Additive Manufacturing of hardmetals: An evaluation of potential processes for tool production

Hardmetals, also known as cemented carbides, have played a huge and often overlooked role in modern industrial development. From the first application in wire drawing dies in the 1920s, hardmetals are today universal and their application areas range from metal cutting and the machining of wood, plastics and composites to the production of glass bottles, aluminium cans and the ubiquitous ball-point pen tip. Can Additive Manufacturing make inroads into a market worth tens of billions of Euros in annual sales? Dr.-Ing. Johannes Pötschke reviews the fundamentals of hardmetal production and considers the most viable AM processes for this complex family of materials. [First published in Metal AM Vol. 6 No. 3, Autumn/Fall 2020 | 15 minute read | View on Issuu | Download PDF]

Most tools used in the oil, gas, and mining sectors, as well as in the metal machining or forming industries, are made from hardmetals. This material class, also known as cemented carbides or sometimes just carbides, can be categorised as composite materials. Hardmetals possess the necessary properties for their intended use, namely high hardness, strength and toughness. As implied by the name cemented carbide, hardmetals primarily consist of very hard carbide grains which are ‘cemented’ together by a comparatively low amount of a ductile metallic binder. The most used hard phase material is tungsten carbide (WC) and the binder metal is mainly cobalt (Co), with typical binder compositions in the range of 10 to 30 vol.% (equivalent to 6 to 18 wt.% Co).

Traditionally, hardmetal parts are produced by a standard Powder Metallurgy shaping process to create green parts that have densities in the range of 55% theoretical density (TD). These green parts are then sintered in vacuum and protective gas atmospheres to 100% TD. While traditionally parts such as cutting inserts or dies are produced by uniaxial pressing, cylindrical parts are often produced by extrusion and more complex parts by Powder Injection Moulding (PIM). Even though this already allows the production of cooling channels for drills or milling cutters, more complex internal shapes and outer tool geometry are currently only possible with a high level of green machining and finishing – if possible at all.

Whilst hardmetals are interesting as new materials for Additive Manufacturing, it should be noted that they were one of the first materials studied, as shown by early tests done in the US by Sachs at MIT in 1995 [1] using Binder Jetting (BJT) or by Zong at UT Austin in 1992 by means of Powder Bed Fusion (PBF) [2]. These early studies showed that the successful processing of hardmetals by AM is by no means an easy task.

