Developments in the Additive Manufacturing of titanium at PM Titanium 2015

The PM Titanium 2015 conference, held in Lüneburg, Germany, from August 31 to September 3, 2015, was the latest in the series of international conferences specifically focused on the processing, consolidation and metallurgy of titanium. As Dr David Whittaker reports for Metal Additive Manufacturing magazine, the ambition to apply titanium AM components in critical applications continues to drive researchers to further understand the influences of processing parameters on achieved microstructure and on the relationships between microstructure and mechanical properties. [First published in Metal AM Vol. 1 No. 3, Autumn 2015 | 15 minute read | View on Issuu | Download PDF]

PM Titanium 2015, the third in the international series of conferences on Powder Processing, Consolidation and Metallurgy of Titanium, was held at the Leuphana University in Lüneburg, Germany, from August 31 to September 3, 2015. The conference attracted an attendance of over 130 delegates from 27 countries. Encouragingly for an area of technology where, to date, the high level of R&D activity has not yet been matched by significant market penetration, several delegates from potential end-users were present, representing the aerospace, biomedical and consumer products sectors.

Within the ten technical session programme, two sessions were devoted specifically to the Additive Manufacturing of titanium and relevant papers also appeared in other sessions. This article reviews selected papers from the programme, all related to the processing of Ti-6Al-4V.

A consideration which is of high significance with regard to the viability of the use of Additive Manufacturing for safety-critical applications is the development of robust knowledge on the influences of processing parameters on achieved microstructure and on the relationships between microstructure and mechanical properties.

The reviewed papers all touch on this consideration by addressing the development of numerical simulation approaches to the modelling of the phase transformations as the melt pool is cooled during the Selective Laser Melting (SLM) process, the influence of post-build heat treatment on mechanical properties of material fabricated by Electron Beam Melting (EBM) and the effect of a surface hardening treatment on wear resistance and bulk mechanical properties of bars produced by SLM.

Multi Phase Field simulation of the Selective Laser Melting of titanium alloy

Peter Holfelder (Technical University of Munich, Germany) and his co-authors Jinming Lu, Christian Krempaszky and Ewald Werner, also Technical University of Munich, reported on work to develop numerical simulation methods to study the influence of process parameters on microstructure during the Selective Laser Melting (SLM) of Ti-6Al-4V.

To gain a better understanding of SLM, many experimental and simulative studies have been reported in the literature over the past two decades. Nevertheless, the process is still not fully understood due to the many inter-relationships of relevant physical effects that must be taken into account and due to the small timescales involved in the laser-material interaction.

In SLM, the metal powder is locally fully melted by a laser and cools down by self-quenching, by free convection of shielding gas and by thermal radiation from the free surface. This thermomechanical treatment of the material and, hence, the microstructure evolution differs substantially from those in conventional processing routes, such as forging, casting or milling. All of the mechanisms defined above were covered by the model presented.

In this model, a major area of novelty related to the proposal to use a CalPhad-based Multi Phase Field (MPF) model to describe the microstructure evolution induced by laser-material interaction. In contrast to the previously published and more conventional approaches, the nucleation and growth processes occurring during the relevant phase transformations are explicitly taken into account on the basis of free enthalpy. This allows a more detailed analysis of high cooling rates on the evolving field quantities.

The description of the phase transformation kinetics conventionally adopted is a fixed relation between phase fraction and temperature, for instance taken from measurements at cooling rates frequently near equilibrium conditions. In this commonly used approach, the phase fraction depends exclusively on the temperature. This simplified approach was included in the reported work, as a basis for comparison with the nucleation-and-growth approach, and was designated as Model 1. The second simulation set-up (Model 2) considered the nucleation and growth processes explicitly.

