What happens when you take the powder out of AM? Charting the rise of wire-based DED with WAAM3D

While most people associate the advantages of AM with small- to medium-sized, complex parts, wire-based Directed Energy Deposition (DED) makes it possible to achieve geometric complexity on a huge scale. Although the adoption rate for wire-based DED does not come close to that of the more widely known metal AM processes, this unique technology has advanced dramatically over recent years, and promises major advantages in a volatile global manufacturing landscape. Dr Filomeno Martina, CEO and co-founder of WAAM3D, explains more. [First published in Metal AM Vol. 8 No. 4, Winter 2022 | 20 minute read | View on Issuu | Download PDF]

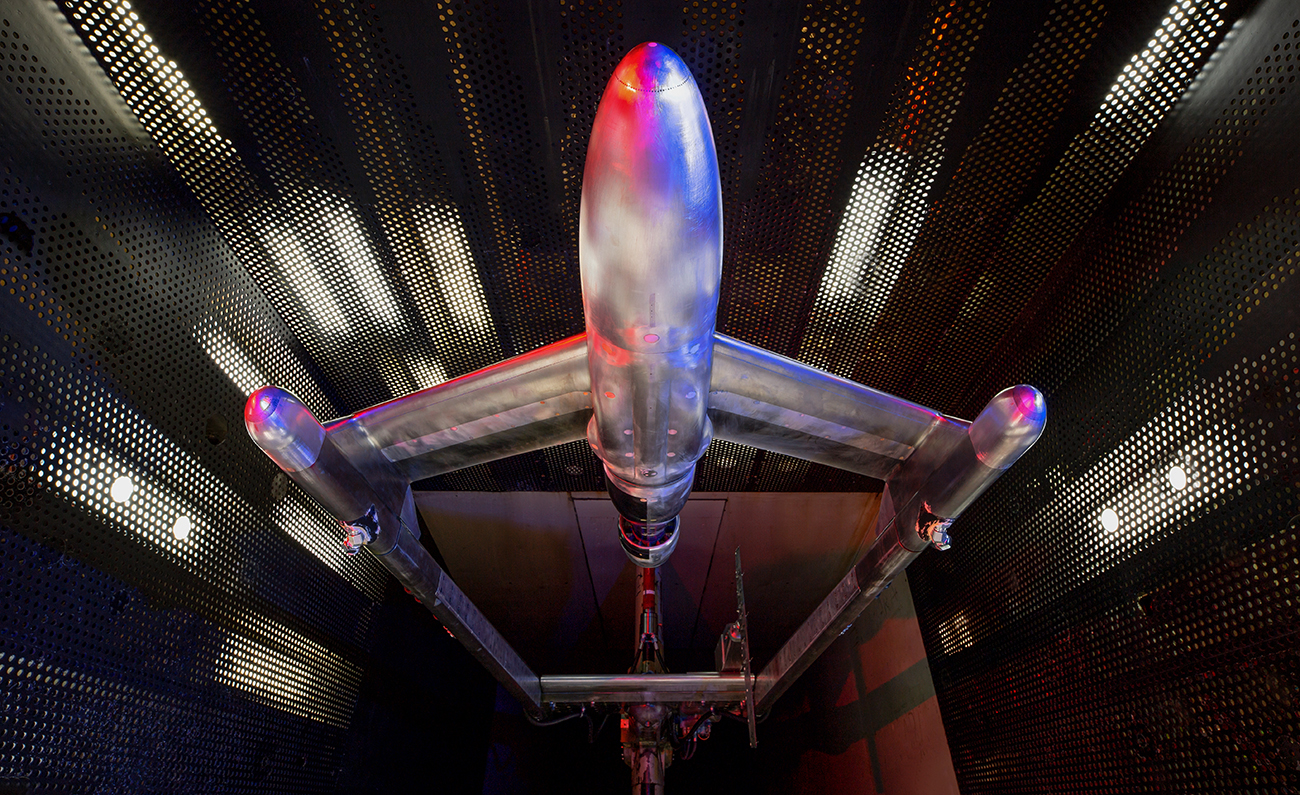

If I mention metal Additive Manufacturing to you, you’ll most likely think about optimised jet engine fuel nozzles, bionic brake callipers, or complex auxetic lattice structures. Lasers; powders; parts that you can hold in the palm of your hand. If you mention metal Additive Manufacturing to me, my mind will wander amongst critical fuselage frames, huge satellite bulkheads, advanced ship propellers. Electric arcs; wires; components that would fill a small bedroom.

