Accelerating AM component design workflow with new optimisation technology

Additive Manufacturing promises huge benefits for industry, but exploiting these in practice can prove difficult. For example, although truss-like component forms will often be found to be much more structurally efficient than traditional forms, identifying these has thus far been laborious and time-consuming. However, a new optimisation approach means that engineers can now directly identify optimised truss forms for AM components, saving time and effort. Prof. Matthew Gilbert of LimitState and the Advanced Additive Manufacturing (AdAM) Centre at the University of Sheffield outlines the technology and its application. [First published in Metal AM Vol. 3 No. 1, Spring 2017 | 5 minute read | View on Issuu | Download PDF]

Additive Manufacturing processes are developing rapidly and are now increasingly being used to produce high value metallic components for the aerospace, automotive and space sectors. In parallel, structural optimisation techniques are also maturing rapidly and engineers can now identify the optimal form for many problems. These new forms are often geometrically complex, and are ideally suited for AM fabrication.

In recent years, engineers have used topology optimisation techniques to generate optimal forms using tools such as Altair OptiStruct and Inspire. This approach works well when the component occupies a relatively large proportion of the available design space – when the so-called ‘volume fraction’ is quite high. However, when the volume fraction is low, a fine numerical discretisation is normally required to identify the optimal form, which is computationally expensive. Worse, designers then have to perform time-consuming manual post-processing to deliver a clear component form and this can make the design workflow in Additive Manufacturing uneconomic for many companies. However, there is now an alternative means of generating truss-like forms that is significantly more direct and efficient.

A discrete optimisation approach

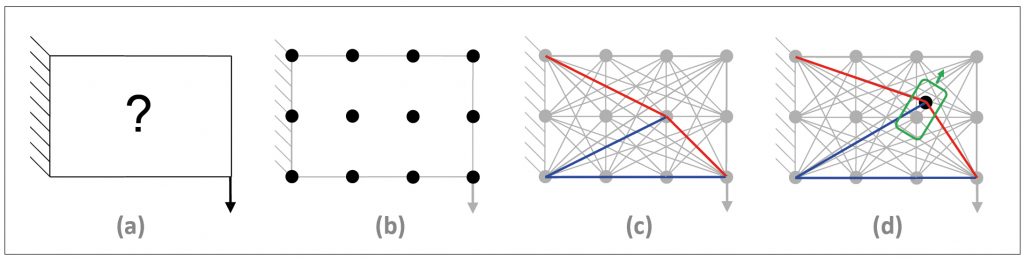

This new alternative to conventional topology optimisation involves a discrete (line-element) optimisation approach, employing layout optimisation (LO) and geometry optimisation (GO). This works particularly well when the engineer has a high degree of design freedom, as truss-like forms will generally be found to provide the most efficient design solutions. Smith et al. [1] recently demonstrated the approach, employing LO to obtain AM component designs. Also, GO can now potentially be applied in tandem with LO to obtain improved solutions, as described by He et al. [2]. The combined approach is shown in Fig. 2.

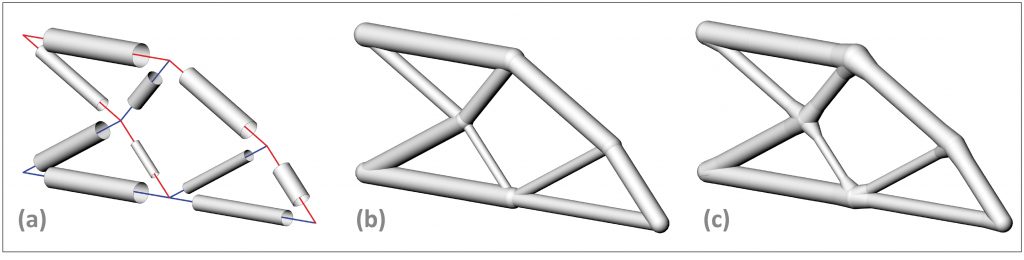

Once a line-element representation has been obtained, this can readily be transformed into a continuum model, suitable for further verification or manufacture, as indicated in Fig. 3. There are four key benefits of this discrete, line-element, optimisation approach:

- Engineers can automatically generate a high-quality solid geometry CAD model, rather than a mesh geometry

- Engineers can take steps to ensure that the optimised design is easy to be manufactured using AM processes. For example, they can specify in the optimisation that members should not be inclined at shallow angles to the horizontal

- Engineers can easily check the absolute structural efficiency of the design, based on the subtended angles between members

- Engineers can rapidly perform structural checks on the optimised form, such as global buckling stability checks.

As ever, there is a trade-off between computational efficiency and optimisation capability. A pragmatic approach, adopted in the recently released LimitState:FORM software, is to use a relatively simple optimisation formulation – linear in the case of the LO phase. As a result, engineers can obtain solutions extremely quickly, typically in seconds or minutes. Engineers can then easily edit and analyse the resulting optimised line-element model, for example adjusting the design to remove thin elements, or checking global buckling stability. The discrete optimisation approach means that engineers can obtain a viable design very quickly after an initial optimisation. This is typically not the case when using topology optimisation.