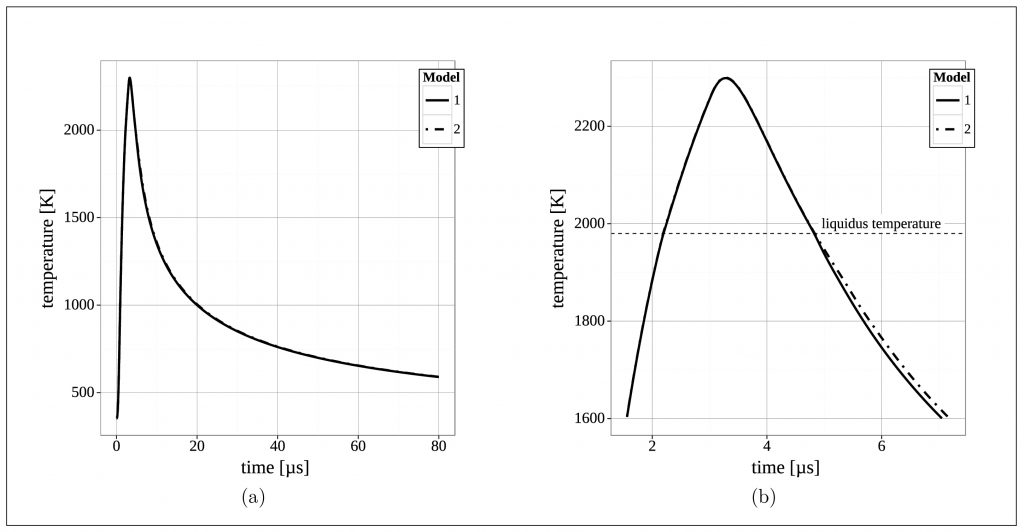

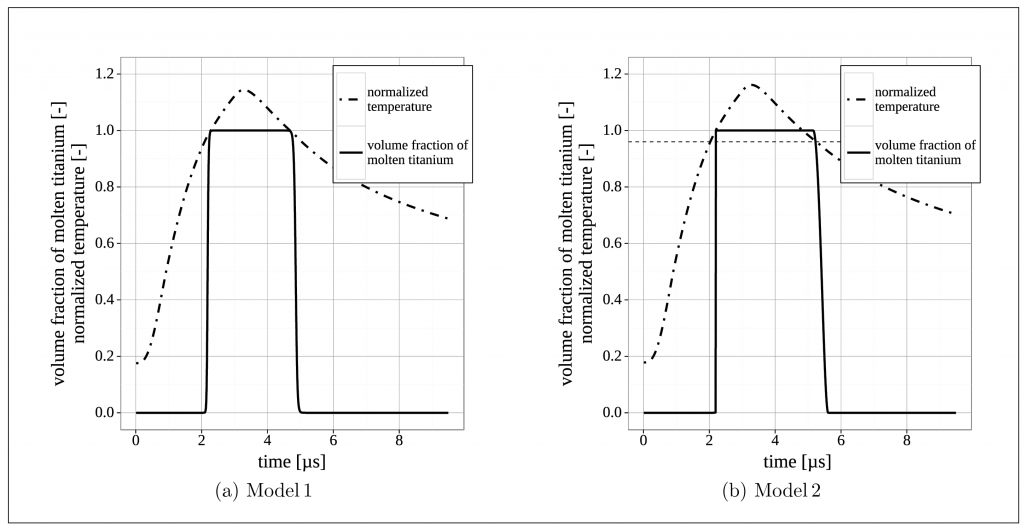

To demonstrate the principle of the Multi Phase Field approach, the phase transformation simulation was limited to the β-phase to molten phase transformation of Ti-6Al-4V and vice versa. The temperature evolution, evaluated at a selected point located at the centre axis of the laser beam, 5 µm beneath the material’s free surface, is plotted in Fig. 2. In Fig. 3, the evolution of the volume fraction of molten titanium and the evolution of the temperature (normalised to the liquidus temperature) are shown for both models.

For both models, the overall behaviour of the temperature evolution is similar during the heating and cooling periods, see Fig. 2a. During the heating period, the temperature vs. time curves are identical. However, during the cooling period, they differ significantly from each other, as soon as temperature falls below the liquidus temperature (approximately 1980 K), see Fig. 2b.

The different temperature evolutions during the cooling period originate from the dissimilar descriptions of phase transition in the two models. Fig. 3a shows that the volume fraction of the molten titanium becomes 1.0 as soon as the temperature at the selected point exceeds the liquidus temperature and is zero if the temperature falls below the solidus temperature. Fig. 3b shows a different but more credible behaviour, because molten titanium is super-cooled, a phenomenon which is observed for many materials.

Knowing that Model 2 allows for super-cooling, the difference in temperature evolution during the cooling period can be explained by the higher thermal conductivity of β-titanium compared to that of molten titanium below the liquidus temperature. Therefore, the heat fluxes decrease when the selected point and its surrounding is in the molten state and the temperature falls below the liquidus temperature. Consequently, the selected point cools down more slowly, which can be seen in the detailed view of the temperature evolution (Fig. 2b). The delay of the β/molten titanium phase transition during the cooling period, shown in Fig. 3b, is caused by nucleation (and growth and the associated incubation time during the nucleation of β-titanium) and the finite interface velocity.