For decades, the majority of the industry has focused on powder-based metal Additive Manufacturing. Particular attention has been on variants based on powder bed AM, which use either electron or laser beams (PBF-EB, PBF-LB) to provide the energy required to melt the powders in the desired pattern, layer by layer. Such technologies have opened previously unattainable doors in terms of design, with mechanical performances maximised whilst minimising mass. The main enablers? Small particles, thin layers and surgically precise heat sources, together delivering net-shape parts. Powder-based developments have been a dream for the modern engineer, enabling them to truly design for function.

A changing manufacturing climate

However, the challenges facing manufacturing are changing, particularly due to the growing pressure to reshore operations and mitigate risk, and the back-to-back disruptions of COVID-19 and the Russian invasion of Ukraine. These global crises have shown how unpredictable globalised supply chains can be. To protect profit margins against inflation, companies are increasingly being forced to rearchitect their supply chains, enabling them to change prices at a higher frequency. The much-needed attention on environment and societal impact is also driving organisations to design both their products and their manufacturing processes for sustainability. Lastly, considering the ever-increasing pace of innovation, manufacturing methods are needed that can launch and improve products more and more quickly.

Arguably, there is scope to seek those changes across the board, not just for relatively small parts, but, perhaps even more importantly, for larger components. There is, however, a necessary trade-off between accuracy and speed with Additive Manufacturing. For those large components that require less precision, processes such as DED-Arc (the ISO/ASTM 52900:2021 term [1] for what WAAM3D Ltd has trademarked as Wire + Arc Additive Manufacturing, or WAAM [2]) can deliver numerous advantages compared to more traditional methods.

What is DED-Arc?

The combination of an electric arc as the heat source and wire as feedstock has been investigated for Additive Manufacturing since the 1990s [3]. Despite the birth of AM being traditionally associated with the rise of stereolithography in the 1980s, the first patent for Directed Energy Deposition was actually filed in 1925 [4] by R Baker, and was for making decorative articles. The patent stated, “This invention relates to ornamental arc welding, more especially to utilising an electric arc, such as is ordinarily employed for electric welding, for the formation of deposits to produce receptacles or containers of ornamental and useful shapes. I have found that metal derived from a fusible metal electrode by the passage of a current therethrough may be so deposited in superposed layers as to form various articles of an ornamental and useful nature, it being among the objects of my invention to produce such objects of various designs” [5]. With the benefit of time and development, AM has become so much more than Baker could ever have envisaged.