The properties and peculiarities of hardmetals

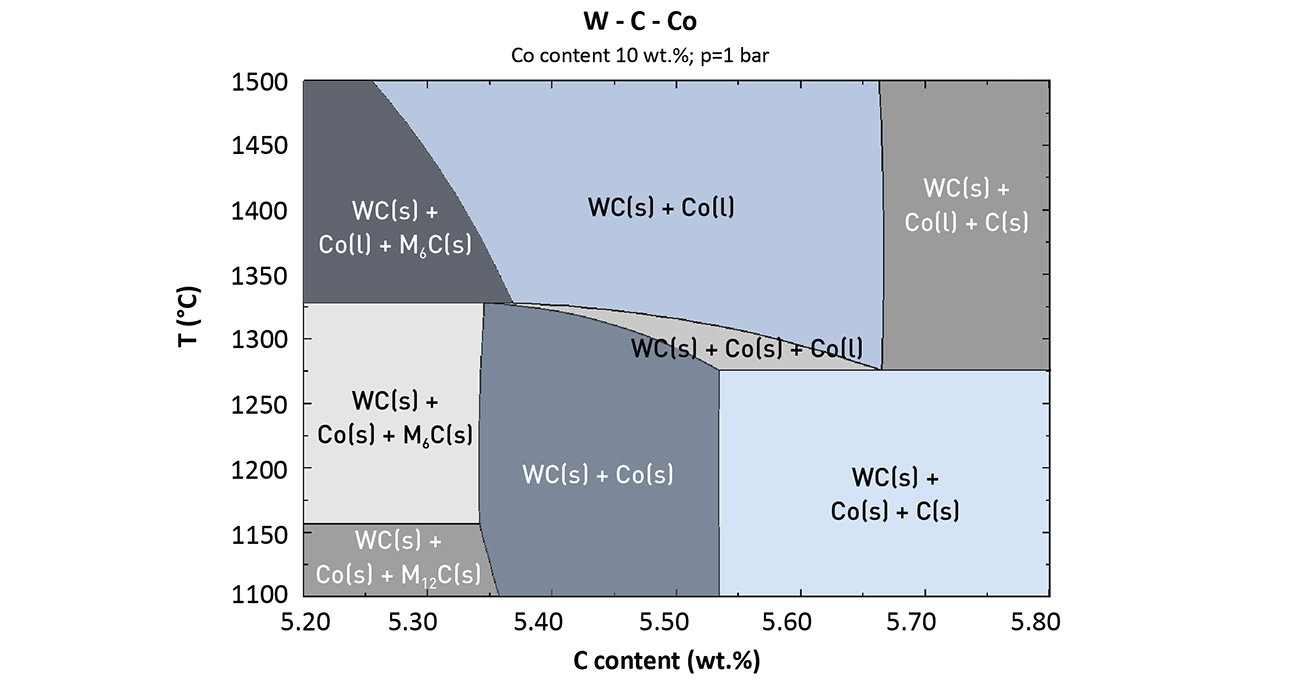

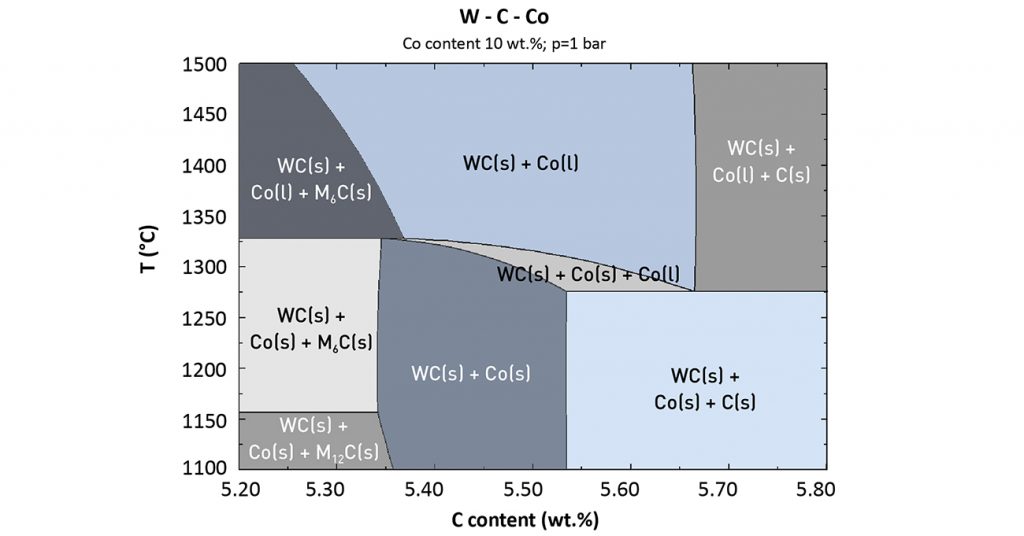

As stated above, hardmetals are composites, consisting of the hard phase tungsten carbide and the metallic binder cobalt. Properties such as high hardness (up to 20 GPa), high bending strength (up to 5000 MPa) and high fracture toughness values (up to 20 MPa*m1/2) are only achieved if the three elements (tungsten, carbon and cobalt) are present in the two phase state of tungsten carbide and cobalt alloy (WC+Co). To achieve this, the carbon content must be within a small compositional window, to avoid free carbon (C) or the formation of complex eta phases (M6C or M12C) when too low amounts of carbon are present, as shown in the phase diagram of W, C and Co (Fig. 1).

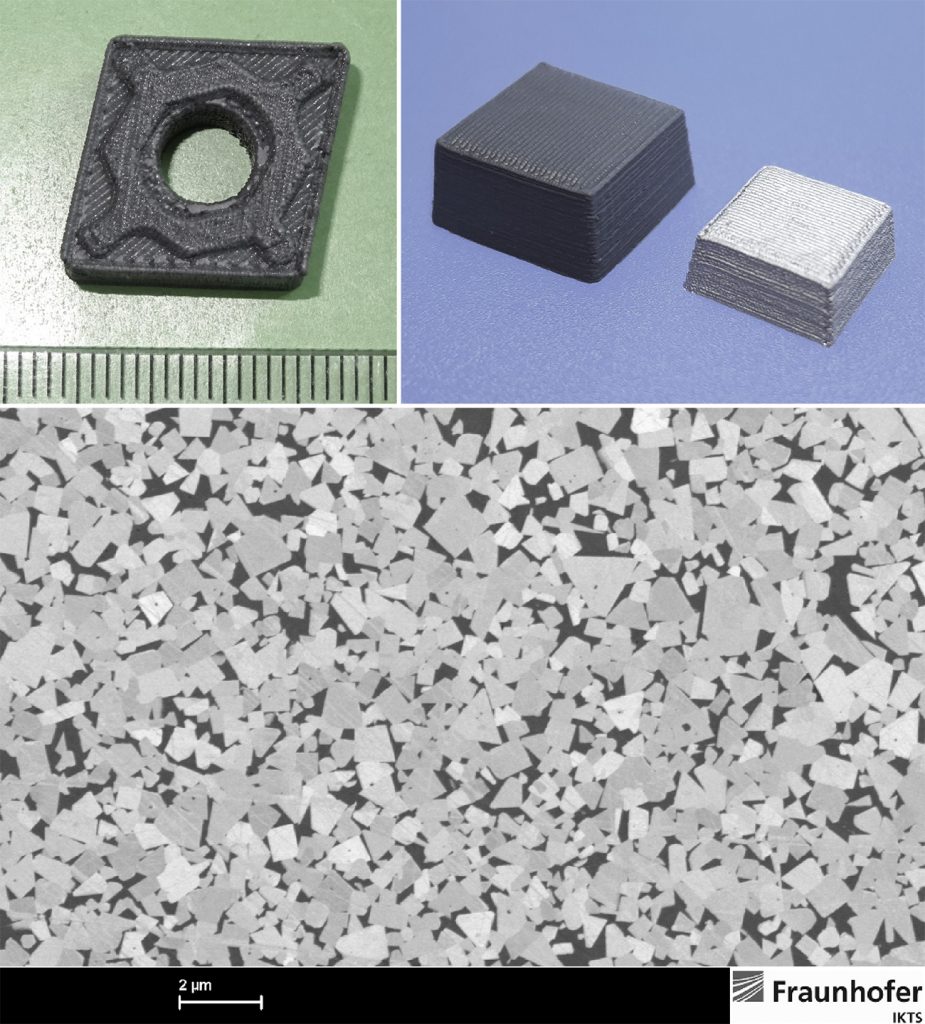

In both these cases, mechanical properties will drop off drastically and a product’s use in tooling would be impractical. Furthermore, to achieve the required properties, the material has to be 100% dense, with only a very small amount of pores (< 0.2 vol.%) in the range of up to 25 µm being allowed. As for microstructural requirements, the tungsten carbide grains, as well as the metallic binder phase, must be distributed within the tool materials as homogenously as possible to guarantee the aforementioned properties, as can be seen in Fig. 2.

