conventional manufacturing methods. Especially with components in small batches, we can now produce components using lightweight construction, quickly and economically based on this technology.”

With the application of Additive Manufacturing, Audi is also focusing on the production of inserts for die casting moulds and hot working segments. The company can positively influence series production processes through conformal cooling, producing parts and vehicle components more cost-effectively. This is made possible by using highly complex, additively manufactured cooling channels, which are tailored to the component and could not be implemented using conventional technologies. Specifically, the optimised cooling performance leads to a reduction of cycle times by 20%, which has a positive effect on energy consumption and the cost of components.

Dr Stefan Bindl, Team Manager at the Additive Minds Innovation Centre, stated, “The close cooperation concerning application and process development, as well as internal knowledge building, makes a significant contribution, which is why Audi can quickly achieve substantial positive effects for their own business by applying our technology.”

Industry’s evolving approach to AM

EOS has seen some significant changes over the last decade in terms of how customers evaluate and use metal AM. “In the first twenty years since the foundation of EOS, in 1989, we saw customers using our technology primarily for rapid prototyping with the sole aim of accelerating product development and speed to market. Today, we see more and more companies investigating how they can use our technology for true serial applications. The challenges they face and the support they need from us are completely different from those early rapid prototyping customers,” stated Kara.

“What is critical today to the successful implementation of metal AM is that companies define one, or several, applications where the use of the technology can be most beneficial. In parallel, they must build up their knowledge as their engineering staff typically have no experience of AM technology. Once a company has implemented AM it needs to prepare itself to act in an agile way to be able to adapt adequately to its customers’ requirements for AM parts,” stated Kara.

Kara believes, however, that the number of companies with a deep knowledge of AM technology is still extremely low. Consequently, today only a few can develop truly radical innovations with AM. “Additive Manufacturing is, however, constantly gaining more awareness as we progress and the potential of the technology is therefore becoming more known. It is a great enabler of radical innovations. It can disrupt markets and create competitive advantages by introducing new business models. To leverage this effect, organisations must focus now on building up expertise. This allows organisations to become the first mover within their industry sector, blocking others from following, as building up IP for AM applications is almost impossible to surpass,” stated Kara.

Kara added that in addition to the potential of AM in terms of design, part integration, customisation and supply chain, companies must also focus on the effects that the technology can have on their markets. “We urge companies to consider the development of AM business models to derive the best possible from this new technology. Companies planning to use AM for serial applications normally have to undergo a substantial transformation to successfully introduce this disruptive technology in their business in a way that it can truly become successful and add value. If start-up teams do not keep an eye on how the market is developing around them, they might run the risk of being overtaken quite quickly.”

Outlook

The metal AM industry is evolving at tremendous speed in terms of process, application and material developments. EOS stated that in recent years it has developed a far clearer understanding of what the greatest needs of its customers are in relation to scaling up AM. Looking to the future, key areas for development activity have been identified as:

- Increasing the productivity, scalability and automation of production systems

- Offering an ever-growing choice of new materials

- Integrating conventional and additive technologies in existing manufacturing environments at the customers’ operations.

“In addition to these topics, we will be constantly improving the support that we offer to our customers, where the number of disruptive innovative AM applications will continue to grow,” stated Kara.

Commenting on GE’s investments in Arcam and Concept Laser, Kara stated that this move in the AM market had not taken EOS by surprise as it reflected the constantly altering competitive landscape in which the company is operating. “With the increasing industrial use of our technology we will see more and more players – including those from other industries – entering the scene. Moves like those of GE will additionally contribute to widening the perception, awareness and understanding of Additive Manufacturing across industries and shows the importance of the technology for the future of manufacturing.”

GE, of course, has not been the only multinational company to make waves in terms of AM investments and application developments. Germany’s Siemens is another example of a company that has innovated in the use of AM to enhance its industrial products. Commenting on what lessons others can learn from these businesses in terms of their approach to the adoption of metal AM, Kara stated, “Both of these companies stepped into this emerging market very early and, as such, have been able to build up specialist knowledge and experience. Today, this gives them a clear competitive advantage. Another result of this is that they now have an IP advantage to block other competitors from entering their AM-driven market. This block is almost impossible to skip and leaves others limited to entering other fields of businesses.”

Through its new Additive Minds service, EOS is well positioned to be a first point of contact for those looking to evaluate AM. This naturally places the company in a strong position when hardware investment decisions are made. Kara concluded, “I believe that we now support our customers with the most extended AM enablement services in the industry. With this, we can ensure that our customers go through their AM transformation adequately supported and successfully to become the AM champions within their industry.”

Contact

Güngör Kara

Director of Global Application and Consulting

EOS GmbH Electro Optical Systems

Robert-Stirling-Ring 1

82152 Krailling/Munich

Germany

Tel: +49 89 893 36 0

Fax: +49 89 893 36 285

www.additive-minds.com

www.eos.info