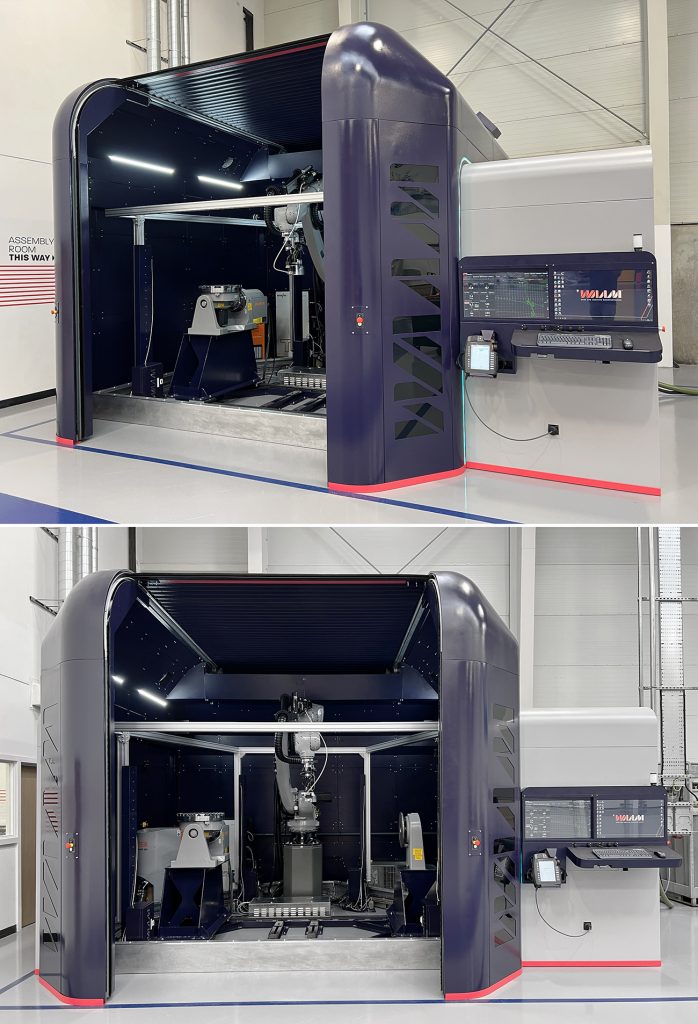

One of the key characteristics of the DED-Arc process (and the one that induces the user to consider it a straightforward technology to master) is its accessibility. In its most basic configuration, the DED-Arc process relies on standard, off-the-shelf welding equipment: welding power sources and torches, and wire-feeding devices. The choice of motion system is largely based on either anthropomorphic robotic arms, often combined with servo positioners, or computer numerical controlled (CNC) gantries. The majority of engineering companies will have access to most, if not all of these items.

It is unsurprising, then, that after the seminal work carried out at Cranfield University (first in the 1990s under the guidance of Prof John Norrish [6], and then with renewed vigour from 2006 onwards under Prof Stewart Williams), many engineers, material scientists, and students have been dipping their toes in the waters of DED-Arc. Academic publications in this field have grown from literally a handful in 2009, when there were no commercial solutions for DED-Arc, to many hundreds in 2021, as the competitive landscape finally begins to get busy and to diversify.

DED-Arc’s raison d’etre

DED-Arc involves a robotic arm tracing slow movements, inside a safe perimeter, possibly within an inert argon environment, with an ionised stream of gas melting wire feedstock in a highly controlled manner. Apart from being a hypnotising process to watch, why is the DED-Arc process becoming so fashionable? The answer can be summed up in one word: waste. This is in the continuous improvement, or kaizen, sense of the word, as DED-Arc helps manufacturers manage issues such as overproduction, inventory, motion, defects, over-processing, waiting, and transport.

