Linear AMS: How an AM service provider is embracing the new infrastructure of on-demand manufacturing

In 2016 SAP and UPS announced their collaboration to develop a supply chain management solution that spans the complete AM process chain, from component evaluation and design to delivery of the final product. Leading US-based AM service provider Linear AMS, a Moog company, is one of several manufacturers involved in the venture. Linear AMS’s Bruce Colter and Moog’s George Small review the drivers behind on-demand manufacturing and present recent developments in materials, applications and component verification. [First published in Metal AM Vol. 3 No. 2, Summer 2017 | 15 minute read | View on Issuu | Download PDF]

Much is made in the contemporary business world of ‘creative disruption’ – reinventing and replacing outdated assets and cultures in favour of improved processes, increased efficiencies and more engaged employees. Manufacturing is certainly not immune to this need, but, as opposed to flexible working or pet-friendly workspaces, manufacturing, particularly in critical industries such as aerospace, defence, transportation and energy, demands more. Disruptive concepts must be followed immediately by a superior infrastructure wherein parts with tight tolerances come to market faster, with orders-of-magnitude improvements in quality and deliverability, all from the hands of a digitally savvy 21st Century workforce.

Some of the world’s leading businesses are currently establishing the pillars of this new infrastructure around the core of metal Additive Manufacturing. Interestingly, these giants are not manufacturing companies per se, but visionaries in software and logistics, reaching out to metal AM process leaders with new thinking, while metal AM itself continues to evolve in response.

At the 2016 Sapphire Now meeting in Orlando, Florida, USA, enterprise resource planning giant SAP SE named Moog Inc. and Linear AMS, a Moog company based in Livonia, Michigan, USA, as co-innovators in its agreement with UPS to, in SAP’s words, “transform the ad-hoc world of industrial 3D printing into a seamless, on-demand manufacturing process from order through manufacturing and delivery.” Stan Deans, President, UPS Global Distribution & Logistics, stated at the event, “Markets are changing rapidly and no company can solve all customer problems on its own. This agreement with SAP adds an important UPS capability to help customers right-size inventories and lower short-run production costs, and help entrepreneurs bring their ideas to life faster than ever.”

Additive Manufacturing ties it all together. With networks becoming tighter in response to unrelenting competition and delivery schedules, one unplanned production halt can bring down an entire supply chain. With this agreement, SAP customers can digitise and streamline production part approval processes and orders can be seamlessly routed to UPS stores equipped with Additive Manufacturing systems or experienced service bureaus such as Linear AMS.

Currently, UPS stores will have systems for additively manufacturing in resins and plastics; Linear AMS has a fleet of twenty metal Additive Manufacturing machines and more than twelve years of processing and troubleshooting experience manufacturing parts from a wide range of materials. “Technology innovations such as 3D printing are revolutionising traditional manufacturing and redefining our notion of the industrial supply chain,” explained Bernd Leukert, member of the Executive Board, Products & Innovations, SAP SE, at the time of the announcement. “By bringing together the on-demand manufacturing and logistics expertise of UPS and the extended supply chain leadership of SAP, we can enable direct digital manufacturing and an on-demand industrial manufacturing network that connects from the manufacturing floor to the customer door.”

In his keynote at the Sapphire Now event, Leukert continued to state that all businesses have a common desire to succeed in the so-called digital age and part of the solution is to deliver a ‘live’ customer experience. “For many years, we, as well as many other companies, have talked about the 360° customer view. Today, we are moving more to a contextual view, a real-time view of each individual customer. That view can get you virtually inside your customers’ heads; you can understand the hopes, the dreams, the mental pictures, which then lets you provide the right product at the right time at the right place,” he said.

In a recent white paper, ‘The Rise of Smart Operations: Reaching New Levels of Operational Excellence’, UPS describes how it conducted research to gauge the pace at which manufacturers are evolving. The results indicate a widening gap between companies that are aggressively embracing smart operations principles and those that are falling further behind. Those companies taking the lead are much better positioned to achieve the level of operational excellence necessary to be competitively effective in today’s demanding markets, says UPS.

Not surprisingly, the research also revealed another prominent success factor — the increasingly important role of external service providers. Manufacturing companies must recognise the need to focus on their key internal competencies while leveraging the scale, technology and skills of those providers that can deliver crucial support processes. This includes enterprise-wide software partners like SAP, logistics experts like UPS and metal AM pioneers like Moog and Linear.

