Volkmann: Making the case for the complete automation of powder handling in AM

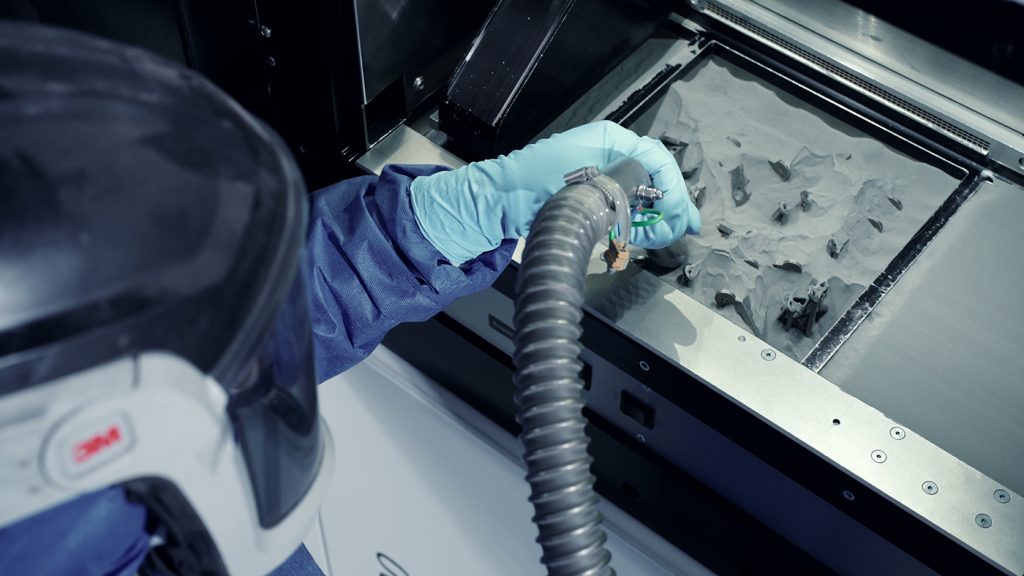

Two worlds collide in Additive Manufacturing. Consider that a Laser Beam Powder Bed Fusion (PBF-LB) machine completes its job fully automatically over many hours. Yet, before and after that, a multitude of manual tasks often still need to be completed. Employees may be required to perform these tasks while wearing personal protective equipment (PPE) to protect themselves from metal dust, compounded by the high labour costs that this manual work incurs. Is this the future of cost-efficient, 24/7 production? Christian Mittmann and Manuel Henser, from Volkmann GmbH, believe that the real solution can be found in the complete automation of powder handling. [First published in Metal AM Vol. 9 No. 2, Summer 2023 | 15 minute read | View on Issuu | Download PDF]