Reduced metal swarf

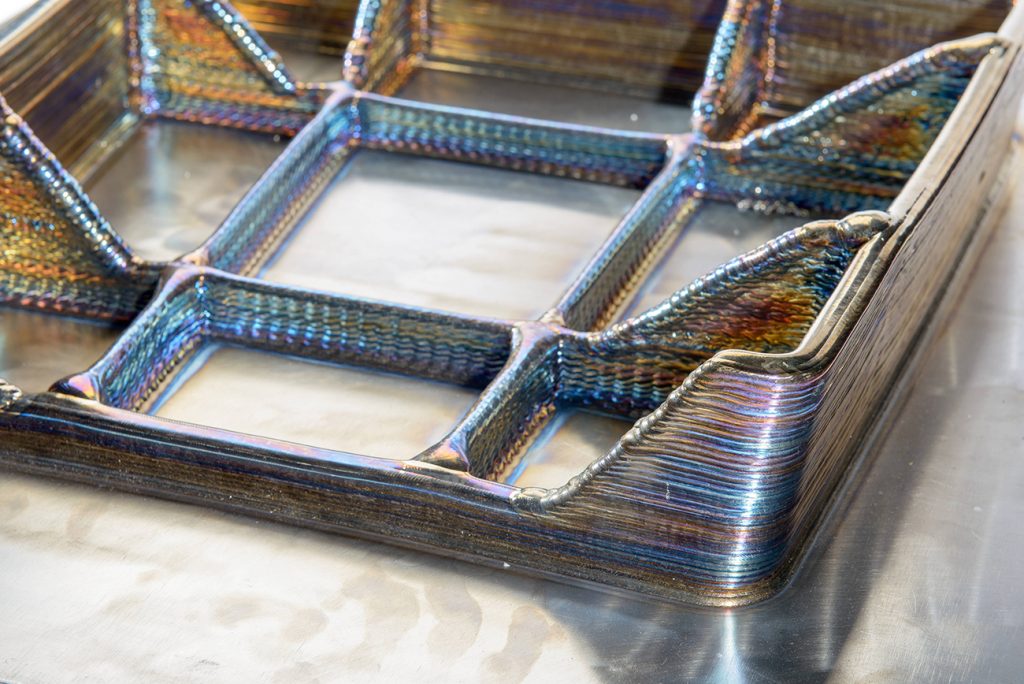

Despite closed die forging making huge strides forward, traditional forging still leads to high material wastage. DED-Arc can significantly reduce the amount of material wasted on component creation. In the aerospace industry, the buy-to-fly (BTF) ratio is the ratio of the mass of the starting billet of material to the mass of the finished part that is flown on the aircraft. The smaller the ratio, the less material is wasted. The BTF ratio for aero engine components can be as high as twenty-five; sometimes, for aerostructures, as high as sixty. DED-Arc can reduce this ratio to less than two. It can’t reduce it to one, however, because the DED-Arc process, by virtue of its thicker layers (typically 1 to 3 mm thick), delivers near-net shape parts, with a couple of machining passes normally required to eliminate surface waviness. With this aside, the impact on cost reduction is still relevant; for example, in Ti-6Al-4V, if the traditional manufacturing route delivers a BTF ratio of four or above, DED-Arc is a cheaper alternative [7,8].

Reduced pre-machining wastage

The moulds and dies used for forging and casting can have long procurement times and high costs. Due to lead time and design cycle pressures, the purchase of tools must sometimes begin before the part’s design has been finalised. To overcome this, many manufacturers add a larger waste envelope into the final geometry of the mould or die, leading to increased levels of material waste to achieve the final product. As DED-Arc is a digital manufacturing process, it requires no tools – apart from the clamps needed to fix the starting feedstock – so the upfront non-recurring cost is virtually eliminated, and design changes can be made whenever needed, eradicating additional geometry waste.

Reduced spare part wastage

For spare part, inventory management and stock keeping there are two types of potential waste: the material itself, if the part isn’t needed, and the energy embodied into the part. Unused stock can lead to significant financial and material waste. Rather than keeping stock that might not be needed, more manufacturers are reducing inventory and logistics costs by focusing on local, on-demand manufacture. This helps them to resolve spare part production and repair issues, as quickly and as cost-effectively as possible.

Improved environmental performance

Because of the material savings achieved using DED-Arc, a manufacturer’s environmental performance can be improved when it comes to component creation and repair. DED-Arc has long been used to repair structures, extending the life of components, and delivering significant energy and CO2 emission savings. Additional environmental benefits can be unlocked by having local DED-Arc centres, thus reducing the impact of logistics. For those manufacturers looking to demonstrate that they are taking the triple bottom line seriously, the DED-Arc process is an important part of the large-scale metal component fabrication toolkit.

Beyond eliminating waste

Moving beyond waste elimination, two more DED-Arc capabilities must not be forgotten:

- The possibility of playing with material composition

- The capability to reliably extend a component’s useful life by carrying out repair or remanufacturing operations

When it comes to material composition, Cranfield University has demonstrated the viability of in-situ alloying by providing as many as three wires of dissimilar composition to achieve a modified aluminium 2024 variant [9]. Indeed, the deposition of graded structures with materials as exotic and challenging as molybdenum, tantalum, and tungsten [10] has illustrated how multi-material components could become the new norm.

In terms of repair and remanufacturing, with the DED-Arc kit able to adapt to depositing on existing structures, service centres could be scattered around the world, to perform local repairs at the point of use. This is already beginning to happen and the potential for it is huge for reducing environmental impact even further by taking transportation out of the process.

A route to industrial exploitation

So, how has DED-Arc made the move to a viable, scalable industrial solution? This is largely thanks to research carried out at Cranfield University. Due to the institution’s long-standing aerospace heritage, and Prof Williams’ previous industrial experience, it made sense that large-scale titanium structural components were the starting point for Cranfield’s DED-Arc research. The growing use of carbon-fibre-reinforced-polymers on commercial aircrafts pushed the fraction of titanium components up, and with machining from forging or billet being the only two routes available, the requirement for a less wasteful and costly manufacturing process became more and more urgent.

The first large-scale parts Cranfield University ever produced, back in 2012, were a 1.2 m-long, 20 kg wing spar for a fast jet, and a 24 kg landing gear rib, both in Ti-6Al-4V. Robots were programmed with Matlab routines and sets of parameters were limited in extent and capabilities. During the process, issues with controlling shape and integrity reliably became obvious. These issues were different from powder-bed technologies, however. That is because in DED, the deposited feedstock’s layer height is not fixed, and thermal effects related to local changes in thermal inertia are immediately visible, and often catastrophic. Considering the scale at which the melt pool is established, even small inaccuracies or perturbations to the stability of melting and solidification behaviour can cumulatively result in large drifts away from the target geometry. Moreover, as HIP is inapplicable as a method to eradicate defects on structures of this size, the geometrical challenge Cranfield faced was compounded by one of structural integrity, with the absolute requirement to avoid discontinuities during the DED-Arc deposition process.

