ADAXIS: On a mission to reduce the layers of complexity in robotic Additive Manufacturing

France’s ADAXIS is tackling two of the most complex advanced industrial manufacturing disciplines head on — Robotics and Additive Manufacturing. Its solution aims to make robotic Additive Manufacturing more accessible to any company that wants it, including for metal processes, irrespective of background or industry sector. Rachel Park spoke with Henri Bernard and Emil Johansson, two of ADAXIS’ co-founders, as well as project partners, to discover their story and ambitions. [First published in Metal AM Vol. 9 No. 3, Autumn 2023 | 10 minute read | View on Issuu | Download PDF]

Necessity is the mother of invention. This centuries-old proverb still has a ring of truth to it, even in the 21st century. It often proves to be a key driver for taking many new business ideas into commercial reality. In the case of ADAXIS, necessity was certainly one driver to the founding of the company, accompanied by passion.

To explain, ADAXIS was founded early in 2021 when four people, Henri Bernard, Guénolé Bras, Emil Johansson and Vasan Churchill, were driven by a shared frustration towards the time-consuming and complex task of programming industrial robots for Additive Manufacturing and the resulting access barriers within the industry.

Prior to 2019, Bernard and Bras (at the ESTIA Institute of Technology in France) and Johansson and Churchill (at the RISE Research Institute of Sweden) simultaneously undertook years of applied research into using industrial robotics for advanced manufacturing. In 2019, serendipity brought all four together following the launch of EIT Manufacturing, an EU-funded institution backing the most innovative manufacturing projects in Europe.

At a match-making event hosted in San Sebastian, Spain, Johansson, who was only in attendance because his manager was unable to be there, “presented a pitch that sparked interest from numerous companies and also got the attention of the team at ESTIA. None of us knew each other at this time, but we joined together for an applied research project that was granted funding.”

The project itself highlighted a number of things, not least the frustrations as outlined above, but also the passion and depth of knowledge across the project’s partners. It also began to lay the foundation for a real solution that could dramatically impact industry. Johansson added, “The project took place during the COVID years (2020-21), so we spent a lot of time sharing ideas and knowledge remotely, which in the end formed a solid foundation for ADAXIS.” Today, ADAXIS is a fully commercialised French-Swedish robotics software company, delivering its innovative solution to a growing customer base.

The challenge that the company is addressing is that each industrial robot comes with different control software, with each Directed Energy Deposition (DED) solution there is different control software, and there are different parameters for each alloy used. The consideration of the almost-unlimited possible combinations of robot, printhead and alloy is a very complicated task of software integration.

The company’s solution? Its AdaOne software takes away the pain of writing custom code for each new system integration.

Technical challenges in robotic Additive Manufacturing

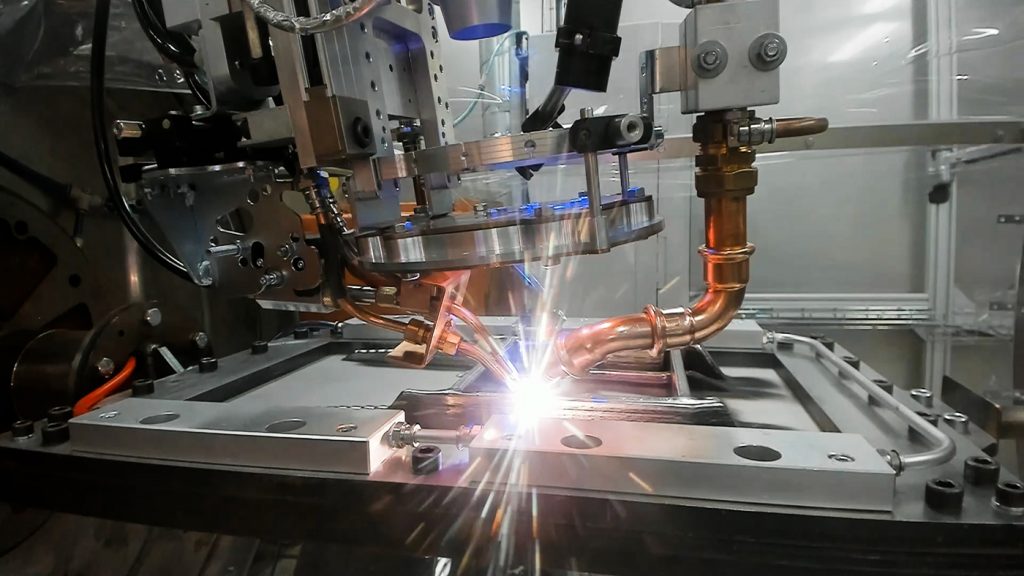

Today, it is possible to use most metal DED technologies on a robotic arm to provide flexibility in deposition rate, surface finish and material choice – from stainless and carbon steels to aluminium and titanium alloys. Each technology has its own unique control challenges and limitations which need to be taken into account during path planning in order to produce defect-free parts. Using the full multi-axis potential of robotic arms for metal Additive Manufacturing requires a fundamental understanding of each process.