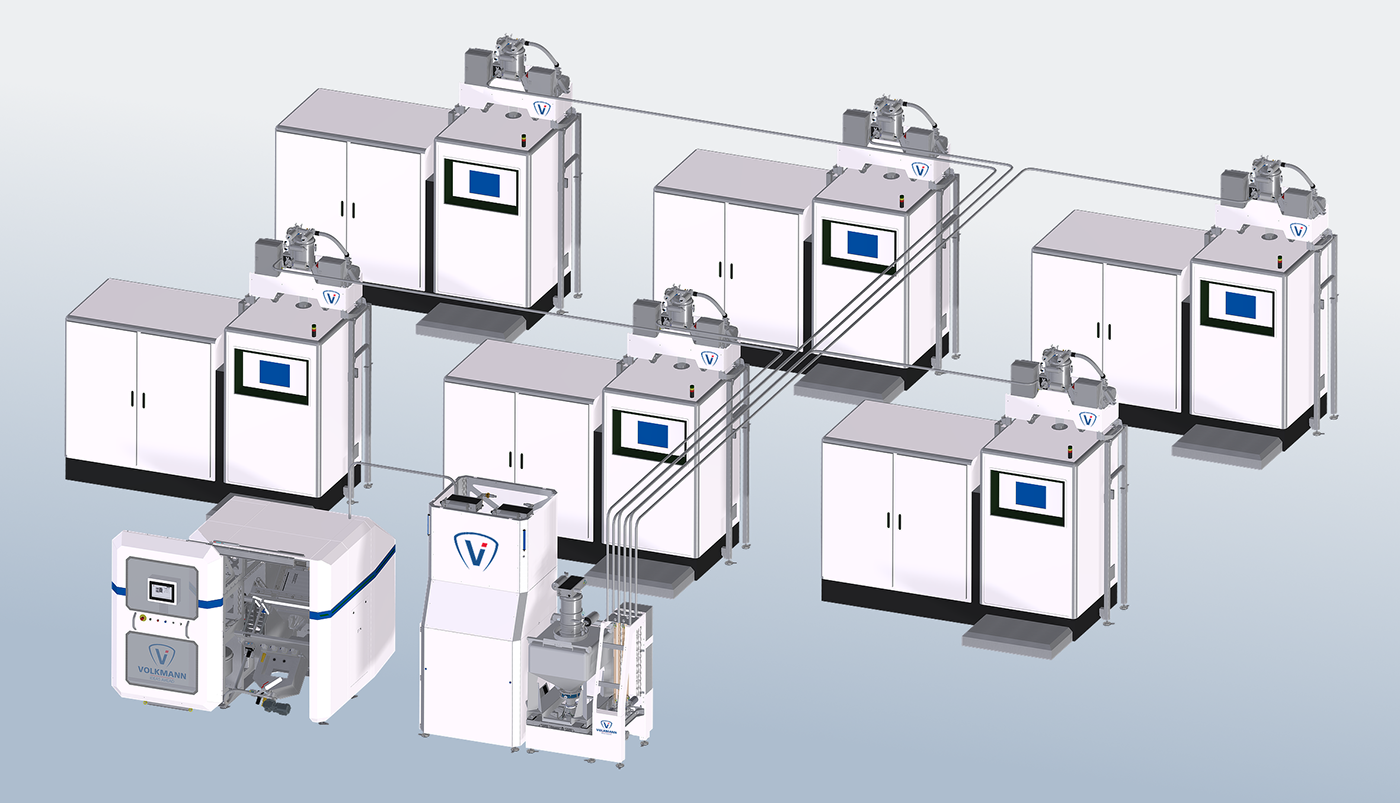

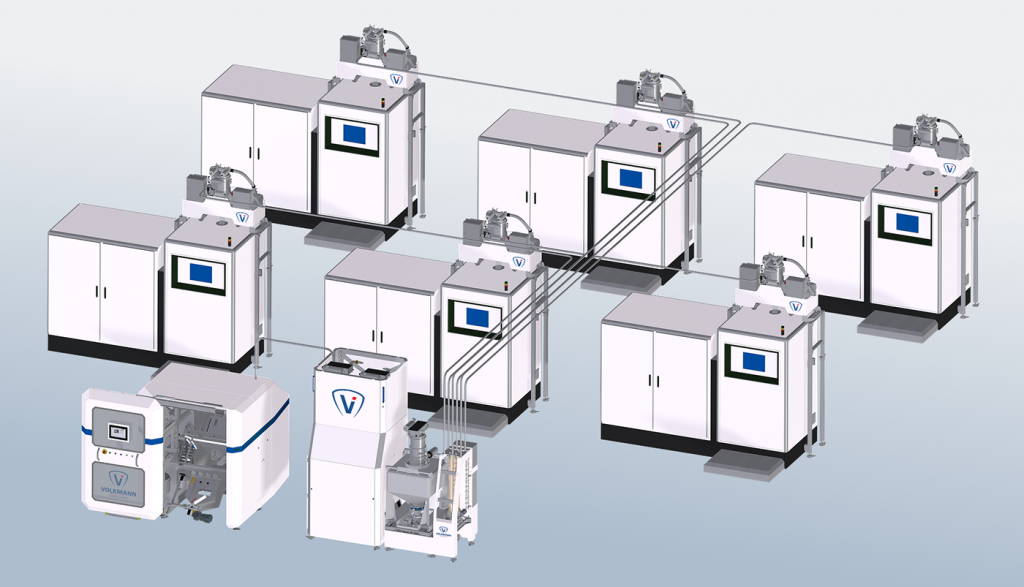

The first 3D printer was introduced approximately forty years ago. Things have changed beyond recognition since then and the industrial Additive Manufacturing of metal parts has expanded rapidly over the past ten years, resulting in highly innovative application areas. Initially used for small prototypes and limited series, the technology has evolved and the components produced have become larger and more complex. Bigger components require larger AM machines and, correspondingly, larger quantities of powder, particularly if there is not just one machine, but several operating in a group or production cell.