Reinventing the industrial supply chain

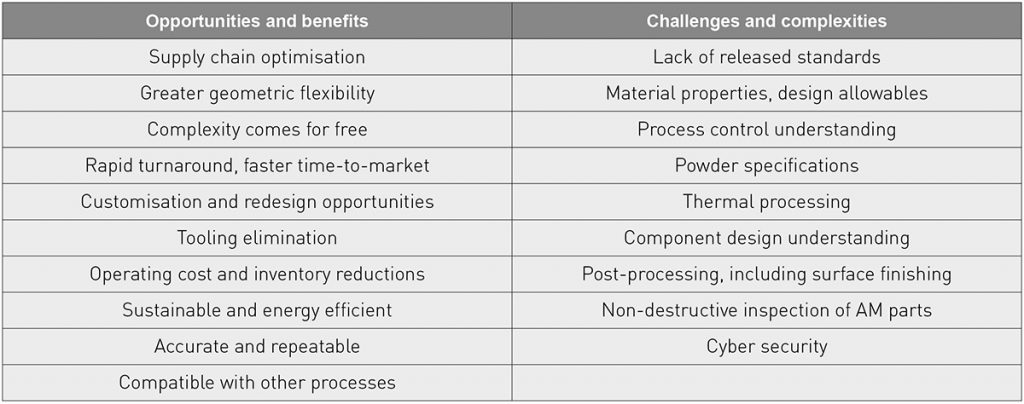

“3D printing has been around since the 1980s, but today there’s really an explosion going on,” states Alan Amling, Vice President of Marketing at UPS Global Logistics & Distribution. “Every week you see something new about it in the press.” Speaking at a 2016 SAP event focusing on the aerospace and defence industries, Amling made the point that manufacturing, and manufacturing’s customers, have followed the same rules of mass production for decades. “But there are numerous advantages that make Additive Manufacturing especially attractive,” Amling says, “like no minimum quantities, no upfront tooling costs, faster production times and more cost-effective customisations.”

“The 3D market is expected to triple over the next three years,” he continued. “If you can imagine that just 5% of manufacturing moves to 3D printing, that would represent $640 billion.”

In fact, Amling envisions Additive Manufacturing as part of a larger, more connected digital economy, taking the previously announced SAP/UPS infrastructure and building even further. In a recent TED talk, he describes a global network where thousands of intelligently connected AM machines are located in key areas all around the world, creating an elastic, on-demand manufacturing cloud.

But why do Amling and UPS, in particular, have such a keen interest in Additive Manufacturing? Well, remember – in addition to delivering millions of packages per day to businesses and consumers worldwide, UPS is also a global supply chain solution provider. “We maintain more than 1,000 global field stocking stations,” notes Amling, “and these warehouses store critical spare parts for companies around the world.” So what happens to this significant segment of the business when inventory is stored virtually and can be created using Additive Manufacturing?

