Link3D offers fully-integrated Additive Manufacturing workflows with Autodesk

November 14, 2019

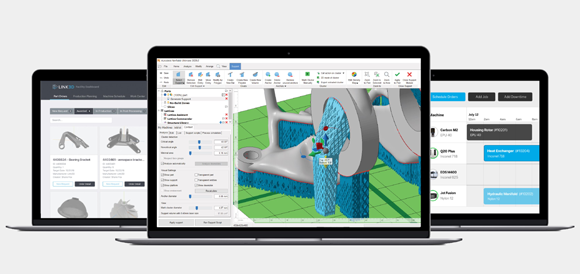

Link3D will offer a new integrated workflow connecting Link3D with Autodesk’s Fusion 360 and Netfabb solutions (Courtesy Link3D)

Link3D, Boulder, Colorado, USA, will deliver a fully-integrated Additive Manufacturing workflow using linked Autodesk software to enable end-to-end traceability. The company will unveil this new capability at Formnext 2019, to be held in Frankfurt, Germany, November 19–22.

According to Link3D, the majority of AM users still operate many tasks manually; managing AM files on disks, generating support structures in a siloed system and managing print jobs with spreadsheets. Build files are also often loaded directly onto AM machines with a USB key, without leaving a digital record, limiting traceability.

With the new integrated workflow, Link3D Additive MES connects bidirectionally into Autodesk® Fusion 360® and Autodesk Netfabb® and can be used in the downstream production process to manually alter and control the data preparation at all stages. This helps ensure proper versioning and access control, while the cloud-based process helps to ensure that no local files are created at any preparation stage.

With an integrated solution using linked Link3D and Autodesk software, organisations can take advantage of the ‘Digital Thread’ by streamlining ordering, build data preparation, scheduling and downstream manufacturing processes. Users with build platforms prepared with Link3D’s 2D/3D nesting tool can queue or launch models into Netfabb for build preparation with a single-click.

Users can then automatically schedule builds from Link3D. All generated data will be automatically stored safely within the system. Autodesk also offers build processor connectivity with hundreds of machine models from most leading machine manufacturers. As a result, select machine manufacturers with connectivity to Autodesk Netfabb can now integrate Link3D’s Production Scheduling software to send build-ready files directly to AM machines.

“By linking Autodesk’s comprehensive additive and subtractive manufacturing solutions with Link3D’s production scheduler, we are excited to help Link3D provide a managed workflow from order intake to post-processing on the shop floor,” commented Alexander Oster, Director Additive Manufacturing at Autodesk.

Vishal Singh, Co-Founder & CTO of Link3D, added, “For a long time businesses were limited with AM workflow options to enable automated build preparation processes; this is the first time we are seeing two market-leading organisations enable tight levels of integration between AM workflow and build preparation software. This is an indication of how the Additive Manufacturing industry is opening up; we look forward to working with Autodesk to develop more solutions that enable scalable production.”