From rapid prototyping to rocket engines: The evolution of 3T Additive Manufacturing

With two decades of experience in part production using Additive Manufacturing technologies, 3T Additive Manufacturing Ltd, based in Newbury, UK, today enjoys a strong position as an international developer and supplier of cutting edge metal AM components. At a time of transition for the company, Metal AM magazine's Nick Williams and Emily-Jo Hopson met with outgoing CEO Ian Halliday and his successor, Nigel Robinson, to discuss the evolution of the metal AM industry to date and the business’s plans for further expansion. [First published in Metal AM Vol. 5 No. 1, Spring 2019 | 20 minute read | View on Issuu | Download PDF]

In 2019 3T Additive Manufacturing Ltd, formerly known as 3T RPD, celebrates twenty years of additively manufactured part production. Throughout this period, the business’s growth has closely tracked the evolution of the AM industry as a whole, moving from the rapid prototyping of plastic products through to end-use part production, the introduction of metal AM and, more recently, a ramping up of production capacity to meet demand for the series production of components.

This year also marks the end of Ian Halliday’s tenure at the helm of the business. Having taken over as CEO in 2005 from the company’s founder, Tim Plunkett, Halliday has guided the company through a long period of growth that has seen fundamental changes in all areas of the industry, from technical capabilities to materials and end-user markets.

Halliday’s experience of Additive Manufacturing, however, extends beyond his career at 3T to the early 1990s where, as Chief Engineer at the Rover Group, he was instrumental in setting up an internal rapid prototyping and rapid tooling facility. It was under his guidance that Rover Group first investigated Stereolithography (SLA) in 1989, resulting, he explained, in a very fragile and very expensive part from a service bureau that, inevitability, no longer exists. The recognition of what the technology could do led to the establishment in 1991 of an in-house rapid prototyping operation that was very much ahead of its time. To give a sense of the scale of this early operation, in 1998 the Rover Group produced 2,200 parts by Stereolithography, 3,200 parts by Selective Laser Sintering (SLS) and 9,500 polyurethane parts from silicon moulds.

Commenting on the transformation of the AM industry over the last twenty years, Halliday stated, “It is always interesting to look back and reflect on the pivotal change points that you have lived and worked through. Some of these points have been technical step changes, others have been commercial in nature or centred around the wider perception of AM.”

“On the technical side, the introduction of the ytterbium fibre laser by EOS was a milestone that enabled the controlled direct melting of a wide range of metallic alloys, whilst The Economist’s 2011 article ‘Print me a Stradivarius’ coincided with a tipping point in the awareness of Additive Manufacturing. Together these were undoubtedly catalysts for the rapid growth of the technology.”

“Various GE purchases then rocked the industry,” Halliday recalled, “starting with the pivotal acquisition of Morris Technologies and its sister company Rapid Quality Manufacturing (RQM) in 2012. This was later followed by the purchase of Avio Aerospaziale in 2013, Arcam and Concept Laser in 2016.”

Halliday also believes that the development of an AM-specific powder supply chain has been crucial for industry growth, citing the arrival of LPW in the metal powder marketplace. “This created price and quality competition that drove down powder prices, which was a critical enabler to growth,” he stated.

As the industry moved towards the series production of end-use components for critical applications, quality systems were urgently needed to instil user confidence in the technology. “The introduction of vision systems was part of a realisation that quality systems had to match those of conventional manufacturing processes if metal AM was to become a true manufacturing/production technology.” This, stated Halliday, was combined with the introduction of user-friendly software solutions for build set-up and build simulation that have led to a ‘democratisation of AM’. “This final point is as significant in the development of our industry as the reduction in build costs, as it brings down the technical barriers to entry for part manufacture.”