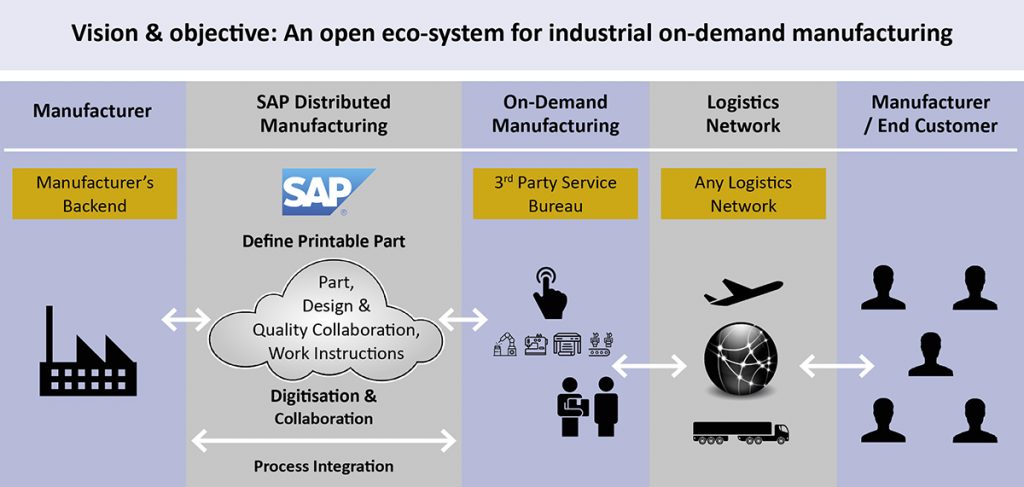

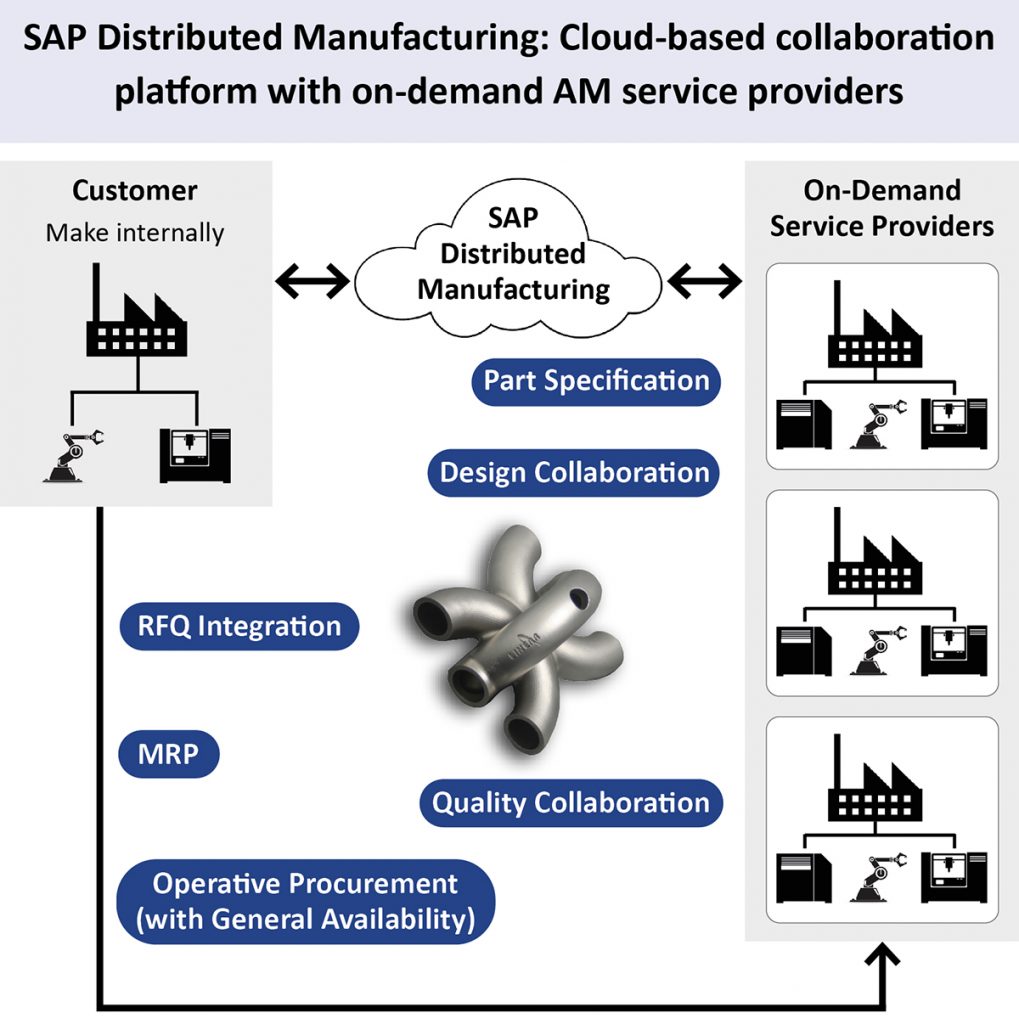

The answer is the disruption portion of the scenario, rethinking manufacturing capacity and its ability to respond to the needs of particular customers. For these customers – after a successful validation period with early access customers and partners – SAP introduced a new solution in 2017 that delivers on its initial promise. SAP Distributed Manufacturing combines standardised, scalable business processes for digitising, approving, certifying and producing parts (Figs. 2, 3). Part of the SAP Leonardo IoT portfolio, it provides a network for discrete manufacturers to collaborate with Additive Manufacturing companies and service providers, materials providers, postal companies and global logistics networks. The solution’s modules for Assessment & Digitisation, Collaboration & Approval and Production provide end-to-end capabilities from pre-production through order, manufacturing and delivery.