Economical high-volume production by Additive Manufacturing can only be achieved with a high degree of automation. This statement applies to all AM processes and specifically concerns pre- and post-build activities. The goal is to achieve fully automated production in 24-hour operation, 365 days a year, trouble-free and virtually operator-free. Due to the rapidly growing production volumes in the AM industry, these requirements are increasingly coming to the fore. Large quantities of metal powder must be quickly conveyed and prepared between the AM machine, the unpacking station and a powder removal/reprocessing station, a task that can no longer be viably performed manually. Not only is it becoming increasingly difficult to find suitably skilled workers, but the need to reduce labour costs continues to grow. This problem is further exacerbated with the return on investment requirement for the AM machines to operate on a 24/7 basis. The motto is ‘Only a printing printer earns money’ rings true.

Historically, AM machine manufacturers have concentrated on the build process itself. The automated handling of the metal powder in the immediate vicinity of the AM machine was too often neglected. Yet the handling of the powder has a considerable influence on powder properties, and thus on the end component. For example, an increased moisture level leads to significantly poorer flow properties, which has a negative impact on the quality of the part produced.

In addition, metal powders can not only be highly explosive – especially as dust – but they are also potentially harmful to health via inhalation. For this reason, occupational health and safety regulations have become increasingly stringent, as has the REACH regulation. All these factors, combined with the ever-increasing scale of powder usage, mean that automated powder handling is essential for efficient and economical Additive Manufacturing, particularly when operating multiple systems. How then is it implemented?

Volkmann GmbH first considered this question when entering the AM market approximately ten years ago. As pioneers in the field of powder conveying, Volkmann had already been able to gather considerable experience in safely transporting powder, expertise which they have successfully transferred to the AM sector. In addition to segregation-free conveying, it was primarily Volkmann’s expertise in equipment for potentially explosive atmospheres (ATEX) that resulted in the first contacts in Additive Manufacturing.

From experience gained in the industry, it quickly became clear that conveying or powder transfer alone was not enough. The market increasingly demanded an all-encompassing powder handling process around the AM machine. Additionally, automation, with constant monitoring of the relevant parameters, could ensure significantly increased process reliability with consistent material supply to the AM machine guaranteed.

