Formnext Live 2019 – Day 3

November 21, 2019

View Day 1 | View Day 2

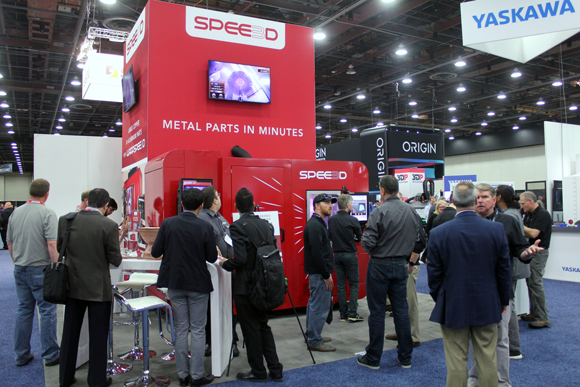

SPEE3D completes ‘world’s fastest live print’ of a metal part

SPEE3D additively manufactured a 1 kg copper sledgehammer in 10 minutes live in front of a crowd on the floor at Formnext in Frankfurt today. The live event was part of a larger demonstration by SPEE3D of their new product ‘SPEE3Dcell’, which combines a SPEE3D AM machine with a heat treatment furnace and a CNC three-axis milling machine.

What we demonstrated here is really just the beginning. We believe ours is the fastest print demonstrated live at a show like this and we challenge other players in the industry to print a 1 kg part faster, whether it be metal, plastic or ceramic. We want to see development in the industry, and we look forward to pushing our technology even faster,” – Byron Kennedy, Co-founder and CEO of SPEE3D

Oerlikon partners with United Launch Alliance to manufacture launch vehicle flight components

Oerlikon AM has announced that it will provide metal additively manufactured qualification and flight components for United Launch Alliance’s (ULA) next-generation Vulcan Centaur rocket. ULA is the world’s most experienced and reliable launch service provider, with more than 130 launches and 100 percent mission success.

ULA is a leader in using Additive Manufacturing to reduce production lead times and increase performance in launch vehicles. Vulcan Centaur will advance the use of AM in rockets, and we are looking forward to the launch in 2021,” – Dr Sven Hicken, Head of Oerlikon’s Additive Manufacturing Business Unit.

Sandvik and Renishaw collaborate to qualify new materials for Additive Manufacturing

Global engineering company Renishaw is collaborating with Sandvik Additive Manufacturing to qualify new AM materials for production applications. This reportedly encompasses a broad range of metal powders, including new alloy compositions optimised for L-PBF process which provide superior material properties.

Digital Metal forms agreement with Elnik Systems/DSH Technologies, LLC

Metal Binder Jetting company Digital Metal has formed a collaborative agreement with Elnik Systems/DSH Technologies, LLC, leaders in the debind and sinter processing technology of metal parts.

View Day 1 | View Day 2

Discover metal Binder Jetting’s future through today’s MIM

PIM/MIM/CIM Showcase Hall 11.0, A51

Metal Binder Jetting is hot at Formnext 2019, with a fast-growing range of machine solutions promising to take metal Additive Manufacturing towards its goal of fast, high-volume production.

With the Metal Injection Moulding industry’s biggest players leading the race to adopt this technology, discover what MIM, the original binder-based production process, is achieving right now in terms of markets, materials and part complexity.

Visit the PIM/MIM/CIM Showcase Hall 11.0

What to look forward to at Formnext

Meltio to debut ‘4D manufacturing’ technology

Referred to as a ‘4D manufacturing’ with ‘3E Metal Deposition’ technology, the company will offer a new deposition head capable of building fully-dense parts from wire and powder simultaneously, without the need for nozzle changes. Read the full story.

Admatec launches Admaflex 300 system for production of large-scale parts

Admatec Europe BV, Goirle, the Netherlands, has launched the Admaflex 300, which it states is the world’s first flexible and open system for high-volume metal and ceramic additively manufactured parts. The system will be showcased for the first time at Formnext. Read the full story.

Link3D offers fully-integrated AM workflows with Autodesk

With the new integrated workflow, Link3D Additive MES connects bi-directionally into Autodesk® Fusion 360® and Autodesk Netfabb® and can be used in the downstream production process to manually alter and control the data preparation at all stages. This helps ensure proper versioning and access control, while the cloud-based process helps to ensure that no local files are created at any preparation stage. Read the full story.