Linear AMS: Experienced service providers at the heart of the system

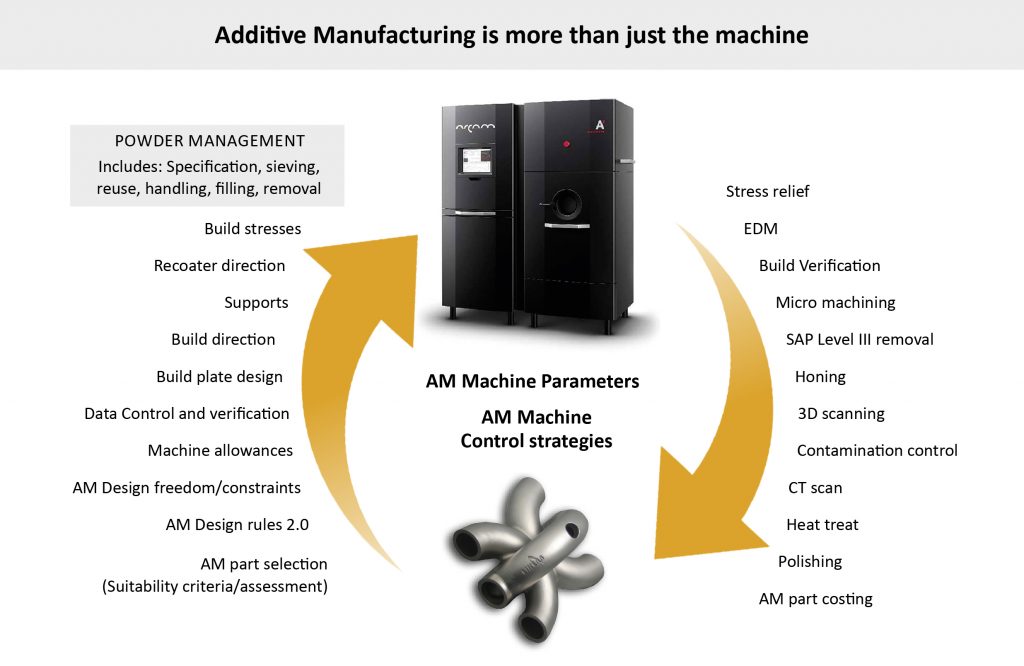

While additive in general and metal additive in particular continue to gain exposure, they are by no means a ‘plug-and-play’ solution for accelerating supply-chain efficiencies (Fig. 4). George Small, Principal Engineer at Moog’s Space and Defense Division, puts it this way: “Our first forays into AM go back over fifteen years. With our background in manufacturing of complex parts, we could easily see the value of direct digital fabrication. Printing of polymer parts for fit checks, prototypes and tooling became commonplace at Moog. However, the real target for us was metal additive parts.”

“Powder bed laser technology looked to be the most mature and suitable for our typical Moog applications,” he continues. “But results of our early trials were disappointing to say the least. Delamination between layers was common, porosity abundant and material properties lacking. Every few years we would try a few more parts at outside service vendors with comparable results. The technology did not seem ready for our demanding applications.”

Additive Manufacturing allows production of parts with complexity that cannot be easily matched by traditional manufacturing methods. It can be used to produce impossible-to-machine features; it can produce parts without seams or joints; often, complex geometric or organic shapes are only possible and practical to produce using Additive Manufacturing methods. However, there are still challenges to be met in getting AM into widespread use (see Table 1).

All of this changed in late 2015, when Moog purchased a majority interest in Linear Mold & Engineering. Founded in 2003, Linear Mold, now Linear AMS, was an early adopter in metal AM, purchasing the second powder-bed fusion machine from EOS in North America (the first purchaser was GE).

The acquisition of Linear brought more than metal AM capacity; it brought full CNC machine shop capabilities, including wire EDM and finishing capabilities. It also brought the most experience in North America in progressing along the metal AM learning curve, including integrating computer-aided design into Additive Manufacturing, developing processing parameters and handling procedures for metal powders and troubleshooting thousands of builds.

Linear CAD Operations Manager Kevin Jonatzke’s experience goes back to the days of rapid prototyping, predating metal AM. “I ran a prototyping company of my own, printing plastic parts,” he explains. “What brought me to Linear, among other things, was the opportunity for design engineering – to take parts from the design stage and work them directly into production.”

“However, it is increasingly difficult to sell a customer on rapid prototyping in manufacturing. Rapid prototyping serves a design function, producing 3D models of design iterations,” Jonatzke continues. “Manufacturing has different expectations, requiring different strategies. There are a lot of variables in building a part and there is no automated CAD software that will take each part model and translate it into the best production strategy. Metal AM, for example, involves anchoring the part to the build plate. Are there constraints in the build direction? Do different support structures make a difference?”