A crucial factor in metal deposition, whether it’s for Additive Manufacturing, repair or any other application, is achieving a uniform and stable melt pool. This is controlled and optimised through common process parameters, including traverse speed, material feed rate, and energy input.

Path planning for Additive Manufacturing and multi-axis deposition brings another level of complexity and additional important factors:

- Orientation of material deposition

- Trajectory generation strategy

- Homogeneity of heat distribution

- Variation in bead height and width

- Variation in workpiece distance

These factors directly impact the final quality of the part, for example dimensional tolerances, internal stresses, and porosity.

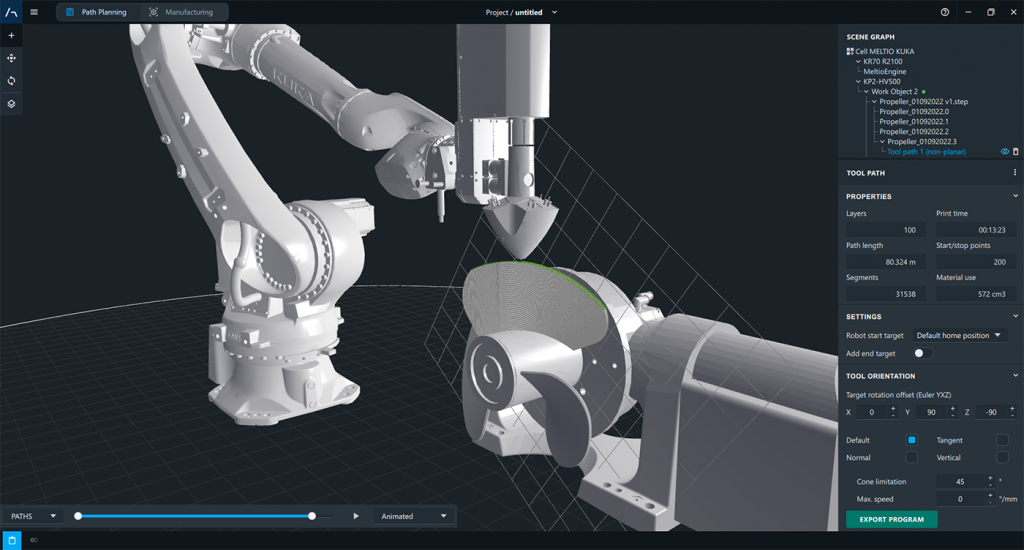

AdaOne has been specially developed to handle the above challenges through its custom-built path planning engine. It can handle state-of-the-art trajectory generation on planar and non-planar substrates and optimises layer height variation and tool orientation to follow part geometries. Each layer can be segmented to adapt deposition strategy and path traversal, and dynamic process control can be used to optimise the different deposition phases.

Henri Bernard further explained, “The mastery of thermal control, and thus process control, becomes pivotal. The approach adopted for piece fabrication substantially influences the final result. Parameters such as fill methods, pause durations, arc restarts, and modes tailored to each specific component are indispensable. None of this is easy, but these features in AdaOne empower users to rapidly, effortlessly, and efficiently program their robots according to their specific application requirements.”

This is where AdaOne stands out: it enables users to precisely and easily configure all of these parameters.

The ability to seamlessly translate this outcome into a precise robotic language (whether KUKA, ABB, Yaskawa, Fanuc, et al) to optimise trajectory (position, orientation, speed, acceleration, interpolation) and the process itself (material feed, power, etc.) becomes vitally important.

The ADAXIS approach is straightforward, according to Bernard, who explained, “We’re streamlining task automation and geometry computation, to facilitate the effortless generation of intricate trajectories in just a couple of clicks. This empowers the operator to use a workflow and enjoy a user experience that is comprehensible to all users, regardless of their levels of expertise in programming.”

He continued, “This endeavour encompasses various facets, including the intricate programming of highly complex parts, automated segmentation based on shape, layers, and modes (perimeter, infill), and the slicing of non-planar components to preserve their form by leveraging the process’s inherent flexibility whenever possible. The integration of material-specific rules, for example, aluminium versus titanium in DED, advanced business rules (consider the distinction between printing a dense, compact 300 kg part versus a delicate topological component), and the flexibility to modify a point, curve, or parameter within a program comprising millions of points are integral. All of this must be achieved while ensuring a seamless and precise simulation, affirming that no issues will arise during actual production. Once satisfaction is attained, the build profile can be saved for subsequent applications.”

And if all of that was not enough, AdaOne also enables real-time monitoring of the system and the process. This invaluable feature allows users to observe the robot’s exact position, speed, material and energy consumption (including laser power/arc current and voltage), shielding gas quantities, and a comprehensive array of secondary parameters essential for a thorough process understanding. This digital twin serves a dual purpose: enhancing process comprehension and configuration, and guaranteeing process repeatability and compliance.

