Distributed manufacturing: Old concept, new relevance, new technology?

In highlighting the vulnerabilities of global supply chains, events such as COVID-19 have inspired renewed interest in alternative forms of organising production. Distributed manufacturing is now seeing early use in fields such as oil and gas and for on-demand spare parts manufacturing. For the first time, large-scale on-demand manufacturing was seen in the supply of emergency PPE at the height of the pandemic. Dr Jennifer Johns discusses how AM can help to address the challenges this new business model presents, and introduces the University of Bristol's £1 million Brokering Additive Manufacturing project, which seeks to produce a revolutionary new brokering method for highly distributed and diverse manufacturing systems. [First published in Metal AM Vol. 7 No. 2, Summer 2021 | 20 minute read | View on Issuu | Download PDF]

We in the industry have long debated the future of manufacturing, pondering how the organisation of production will be configured in the short and long terms. Events since March 2020 have contributed to renewed interest in how and why manufacturing could – or should – change to meet new demands. COVID-19, political shifts towards protectionism illustrated by Brexit, global recession, and events such as the container ship Evergiven’s blockage in the Suez Canal, have highlighted the vulnerabilities of geographically extensive supply chains. These widespread value chains are, however, the backbone of the global economy, supporting high-volume mass production in lower cost economies, facilitating consumer demand for the rapid delivery of products, and enabling lead firms to organise their production more efficiently and flexibly. The activities of leading firms in this global economy can be characterised as being driven by three dynamics: 1) cost, 2) flexibility and 3) speed. This has created a complexity of organisational configurations based on degrees of externalisation of functions, different business models and various means of exercising control and coordination.

Until recently, we could have assumed that the current manufacturing landscape – built on the premise of standardised, high-volume production and large, centralised factories – would continue. Communication and transportation technologies enable the levels of control and governance necessary, with almost the whole globe ‘conquered’ by the unstoppable globalisation machine and underpinned by essential global value chains maintaining the status quo.

Now, we are all aware that there is a large question mark hanging over our understanding of the most appropriate way to organise production; even the general public is increasingly aware of the challenges facing the contemporary system. All industry sectors are pondering how to respond to difficult circumstances. In the short-term, particular supply chain disruptions have to be tackled: for example, the shortage of semiconductor chips causing automotive factory closures. Meanwhile, alongside firefighting tactics, questions are being asked about what the immediate future may hold in terms of alternatives to centralised, mass production. This article focuses on distributed manufacturing and the potential role of Additive Manufacturing in new systems of production.

The conversation around distributed manufacturing has heightened since March 2020, due to the disruption to geographically extensive supply chains and the scramble for Personal Protective Equipment (PPE) production, particularly during the first wave of the pandemic. The flexibility and speed of delivery from additive manufacturers made headline news, and we witnessed the visibility of the AM community increase as it came together to meet critical demand. This seemed to herald a new age in local, collaborative production, utilising the special characteristics and capabilities of AM, signalling a maturing of the sector to those outside the industry. Buoyed by this impressive emergency response, we now have time to pause and reflect on how (or even if) this successful ‘case study’ could instigate broader, more systemic changes in which production is more localised.