“What we are moving into is taking designs for traditional manufacturing and optimising them for metal AM. It is definitely a team effort to take the same geometry and strength requirements from conventional manufacturing and approach them from a metal printing perspective. There are great customers, who help take on the challenges and new perspectives metal AM provides, and there are customers who have built parts and then refused to rebid on the project because of the difficulties. To my knowledge, there are not a lot of companies that share the kind of process knowledge that puts customers months, if not years, ahead of trial-and-error part design and development. As I said before, there is no automated CAD software that will build each part from a model. The difference is production experience.”

Metallurgy and materials handling

Bob Henderson, Linear’s Director of Additive Manufacturing, cites metallurgy expertise and material-handling procedures as factors to consider in establishing a complete production infrastructure. “We purchase a lot of 20 to 60-micron metal powder and how we handle it, in what conditions and how we process it makes a big difference in the final outcome.”

“Many factors, such as how you sieve metal powders to the proper particle size, at what temperature and humidity you store and handle the metal powders, can make a big difference in part quality,” he adds. “We have a measurement we call build failure. It is not a gold star for us, nor is it good for the customer, but having increased knowledge and tighter controls over the management of our powders helps us reduce our failure rate.”

“Take residual stress, for example. Stress relief is one critical post-processing activity that will positively affect residual stress. Basically, it involves taking the chamber temperature up, then slowly bringing it down. Hand in hand with residual stress is porosity. The Hot Isostatic Pressing (HIP) process essentially squeezes the part like a sponge. Now you cannot cure every kind of porosity, but Linear continues to develop effectiveness tests that help us determine which process is more effective and why.”

Henderson adds, “All of this is for solving real problems for real parts in real applications. We came up with a real beauty recently. There is a standard mechanical properties test that uses tensile test bars. As we were building metal parts, we also built a bunch of test bars along the perimeter of the coupon and then introduced a number of variables – interrupting the build for various periods of time, opening the chamber and releasing the argon gas and then restarting the process, that kind of thing. What we are doing is building a unique set of specifications on build interruptions backed up with data. This could go on for a couple of years, testing multiple materials on multiple machine types under multiple conditions.”

High performance aluminium alloys: F357

A357 aluminium alloy is a popular choice in many industries, including aerospace, defence and automotive, due to its strength, weight, machinability and other performance characteristics. F357, the beryllium-free version of A357, has a tensile and yield strength comparable to A357, but eliminates the inherent safety hazard of working with beryllium. According to the United States Department of Labor, exposure to, contact with or inhalation of beryllium is known to cause lung cancer.

Unfortunately, design and mechanical engineers wishing to make F357 components have to rely on castings and their inherent trade-offs. Tooling to make castings is expensive and complex components can greatly drive up tooling costs, dampening innovation.

This situation has, however, changed significantly thanks to AM technology and Linear AMS, together with engineering support from parent company Moog Inc., is now successfully printing F357 on its Direct Metal Laser Melting (DMLM) equipment. “Not only is this a significant technical achievement, it is a real culture shift in the way Linear is now operating,” states Chris Jastrzembski, Additive Manufacturing Account Manager. “With Moog’s input, we are developing new material parameters constantly. Printing F357 is a direct result of that work.”

That Linear AMS also has a full CNC machine shop for post-processing additively manufactured parts adds to the company’s capabilities. “Securing and qualifying metal powders and printing new materials is a great example of the partnership between Linear’s capacity and Moog’s engineering support and deep involvement in aerospace and defence,” Jastrszembski adds. “We are continuing to collect mechanical data and explore printing parameters based on powder density, surface finish, laser power, scan speed and many others.”

There is definitely a buzz at Linear over printing F357 and continually exploring other materials, including copper grades used in combustion chambers and thermal transfer equipment. “It is very proactive as far as customers are concerned,” Jastrszembski explains when asked about customer feedback. “They are finding they do not have to alter prints or drawings drastically to take advantage of 3D printing. From our perspective, pushing the envelope on new materials and metallurgical processing is not only exciting, it is affecting and improving what we are already doing every day with existing materials.”