Turning old into new – the reprocessing of used metal powder

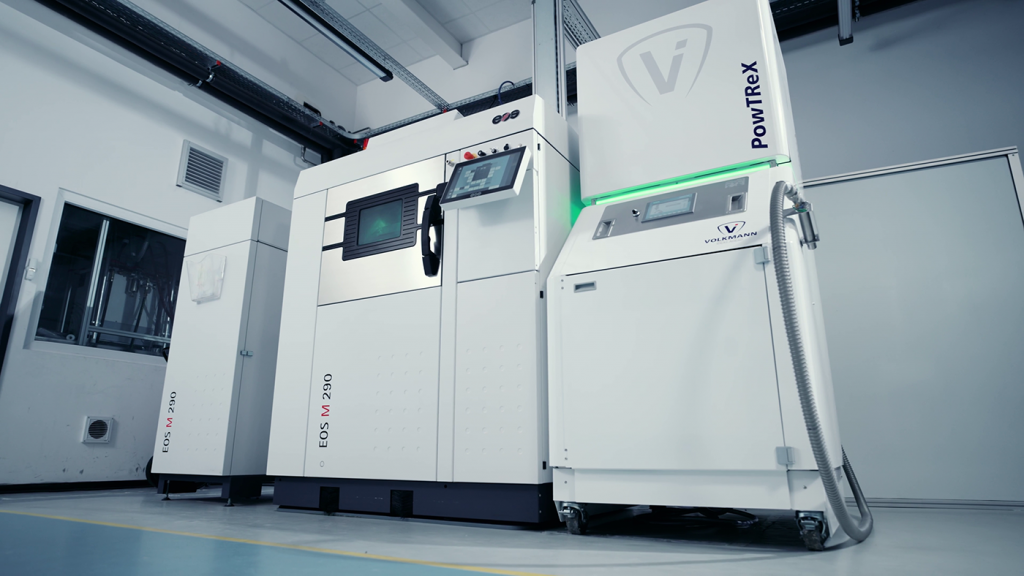

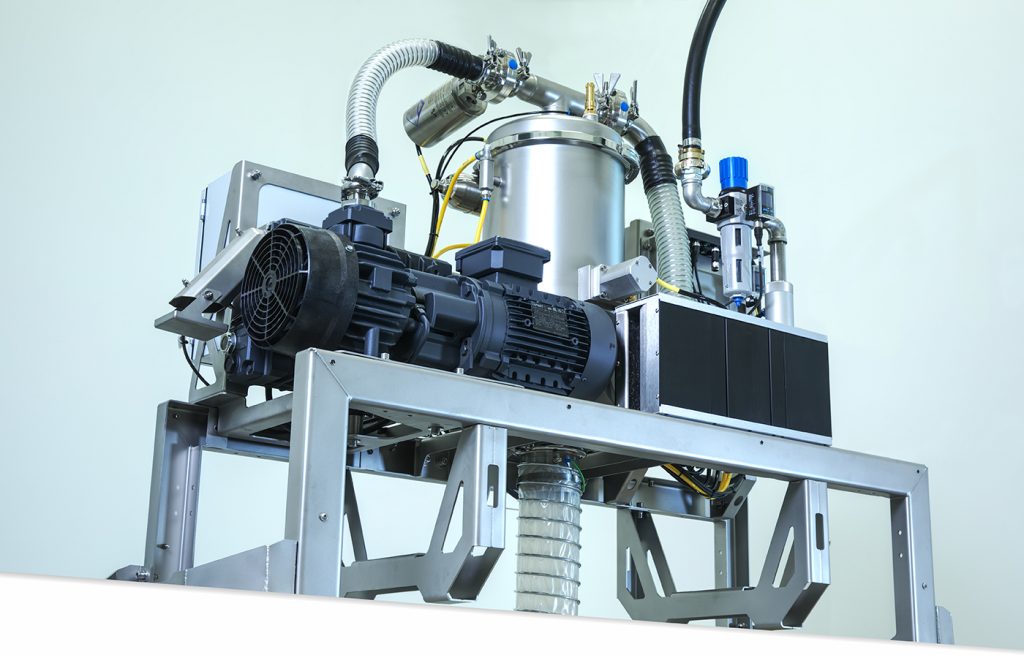

The excess metal powder in a build chamber – powder that has not been formed into a part or support structure – must be completely recycled and made available for subsequent builds. This makes optimum use of expensive powder and achieves more sustainable, economical production. For this reason, Volkmann introduced its first screening system, the PowTReX, in 2018 and has continued to develop and refine it to this day. The minimal space requirement allows it to be set up in the direct vicinity of the Additive Manufacturing machine and thus easily integrates into the production process. Agglomerates and foreign bodies are removed by a highly-efficient ultrasonic screener. The system has proven its reliability with a wide range of metal powders including aluminium, copper, titanium, Inconel and even tungsten. It is used in the aerospace, automotive, medical technology industries, and many more.

The path to the ‘closed powder loop’