As for processing, it is important to keep in mind that tungsten is a quite heavy element and that tungsten carbide based hardmetals, therefore, have densities in the range of 13 to 15 g/cm³. Even small green parts therefore have a high weight, which can influence the green part stability or shrinkage during sintering.

Sintering of hardmetals takes place slightly above the eutectic temperature within the W-C-Co system of 1,310°C, as so-called liquid phase sintering. With a further increase of sintering temperature, more and more W and C can be dissolved within Co, increasing the amount of the liquid phase. However, if the temperature is too high, the metallic binder can evaporate.

With an even further increase of sintering temperature (ca. > 2,800°C), the hard phase tungsten carbide can disintegrate due to decomposition of WC into W2C and C [3]. For handling and safety reasons it has to be further noted that cobalt is classified as a Cancerogenic Mutagen Reprotoxic (CMR) material, for which special care has be taken during processing [4].

It is also noteworthy that, in contrast to many ceramics, hardmetals are not transparent to light. Light-based lithography AM technologies could therefore only be used with indirect crosslinking approaches, limiting resolution and speed.

Potential AM processes

In principle, the whole range of AM technologies is available for hardmetals and quite a few have been tried already. However, due to the peculiarities of hardmetals, the following aspects limit the choice:

- Hardmetals consist of around 70 to 90 vol.% of the ceramic hard phase tungsten carbide (WC), thus the metallic binder content is accordingly low

- WC cannot be melted, but decomposes above ≈ 2,800°C [5]

- Cobalt has a low vapour pressure and is classified as a CMR material

- WC has a density of 15.67 g/ cm³, so green parts are quite heavy

- WC is not transparent for any wavelength of light.

Considering the above, Electron Beam Powder Bed Fusion (PBF-EB) has to be excluded because of its intensive energy input, resulting in the decomposition of WC and the evaporation of Co. Also, VAT Photopolymerisation (VPP), also known as Stereolithography (SLA), is excluded because of the non-transparency of WC. Even though there are a few publications concerning both the PBF-EB [6] and VPP [7] of hardmetals, these processes are excluded from this report for the previously mentioned reasons and the results that can be anticipated.

The most promising results, however, have so far been achieved with Laser Beam Powder Bed Fusion (PBF-LB), Binder Jetting (BJT), Material Extrusion (MEX) and Material Jetting (MJT). In the following subsections, results for each of these AM technologies will be summarised and discussed accordingly.

Laser Beam Powder Bed Fusion

PBF-LB processes, also known as Selective Laser Melting, Direct Metal Laser Sintering, Selective Laser Sintering, Laser Beam Melting etc., belong to the powder bed-based group of AM technologies and were among the first AM technologies evaluated for the production of hardmetal parts. In contrast to Binder Jetting or filament-based Material Extrusion processes, the PBF-LB process ideally creates a fully dense part in a single-step.

As mentioned in the introduction, PBF-LB, then referred to as SLS, was one of the first AM technologies tested for hardmetals. The tests conducted at UT Austin used agglomerated hardmetal powder (presumably thermal spray powders) with a composition of WC-12 wt.% Co and showed that the principle of fabrication of hardmetal parts is possible [2]. However, these parts were nowhere near dense, reaching approximately 60% TD. Further work by Kruth at the KU Leuven, Belgium, between 1996 to 2003, showed that, even with an increase of metallic Co to 30 wt.%, no dense parts could be made by PBF directly [8, 9]. Work in 1999 by Fraunhofer IKTS and IWS in Dresden, in cooperation with the University of Mittweida, all in Germany [10], showed that, with optimised granulated and pre-sintered granules, samples with densities above 60% of theoretical density can be achieved, which can be increased to nearly full density by a subsequent step combining sintering and Hot Isostatic Pressing (SinterHIP).

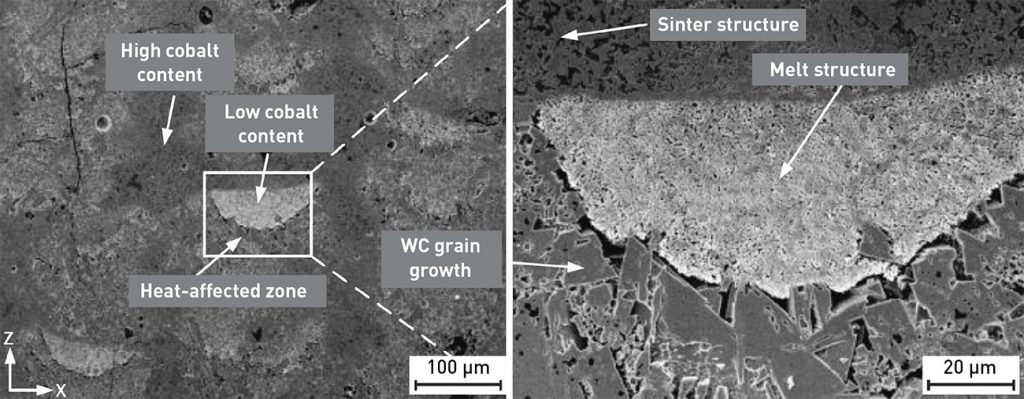

However, as also shown by other studies, the required energy input (laser power) to achieve sufficiently dense samples resulted in defects such as abnormal grain growth and local decomposition of WC into W2C and carbon, as well as the unwanted formation of eta phases. Furthermore, the evaporation of Co, reducing the residual Co content of the hardmetal, led to the fact that often the composition of the produced part did not match that of the starting powders used [11].

