Launcher schedules first full-scale test of its E-2 rocket engine

November 12, 2019

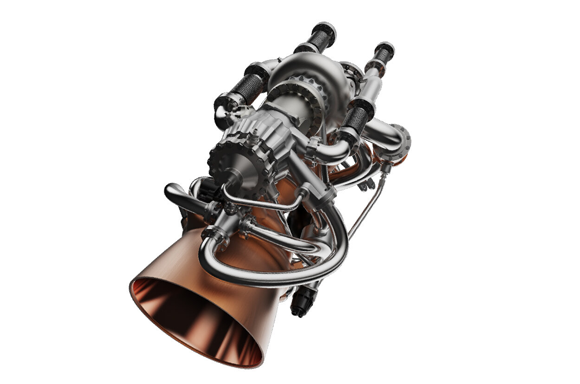

Launcher’s E-2 rocket engine features a combustion chamber additively manufactured from copper in a single part (Courtesy Launcher Inc)

Launcher Inc., headquartered in Brooklyn, New York, USA, has scheduled the first full-scale test of its E-2 rocket engine for mid-2020 after securing a $1.5 million award from the U.S. Air Force and taking delivery of the engine’s copper additively manufactured combustion chamber.

The copper alloy chamber was produced by AMCM GmbH, Starnberg, Germany, an EOS company, on AMCM’s M4K machine. It is said to be largest liquid rocket engine combustion chamber additively manufactured in a single part, measuring 86 cm tall with an exit nozzle diameter of 41 cm.

According to Launcher, the combustion chamber and injector are critical parts of its E-2 engine, said to be the highest performance engine for small satellite launch vehicles currently in development. The first full-scale test fire is scheduled for Q2 2020 and the company states that it has already achieved its target combustion performance of 98%+ combustion efficiency using sub-scale versions of the E-2 engine additively manufactured with the same machine and materials.

AMCM will be exhibiting a full-size Launcher E-2 combustion chamber mock-up at Formnext 2019, Frankfurt, Germany, from November 19–22.