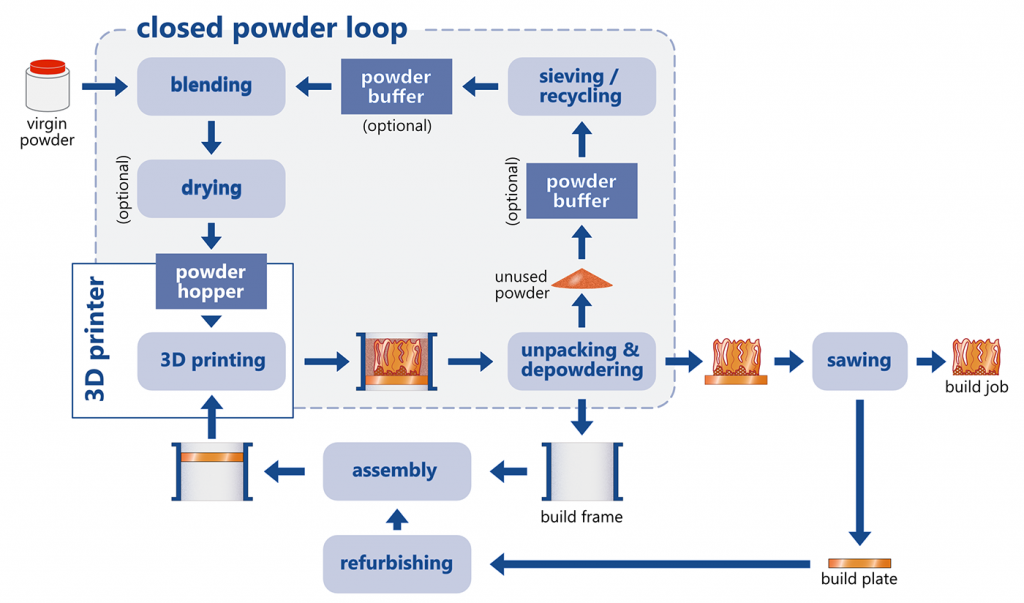

Closed powder loop is the term used to describe the completely closed circuit of powder handling around Additive Manufacturing. This loop includes the following process steps:

- filling the AM machine with metal powder

- the unpacking and depowdering of the build job, and thereby the extraction and collection of the unused metal powder

- the cleaning and reprocessing (sieving) of the used powder

- the mixing of reclaimed metal powder and virgin powder in a defined mixing ratio

- the intermediate storage or buffering of the metal powder

- and closing the loop: refilling the AM machine with metal powder.

With Volkmann’s participation in the IDAM research project [1] (Fig. 5), however, a complete and fully automated powder closed loop was achieved for the first time, integrated with the AM machine. In addition, the automatic unpacking and depowdering of the build job and frame was also integrated into this process. This represents a new milestone in the automation of Additive Manufacturing.

![Fig. 5 The IDAM pilot plant at BMW Group. In the IDAM research project, fully automated Additive Manufacturing production lines for automotive series production were developed by 12 companies and research institutes under the leadership of the BMW Group and GKN Additive from 2020 until 2022 [1] (Courtesy BMW Group)](http://www.metal-am.com/wp-content/uploads/sites/4/2023/07/fig-05-3-1024x632.jpg)

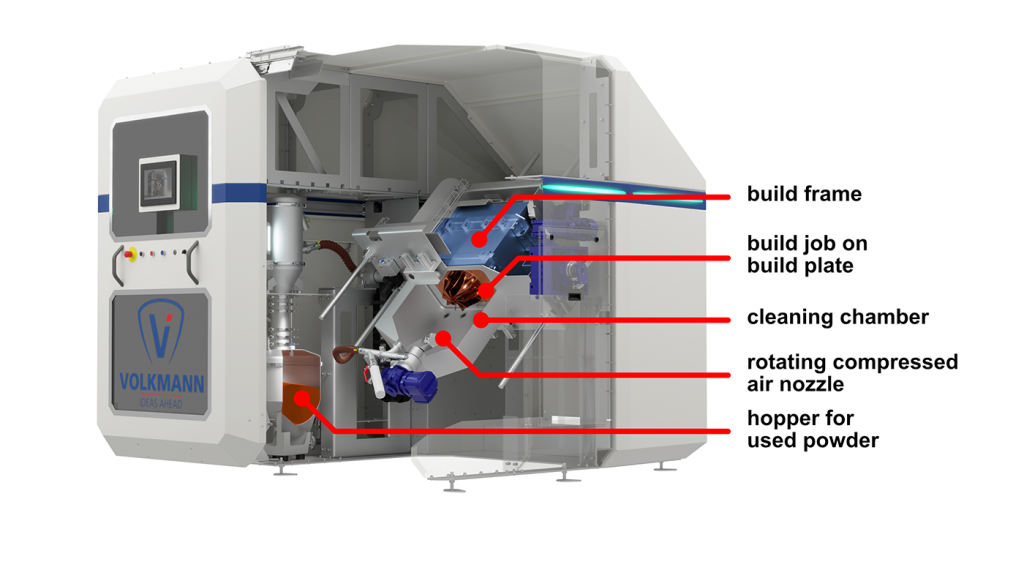

During the IDAM research project, Volkmann developed the world’s first single-step fully automated unpacking and depowdering station for PBF-LB components. The build job is completely depowdered in a single step until it is completely free of powder residues, with the unused metal powder recovered for reuse. The direct removal of powder after a build results in significant advantages of reduced process times and increased productivity. This is a significant improvement over current processes that require the initial bulk unpacking of powder at the AM machine, followed by a separate second step of removing the remaining powder residue from the part in a different piece of equipment.