The Cranfield team faced many challenges along the way. The first issue was developing software tools for trajectory generation, parameter allocation and process monitoring and control, that could achieve the efficiency and rigour needed for such levels of consistency. Cranfield initially tried to work with existing providers of Computer Aided Manufacturing software, but eventually a DED-Arc-specific tool-path-planning solution was born (WAAMPlanner®). This was complemented by process algorithms, analytical solutions, and fluid-flow models that, based on geometry and alloy, would calculate location-specific primary process parameters (WAAMKeys). From an industrial perspective this development was crucial, as it enabled the prompt translation of preform design to executable machine programmes, minimising parameters’ development effort.

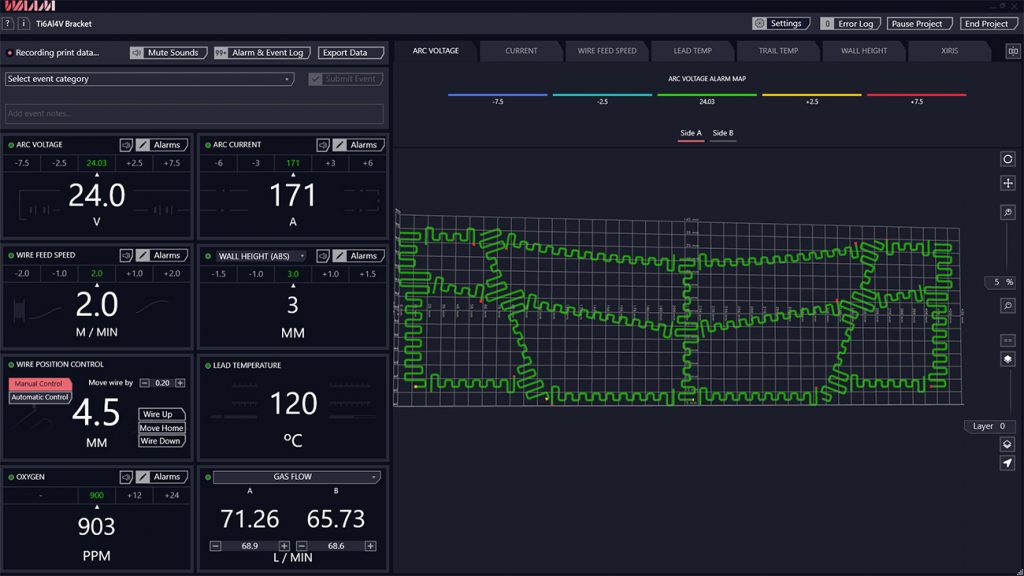

Another challenge has been to be able to demonstrate compliance in a repeatable manner for DED-Arc components. To achieve this monitoring and control accountability, a radically different approach to sensing had to be conceived and delivered – after all, without measurement there is no appreciation of a process’ recurring performance. However, the difficulty that had to be overcome was to avoid inundating the operator with an unmanageable quantity of data. As a result of this conundrum, WAAMCtrl® was developed to record and structure the data into a user-centric dashboard, featuring real-time colour-coding of the 3D picture of the build based on actual vs expected data, automatic following of the end-effector’s digital twin, and through-layers navigation to review and monitor the state of the part.

Modelling and simulation were other hurdles that had to be overcome. Initially, the floorplan of a prototype system with two robotic arms was sketched out that had each sliding onto 10 m tracks, on either side of a pair of rotators and tailstock. A 6 m aluminium beam was manufactured (Fig. 8), and the team was deceived into thinking that a big format machine equalled being able to build huge parts. Once the same system was upgraded to build with titanium alloys, the deposition of a 2 x 1 m fuselage frame was attempted. However, it didn’t go to plan; the first trial had to be aborted two layers in due to catastrophic buckling distortion. Despite being deposited on an 18-mm-thick Ti-6Al-4V substrate, one of the corners came up by a foot once unclamped.