During the heating period, the assumed small wetting angle for the nuclei of molten titanium leads to a high nucleation rate per cell when the transformation temperature is exceeded. This high nucleation rate leads to a nearly instantaneous transformation from β-titanium to molten titanium. Therefore, the temperature vs. time curves for the two models are indistinguishable.

The authors concluded that the nucleation-and-growth model provides a thermodynamically motivated description of the phase transformations during melting and re-solidification and that this model can capture the effect of super-cooling of molten titanium leading to a different temperature evolution compared with the commonly used approach, which assigns the phase fraction to a temperature value. Therefore, this model is physically reasonable for high cooling rates, because the incubation time of nucleation is considered.

The proper choice of particular material parameters, e.g. the interface mobility, is challenging, but could be performed by inverse analysis of measured relationships between phase fraction and temperature. Despite the current uncertainties, the chosen approach is able to provide a better understanding of microstructure evolution during SLM than the commonly used approach.

The influence of the chemical composition on the free enthalpies can be predicted by the CalPhad method. Adding the CalPhad method to the proposed model allows the study of the influence of the material chemical composition on the phase transformation. Furthermore, the model can be extended to simulate the growth of single grains to allow a deeper insight into microstructure evolution during the SLM process.

Mechanical properties of heat treated titanium alloy fabricated by Electron Beam Melting

Alexander Kirchner (Fraunhofer IFAM, Dresden, Germany) presented a paper on the influence of post-build heat treatment on mechanical properties of material fabricated by Electron Beam Melting (EBM) on behalf of his co-authors Burghardt Kloden, Thomas Weissgarber and Bernd Kieback (also Fraunhofer IFAM, Dresden) and Achmin Schoberth, Daniel Greitemeier and Sarah Bagehorn (Airbus Group Innovations, Munich, Germany).

The advantages associated with powder bed Additive Manufacturing of titanium components are well recognised: the high freedom of design enabling the fabrication of structurally optimised, lightweight parts; the dramatic reductions in lead times; the improved utilisation of expensive material and the capacity for a high degree of product customisation.

However, for applications in safety-critical parts, certainty regarding the achieved static and fatigue strength is also mandatory. This is a challenging issue in view of the complex influences of build parameters, heat treatments and surface quality.

