Formnext Live 2019 – Day 1

November 19, 2019

Siemens launches Additive Manufacturing Network

The TruPrint 2000, on display at Formnext 2019

Trumpf announces TruPrint 2000

Trumpf has presented its new multi-laser metal AM system, the TruPrint 2000. The machine has a compact footprint and is said to be targeted at the medical and dental implant industries and to enable economical and consistent builds.

AM Solutions exhibits innovative solutions at Formnext

AM Solutions, the Rösler group’s brand for all activities around AM, is presenting itself at Formnext as a competent partner for resolving any issues regarding design/engineering, the actual build process and post-processing, including surface refinement, of metal and plastic components made by AM. Numerous solutions for automated post-processing will be presented live at the AM Solutions exhibition booth.

GE Additive’s stand at Formnext 2019 (Courtesy GE)

GE Additive announcements from Day 1

GE Additive has made a number of announcements at Formnext so far, unveiling its Arcam EBM Spectra L and the new Concept Laser M2 Series 5, launching the Arcam PRS 30 powder recovery station and Arcam EBM D-material support for pure copper and highly-alloyed tool steel, and releasing its Arcam EBM Build Performance Analyser.

Desktop Metal’s just-announced Shop System, combining AM machine and sintering furnace (Courtesy Desktop Metal)

Desktop Metal announces Shop System

Desktop Metal has just announced a new binder jet Additive Manufacturing system. The Shop System is scalable and modular and incorporates AM machine, depowdering and sintering units. With a spot size of 16 microns per drop, 1600 native single pass DPI and distributing up to 670 million drops per second, it is also said to be the highest resolution single pass Binder Jetting system on the market.

Jonah Myerberg introduces the Shop System at Formnext

Shop owners have been enamoured by the versatility, speed and cost reduction that binder jetting technology can provide, but until now, it hasn’t been accessible to them. The Shop System offers users the same fully-dense metal parts at an affordable price that works in harmony with machining on the shop floor. What’s more, the system enables owners to both save and make money by eliminating tooling costs, lowering lead times, and bringing in new business because of an improved part-cost equation.” – Jonah Myerberg, co-founder and CTO, Desktop Metal.

General availability for the Shop System is Fall 2020. Prices start at $150,000.

Divergent to purchase five pre-production machines from SLM Solutions

Since 2017, SLM Solutions and Divergent Technologies have been working to co-develop a next generation multi-laser L-PBF AM machine. To accelerate the development and time to market of the next generation machines, Divergent will purchase five pre-production machines that will be used for factory integration and ‘system bulletproofing’ at its showcase facility in Los Angeles, California, USA. According to Divergent’s CEO, Kevin Czinger, it plans to use the next-generation machines to meet production demand for a number of major global carmaker programmes.

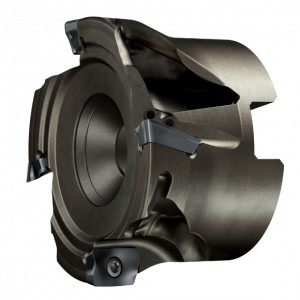

Sandvik and BEAMIT are showcasing new parts and powders

Earlier this year, Sandvik acquired a significant stake in BEAMIT. The joint Sandvik-BEAMIT booth at Formnext features several industrial AM customer use-cases in a wide range of materials, produced using a variety of AM processes, along with Sandvik’s of Osprey metal powders, including its new nickel-based superalloys and titanium.

Sandvik’s additively manufactured CoroMill titanium milling cutter, also on display at Formnext 2019

ExOne has expanded its collaboration with Elnik Systems

The ExOne Company is expanding its collaboration with Elnik Systems and DSH Technologies, LLC, to improve the standardisation of sintering for parts made using binder jet Additive Manufacturing. The design freedom offered by AM is creating new challenges in sintering green metal parts that deliver predictable dimensional tolerances and meet other requirements. The process often involves some trial and error with sacrificial parts. The new collaboration aims to standardise and simplify this end-to-end process.

ExOne metal 3D printers already deliver industry-leading density and repeatability, and now we’re working to ensure that the final sintering step is as easy as possible for our customers — a seamless end-to-end process that delivers a quality result” – John Hartner, ExOne CEO.

More coming soon.

Product launches and announcements from Additive Industries

During a press breakfast this morning, Additive Industries made a number of significant announcements, including the launch of two product launches at Formnext. The first, an industrialised powder load tool (PLT) offers automated powder loading and unloading to eliminate manual powder handling. The second is an uprade to the MetalFAB1 system, titled U20-1, with a new and improved primary nozzle, exhaust manifold and side shields; updated machine control software; and improved usability and user support.

The company also announced a new partnership, as Fraunhofer joins its customer base to collaborate on the integration of L-PBF into industrial process chains, and the launch of the not-for-profit ‘AM Quality Cooperative’, a cooperative of Additive Industries and its customers to source, qualify, supply and manage metal powders for AM.

Available to view at Additive Industries’ stand are the results of a commissioned study by AMPower, which evaluated the MetalFAB1 in comparison with fifteen competing Laser and Electron Beam Powder Bed Fusion (EB and L-PBF) machines for the production of four typical Ti-64 parts. For all four parts, the MetalFAB1 was found to have the lowest cost-per-part.

More coming soon.

Dyndrite introduces new AM build processor

The company’s AMT software is built upon its Accelerated Computation Engine (ACE), an innovative GPU-powered geometry kernel, and provides powerful manufacturing-oriented features. Reported capabilities include native CAD file import for maximum quality of additively manufactured output, as well as an integrated Python application programming interface (API) for customisable scripting of interactive, automated workflows.