The growth of 3T as a metal AM producer

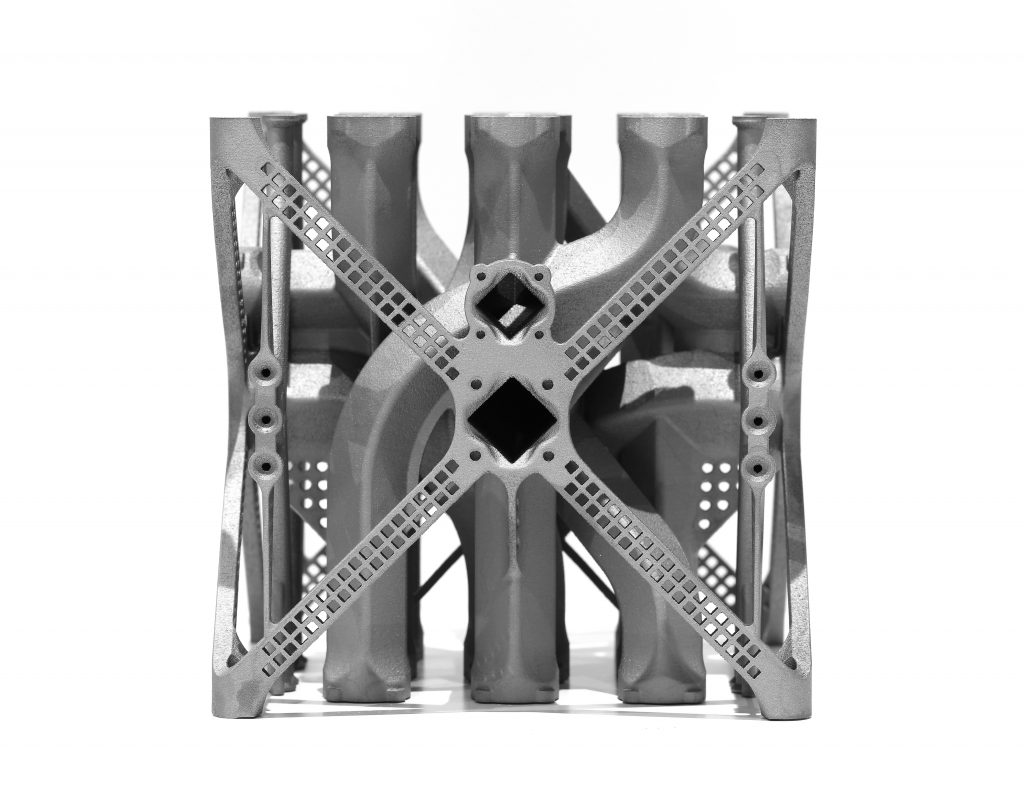

3T is today a leading European commercial AM parts producer and serves an international portfolio of clients in industries including aerospace, automotive, motorsport, oil & gas and general engineering. It is also one of several EOS ‘e-manufacturing partners’ and benefits from a close relationship with the German machine builder, operating twenty-four EOS AM machines, including twelve M 290s and four M 280s (Fig. 2). The business is today within the portfolio of Dr Hans J Langer companies.

“Having started with metal Additive Manufacturing in 2007, we quickly established ourselves as one of the prime movers in the industry. The marketplace was not ready for metal AM parts at that time, so 3T had to put a lot of work into educating customers and developing the market,” stated Halliday.

“Hiring key skilled AM experts enabled a ‘quick start’ for us, but the hard work is in building up a team, the quality systems and the infrastructure on minimal investment,” he continued. “We secured aerospace OEM series production contracts early on, and this enabled us to grow whilst driving forward quality system development.”

In 2008, the company made the strategic move to start manufacturing dental copings, gaining ISO 13485 certification as a direct result. “Although the dental market wasn’t ready for AM until at least 2012, the ISO13485 systems made it a lot easier for us to gain AS9100 certification and hence opened the door to the aerospace world,” explained Halliday.

3T hired Dr Mark Beard – now with Dutch AM machine producer Additive Industries – in 2012 to help establish a robust R&D team, “something that is strategically critical to any technical company, and something we are very proud of,” Halliday stated.

Despite this early entry into metal AM, it wasn’t until 2015 that 3T began making a profit from the technology. “This was a major milestone because it showed that the industry genuinely had the future potential that we had believed in up to that point,” Halliday recalls. “Now, twelve years after starting with metal Additive Manufacturing, the metals side of the technology generates roughly 75% of the company’s total sales.”

3T is now strengthening its complete offering to clients, with a New Product Introduction (NPI) team that streamlines the whole component development process and, more recently, a significant expansion of its post-processing operations. “The setting up of 3T’s New Product Introduction team was important in that it signalled to our customers that we were serious about production metal AM. This capability set 3T apart at the time and continues to be a major benefit to the business.”