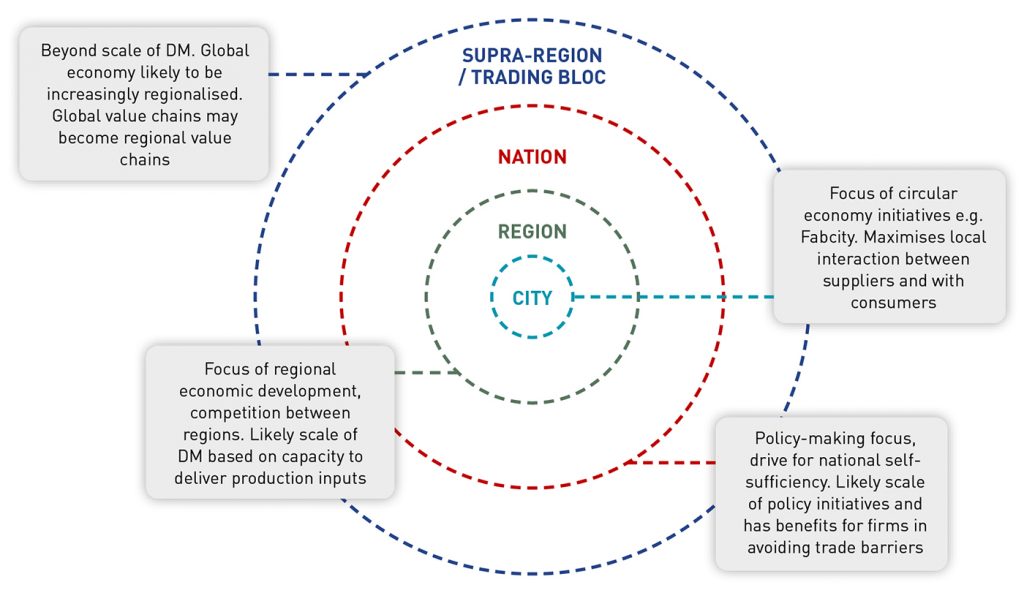

Some clarity, therefore, is needed on precisely what ‘distributed manufacturing’ is. As Fig. 2 shows, there are currently multiple scales at which distributed manufacturing is being discussed and/or implemented. The term refers to the technology, systems and strategies that change the location and scale of the organisation of manufacturing. The term is now used to signal a transformative shift towards new localised forms of production, focusing less on economies of scale and more on economies of scope. Small, flexible and scalable decentralised production sites can operate through a digital network, in contrast to centralised models.

Digitalisation is key to this connection between localised production sites.

Why is this model attractive? And why is now the time? The potential advantages of a distributed network of manufacturing are clear, and this manufacturing model offers the potential to solve some pressing problems.

Geographical contraction

The geographical contraction in supply chains reduces dependency on linkages that may be vulnerable to disruption by global events, including weather events and fluctuations in transportation costs (never mind global pandemics).

Greater flexibility and agility

It offers greater flexibility and agility compared to the fixed models of production. During times of uncertainty, greater flexibility is going to become an increasingly significant competitive advantage.

Proximity to consumers

Proximity to consumers can result in faster delivery, greater customisation and a more sustainable model. This helps with the broader agenda around environmental sustainability, and shifts in consumer demands around both sustainability and customisation.

Increased communication and collaboration

Closer geographical proximity between suppliers can increase communication and collaboration, and increase the speed of innovation in design and production – at least in theory. Geographers have been debating the assumed benefits of clustering and agglomeration for decades, but the potential is there.

Greater efficiency and resilience

Distributed manufacturing has the potential for greater efficiency and resilience through local sourcing of materials and other resources.

Changing relationships

The relationship between producer and consumer may change as the user becomes more active in the design and production of goods.

Increased national reshoring

Distributed manufacturing helps meet a pressing political agenda in many countries to increase levels of national sovereignty and reshoring. While it is unlikely that this will directly drive a distribution model, political support for organisational changes could create opportunities via government funding and tax relief on new investments. (A note of caution here – the goals sought by politicians in their desire for more national production do not necessarily overlap with those of industry – and national government responses vary widely in the scope and value of their investments in manufacturing.)

Where can we currently see distributed manufacturing in use?

Sectors in which we are seeing early-stage use include the production of on-demand personalised consumer goods, the supplementation of shortfalls in local demand for pharmaceuticals, and the production of spare parts in remote locations such as oil and gas rigs (Fig. 3). These examples, however, tend to be relatively isolated rather than acting as part of the kind of wider system of production that the term ‘distributed manufacturing’ alludes to. The closest we have come to larger scale distributed manufacturing is the production of PPE during the early stages of the COVID-19 pandemic, in which large volumes of PPE were produced by networks of SMEs and large manufacturers, typically located near the consumers (predominately hospitals) (Fig. 4).

It is clear that distributed manufacturing could offer some solutions to current manufacturing problems, and the role of Additive Manufacturing in this context is obvious. The advantages of this model mirror the capabilities of AM: flexibility; speed of delivery; sustainability gains through reductions in materials use; the broader increases in functionality through design for AM and its ability to be deployed across many parts of society, including in homes, educational settings and offices, in addition to more traditional factory settings. Indeed, if we return to the advantages of a distributed network as discussed above, you may have been thinking: ‘AM can do all that, too’. If manufacturing is to start shifting to more localised production, a huge window of opportunity presents itself specifically to AM, in contrast to traditional production methods.