Does powder handling degrade the quality of the metal powder, and what is the effect of contact with the ambient air and exposure to oxygen? After many years of research and countless tests during the IDAM project, the parameters relevant to the build process were increasingly narrowed down. The results identified that oxygen has no significant influence over most metal powders in regards to build quality. During handling, conveying and storage, costly displacement of the atmosphere by an inert gas can thus be dispensed with. Closed loop inert gas operation can still be implemented where regulations or customer process standards require a specific low oxygen content.

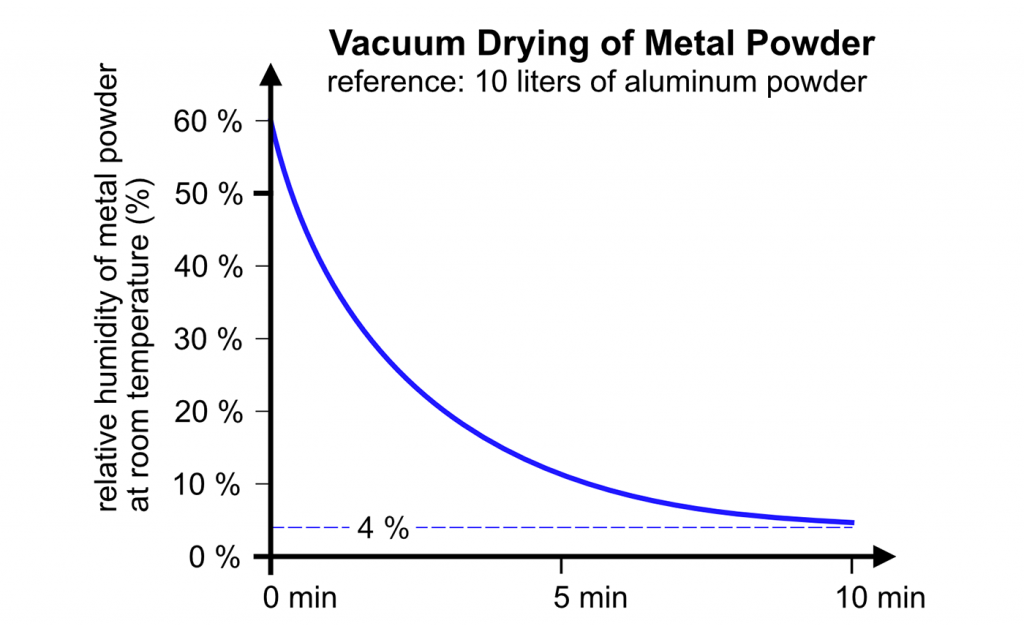

However, the adsorption of moisture by the metal powder has a very serious effect on its flow properties, and is noticeable, among other things, when the powder layers are applied in the AM machine. The investigations were able to prove that components produced from moist metal powder have a poorer quality, a lower material density and higher porosity. Metal powders are generally highly hydrophilic and adsorb moisture even from relatively dry gases, including some inert gases.

The influence of humidity on metal powder has been analysed in a number of studies, including one by the Fraunhofer Institute of Laser Technology (ILT) together with FH Aachen – University of Applied Sciences and RWTH Aachen University – Chair for Laser Technology (LLT) [2].

The good news is that drying can fully restore the original powder quality. Even in batches with variation in moisture content, the metal powder can be dried to a uniform and reproducible level. Surprisingly, virgin metal powder should also be dried before use since it may also have adsorbed moisture during transport and storage. When using a vacuum, drying a batch of metal powder only takes a few minutes. In addition, the technological effort for vacuum drying is comparatively simple and can be implemented in a compact design. The optimal solution is to integrate the vacuum drying process into the vacuum conveying system, whereby drying takes place directly before the AM machine is filled.

Volkmann incorporated all of these findings into the two pilot lines of the IDAM project at their project partners BMW and GKN, building the world’s first prototypes with an unprecedented degree of automation, while at the same time reducing component costs. From the findings and prototypes of the IDAM project, Volkmann developed new, market-ready and significantly more compact modules with minimal space requirements.

