SPEE3D to launch new SPEE3Dcell at Formnext 2019

November 14, 2019

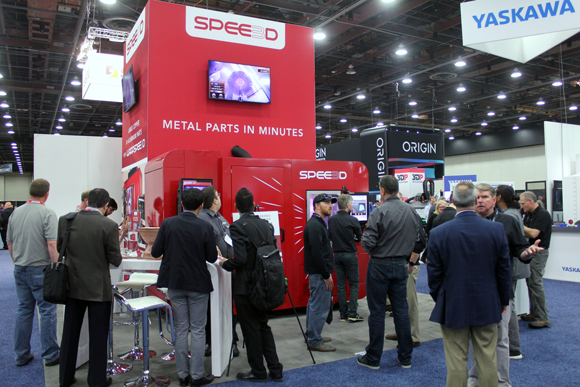

SPEE3D’s live production demonstration at Rapid + TCT in Detroit, Michigan, USA, May 2019 (Courtesy SPEE3D)

SPEE3D, Melbourne, Australia, will launch its new SPEE3Dcell product at Formnext 2019 in Frankfurt, Germany, running from November 19–22, 2019. This new Additive Manufacturing cell will be demonstrated with the production of copper parts live on the tradeshow floor.

SPEE3D’s patented technology uses what it calls ‘supersonic 3D deposition’ (SP3D). SP3D deposits metal powders by using a rocket nozzle to accelerate air up to three times the speed of sound, delivering manufacturing-grade, high-density metal parts.

SP3D rapidly manufactures low-cost and casting-grade parts suited to a range of commercial and industrial applications. Parts can be produced in single or high-volume production quantities, economically, on-demand and at speeds that are claimed to be 100 to 1,000 times faster than traditional metal AM technologies.

A part produced using SPEE3D’s supersonic 3D deposition technology, as displayed at Rapid + TCT 2019

At Formnext 2017, SPEE3D introduced its first AM machine, the LightSPEE3D, which it believes to have been the world’s first machine to additively manufacture metal parts in minutes instead of hours or days. In 2018, the company introduced a large-format version of the machine titled the WarpSPEE3D.

The SPEE3Dcell combines a SPEE3D machine with a heat treatment furnace and a three-axis CNC milling machine. For the duration of Formnext, it will be demonstrated live, as it builds sparkless copper hammers at six minutes per hammer, finishes and assembles them on the trade show floor, showcasing its speed, affordability and scalability.

Byron Kennedy, Co-founder and CEO of SPEE3D, stated, “We are looking forward to Formnext 2019. We are excited to share the latest developments in metal 3D printing with the manufacturing world.”