The Dyndrite Accelerated Computation Engine is a genuine paradigm shift and promises to do for 3D printing what Adobe and PostScript did for 2D printing in the 1980s” – Harshil Goel, founder and CEO, Dyndrite.

What to look forward to at Formnext

Meltio to debut ‘4D manufacturing’ technology

Referred to as a ‘4D manufacturing’ with ‘3E Metal Deposition’ technology, the company will offer a new deposition head capable of building fully-dense parts from wire and powder simultaneously, without the need for nozzle changes. Read the full story.

Admatec launches Admaflex 300 system for production of large-scale parts

Admatec Europe BV, Goirle, the Netherlands, has launched the Admaflex 300, which it states is the world’s first flexible and open system for high-volume metal and ceramic additively manufactured parts. The system will be showcased for the first time at Formnext. Read the full story.

Link3D offers fully-integrated AM workflows with Autodesk

With the new integrated workflow, Link3D Additive MES connects bi-directionally into Autodesk® Fusion 360® and Autodesk Netfabb® and can be used in the downstream production process to manually alter and control the data preparation at all stages. This helps ensure proper versioning and access control, while the cloud-based process helps to ensure that no local files are created at any preparation stage. Read the full story.

SPEE3D’s live production demonstration at Rapid + TCT in Detroit, Michigan, USA, May 2019 (Courtesy SPEE3D)

SPEE3D to launch new SPEE3Dcell

The SPEE3Dcell combines a SPEE3D machine with a heat treatment furnace and a three-axis CNC milling machine. For the duration of Formnext, it will be demonstrated live, as it builds sparkless copper hammers at six minutes per hammer, finishes and assembles them on the trade show floor, showcasing its speed, affordability and scalability. Read the full story.

EOS will demonstrate its Shared Modules solution for AM

The company states that the various modules plus transport systems and control centre software enable users to implement equipping, unpacking, transporting and sieving activities in parallel with the AM build process on the EOS M 400 seires. A manual and automated EOS Shared Modules set-up are available for this purpose. Read the full story.

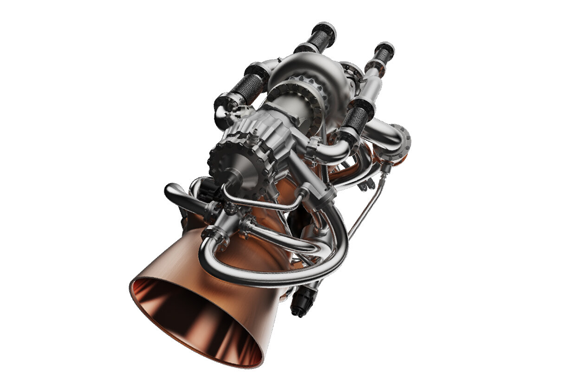

AMCM will exhibit a full-size Launcher E-2 combustion chamber mock-up

The copper alloy chamber was produced for Launcher, Inc. It is said to be the largest liquid rocket engine combustion chamber additively manufactured in a single part, measuring 86 cm tall with an exit nozzle diameter of 41 cm. Read the full story.

Launcher’s E-2 rocket engine features a combustion chamber additively manufactured from copper in a single part (Courtesy Launcher Inc)

GFMS & 3D Systems will showcase their combined metal AM parts and solutions

To highlight the benefits of their jointly developed metal AM workflow, GF Machining Solutions and 3D Systems will showcase two metal additively manufactured parts; a spinal fusion cage for orthopaedic surgery and a lightweight bracket used in the aerospace industry for satellite technology. Read the full story.

Additive Manufacturing / 3D Printing Standards Forum

For the second time since its first appearance on the programme at Formnext 2018, an Additive Manufacturing / 3D Printing Standards Forum will take place at Formnext on November 19. Organised by the U.S. Commercial Service, the forum will bring together experts from industry, research institutions, standards development organisations, professional societies, and government to address key themes focused on standards development in Additive Manufacturing technologies. Read the full story.

Fehrmann Alloys will exhibit its AlMgty high-performance alloy

AlMgty is said to offer a tensile strength of 355 Mpa, yield strength of 220 MPa, and elongation of 19% as-built. It is resistant to corrosion and anodizable, and does not rely on expensive alloying components such as scandium. Read the full story.

BeAM will showcase its new generation of DED machines

BeAM will exhibit its new generation of DED machines, the Modulo 250 and Modulo 400. There will also be a demonstration of how the Modulo 250 machine can be installed in the Flexcare Anywhere Factory, a modular and mobile factory concept offered by AddUp Group Read the full story.

BeAM will present the new features of its Modulo 400 system as well as the Modulo 250 as part of its showcase at Formnext 2019 (Courtesy BeAM)

Fehrmann Alloys will exhibit its AlMgty high-performance alloy

AlMgty is said to offer a tensile strength of 355 Mpa, yield strength of 220 MPa, and elongation of 19% as-built. It is resistant to corrosion and anodizable, and does not rely on expensive alloying components such as scandium. Read the full story.

The winners of the 2019 Purmundus Challenge will be announced

The awards given to the winners are said to be worth a total of €30,000. In addition to the first three places, a ‘special mention’ and an ‘innovation prize’ will also be given. One finalist will also be awarded the prize for the ‘people’s choice’, voted for by visitors to Formnext 2019. Check out the full list of metal AM finalists.