“The most recent milestone relates to the scaling up of our metal post-processing capabilities. Completing this process chain enables us to give a complete and highly competent service to our customers, from design to delivery. Coupled with a large Additive Manufacturing capacity, the inclusion of in-house finishing, high-end 5-axis CNC and vacuum heat treatment sets us apart as one of the most capable full process chain AM manufacturers globally.”

Additive Manufacturing: Expectations and realities

As someone who has been involved in Additive Manufacturing for more than two decades, Halliday has keenly observed the changing nature of the industry. Comparing his early expectations with the reality of the industry’s growth, he stated, “The most consistent factor has been that the rate of uptake has taken two to three times longer than I had expected – or let’s say hoped for. What is obvious to one person is not necessarily obvious to all. The process of integrating a new technology is cumbersome and slow. It is a people-centric challenge interwoven with the vagaries of technical developments, perceptions and the business world in general. I now know that a major project can take two to three times longer than I expect, but it still surprises me when it does! That said, most of the strategic development models that I envisaged in 2007 were correct, but generally the timescales were too optimistic.”

“Of course, my perceived AM uptake model had some surprising exceptions that seemed to break the rules, but perhaps this simply demonstrated that sometimes, if you don’t know there are rules, you just do what you want to,” he continued. “One customer didn’t care about how we made the part at all, they simply wanted it when they needed it and to the right quality. Their uptake cycle was in effect a matter of weeks, not the usual years that we commonly encounter. The biggest obstacle was the time needed to gain PPAP [Production Part Approval Process] certification for the parts, then straight into production and onto a road-going vehicle.”

Halliday suggested that the sale of Morris Technologies to GE was a big surprise, serving to highlight that metal AM was entering a dynamic new era. However, he added, “it has not surprised me that the development of metal Additive Manufacturing has followed the same course as all other new technology introductions and followed the same rules and trends.”

Nigel Robinson, who has served until recently as Director of Operations at 3T, will shortly succeed Halliday as CEO. Robinson has seen a rapid expansion in the market for metal AM components in the five years that he has been with the firm, telling Metal AM magazine: “The market has evolved dramatically in the years I have been at 3T. In 2014 the majority of our customers were either going through validation of AM as a true solution to their production needs or they just knew they needed to get into it without knowing where to start. The 3T team understands this and our passion is to take our customers through this journey no matter if they are an early adopter or looking for a serial production partner.”

Much of Robinson’s effort has so far been focused on putting the business on a footing to efficiently manage the introduction and development of new products and meet customer demands in terms of quality and delivery. Commenting on the most significant improvements that have been introduced, and how the ‘customer experience’ has changed in recent years, Robinson stated, “Our whole customer experience is changing as their requirements evolve. Today, the AM build process is only part of the story, so implementing the full process supply chain is critical to give our customer turnkey ready-to-use parts.”

To facilitate this, recent infrastructure investments have included an in-house powder quality control laboratory, a large heat treatment vacuum furnace, full multi-axis machining equipment, and equipment for automated finishing, hand finishing and final inspection. “The biggest investment, however, comes with the people who work at 3T,” stated Robinson. “Recruiting the right people with either experience in Additive Manufacturing or from related industry sectors has been critical to help us meet our customer expectations. As the years have passed our valued customers view 3T as a certified supplier and judge our quality and delivery performance as they would any other conventional supplier in their value chain. In addition, our technical support offering gives customers access to our design for AM courses, application engineering, NPI and R&D teams.”

Commenting on the speed of industry expansion, Robinson stated, “We are already seeing many positive results from our investments in NPI and post-processing. However, when you implement a new process sometimes you have no idea of how fast the market will react. As an example, when we implemented our first 5-axis machining centre I told our new machining team to expect a slow ramp up in the first few months. How wrong I was! Within the first week the machine was fully booked and I was pulling a business case for a second one. This is just one of many examples of managing a growing business in a growing sector.”

The company recognises that key to continued success are dedicated and skilled employees and, in the context of an environment where there is an AM skills shortage and lively business for the recruitment industry, 3T works hard to retain key staff as well as to plan for future workforce expansion. “We will only retain staff if we make their job interesting, fun and give them a secure and positive future,” Robinson noted. “So that is central to our philosophy as a business. The 3T team wants our company to be the best place to work in our industry. Although direct AM skills are indeed rare, taking on top people and training them is a good alternative, despite taking one to two years before some of their skills are sufficiently robust. That of course does make our staff more of a target, and hence we go back to the above statement about how to increase our chances of retaining key people.”