SPEE3D’s live production demonstration at Rapid + TCT in Detroit, Michigan, USA, May 2019 (Courtesy SPEE3D)

SPEE3D to launch new SPEE3Dcell

The SPEE3Dcell combines a SPEE3D machine with a heat treatment furnace and a three-axis CNC milling machine. For the duration of Formnext, it will be demonstrated live, as it builds sparkless copper hammers at six minutes per hammer, finishes and assembles them on the trade show floor, showcasing its speed, affordability and scalability. Read the full story.

EOS will demonstrate its Shared Modules solution for AM

The company states that the various modules plus transport systems and control centre software enable users to implement equipping, unpacking, transporting and sieving activities in parallel with the AM build process on the EOS M 400 seires. A manual and automated EOS Shared Modules set-up are available for this purpose. Read the full story.

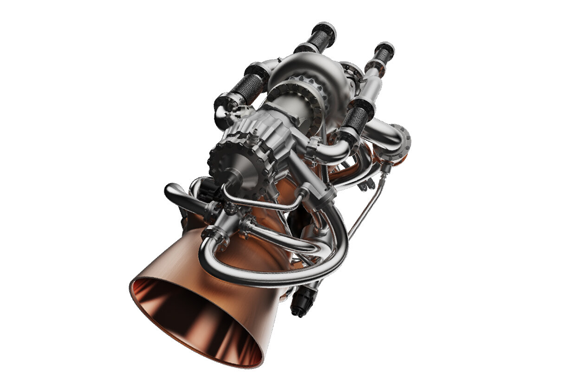

AMCM will exhibit a full-size Launcher E-2 combustion chamber mock-up

The copper alloy chamber was produced for Launcher, Inc. It is said to be the largest liquid rocket engine combustion chamber additively manufactured in a single part, measuring 86 cm tall with an exit nozzle diameter of 41 cm. Read the full story.

Launcher’s E-2 rocket engine features a combustion chamber additively manufactured from copper in a single part (Courtesy Launcher Inc)

GFMS & 3D Systems will showcase their combined metal AM parts and solutions

To highlight the benefits of their jointly developed metal AM workflow, GF Machining Solutions and 3D Systems will showcase two metal additively manufactured parts; a spinal fusion cage for orthopaedic surgery and a lightweight bracket used in the aerospace industry for satellite technology. Read the full story.

Additive Manufacturing / 3D Printing Standards Forum

For the second time since its first appearance on the programme at Formnext 2018, an Additive Manufacturing / 3D Printing Standards Forum will take place at Formnext on November 19. Organised by the U.S. Commercial Service, the forum will bring together experts from industry, research institutions, standards development organisations, professional societies, and government to address key themes focused on standards development in Additive Manufacturing technologies. Read the full story.

Fehrmann Alloys will exhibit its AlMgty high-performance alloy

AlMgty is said to offer a tensile strength of 355 Mpa, yield strength of 220 MPa, and elongation of 19% as-built. It is resistant to corrosion and anodizable, and does not rely on expensive alloying components such as scandium. Read the full story.

BeAM will showcase its new generation of DED machines

BeAM will exhibit its new generation of DED machines, the Modulo 250 and Modulo 400. There will also be a demonstration of how the Modulo 250 machine can be installed in the Flexcare Anywhere Factory, a modular and mobile factory concept offered by AddUp Group Read the full story.

BeAM will present the new features of its Modulo 400 system as well as the Modulo 250 as part of its showcase at Formnext 2019 (Courtesy BeAM)

Fehrmann Alloys will exhibit its AlMgty high-performance alloy

AlMgty is said to offer a tensile strength of 355 Mpa, yield strength of 220 MPa, and elongation of 19% as-built. It is resistant to corrosion and anodizable, and does not rely on expensive alloying components such as scandium. Read the full story.

The winners of the 2019 Purmundus Challenge will be announced

The awards given to the winners are said to be worth a total of €30,000. In addition to the first three places, a ‘special mention’ and an ‘innovation prize’ will also be given. One finalist will also be awarded the prize for the ‘people’s choice’, voted for by visitors to Formnext 2019. Check out the full list of metal AM finalists.