In addition, the evaporated Co can deposit within the PBF-LB machine and is a risk regarding CMR issues. Nevertheless, nearly dense samples (98.5% TD) were achieved by researchers from Fraunhofer IPT, Aachen, between 2007 and 2009 [12, 13] with Co contents as low as 25 wt.%. However, in addition to unwanted phases, thermal stress induced cracks and pores within the more or less dense microstructure now appeared due to the high laser power used. Similar results in 2015 at Fraunhofer IPK, Berlin, showed (Figs. 3–4) that interesting geometries are possible, but that the microstructure and the mechanical properties were significantly inferior to conventionally produced parts [11].

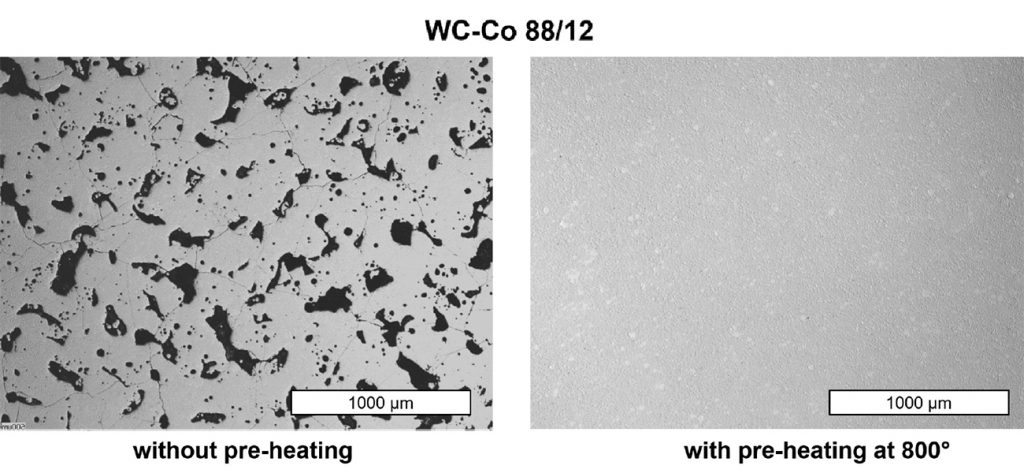

To address these issues, researchers at the University of Applied Sciences, Cologne, Germany, came up with the idea of preheating the powder bed to avoid thermal cracks and lowering the required energy input [14]. As shown in Fig. 5, preheating of the WC-12Co powder bed resulted in crack- and pore-free parts with five times higher bending strength values (~1000 MPa instead of ~200 MPa) as compared with parts produced with the standard PBF process.

Additional heat treatment by SinterHIPing of the PBF + preheating resulted in parts with further improved properties. However, abnormal grain growth as well as Co evaporation and the local decomposition of the WC phase still resulted in significantly inferior properties in comparison with conventionally shaped and sintered hardmetal parts [15].

Binder Jetting

Another powder bed-based AM technology is Binder Jetting (BJT). When it was first developed in 1990 by Prof. Sachs at MIT it was simply called ‘three-dimensional printing,’ or 3DP [16]. In contrast to PBF processes, BJT is a two-step sinter-based AM technology in which the built green part must undergo a subsequent densification process achieved through sintering.

In the first work in the area of hardmetals Sachs and colleagues between 1995 and 1998 used spray granulated WC-10 wt.% Co powders and produced simple bars with a green density of around 25% TD. However, due to this low green density (conventional pressed parts have ca. 55% TD), sintering at conventional temperatures (1,440°C) led only to sintered part densities of 60.9% TD [1, 17].

Further work was done in a national project at Fraunhofer IPT with partners from the tooling industry from 2007 to 2009 [18]. They used a granulated and pre-sintered WC-25 wt.% Co powder and a R2 BJT machine from Prometal RTC, Augsburg, Germany, now part of ExOne. After sintering (presumably gas pressure assisted SinterHIP sintering), crack free microstructures with densities above 99% TD and hardness values of around 1020 HV0.5 could be achieved.