Aiming for the stars

These new developments are tested and applied almost exclusively in two industries: motorsports and aerospace. Additive Manufacturing technology is already state of the art in both industries; nevertheless, the market for additively manufactured parts in aerospace, and the commercial space industry in particular, are experiencing high growth. Entire rocket engines can now be Additively Manufactured in one piece. Southern California is, as it has so often been, the epicentre of the new technology.

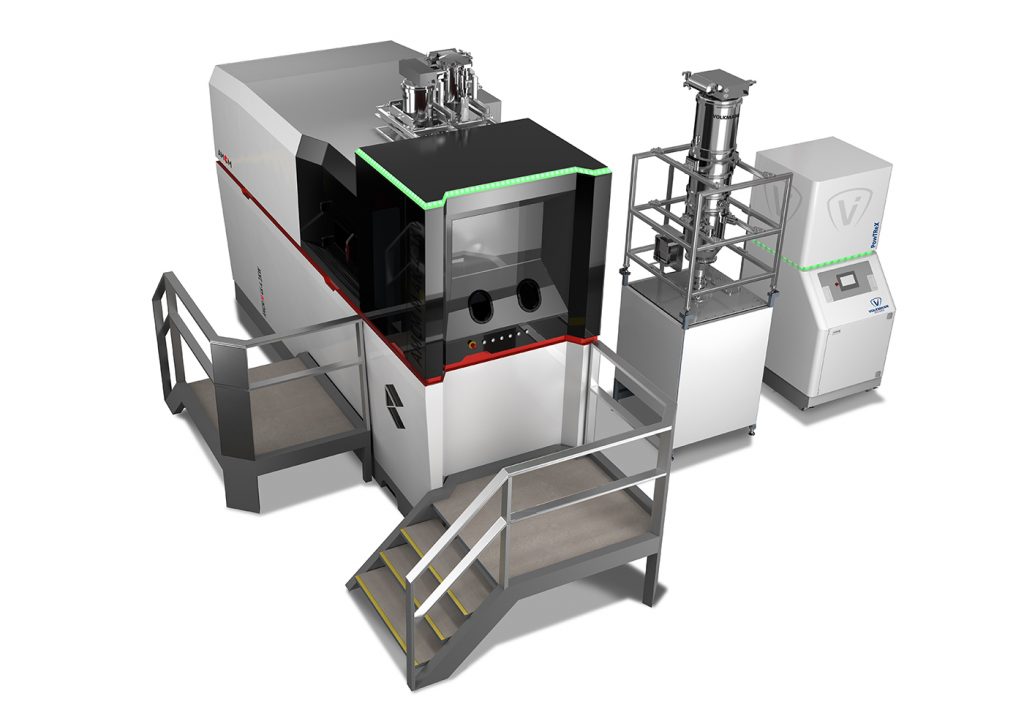

An example of Volkmann’s complete powder handling automation for Additive Manufacturing can be seen in a customer‘s new production plant in California, USA. The first expansion stage comprises of a four AM machine cell and was scheduled to begin operations in June 2023. Components for rocket engines and other aerospace items will be manufactured at the facility, with Volkmann supplying the fully automated closed loop handling powder system.

Many manufacturers of AM machines are now increasingly involved in solutions for the handling of metal powder. Volkmann is integrally a part of this through close cooperation with several machine manufacturers who understand that users expect a more holistic concept for the entire AM production chain.

Furthermore, end users are increasingly taking the initiative. In most projects, this takes place in the context of production expansion and the acquisition of new Additive Manufacturing machines. For existing equipment, however, a closed powder circuit can be retrofitted.

Authors

Christian Mittmann and Manuel Henser

Volkmann GmbH, Germany

[email protected]

[email protected]

www.volkmann.info

Dominick Fortuna

Volkmann, Inc., PA, USA

[email protected]

www.volkmannusa.com

References

[1] www.metal-am.com/bmw-reports-successful-integration-of-automated-am-car-parts-production-line/

[2] ‘Investigation on the influence of powder humidity in Laser Powder Bed Fusion (LPBF)’ www.sciencedirect.com/science/article/pii/S2212827122009830

Download Metal AM magazine