How might this happen?

A series of interrelated processes are leading an incremental movement towards distributed manufacturing, but these are operationalised in a piecemeal fashion varying by sector and geography. We are seeing some reshoring (shift in production from low cost economies back to home countries), which necessitates local sourcing. We also see some elements of distribution in talk of the ‘factory of the future’ – or, digitised and automated factories which can be located in advanced economies due to the significant reduction in labour costs. Neither, however, contributes to a wholesale movement towards distributed manufacturing. AM offers us some examples of this model, such as the production of dental crowns, implants, dentures and appliances which are produced at an increasingly localised scale (ultimately being built in the dentists’ offices). At present, with the exception of a handful of examples, localised production is still contained within the existing centralised production system. The status quo perpetuates.

That leads us to ask where the drivers for more transformative change may come from if there is still a degree of inertia in industrial AM. It may lie in the increasing re-integration of the community-led aspects of AM within the industrial arena. The two halves of the sector can be seen to be coming together, driven by the increasing sophistication of desktop machines. For decades, the AM community, focused on domestic applications, has long been voicing the desire to use the technology to return to aspects of artisanal production, develop circular economies, develop ‘prosumers’ (individuals who produce and consume their own goods), democratise digital technologies and relocalise production. As illustrated by the PPE production response, hundreds of thousands (even millions) of AM machine owners are connected through platforms such as 3D Hubs, and meeting in FabLabs, Makerspaces, Barclays EagleLabs, etc. These ‘Makers’ have found renewed relevance, which, when combined with expertise from AM, could contribute to the ability of Additive Manufacturing to facilitate a distributed network.

The main challenges

There are many challenges with regard to the development of distributed manufacturing, some of which apply to all manufacturing methods, others specifically to AM:

Infrastructure

There may be issues around infrastructure and the capacity of localised regions to support distributed manufacturing. Following decades of under-investment in manufacturing, the capacity of the UK to respond to increased demand is likely to need assistance. Key questions remain around where in the UK this distribution is likely to take place and the degree to which it will cluster around existing manufacturing sites. A truly distributed system would see manufacturing located in close proximity to the consumer, but the legacy of manufacturing to date is likely to skew where distributed manufacturing emerges.

What is ‘local’?

Of course, this varies depending on the context. The political drive for distributed manufacturing is currently national, as part of the drive for sovereignty over manufacturing. However, if and when distribution occurs, the focus may well shift to the regional scale as different parts of countries vie for manufacturing to take place in their territories.

Governance and regulation

The governance and regulation of this sort of distributed network is embryonic and uneven. There will be issues to tackle around intellectual property (IP) which is more fluid in distributed manufacturing. IP monitoring during production will be needed to prevent copyright infringement. An associated risk is the relative immaturity of the software needed to manage the implementation of this model and the security of its networks (although some work is being done on this by organisation such as the SDAM [Secure Distributed AM] Alliance). Some regulatory issues will be broader – take for example, regulation of manufacturing production. Can we produce in neighbourhoods and cities? Will this be permitted by local government? Desired by local populations?

Material availability

The range and quality of materials, while expanding, still needs improvement in order to support distributed manufacturing. There is an increased focus on recovery and recycling of materials, but distribution will still be supported by materials supply chains that – depending on the nature of the material – may be global, given the uneven distribution of natural resources across the world. The present supply of raw materials already has some problems, with rising prices, so this needs to be considered as we consider a future that includes distributed manufacturing. Raw material supply chains will have to adapt from the centralised system to delivery to a more distributed network, making logistics in pre-production more significant than at present.

Standardisation and certification

Standards, capability and certification is a challenge that needs some elaboration in the AM context, and on which there is much work taking place. In a distributed system, greater governance to ensure standards are maintained across different sites is needed along with rigorous certification of production.

Process development

The development of design & manufacturing processes that can characterise and factor in the nature of distributed manufacturing capability so that designers are able to design products that are able to take full advantage of this network.