The team went back to the drawing board, and new tooling solutions were developed, based on conformal and compliant approaches, which were subsequently tested on scaled geometries. FEA models assisted in the optimisation of the build sequence, section by section, side by side, layer by layer. Also, the precise primary deposition parameters required to walk on the razor’s edge of feasible process, design compatibility, geometric integrity and validity were recalculated. The second and final modelling attempt was successful, and, to date, that frame is still the largest part that has ever been deposited in Ti-6Al-4V.

The breadth of software was being broadened, but this had to be underpinned by a comparable improvement in the hardware capability. Since the creation of the basic WAAM3D system described early on, it now features a long list of core and accessory hardware solutions, ranging from new sensors to improvements to automation aspects. A case in point is ShapeTechTM, which is perhaps the most awaited feature: a laser interferometer intervenes right behind a live melt pool, extracting the layer height and the profile of the deposited structure, instantaneously. Also, the Fume Management System (FMSTM), which inexpensively offers the capability to establish and maintain an inert argon atmosphere, whilst containing and filtering all fumes.

What is next for DED-Arc?

The WAAMMat consortium was officially launched in 2012 [11], as a rolling technology development programme at Cranfield University. It comprises of a series of individual projects and activities that were brought together under one umbrella programme. Each of these projects or activities has its own individual objectives and is continually evolving, with mixed funding coming from industry, agencies, and the partnering universities themselves. To date, approximately £10 million has been invested in activities from technology readiness levels (TRL) 1 to 5, with another £5 million of planned future funding activities at Cranfield University, the University of Manchester, Coventry University, and the University of Strathclyde. WAAM3D Ltd took over the higher TRL activities from 2018 onwards.

So, what is today’s academic focus for DED-Arc? The challenge set out by the regulators is clear: the production of high-integrity parts by an unsupervised, robust manufacturing process. Additionally, DED-Arc needs to answer the question of how the process be applied to as many parts as possible. The answer to both these requirements lies in on-board process validation, in-process cold-work, and increased productivity.

On-board process validation

One of the limits of part qualification today is the extensive mechanical testing campaign required to demonstrate compliance of a component on a geometry-by-geometry basis. A more flexible framework is needed:

- Firstly, the relationship between the thermal field experienced in a location, and the resulting microstructure and mechanical properties, must be established upfront

- Secondly, an acceptable range of thermal fields that would give acceptable mechanical properties must be identified

- Thirdly, an FEA simulation needs to be run on the target geometry, based on its set of process parameters and the DED-Arc toolpath plan, to uncover potential regions of expected criticality (i.e., where the thermal field might be out of the qualified band). If necessary, corrections to process parameters and the DED-Arc toolpath plan can be undertaken at this point to address any issues

- Finally, when the geometry is being deposited, advanced sensors are needed to demonstrate that the thermal field experienced during deposition is indeed the qualified one, location by location

As previously mentioned, one of the challenges for Additive Manufacturing is that geometry and properties are produced at the same time. However, with the above framework – firmly grounded in physics and material science – combined with novel sensing hardware, the time and cost required to qualify a component can be dramatically reduced.

In-process cold-work

It shouldn’t come as a surprise that alloys designed to be thermo-mechanically processed do not give of their best when the mechanical aspect is missing. To address this, Cranfield University has been investigating the addition of in-process cold-work via rolling or peening methods since 2010. This was initially to control residual stress in welded structures, and later to refine microstructures in DED-Arc deposits. The alternation between additive and cold-work passes has been a phenomenal tool to increase the mechanical performance of a growing list of alloys of titanium, nickel, aluminium, iron, tantalum, Ti-6Al-4V, maraging steel, superalloy 718, Al-Mg-Sc, and others. These chemistries are now showing a forged level of mechanical properties.

Increased productivity

More and more environmental analyses are showing that DED-Arc is the better choice from both embodied energy and CO2 standpoints. However, especially for materials of relatively low value, cost can remain in favour of traditional technologies, with the deposition rate being the dominant driver. Judging by publicly available information (both academic and commercial), the predominant choice is still to rely on welding power sources and processes, which, whilst well established and readily available, do have tangible limits when used in an additive context.

Cranfield and WAAM3D are working in partnership on two fronts: developing radically new approaches to delivering energy and controlling the resulting melt pool. The first, based on the hybridisation of lasers and electric arcs, is to increase deposition rates, overcome the limitations of single axisymmetric heat sources and achieve independent control of layer height and wall width.