“In addition to simply taking on qualified engineers and other disciplines, we have a strong and healthy apprenticeship programme, which will help to fulfil our skills requirements in the medium and long term.”

Client case study: Launcher

From NASA and SpaceX to a new generation of smaller companies looking to carve a niche in the expanding small satellite delivery market, the space industry has fully embraced metal Additive Manufacturing. 3T is supporting smaller companies with highly engineered rocket components that rely on its AM materials and production expertise.

“The space sector is one of the most fascinating industries to work with. The natural performance benefits with Additive Manufacturing through weight loss, thermal efficiencies, etc, are well-documented but the industry is forwardly thinking about the next ten years so. Therefore, taking cost out of the product without compromising quality is a critical expectation,” stated Robinson.

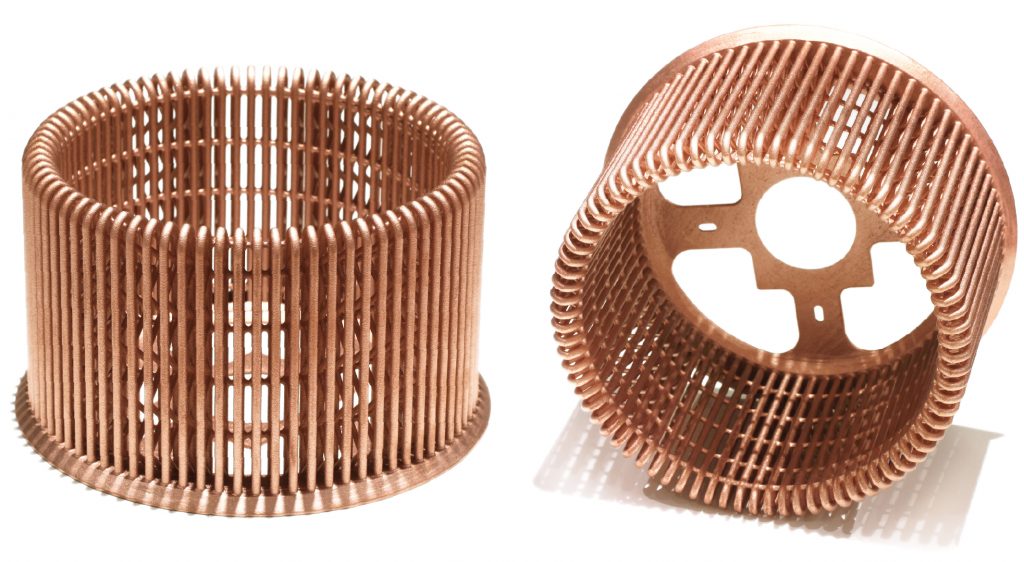

3T and US-based rocket start-up Launcher have developed a close and successful working relationship in recent years, thanks in part to 3T’s capabilities in copper AM. Commenting on how this relationship was formed, Robinson stated, “When our collaboration started, the Launcher team was already using Additive Manufacturing to build its thrust chamber (Figs. 6-8), and their first test firing was with an Inconel version that they sourced in the United States. They approached 3T when they heard we could build in copper and the relationship grew from there. Launcher appreciated the collaborative ethos that both companies are based on.”

The use of a CuCrZr alloy in the Launcher application was attractive because of its high-efficiency cooling, leading to a longer chamber life and reduced costs compared to conventional production. The copper part was also proven to be twenty times more conductive than the comparable Inconel part, resulting in a coolant temperature of 280°C compared to 153°C for Inconel.

Max Haot, Founder and CEO of Launcher, told Metal AM magazine, “As part of our pursuit to build the highest performance additively manufactured liquid rocket engines, we were always hoping that one day we would be able to manufacture our chamber in copper alloy rather than Inconel but had not come across a service provider with this capability. Copper alloy is widely accepted as the highest performance material for cooling liquid rocket engines – Inconel is a compromise. When we heard that 3T was able to do this, we immediately partnered with them and went from quote to successful test fire in less than eight weeks. We achieved the highest performance oxidiser fuel mix ratio for kerosene and liquid oxygen (2.62) for a 45-second duration fire on the first test campaign with the AM engine from 3T.” (Fig. 9).