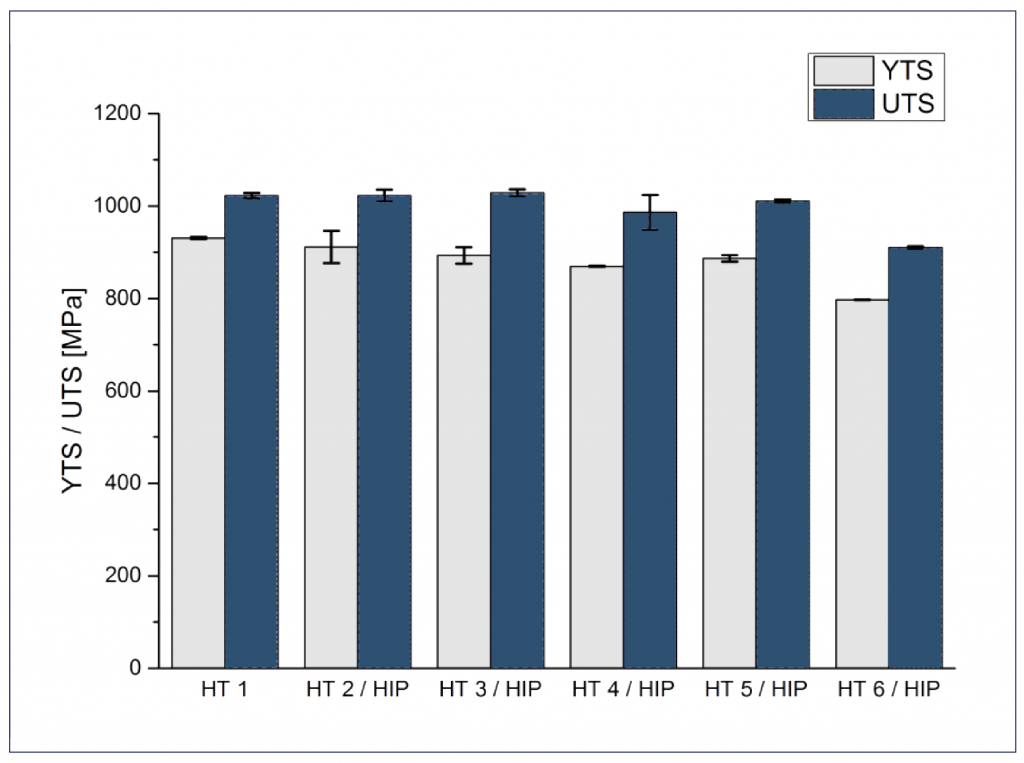

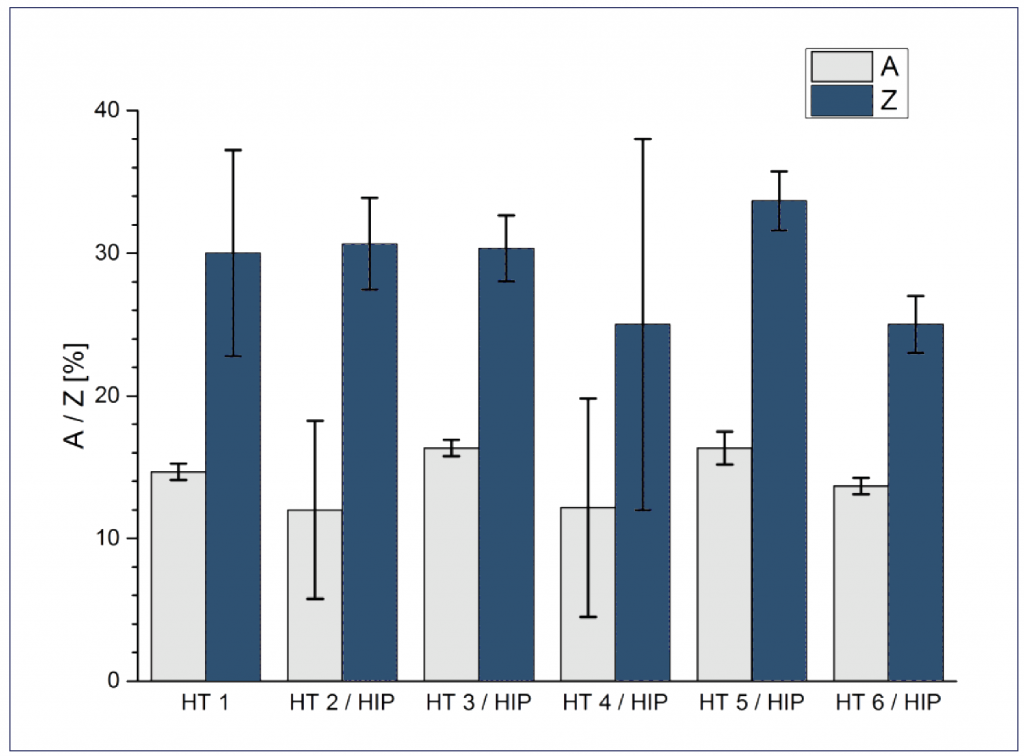

In the reported work, Ti-6Al-4V specimens, built by EBM, were subjected to heat treatments adapted to various application scenarios. Sample blanks were oriented in the build space such that the direction of subsequent mechanical testing coincided with the build direction (z-axis). These sample blanks were subjected to heat treatments between 650°C and 1050°C, designated as HT1 to HT6 in ascending order of treatment temperature. Treatments HT2 to HT6 also included Hot Isostatic Pressing (HIP) treatments with pressures up to 200 MPa and durations ranging from 0.2 h to 2 h, with the aim of removing residual porosity. Test samples, for tensile testing, high cycle fatigue testing and crack growth rate determinations, were machined from the blanks.

As the powder bed and the parts are kept at a temperature around 700°C during the EBM build process and are then cooled down slowly, the as-built parts have effectively been subject to an annealing treatment and dense specimens combine UTS of more than 1000 MPa with good ductility. A post-build heat treatment at 650°C (HT1) delivers virtually identical static properties to the as-built condition at a UTS of 1023 +/- 5 MPa and an elongation of 14.7 +/- 0.6%. Heat treatments at temperatures above 700°C produce very marginal changes in static tensile properties (see Figs. 4 and 5). For instance, treatment HT3/HIP gives a UTS of 1029 +/- 8 MPa and an elongation of 16.3 +/- 0.6%. The treatment at the highest temperature (HT6/HIP), in fact, produced a significant drop in UTS to 910 +/- 2 MPa.