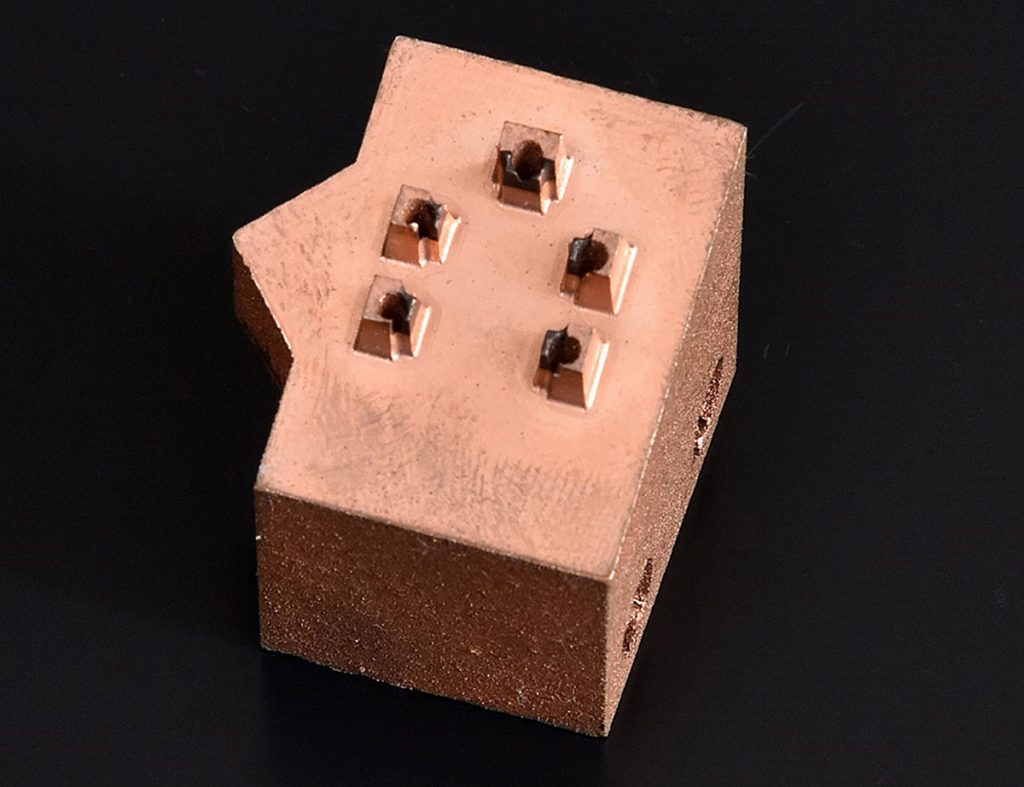

The growth of copper as an AM material

“There is a lot of interest in thermal stabilisation projects for copper components, due to copper’s excellent heat-transfer properties and electrical conductivity,” states Paul Breeding, Director Of Engineering/Additive at Linear. “Tie in all the advantages of metal AM in removing design constraints and expanding part configuration choices, compared to conventional milling and turning, and copper becomes a very exciting choice for particular parts.”

Industries such as aerospace and automotive are breaking new ground in printing copper components. As recently as 2015, NASA announced its first full-scale additively manufactured copper part, a combustion chamber liner. “We are not trying to just make and test one part,” a project leader reported. “We are developing a repeatable process that industry can adopt to manufacture engine parts with advanced designs. The ultimate goal is to make building rocket engines more affordable for everyone.”

Process development is an ongoing mission that Linear AMS shares as well. “It is a very interesting time in the industrial space with Additive Manufacturing,” Breeding continues. “Team building, participating in standards discussions and improving process controls are just some of our efforts aimed at bettering our engineering and metallurgical understanding of not only copper, but all the materials our customers want.”