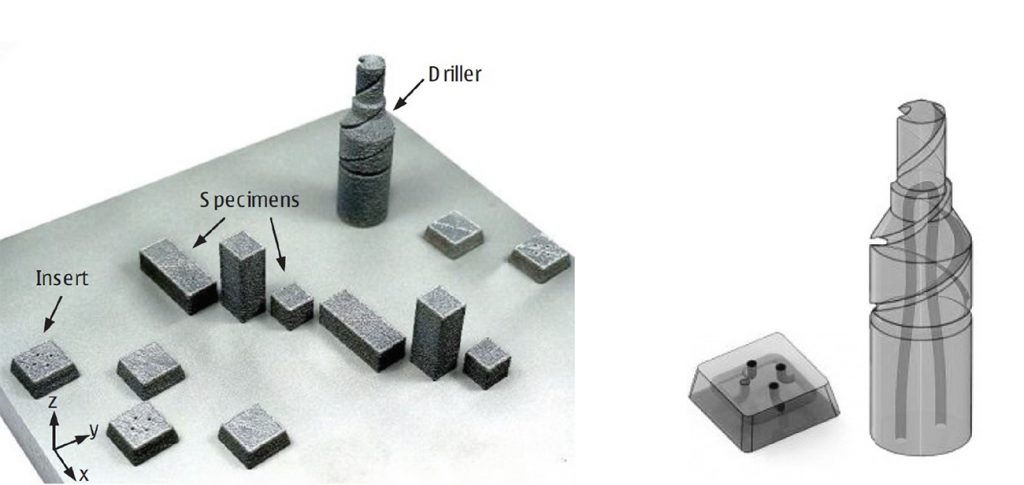

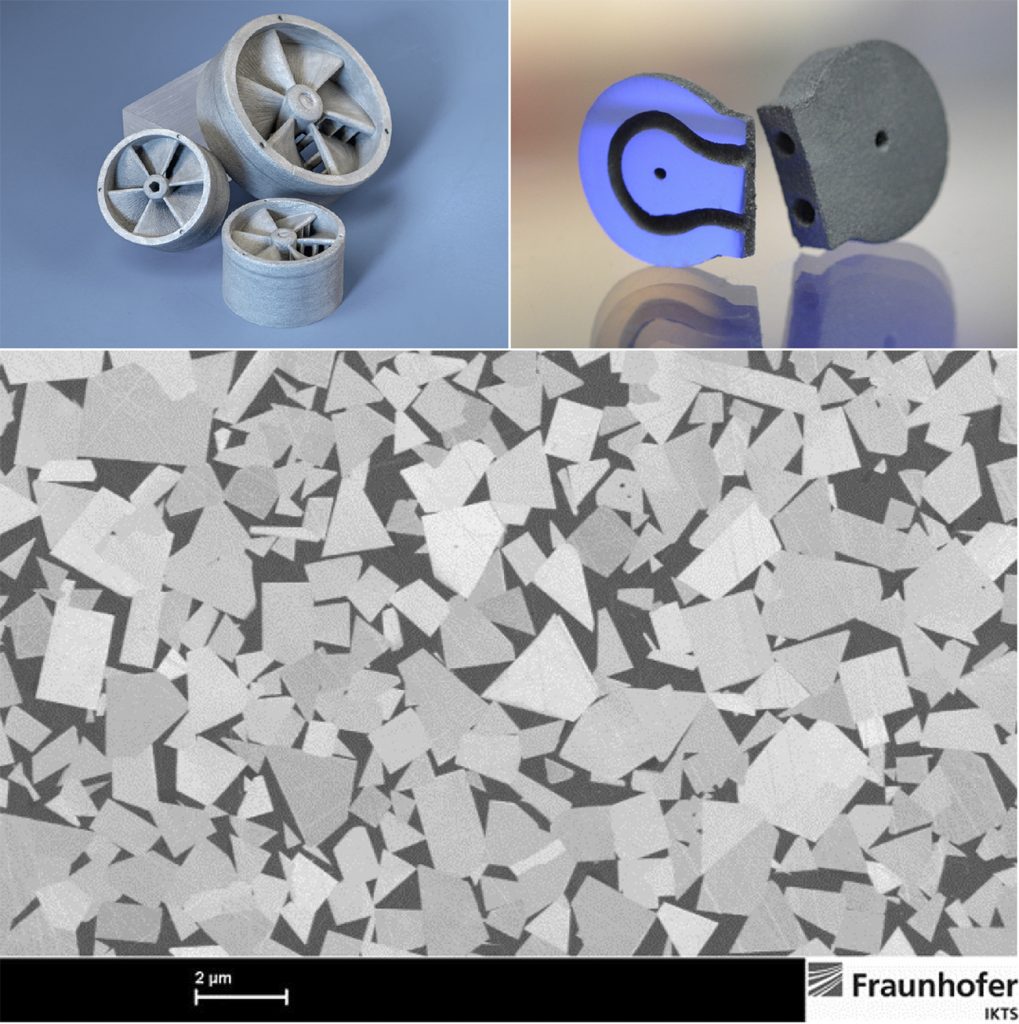

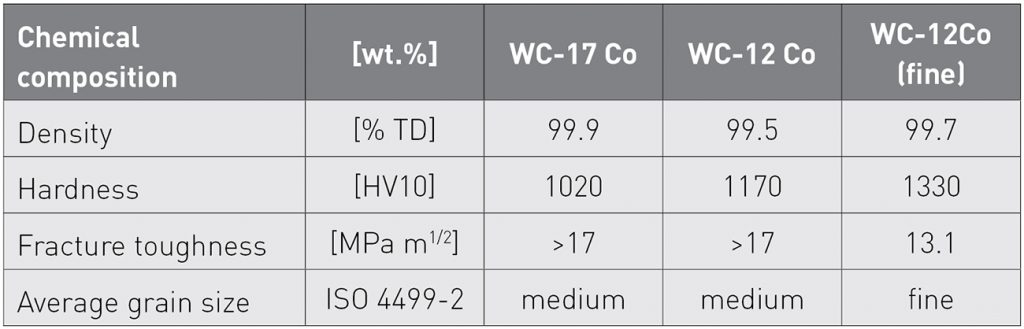

Further work done at Fraunhofer IKTS in Dresden, Germany, with pre-sintered WC-Co granules in 2015 to 2016 [19, 20] showed, for the first time, that hardmetal compositions with typical Co contents in the range of 12 to 20 wt.% could also be successfully processed by BJT (Fig. 6). As seen in Table 1, different compositions can be processed and different properties achieved.

In recent years, a slightly modified process called ‘Solvent on Granule 3D-Printing’ was also successfully used to produce similar complex parts with Co-contents of 17.7 wt.% Co [21].

So far, however, dense hardmetal parts with mechanical properties comparable to conventionally produced parts have only been achieved by Binder Jetting for hardmetal compositions with ≥ 12 wt.% Co. Results for the widely used hardmetals compositions with 6 to 10 wt.% Co have, to date, not been published.

Furthermore, it should be kept in mind that, due to the comparatively low green density of BJT green parts, shrinkage is greater than with conventional pressed parts, resulting in more problems with distortion after sintering. The reason why the use of lower Co levels is difficult is because of an insufficient amount of liquid phase during sintering, which in turn is needed for the greater shrinkage of BJT parts.