In the case of Launcher and 3T, success can in part be attributed to the dynamic relationship between team members at both companies. Robinson explained, “We have an application engineer who is a rocket engine fanatic and could relate directly to the customer’s requirements and therefore led us to an innovative AM solution. This proactive relationship between our application engineer and the Launcher team was one of the factors to the success of the project.”

“We are delighted that our affiliated company AMCM is working with 3T to produce the required large-scale copper parts and we have both identified a number of sectors that would benefit from this size of application. A customised AM machine is on track to deliver 1000 mm Z-height parts within the next few months.”

3T made its first copper parts on a standard EOS M 290 in 2014, displaying the 3T heat exchanger at Formnext in 2015. This development served to demonstrate its capabilities in materials development and led the way to its current leading position in the AM rocket engine manufacturing market.

Commenting on how other end-users could learn from Launcher’s success to date, Robinson stated, “The Launcher team already had a very good understanding of the benefits and limitations of the use of Additive Manufacturing. However, being involved at the design stage was critical to get the most out of the opportunity of the concept. Our advice to all our customers is where possible to get 3T’s application engineers involved at the design stage so we can give advice on maximising the optimisation for DfAM.”

Copper is a material that is now becoming increasingly talked about in relation to AM. Commenting on the specific challenges of processing this material, Robinson stated, “Whilst 3T’s copper developments go back to 2014, it has taken a number of years to perfect the process. Unsurprisingly, the secret is not just in the build process but the complete production chain, including heat treatment and post-processing. Since launching copper, we have seen various industries become interested in the material. Particular interest is coming from customers for electrical and cooling applications, where thermal efficiencies are improved through the combination of copper and AM’s design capabilities.”

Advice on AM design and applications

After so many years in the business, Halliday is quickly able to distinguish between enquiries that are viable and those that are not. Based on this knowledge, he has some basic advice for designers who are unfamiliar with AM on how to approach both the technology and potential production partners. “Firstly, AM will not solve all your problems, it is simply another manufacturing tool in the toolbox, albeit an excellent one,” he explained. “Try and learn enough about the benefits and shortfalls of AM to be able to identify which of the components that you design can be genuinely enhanced from the use of AM. This will help you select the right parts for AM, which can then be designed for manufacture by AM, but taking into account the beneficial and necessary use of conventional technologies for finishing, including CNC machining in particular.”

“Consider opportunities to combine parts and improve system performance through the use of AM – look more broadly than your own components on a system level if possible. Finally, be passionate about your design and the potential for using AM, but don’t expect it to do everything, and always include other manufacturing processes in your thinking.”

The future

3T has ambitious plans for the future that centre on a continuing expansion in internal capacity, whilst supporting key customers with complete AM installations on their own sites and pushing for an international expansion of the 3T business.

Halliday told Metal AM, “We are working on all three options, and expect the future of the company to develop in these directions. The centre of service, R&D, product development and production of 3T will remain in the UK for many years to come. However, if the company is to benefit from the knowledge built up over the last twenty years in AM, we need to multiply the use of that knowledge by supporting our customers through the AM journey to create their own stable production facilities either run by the customer or 3T”.

Halliday added, “The development and protection of 3T UK is therefore the priority, however we have already benefitted 3T UK by helping non-competitor customers to develop their own in-house facilities. In addition to training and know how sharing, we are setting up a 3T site in Japan and will do the same in the USA. A global reach has many advantages, increasing opportunities, balancing risk and helping to balance the workload of each individual ‘hub’ by sharing production demand where viable. These three tenets of the 3T strategy have been a vision for over a decade, so it is uplifting to see the strategy starting to become a reality.”

Contact

Nigel Robinson

Operations Director

3T Additive Manufacturing Ltd

Fulton Court

Wofford Way

Greenham Business Park

Newbury, RG19 6HD

UK

Tel: +44 1635 580 284

[email protected]

www.3t-am.com

Authors

Nick Williams

Managing Editor

Metal AM magazine

[email protected]

Emily-Jo Hopson

Assistant Editor

Metal AM magazine

[email protected]