Conformal Cooling: building the unmachinable

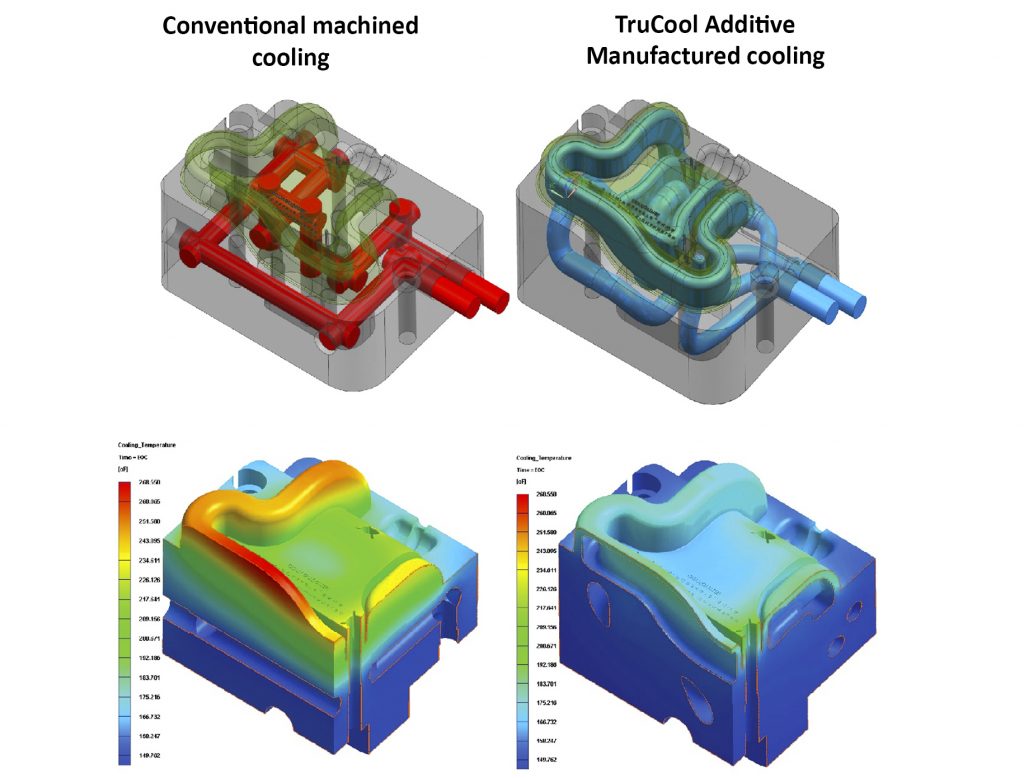

Milacron Holdings Corp., a leading industrial technology company serving the plastics processing industry, has announced that its DME product brand, a leader in mould components, moulding supplies and industrial supplies, is partnering with Linear AMS to offer metal additively manufactured conformal cooling products to help improve productivity in the moulding industry.

TruCool® is a new line of DME products designed to help mould-makers and moulders with mould cooling. DME’s conformal cooling solutions through Linear use metal AM to produce highly complex cavities, cores and components with conformal cooling channels. The AM process achieves shapes, paths and channel geometries impossible to obtain with conventional tooling. “We build the unmachinable!” stated David Baucus, DME Product Manager, adding, “The conformal cooling solution places cooling channels at the optimal distance from the mould surface, consistently following the geometric shape of any mould insert for any customer part, allowing the mould to maintain a targeted, consistent temperature that allows for complete thermal control with cooling times reduced up to 100%. This technology also allows for conformal venting solutions for those hard to reach areas of trapped gases, when requested by the moulder.”

“Conventional mould cooling has remained largely unchanged for decades. DME’s partnership with Linear AMS is a huge step forward for the industry,” added Peter Smith, DME President. Smith added, “Our real world, in-field results show a significantly reduced total cycle time – between 15 and 60% depending on part complexity, shortening the time needed to run the part and improving part quality. That is a significant cost saving every moulder would be interested in. Likewise, OEM/product designers will benefit from the technology as it broadens the scope of part design, allowing for advancements in plastic part production and application use.”

“We have taken the lessons from over a decade of building DMLM parts and established design rules and process controls that enable us to make excellent quality components that meet or exceed customer expectations,” states David Hodge, Linear AMS General Manager. “We are excited to partner with DME, a leader in the moulding industry, who shares our focus for serving customers with superior products. When a customer is moulding millions of parts, seeing significant process gains is a real eye-opener.”

Digital part verification

Moog is contributing significant effort toward strengthening the metal AM infrastructure even further. By using Blockchain, the technology behind the digital currency Bitcoin, Moog Inc. and Identify3D (San Francisco, California, USA) are together launching VeriPart™; a cloud-based, open-standard digital part verification system that is re-imagining and re-making the part verification process.

Watch The Antiques Roadshow more than once and you will hear the word ‘provenance’ pop up. Meaning to establish the true origin or source of an object (from the Latin provenire, ‘to come forth’), a lack of or unknown provenance implies (a) questionable if not shoddy workmanship; (b) that the item is counterfeit and/or (c) that it is illegal.

Now, take an example from the real world. Last year, a nineteen-year-old turbine disk violently broke apart inside the engine of an American Airlines jetliner taking off from O’Hare International Airport in Chicago, sparking a massive fire and a wide-ranging probe into General Electric’s CF6 engines. The ‘uncontained’ failure, which hurled fragments as far as half a mile from the scene, is certainly unusual given modern protective casings, but at least four other planes powered by the same GE engine family have experienced serious malfunctions since 2000.