Material Extrusion

Material Extrusion (MEX), widely known as Fused Filament Fabrication (FFF) when using a filament-based feedstock, is, like Binder Jetting, a two-step sinter-based AM technology. However, in contrast to BJT or PBF, it is not powder bed based but is a ‘free form’ AM process. Here, particle-filled thermoplastic filaments are produced by mixing, kneading and extrusion. These can then be used in standard MEX machines. Within these filaments, the volume percentage of particles (solid content) can easily be in the range of 50 to 60%, resulting, for hardmetals, in shrinkage ratios comparable to conventional powder injection moulded or even pressed parts.

Since, in MEX, layers and volumes are produced by a layer-wise deposition of filaments, the production of 100% dense parts (after sintering) is complicated due to the anticipated presence of cavities resulting from the potential gap between deposited filament layers. Examples of such problems, in the case of hardmetals, were shown by Lengauer et al. in 2019 [22].

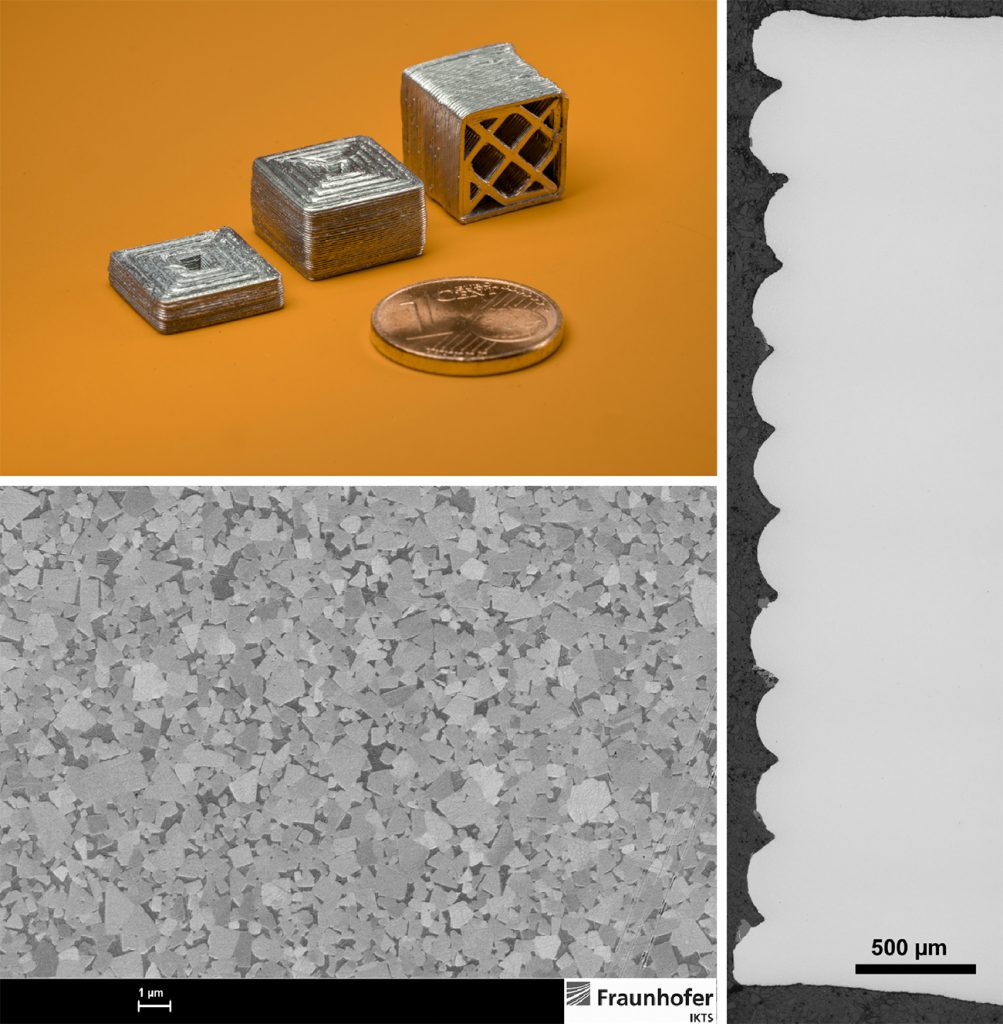

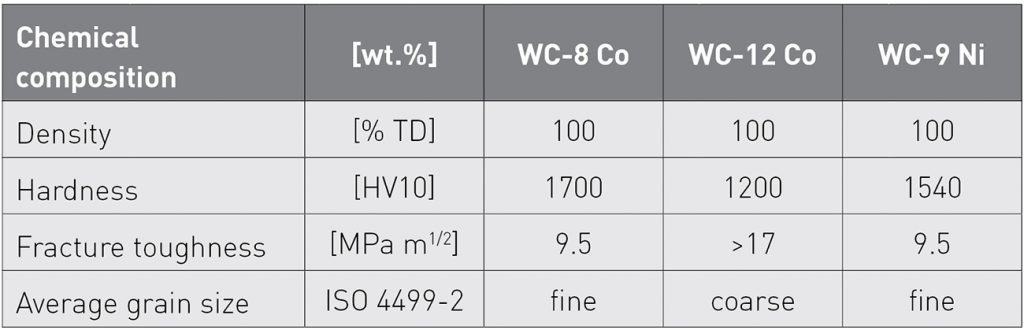

Work done on FFF of hardmetals at Fraunhofer IKTS shows that cavity- and pore-free parts can be produced (Fig. 7) and that, due to the low shrinkage, hardmetal compositions with Co contents as low as 8 wt.% and with nickel as a binder element can also be produced (Table 2), resulting in hardness values of up to 1700 HV [23].