The second, that is much closer to commercialisation [12], leverages on multiple asynchronous wire feeds to achieve increased process efficiency, delivering substantially higher deposition rates, fully independent material and energy feed rates, and full thermal and geometry control. For the latter, compared to metal inert/active gas processes, the increases in deposition speed have been measured as being as high as 10 X for some materials, making the exploration of wider horizons of economic feasibility a much more realistic prospect.

Outside Cranfield University, it is worth mentioning other institutions that have contributed on both the academic and industrialisation fronts. Work at Oak Ridge National Laboratory (ORNL), USA has been on-going for several years, focusing on material science and computational modelling to assist industrial part building. They have recently demonstrated viability of multi-robot deposition to increase part size and deposition rates. After his tenure at Cranfield University, Prof. Norrish continued his research at the University of Wollongong, Australia, focusing on robotic DED-Arc. The group has published vast amounts on residual stress characterisation, material and mechanical properties characterisation, process developments, and CAM software, amongst several other areas of activity.

Applications overview

A recent article published by a team at NASA [13] recaps the rules to match processes and applications properly. It is an excellent starting point, although with the field moving rapidly, we must constantly reassess where to look to extract DED-Arc’s fullest potential. Based on the points summarised in this article, it should not surprise that, to date, typical applications have been:

- Frame structures for the aerospace sector, with Ti-6Al-4V being the predominant alloy

- Pressure vessels and other rotational geometries, in Ti-6Al-4V but also nickel-base alloys, also for aerospace

- Flanges, elbows, connectors and other components in carbon steel and nickel-base alloys for the energy sector

- Propellers and other bronze parts, for the marine and related industries

- Tools, dies and moulds, made ex-novo but also repaired

In general, parts made with relatively cheap alloys benefit from better management of inventory and lead times, as well as supply chain flexibility. Additionally, parts made with relatively expensive alloys benefit from financial savings related to reduced material consumption.

DED-Arc has the potential to revolutionise manufacturing

For a long time seen as the less sexy branch of metal Additive M, DED-Arc has been confined to a few laboratories. However, those working on it have kept pushing the boundaries of what is possible, gaining larger and larger industrial traction and opening novel market segments. Crucially, these are not just around hardware, but also for the much-required software packages, as well as materials. DED-Arc has now grown to embrace a vibrant global ecosystem of universities, spin outs, and scale ups.

Whilst DED-Arc today is still a few years behind powder-based AM in terms of broader industrial adoption, it undoubtably has huge potential to revolutionise the manufacture of metal parts, possibly even more than powder-based Additive Manufacturing technologies.

It is a matter of time, effort, and errors. However, in the not-too-distant future, we will be remembering the struggles at the beginning of this century with a smile, whilst flying the world in planes, exploring the seas in vessels, and visiting Mars in rockets – all containing components made by DED-Arc.

Contact

Filomeno Martina

CEO and co-founder, WAAM3D

5 Thornton Chase, Milton Keynes, MK14 6FD, UK

References and footnotes

[1] BS EN ISO ASTM 52900 2021

[2] A registered trademark of WAAM3D Limited, application number UK00003147979, UKIPO; and 017992080, EUIPO

[3] R Acheson: ‘Automatic welding apparatus for weld build-up and method of achieving weld build-up’; US patent no. 4 952 769 1990

[4] R Baker: ‘Method of making decorative articles’; US patent no. 1 533 300 1925

[5] https://patents.google.com/patent/US1533300A/en

[6] Ribeiro, Fernando & Norrish, John. (1996). Case study of rapid prototyping using robot welding: ‘square to round’ shape

[7] Martina and Williams, 2015. Wire+arc additive manufacturing vs. traditional machining from solid: a cost comparison, Cranfield University

[8] This ‘break-even’ point depends mostly on material cost and deposition rate, and it changes from alloy to alloy

[9] Pickin et al.: ‘Control of weld composition when welding Al alloy’, Science and Technology of Welding and Joining, 2009, 14 (8), 734-739

[10] Marinelli et al.: ‘Functionally graded structures of refractory metals by wire arc additive manufacturing’, Science and Technology of Welding and Joining, 2019, 24 (5), 495-503

[11] Wire Arc Additive Manufacturing Maturation, www.waammat.com

[12] www.waam3d.com/projects/HPWAAM; www.waam3d.com/projects/LAMM

[13] Gradl et al.: ‘Robust Metal Additive Manufacturing Process Selection and Development for Aerospace Components’, Journal of Materials Engineering and Performance, 2022, 31, 6013–6044.