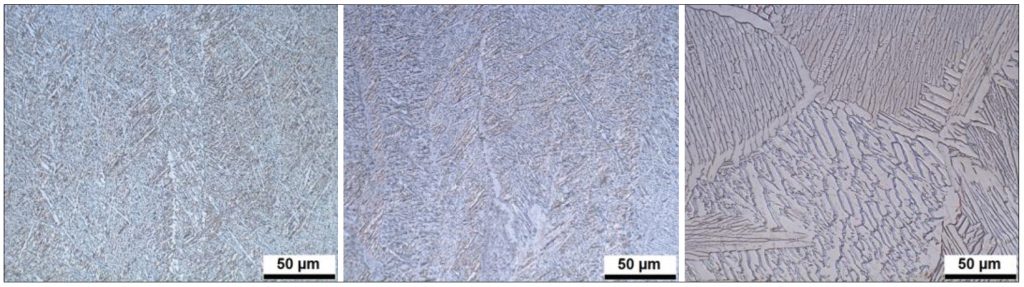

The drop in UTS at high treatment temperatures can be correlated with observed microstructural changes. As can be seen in Fig. 6, the structure of HT1, tempered at the lowest temperature, is a very fine basket-weave pattern. The maximum thickness of the α-platelets is about 3 µm. Upon increasing temperature, the α-phase thickness grows slightly, especially along the prior β grain boundaries. Sample HT3 /HIP contains a few α-platelets of up to 8 µm in thickness. Specimen HT 6/HIP, tempered at the highest temperature, exhibits a distinct coarsening of the α-phase with plate thickness up to 15 µm and the initiation of globularisation.

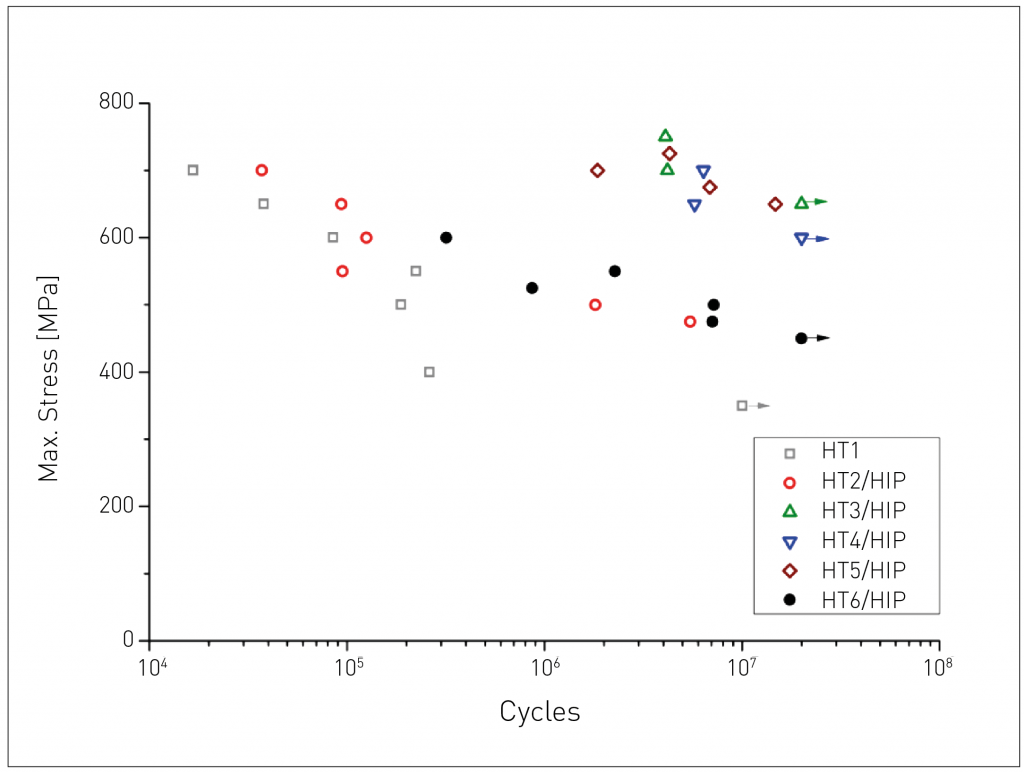

In contrast to the static properties, significant increases in fatigue resistance can be generated by combining HIP and thermal treatments. As shown in Fig. 7, specimen HT1, heat treated at the lowest temperature, reached the fatigue limit of more than 107 cycles at 350 MPa. This agrees well with the published value of 340 MPa for as-built samples. Reducing any remaining porosity by HIP first lifts the “knee” above 106 cycles, as can be seen for sample HT2/HIP. HIP treatments at higher temperatures (HT3 to HT5) lift the S-N-curve to higher stress levels with a fatigue limit at approximately 600 MPa. In the case of HT3/HIP, a run-out at a stress level of 650 MPa was even observed. A further temperature increase leads to a reduction in HCF stability, as can be seen for HT6/HIP. In comparison, the fatigue limit of chemically polished, double vacuum-arc remelting forging stock, has been quoted in the literature as 550 MPa. Very similar values of 500 to 550 MPa have been quoted for machined, SLM-fabricated Ti-6Al-4V.