Thus, and in contrast with PBF and BJT, MEX can achieve dense parts with low cobalt contents and high hardness values. However, due to the high amount of organic thermoplastic backbone binder, debinding has to be calibrated to the thickest dimension of the as-built part, thus limiting the manufacture of larger parts without inner channels because of the very long debinding time needed to remove the binder components. Furthermore, MEX using filaments is, in standard machines, a single process, meaning one part is created at a time, making it significantly slower than PBF – even more so when compared with BJT.

Material Jetting

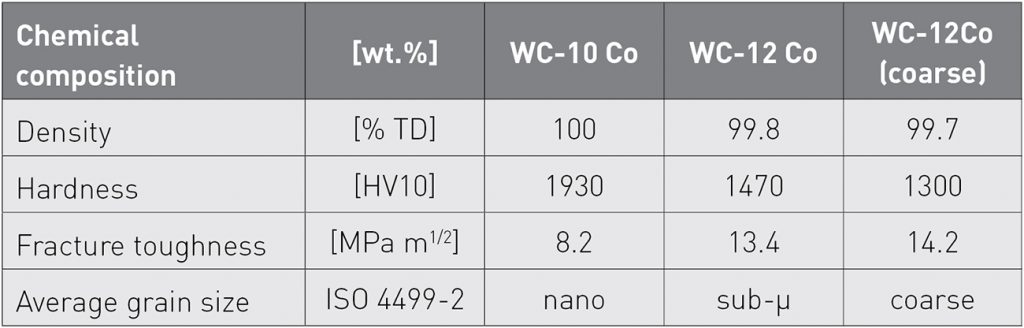

Another technology investigated for the Additive Manufacturing of hardmetals is the thermoplastic 3D printing (T3DP) process developed by Fraunhofer IKTS [24]. Because of its jetting-like process, it belongs to the MJT category of AM processes. Like MEX, thermoplastic 3D-Printing is based on the selective deposition of molten, particle-filled thermoplastics. However, in T3DP, droplets rather than filaments are deposited. The thermoplastic binder system used consists of different waxes and additives. This results in low viscosities at relatively low temperatures and solidification by cooling. Work done at IKTS, starting in 2016, showed that T3DP can be used for hardmetals with low Co contents and small tungsten carbide grain sizes [25, 26]. Work done for the manufacture of cutting inserts and test structures showed that, with nanoscaled WC powders and Co contents of just 10 wt.%, fully dense parts with a perfect microstructure (Fig. 8) and hardness values of above 1900 HV can be achieved (Table 3).

Currently, the vertical resolution of T3DP is around 80 to 100 µm and the horizontal resolution is 250 to 350 µm, bringing it in the range of standard BJT produced parts. In T3DP, a quite high solid loading in the range of 50 to 60% ensures low shrinkage and subsequent distortions. However, as with MEX, debinding has to be addressed, limiting the parts sizes in the case of larger bulk parts.

Summary and conclusion

Even though hardmetals have not yet been successfully commercialised by the AM industry, they are a promising material for a number of AM processes. Sinter-based AM technologies, such as Binder Jetting, Material Extrusion and Material Jetting, seem to be the AM technologies with the highest potential for industrial use, as they appear to be the only ones capable of delivering the specific requirements for hardmetal tooling, namely full density, microstructures with a homogeneous distribution of WC and Co and the maximum possible ratio of hardness and fracture toughness combined with high bending strength values above 3000 MPa.

These properties are similar to conventionally manufactured parts with the same grain size and metallic binder content. PBF-produced hardmetal parts currently show significantly inferior properties due to the formation of cracks, unwanted phases and inhomogeneous microstructures.

So far, each of the potential technologies that have been highlighted appear to have strengths and weaknesses, depending on the material composition, production speed, accuracy and part size achievable.

For hardmetals parts with sizes of up to several centimetres and hardness values of up to 1400 HV, BJT is a fast and suitable process. However, for smaller parts with higher hardness values up to 1800 HV, MEX and, for delicate parts with hardness values of up to 1900 HV, MJT, appear most suitable.

In the future, adjusted materials for BJT and optimised process parameters for MEX and MJT will most likely overcome the current limitations of the Additive Manufacturing of hardmetals and will open the field to even more challenging possibilities, such as the multi-material printing of tools with different hardmetal compositions, resulting in specific tailored properties in different parts of a tool.

Author

Dr.-Ing. Johannes Pötschke

Group Leader, Hardmetals and Cermets

Fraunhofer Institute for Ceramic Technologies and Systems IKTS

Winterbergstrasse 28

01277 Dresden

Germany

Tel: +49 351 2553-7641

[email protected]

www.ikts.fraunhofer.de

Acknowledgments

The author thanks Markus Mayer, Uwe Scheithauer, Steven Weingarten, Hans-Jürgen Richter, Christian Berger and Tassilo Moritz (all Fraunhofer IKTS) as well as Tobias Schwanenkamp (University of Applied Sciences Cologne) for their input and additional material for this article.

References

[1] Caradonna MA. The fabrication of high packing density ceramic powder beds for the three dimensional printing process. Thesis (Master of Science). Boston, MA; 1997.

[2] Zong G, Wu Y, Tran N, Lee I, Bourell DL, Beaman JJ et al. Direct Selective Laser Sintering of High Temperature Materials. Center for Materials Science & Engineering 1992:72–85.

[3] Kurlov AS, Gusev AI. Tungsten Carbides: Structure, Properties and Application in Hardmetals. 184th ed.: Springer; 2013.

[4] ECHA. Substance information on: Information on, https://echa.europa.eu/substance-information/-/substanceinfo/100.028.325.

[5] Kurlov AS, Gusev A-I. Tungsten Carbides and W-C Phase Diagram. Inorganic Materials 2006;42(2):121–7.