Imagine if there were a perfect trail, entirely digital and immediately accessible, for checking all part approvals from design through production. Industries with critical part-performance requirements, including aerospace, defence, automotive, medical and more, have part-checking requirements built into the supply chain. Hundreds of millions of dollars are spent verifying part and process quality – with varying degrees of success – from antiquated and time-consuming job tickets and paper trails to complex, Big Data-inspired computerised systems requiring an extensive, customised and costly IT infrastructure. Manufacturing companies without the knowledge or resources to invest in part verification are effectively cut out from acquiring or growing any business in complex-part manufacturing.

“Many industries are fraught with counterfeit parts, from aerospace and defence to vitamins and supplements,” explains Moog Director James Regenor. Every action in the supply chain – obtaining raw materials, confirming and finalising part design adjustments, manufacturing, post-processing, shipping – generates microbursts of data, energy and bandwidth. “Blockchain-based technology allows the capture of these data and the verification of each transaction digitally at every step of the process,” Regenor continues. “Essentially, this creates a digital ledger system, available any time, to any participant, whenever needed.”

Making and preserving truth

In a 2015 article, entitled “The great chain of being sure about things,” The Economist wrote that “the cryptographic technology that underlies bitcoin, called the ‘blockchain’, has applications well beyond cash and currency. It offers a way for people who do not know or trust each other to create a record of who owns what that will compel the assent of everyone concerned. It is a way of making and preserving truths.”

In a manufacturing world of digital part designs, whose files not only establish design provenance but also power CNC machining and Additive Manufacturing equipment, establishing and preserving truth along each step of design and manufacturing is an essential commodity.

According to The Economist, the blockchain began life in the mind of Satoshi Nakamoto, the brilliant, pseudonymous and so far unidentified creator of bitcoin – a “purely peer-to-peer version of electronic cash,” as he put it in a paper published in 2008. To work as cash, bitcoin had to be able to change hands without being diverted into the wrong account and to be impossible for the same person to spend twice.

To fulfil Nakamoto’s dream of a decentralised system, the avoidance of such abuses had to be achieved without recourse to any trusted third party, such as the banks that stand behind conventional payment systems. So the blockchain became this trusted third party; a database that contains the payment history of every bitcoin in circulation, providing proof of who owns what at any given juncture.

This distributed ledger is replicated on thousands of computers – bitcoin’s ‘nodes’ – around the world and is publicly available. However, for all its openness, it is also trustworthy and secure. This is guaranteed by the mixture of mathematical subtlety and computational brute force built into its ‘consensus mechanism’ – the process by which all nodes agree on how to update the blockchain in the light of bitcoin transfers from one person to another.

Adjusting blockchain to part verification essentially and efficiently digitises the paper trail for design through manufacturing. Hundreds of process participants – designers, engineers, raw material buyers, equipment operators, process specialists, schedulers, shippers and all the supervisors in between – can generate thousands of ledger pages across ad hoc networks, which effectively establish peer-to-peer trust as parts move through production. Part provenance is established every step of the way.

“Using VeriPart as the platform for a cloud-based project management system makes authenticity, status availability, quality and security immediately available up and down the network to any participant that needs it,” states Regenor. “Such a process also becomes self-policing, quickly identifying under-performers and thereby strengthening the supply chain. Design and manufacturing owners retain their ownership and can aggregate and reward intellectual property from all stakeholders. VeriPart-verified parts are guaranteed authentic because all the materials, design changes and manufacturing processes are certified and traceable.”

Take the engine disk example mentioned earlier. Now, imagine an aerospace Maintenance Repair and Overhaul worker being able to scan a metal AM replacement part and know 100% that it is not counterfeit and be able to look up the data to validate its origin and production.

Conclusion

Through network-wide software solutions, domestic and international logistics expertise and the ever-evolving capabilities of metal AM production, including seamless digital part verification, the technology’s ability to disrupt the conventional manufacturing supply chain is very real. As demonstrated in this article, the infrastructure to support metal Additive Manufacturing as it embraces the potential of on-demand manufacturing is very much in place.

Authors

Bruce Colter

Director, Linear AMS

12926 Stark Road

Livonia, MI48150

USA

Email: [email protected]

George Small

Principal Engineer, Moog Inc.

400 Jamison Rd.

East Aurora, NY 14052

USA