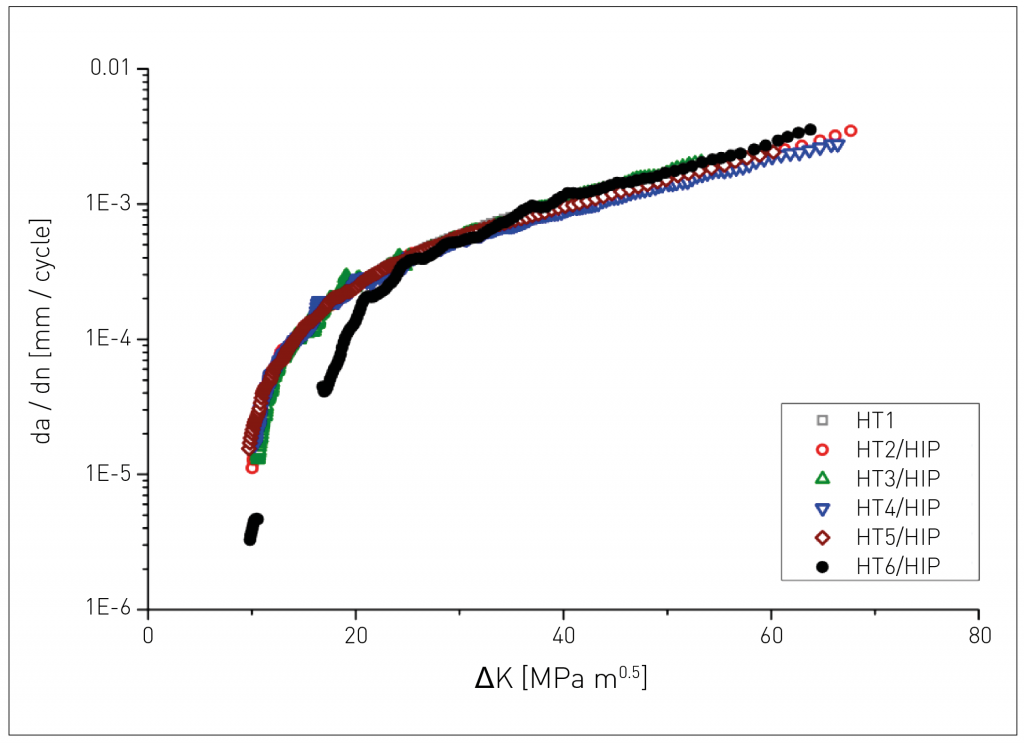

On the other hand, the treatment at the highest temperature (HT6/ HIP) has been observed to generate beneficial effects in terms of crack propagation rates. The crack propagation rates of the EBM-built samples are plotted in Fig. 8. The results coincide with each other except for HT6/HIP. This implies that the temperature increase from HT1 to HT5/HIP does not influence crack propagation noticeably. At a stress intensity range ΔK of 20 MPa√m, a crack growth rate of 2.5×10-4 mm/cycle was observed. This value is in good agreement with the data for solution treated and overaged Ti-6Al-4V exhibiting a bimodal microstructure. The data presently available shows that the plane strain fracture toughness KIC exceeds 50 MPa√m for all heat treatments.

HT6, however, causes a distinct retardation of crack growth at ΔK below 20 MPa√m. From data points at very low rates of crack growth a threshold of 10 MPa√m can be estimated. This is higher than the threshold value of 3.5 MPa√m cited for SLM-fabricated Ti-6Al-4V in the as-built state.

The fracture surfaces of samples HT1 to HT5/HIP are smooth, whereas the fracture surface of HT6/HIP features a higher roughness. High roughness of the fracture surface is linked to crack closure in titanium with a large α-colony size. This, together with the lower tensile yield strength, leading to a larger plastic zone at the crack tip, is responsible for the reduced crack propagation rate observed in sample HT6/HIP.

Influence of gas nitriding of titanium alloy bars made by Selective Laser Melting

A paper presented by Stella Raynova, University of Waikato, New Zealand, on behalf of the authors Aamir Mukhtar, Peter Franz, Warwick Downing and Graeme Smith (TiDA Ltd. New Zealand) and Ben Jackson (University of Waikato), studied the influence of a gas nitriding treatment on the mechanical properties of Ti-6Al-4V bars produced by Selective Laser Melting.