The grand challenge AdaOne has solved through automatic configuration and initiation is to deliver these features and facilitate them with just three clicks. This is literal – not figurative!

Talking applications

ADAXIS is already seeing successful deployments of its software. The company quotes that AdaOne is currently running on more than 200 industrial robots globally, allowing them to produce AM parts in a range of materials. Of these, eighty are being used to produce metal components.

Bernard expanded on this, stating, “AdaOne is being used across many industry sectors and we are seeing feedback from users that are directly printing large, complex parts as well as some users that are utilising robotic AM to repair existing parts. You can probably guess that I can’t go into details on specific applications, but, to give you an idea, companies in the aerospace and defence sector are working with us. The transport sector features heavily, notably for train parts and brakes. Unsurprisingly, the energy sector also features strongly for blades and turbines. The versatility that AdaOne brings to their existing industrial robot capabilities is proving to be very useful. As is the flexibility. The feedback we have received highlights that this is in relation to the technology itself in fulfilling previously difficult applications, but also geographically flexible because the equipment can be moved between locations, to meet requirements at the place of need.”

He continued, “Across our community of metal AM users, we are also starting to see a new hybrid approach. Because of the nature of the DED process, which allows users to print a wide variety of metal materials onto a substrate (which can be an existing part, or part of a part), manufacturers are combining traditional manufacturing processes with robotic AM, where complex features can be produced with AM only where they need it. This approach is proving to save time and money for our users.”

Johansson described how ADAXIS has worked with early adopters from the beginning and has grown its user base over the past eighteen months, “Early on during the first year, we contacted about ten companies that we had worked with to be pilot users and worked with them throughout that first year until one year later, in 2022, we launched the product commercially. From there we have basically penetrated every industry sector in one way or another and today we run more than 200 robots as industrial AM machines.”

Successful partnerships

The ADAXIS leadership team views partnerships as a foundational growth strategy for the company. These partnerships span the AM ecosystem and include OEMs and metal material companies. ADAXIS is currently working closely with Addimadour, an R&D centre located in Bayonne, France, not far from ADAXIS, that is dedicated to large-scale metal AM. It is equipped with technologies for laser-based DED (DED-LB) and arc-based DED (DED-Arc), laser cladding, and Cold Spray Additive Manufacturing (CSAM). Backed by the Compositadour platform, Addimadour was launched in 2017 by, and for, companies to support the development of their metal AM projects.

According to Addimadour’s Pierre Michaud, “We see robotic AM as a key enabling technology for large-scale complex parts manufacturing. Robotic AM enables repeatable precision for highly-complex components of any size. It is also a very flexible technology that can cater to a wide variety of material specifications. At Addimadour, we provide tailored research and engineering capabilities together with training for students and company engineers at different levels.”

He continued, “Our advanced robotic AM capabilities are significantly enhanced by our partnership with ADAXIS. The ADAXIS software controls our robotic systems simply and painlessly. The software eliminates the time-consuming and complex programming of our industrial robots for Additive Manufacturing which has always been a bottleneck. ADAXIS has helped us transform how we operate robots for Additive Manufacturing in the most positive way.”

ADAXIS has also established successful and ongoing collaborations with several other key organisations. This includes industrial applications with Procada based in Sweden; Fortius Metals based in Colorado, USA; and Exafuse based in Germany; as well as partnerships with leading universities and research institutes, such as Politecnico di Milano, Italy, Technalia and AIMEN in Spain, CCAT in Connecticut, USA, Tampere University of Applied Sciences, Finland, and Nagaoka University of Technology, Japan.

Procada is a startup specialising in controller solutions for large scale laser DED — with wire feedstock — for critical applications in sectors such as energy, marine and aerospace. Petter Hagqvist, CTO at Procada AB commented on the partnership between Procada and ADAXIS, stating, “At Procada, we have identified the process of turning a CAD-file into robot movements as a critical link in the chain for realising reliable DED builds. For our wire/laser DED process, tool positioning and build path planning is especially crucial due to the unforgiving process dynamics. ADAXIS’ solution to these problems, for us, seems to be a particularly competent and flexible one that suits our needs very well.”

Fortius Metals has developed proprietary robotic AM welding wires designed specifically for wire DED Additive Manufacturing processes using arc, laser and electron beam energy sources. The company has a complete wire manufacturing capability located at its Lafayette, Colorado, facility and utilises AdaOne software.

Conclusion

When the ADAXIS team say they want to keep it simple and accessible, they really mean it. Bernard rounds up, “We deliver AdaOne as an on-premises software, and we keep it really straightforward — one key allows AdaOne to be activated on one computer and program an unlimited number of robots. It is competitively-priced and as a company we offer ongoing support and encourage community engagement and sharing. This means that robotic AM becomes accessible, cost-efficient, and easy to use.”

Contact

Ulf Lindhe

Chief Marketing Officer

ADAXIS

[email protected]

www.adaxis.eu