[6] Konyashin I, Hinners H, Ries B, Kirchner A, Klöden B, Kieback B et al. Additive manufacturing of WC-13%Co by selective electron beam melting: Achievements and challenges. Hardmetals – raw materials, technologies and applications 2019;84:105028.

[7] Rieger T, Schubert T, Schurr J, Kolb D, Riegel H, Bernthaler T et al. Cemented Carbide Development for Additive Manufacturing (AM). In: Euro PM2019 Congress & Exhibition Euro PM2019 proceedings 13-16 October 2019, Maastricht Exhibition & Congress Centre (MECC), Maastricht, Netherlands. Shrewsbury, United Kingdom: European Powder Metallurgy Association (EPMA); 2019, 1–6.

[8] Laoui T, Bonse J, Kruth J-P, Froyen L. Influence of Powder Parameters on Selective Laser Sintering of Tungsten-Carbide Cobalt. In: Campbell (Hg.) 1998 – Proceedings of the 8th European; 1998, 271–280.

[9] Kruth J-P, van der Schueren B, Bonse JE, Morren B. Basic Powder Metallurgical Aspects in Selective Metal Powder Sintering. CIRP Annals 1996;45(1):183–6.

[10] Mattiza D. Untersuchungen zum Selektiven Laser-Sintern von Hartmetallen und hochschmelzenden Nichteisen-Metallen: Diplomarbeit. 1st ed; 1999.

[11] Uhlmann E, Bergmann A, Gridin W. Investigation on Additive Manufacturing of Tungsten Carbide-cobalt by Selective Laser Melting. Procedia CIRP 2015;35:8–15.

[12] Gläser T. Untersuchungen zum Lasersintern von Wolframkarbid-Kobalt. 1st ed. Aachen: Apprimus Verlag; 2010.

[13] Gläser T, Arntz K, Schlüter M, John T, Bechmann F, Döhler R et al. Generative Fertigung von Extrusionswerkzeugen aus Hartmetall – GENIAL. Aachen; 2009.

[14] Schwanekamp T, Reuber M. Parameter study on laser beam melting of WC-Co at 800°C pre-heating temperature. In: Proceedings of 7th International Conference on Additive Technologies: Interesansa – zavod, Ljubljana; 2018, 78–84.

[15] Schwanekamp T, Marginean G, Reuber M. Thermal Post-Treatment of Additively Manufactured WC-Co Processed by Laser Powder Bed Fusion. In: Euro PM2019 Congress & Exhibition Euro PM2019 proceedings 13-16 October 2019, Maastricht Exhibition & Congress Centre (MECC), Maastricht, Netherlands. Shrewsbury, United Kingdom: European Powder Metallurgy Association (EPMA); 2019, 1–6.

[16] Sachs EM, Cima M, Cornie J. Three-Dimensional Printing: Rapid Tooling and Prototypes Directly from a CAD Model. CIRP Annals 1990;39(1):201–4.

[17] Kelley A, Sachs EM. Tungsten carbide-cobalt by Three Dimensional Printing; 1998.

[18] Gläser T, Arntz K, Schlüter M, John T, Bechmann F, Döhler R et al. Gemeinsamer Ergebnisbericht zum BMBF – Verbundprojekt: Generative Fertigung von Extrusions-werkzeugen aus Hartmetall – GENIAL. Bericht Lasersintern HM; Förderkennzeichen 02PU2220. Aachen; 2009.

[19] Pötschke J, Berger C. Fraunhofer 3D prints hardmetal tools. Metal Powder Report 2017;72(1):69.

[20] Pötschke J, Berger C, Richter H-J, Scheithauer U, Weingarten S. ADDITIVE MANUFACTURING OF HARDMETALS. In: EPMA – European Powder Metallurgy Association, editor. Euro PM2017 Proceedings; 2017.

[21] Carreño-Morelli E, Alveen P, Moseley S, Rodriguez-Arbaizar M, Cardoso K. Three-dimensional printing of hard materials. Hardmetals – raw materials, technologies and applications 2020;87:105110.

[22] Lengauer W, Duretek I, Fürst M, Schwarz V, Gonzalez-Gutierrez J, Schuschnigg S et al. Fabrication and properties of extrusion-based 3D-printed hardmetal and cermet components. Int. J. Refract. Met. H. 2019;82:141–9.

[23] Berger C, Abel J, Pötschke J, Moritz T. Properties of Additive Manufactured Hardmetal Components Produced by Fused Filament Fabrication (FFF). In: Euro PM2018 Congress & Exhibition Euro PM2018 proceedings 14-18 October 2018, Bilbao Exhibition Centre (BEC), Bilbao, Spain. Shrewsbury, United Kingdom: European Powder Metallurgy Association (EPMA); 2018.

[24] Scheithauer U, Schwarzer E, Poitzsch C, Richter H-J, Moritz T, Stelter M. Method for producing ceramic and/or metal components (WO-Patent 2015/177128 A1).

[25] Pötschke J, Weingarten S, Scheithauer U, Mayer M, Moritz T. Thermoplastic 3D Printing of Hardmetals. In: Euro PM2019 Congress & Exhibition Euro PM2019 proceedings 13-16 October 2019, Maastricht Exhibition & Congress Centre (MECC), Maastricht, Netherlands. Shrewsbury, United Kingdom: European Powder Metallurgy Association (EPMA); 2019, 1–6.

[26] Scheithauer U, Pötschke J, Weingarten S, Schwarzer E, Vornberger A, Moritz T et al. Droplet-Based Additive Manufacturing of Hard Metal Components by Thermoplastic 3D Printing (T3DP). Journal of Ceramic Science and Technology 2017;8(1):155–60.