Business model uncertainty

More work needs to be done on understanding distributed manufacturing business models, in addition to the prevailing need to better develop and communicate viable business models for AM.

Addressing these challenges with AM

These challenges apply to traditional forms of manufacturing, but these methods of production will have their own issues when engaging with distributed manufacturing. For example, while standards and certification may be more straightforward for traditional manufacturing, there will nonetheless be issues around how this operates across multiple sites in a distributed system. As the geographies of operations shift, new problems can arise that disrupt the status quo. As a comparatively newer set of technologies, Additive Manufacturing could prove to be more flexible and responsive, given that the sector itself is constantly pressing for systemic change across multiple aspects of manufacturing. Distributed manufacturing represents an opportunity for AM to demonstrate its capacity to deliver on many of the transformative claims that have been made about the technology. Indeed, AM was supposed to cause a relocalisation of production. This hasn’t yet come to fruition, but the combined forces outlined at the start of the article have created a window of opportunity for AM to help drive a future in which more distributed models of production are possible. Here, the flexibility of AM – particularly its freedom from the fixed constraints of tooling new production lines – makes it a logical and central part of this distribution process.

To address many of the challenges outlined above, a key issue will be that of coordination and collaboration, something which is not easy during times of uncertainty and business pressure. Even so, there is a pressing need for independent arbitrage of communication and coordination of efforts to tackle these barriers to distributed network. History shows us that disruptive shifts in manufacturing rarely occur overnight, and when they do, a critical mass of engagement is needed from industry and its supporting institutions. At present, there are some critical limitations to the widespread adoption of distributed manufacturing, with coordination being a key factor.