Examples

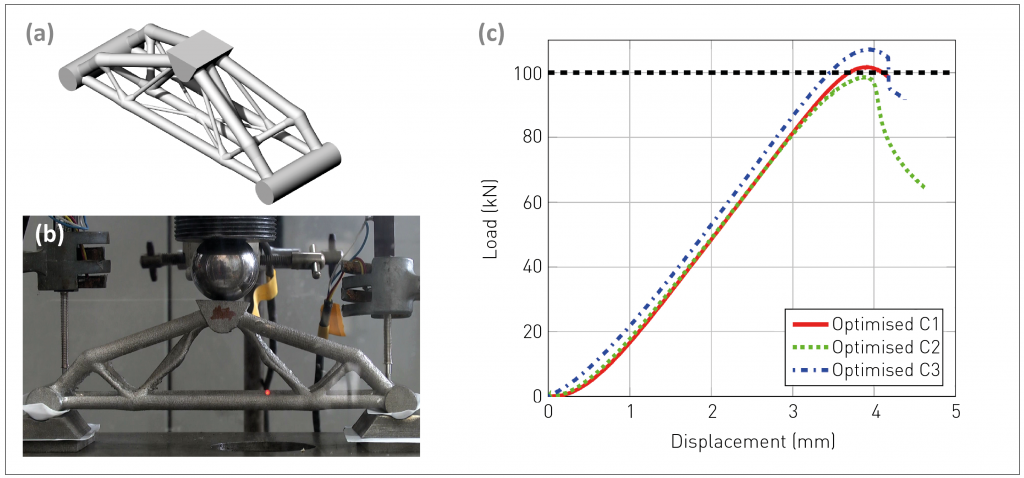

The simple beam design shown in Fig. 4 was obtained automatically using LO, and was shown, through load testing [1] to be capable of carrying the target design load. In this case, specimens were manufactured using titanium Ti-6Al-4V via the Electron Beam Melting (EBM) process.

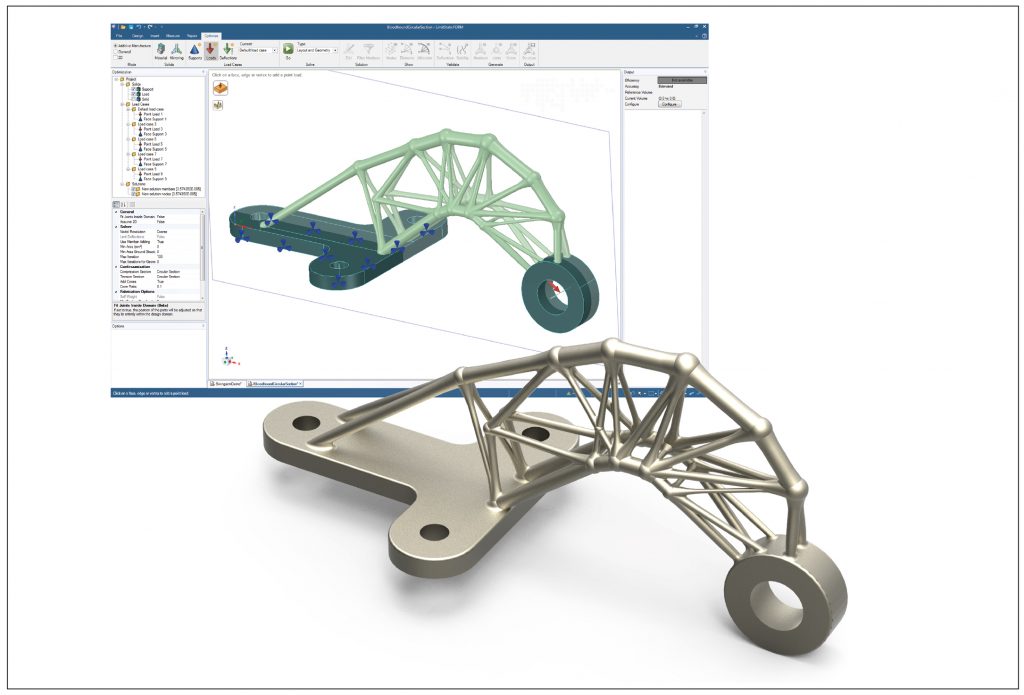

The discrete optimisation approach was also recently used to develop a new airbrake hinge design for the Bloodhound supersonic car project, as shown in Fig. 5. The resulting design is almost 70% lighter than the original. Also, the use of GO and the ability to interactively edit the solution using LimitState:FORM led to a simpler form compared to that proposed previously by [1].

Conclusion

LimitState now offers a rapid and effective alternative to traditional optimisation techniques for AM components. The new discrete optimisation approach speeds up the process of identifying structurally efficient designs and is particularly suitable for problems where there is significant design freedom.

Discrete optimisation offers several key advantages over existing topology optimisation:

There is no need to specify a volume fraction in advance, avoiding the need to find an appropriate value by trial and error

- Solutions can be obtained more rapidly, typically in seconds or minutes, rather than hours or days

- It is possible to interact with the resulting optimised design, and to perform verification checks

- The need for time-consuming remodelling of the solution is significantly reduced.

The approach helps to address one of the main obstacles to widespread adoption of AM, and the use of lightweight forms in manufacturing.

Author

Matthew Gilbert

LimitState Ltd

217 Portobello

Sheffield S1 4DP,

UK Email: [email protected]

www.limitstate.com

References

[1] Smith CJ, Gilbert M, Todd I & Derguti F, ‘Application of layout optimization to the design of additively manufactured metallic components’, Struct. Mult. Opt., 54(5), 1297–1313, 2016.

[2] He L, & Gilbert M, ‘Rationalization of trusses generated via layout optimization’, Struct. Mult. Opt., 52(4), 677-694, 2015.

[3] LimitState Ltd, LimitState:FORM software, 2016. www.limitstate3d.com

The financial support of EPSRC (project ref. EP/K025775/1) and Innovate UK (ANVIL project, ref. 101483) is acknowledged.