SLM offers a number of advantages compared to conventional production techniques such as a reduction in production steps, high material use efficiency and near net shape production capability. The layer by layer building processes in SLM enables the production of parts with a high geometrical complexity, allowing a greater freedom of design.

However, the unique conditions during the SLM process can also give rise to problems. Because of the short interaction times and accompanying highly localised heat input, large thermal gradients exist during the process. These lead to the build-up of internal stresses, attributed to shrinkage during cooling. The rapid solidification also leads to segregation phenomena and the development of non-equilibrium phases (columnar growth).

To overcome these problems and strengthen SLM parts, different heat treatments (i.e. stress relieving, annealing) and thermo-chemical treatments have been applied. One candidate thermo-chemical treatment, gas nitriding, has been extensively studied for wrought titanium alloys and it has been observed that a surface phase of α(N)-Ti is created, which impedes the movement of dislocations or defects at the surface and provides a layer of significantly different mechanical properties than the bulk material. Ongoing gas nitriding forces the diffusion of α(N)-Ti from the surface into the unsaturated matrix.

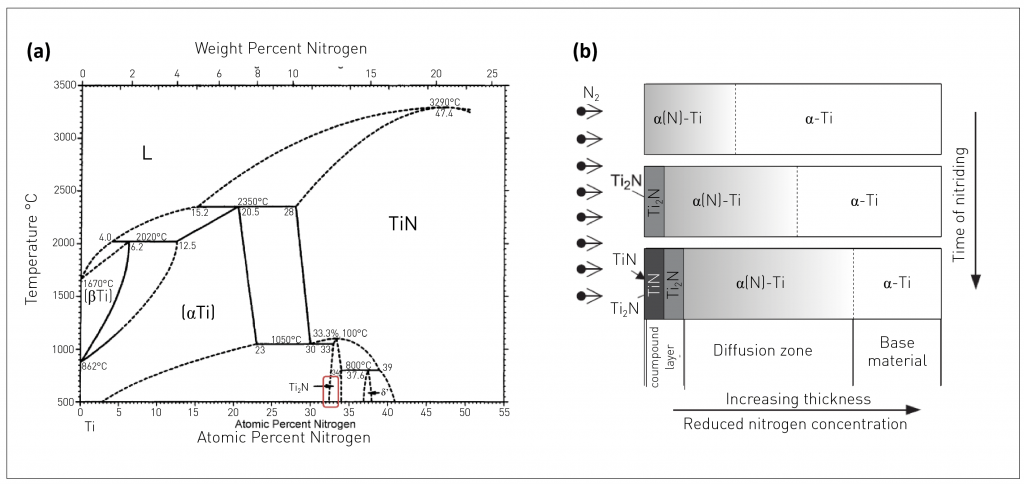

Between 200°C and 500°C, nitrogen is present as α(N)-Ti only in the first hundred nanometres with an average concentration of 30at%, as highlighted in the Ti–N Phase Diagram (Fig. 9a). With higher treatment temperatures, a “compound layer” is formed at the surface as the nitride begins to nano-crystallise preferentially to Ti2N and subsequently to TiN. An increased depth of the diffusion zone (consisting mainly of α-Ti solid solution enriched with precipitated nitrogen) can also be observed on increasing treatment duration. Fig. 9b shows the influence of time on the structural state of the surface layers during gas nitriding of wrought titanium alloys.

In the reported study, several heat treatments were investigated to find suitable nitriding processing parameters to strengthen SLM Ti-6Al-4V parts and gas nitriding was then combined with an adapted heat treatment below the β-transus temperature for interstitial hardening.

SLM parts were placed in a vacuum sintering furnace, heated to an elevated temperature with a heating rate of 10°C/min and furnace cooled to room temperature and high purity nitrogen gas was introduced with a fully controlled gas flow regulator. Gas nitriding trials were carried out over the temperature range from 800°C to 1030°C and for times from 3 hours to 6.5 hours (see Table 1).