Brokering Additive Manufacturing

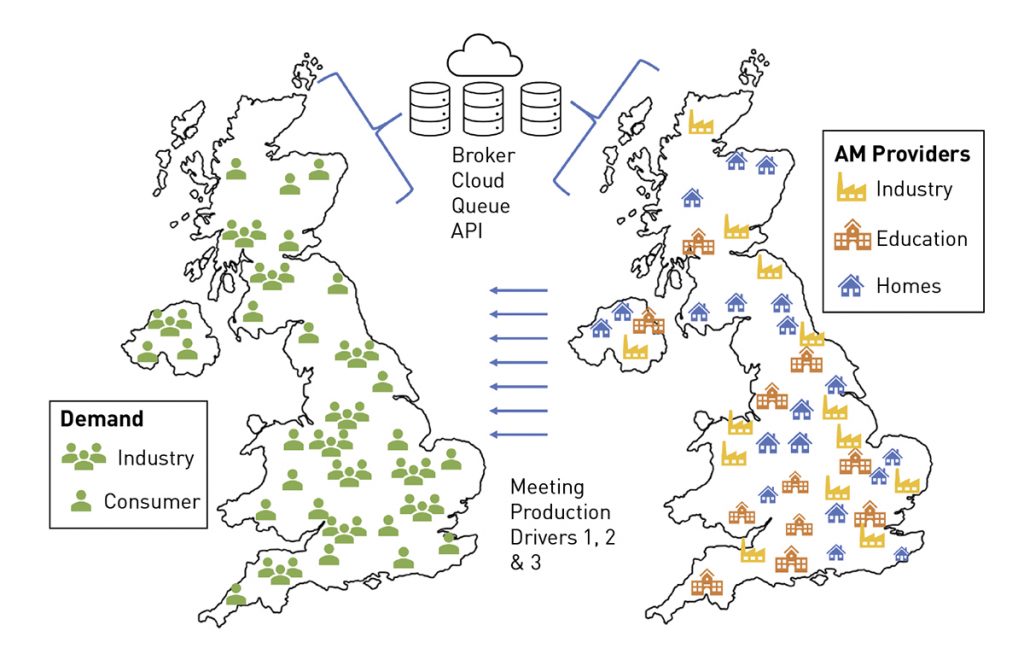

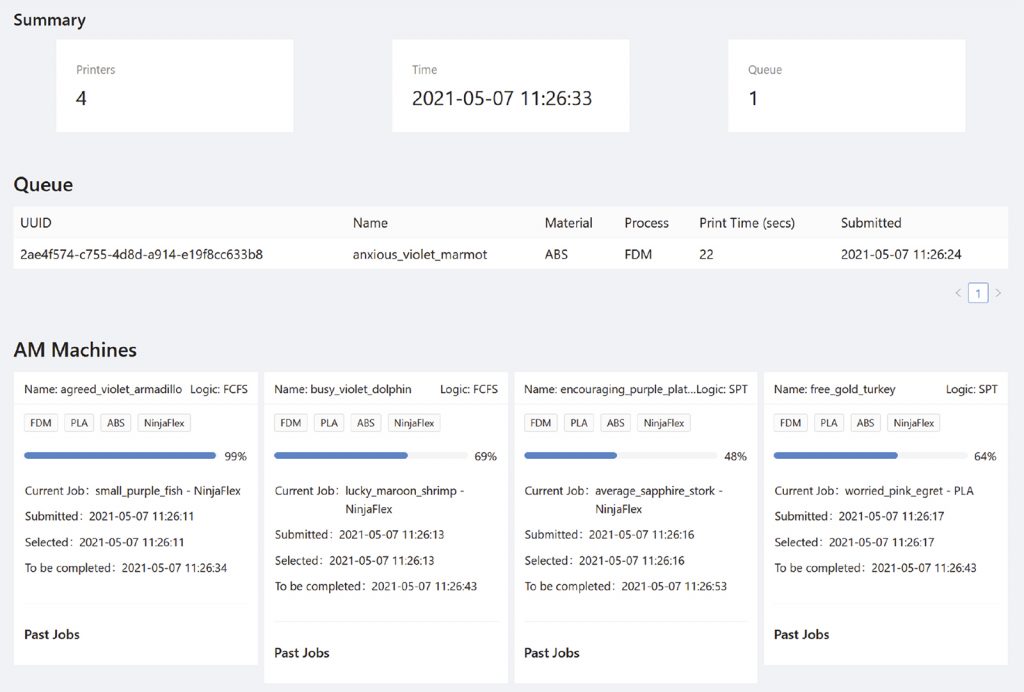

The University of Bristol has been awarded a £1 million grant by the UK Research Council (via the Engineering and Physical Sciences Research Council/EPSRC), called Brokering Additive Manufacturing (BAM), to produce revolutionary means of brokering jobs for highly distributed and diverse manufacturing systems to meet national demand for greater supply chain flexibility in the context of uncertainty and disruption due to factors such as COVID-19 and Brexit. BAM’s vision is of a queue, potentially cloud-based, where jobs can be submitted and offered to the entire AM capability of a local, regional, national and/or global community, and enabling human-led (e.g., technician, organisation), machine-led (e.g., individual AM machines and/or collective) and/or hybrid brokering. The queue would be capable of Big Demand and will enable suppliers to barter for jobs on a multi-scale basis, from single consumer to million plus components from organisations (see Fig. 6).

This approach enables governance/decision-making to be maintained with the clients and suppliers – be it human, machine or hybrid-led – and provides transparency for the clients in the AM capability and capacity afforded by the system. Suppliers can shift their production to meet the needs of the queue resulting in amorphous supply chains. In one moment, the queue may lead to a demand for one item (e.g., PPE), while, in another, a lack of demand could lead to competitive bartering. Supporting the entire spectrum of interaction, AM capability and production constraints provides the fundamental step-change in production capability.

Led by Dr James Gopsill, BAM brings together world-leading researchers from the Schools of Civil, Mechanical and Aerospace engineering and Business Management, 300 + leaders in the AM industry (including Renishaw, GTMA, AT 3D Squared), Model-Based Systems Engineering (including CFMS), and industry/government initiatives (such as Reshoring UK) to create novel brokering of highly-distributed and diverse manufacturing systems. Industry engagement is critical to the project.

Author

Dr Jennifer Johns

Associate Professor in International Business

School of Management

University of Bristol

UK

For further information visit the website of the Design and Manufacturing Futures Lab at

https://dmf-lab.co.uk/ or follow the group LinkedIn page at

www.linkedin.com/groups/9057578/