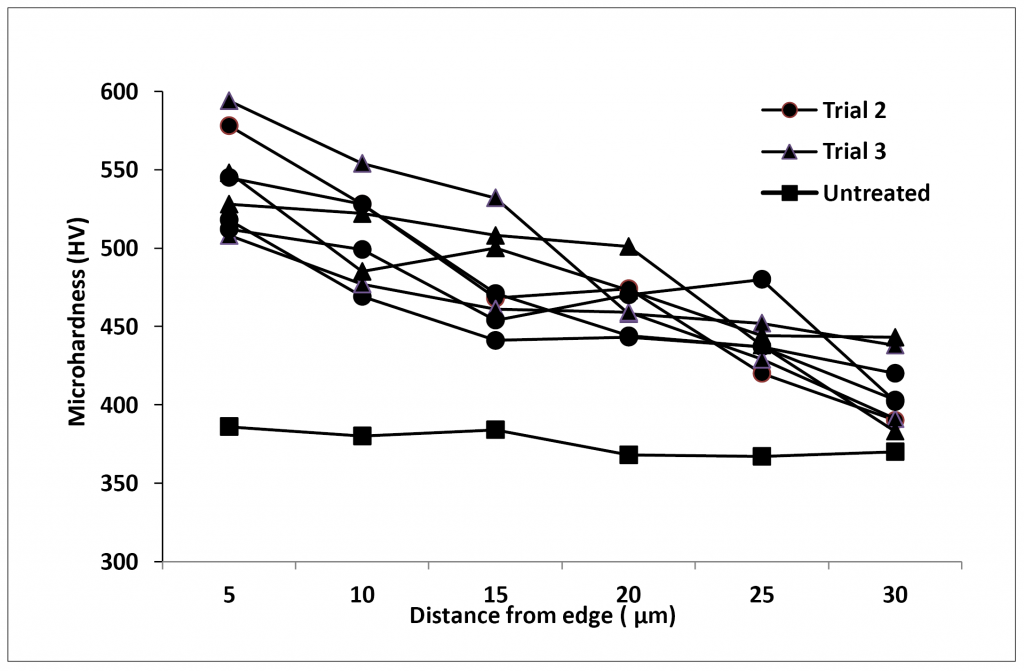

The creation of a compound layer of Ti2N and TiN during the gas nitriding of the SLM titanium alloy parts was confirmed by X-ray Diffraction (XRD) Analysis and Energy Dispersive Spectroscopy (EDS). The depth of the diffusion layers created by the treatments for 4 and 5 hours at 900ºC was assessed through the use of micro-hardness plots and was demonstrated to be around 30 µm (Fig. 10). The property data in Table 1 demonstrate that the surfaces of the SLM Ti-6Al-4V bars after gas nitriding showed remarkably high values of microhardness (>600 HV) as compared to untreated SLM bars, making the material condition a candidate for applications demanding high levels of wear resistance.

In all cases, the tensile properties of the gas nitrided samples were inferior to those of the untreated SLM bars. However, the treatments at temperatures below the β-transus (e.g. 900°C) minimised this loss in tensile properties and provided levels acceptable for many applications. On the other hand, nitriding above the β-transus temperature (e.g. 1030°C) gave significantly lower tensile properties.

The improved wear resistance of SLM Ti-6Al-4V gas nitrided below the β-transus temperature, in combination with useful levels of tensile properties, promises to open up a range of applications and this was demonstrated through one specific example. The requirements of the “Rescue Knife” (Fig. 11), supplied by Victory Knives (New Zealand) to the Americas Cup Safety Team (2013), were for a state-of-the-art, light-weight, small knife, with high corrosion and wear resistance, that was strong enough to cut through marine ropes. These goals were achieved using Selective Laser Melting of Ti-6Al-4V alloy powder followed by surface hardening using gas nitriding.

References

[1] P Holfelder et al., A Phase Field approach for modelling melting and re-solidification of Ti-6Al-4V during selective laser melting, as presented at PM Titanium 2015, August 31 to September 3, 2015 Lüneburg, Germany

[2] A Kirchner et al., Mechanical properties of Ti-6Al-4V fabricated by Electron Beam Melting, as presented at PM Titanium 2015, August 31 to September 3, 2015 Lüneburg, Germany

[3] A Mukhtar et al., Mechanical behaviour of gas nitrided Ti6Al4V bars produced by Selective Laser Melting, as presented at PM Titanium 2015, August 31 to September 3, 2015 Lüneburg, Germany.

Author

Dr David Whittaker

231 Coalway Road

Wolverhampton

WV3 7NG, UK

Tel: 01902 338498

Email: [email protected]

PM Titanium 2015 Conference Proceedings

For anyone seeking greater detail on the reviewed papers or access to the wider range of papers, relevant to Additive Manufacturing of titanium and titanium alloys, the full proceedings of the conference will be available in early 2016. Those with an interest in obtaining a copy of the proceedings can register their interest by e-mailing Thomas Ebel: [email protected]