Trumpf: Overcoming barriers to the adoption of Additive Manufacturing in the aerospace sector

Additive Manufacturing is arguably the ideal production method for numerous aerospace applications, particularly where lightweighting and part consolidation are concerns – yet no other industry takes such a cautious approach to embracing new manufacturing methods and imposes so many hurdles on the path to certification. In this article, Germany’s Trumpf GmbH + Co. KG tracks the production journey of one part for Spain’s Ramem S.A., as well as looking at further cases from the aerospace industry. [First published in Metal AM Vol. 5 No. 4, Winter 2019 | 15 minute read | View on Issuu | Download PDF]

Safety is the highest priority in the aerospace industry. That’s why it takes such a long time for new manufacturing methods to reach the shop floor, even though companies are constantly searching for new ways to cut high material costs and reduce component weight. The industry’s cautious approach to fully embracing the promise of Additive Manufacturing therefore comes as little surprise – and only the most tenacious efforts to drive its adoption are likely to be successful.

Headquartered in Ditzingen, Germany, Trumpf enjoys a trusted reputation in the aerospace industry. As a leading producer of machine tools and lasers for industrial manufacturing, the company produces a number of Additive Manufacturing systems, including machines based on Laser Powder Bed Fusion (L-PBF) technology, which the company refers to as Laser Metal Fusion (LMF), ranging from the compact TruPrint 1000 to the larger scale TruPrint 5000. Also available is Laser Metal Deposition (LMD) technology, which can be applied with the machines TruLaser Cell 3000 and TruLaser Cell 7040. In providing both L-PBF and LMD technology from one source, Trumpf is able to offer its customers suitable technologies for a wide range of applications in the aerospace industry. In addition to its machines, the company provides a complete solution comprising digitalisation and servicing.

Aerospace case study: rakes

Spanish supplier Ramem S.A. specialises in the design and manufacture of mechanical and electromechanical devices. Headquartered in Madrid, it produces a wide variety of parts, including aerospace components with complex geometries and sophisticated technical requirements. As Silvia López-Vidal, the company’s R&D Manager, explains, “We do a lot of high-mix, low-volume work in this field, which is why we have long been interested in Additive Manufacturing. When it comes to reducing weight, cutting down the number of subassemblies and slashing costs, AM offers far more potential than conventional methods.”

Ramem is interested not only in the opportunities offered by AM, but also in the strategic benefits it brings. “AM will eventually make the leap into industrial-scale production in the aerospace sector, too. So we’re making sure we’re prepared for that moment by building up the necessary expertise in advance.”

Ramem’s engineers always have AM in the back of their minds, and constantly analyse the parts they produce to determine whether AM could add value to the manufacturing process. A rake is one example of a part that offers particular promise for transitioning to AM. Rakes are used in engine development to take the high-precision temperature and pressure readings which help engineers assess engine performance. Mounted directly in the path of the engine’s air flow, these parts must be made to very high standards in order to withstand the extreme temperatures and tensile and compressive loads they are exposed to. A rake, therefore, is a highly complex part that must conform to precise dimensional requirements and feature a smooth, aerodynamic surface in order to deliver accurate measurements; a textbook example of a part which might be better produced by metal AM.

Rakes consist of four components that must be painstakingly milled, assembled manually and then welded individually. At their core are several internal tubes that serve as channels, with a wall thickness of < 0.3 mm. These channels are inserted into the rear of the elongated body of the rake and welded into place on the Kiel heads. The body of the rake is then sealed with a cover plate. “Those delicate channels must be inserted with maximum precision,” explains López. “If just one of the welded Kiel heads is out of position, the whole rake has to be scrapped. The Kiel heads have dimensional tolerances of +/- 0.05 mm and feature a narrow, continuous opening, at the end of which the flow sensors are integrated.”

Ramem’s engineers immediately saw that the delicate rakes were perfect candidates for Additive Manufacturing. The challenge, of course, was to design them in a way that would be compatible with AM. This task was tackled by Prodintec, an RTO that specialises in redesigning parts for Additive Manufacturing. Prodintec succeeded in reducing the number of components from four to one. Yet the results of the first trial builds were disappointing, says López-Vidal. “The rakes were deformed during production, and the printing process deposited powder and other solids in the narrow channels. What’s more, the Additive Manufacturing process wasn’t meeting requirements – neither for dimensional accuracy nor for a smooth, pore-free rake surface.”

López-Vidal and her team were not discouraged by this setback. At Formnext 2017, they visited Trumpf’s booth and explained the problems they were facing to Julia Moll, Project Manager Additive Manufacturing, and her team. “The Trumpf developers were confident they could solve our problems with their lasers and powder,” recalls López-Vidal. Using the CAD drawing from Prodintec as a starting point, the Trumpf team set out to find a solution. “The biggest challenge in the printing process was the issue of part orientation,” explains Moll. “We had to align the part in such a way that we could print it without support structures, because we wouldn’t have been able to attach those to the highly fragile Kiel heads or anywhere inside the part. We also had to rule out any risk of thermal distortion. That wasn’t easy because the rakes are on one hand very thin-walled but also massive in volume on the upper part.”

A TruPrint 1000 was used to additively manufacture the parts. This machine offers a build volume of about 100 mm x 100 mm and has a 200 W laser for the AM of delicate structures. Using this machine, the results ticked all the right boxes from the first prototype, says Moll. “A 3D scan enabled us to demonstrate that it had the required level of geometric accuracy, and using micrographs we established a density of 99.95%.”

But the experts were keen to get even more accurate information, so they sent the prototype for a CT scan at Yxlon, a developer and producer of X-ray and computed tomography inspection systems. The company verified the uninterrupted continuity of the channels and the size of the pores. The Trumpf experts also automatically ascertained and checked over forty measurements inside the part. The results were positive, showing clear channels and the required dimensional accuracy, including the stipulated pore size of less than 100 µm.

“Redesigning the part has cut throughput times and reduced the amount of material we use by around 80%,” stated Moll. “All in all, the decision to 3D print the rakes has reduced our overall costs by around 74%. That’s a whole order of magnitude in this industry.”

López-Vidal is optimistic that this part’s manufacturing journey signifies AM’s ability to provide practical solutions in the aerospace industry. “The key is to stay up to speed with this new method and keep decision-makers up-to-date with the opportunities offered by Additive Manufacturing. Rakes are yet another example of just how much potential AM has to offer.”

“But the aerospace industry is a challenging market, and it will take us a while to convince our customers to use Additive Manufacturing for structural components and other key assemblies,” she continues. “Nevertheless, we and other big suppliers are steadily expanding our strategic expertise in AM methods – and that’s a clear sign of how confident we are that this technology will ultimately succeed.

Aerospace case study: satellite mounting structure

Despite the acknowledged barriers to adoption in the aero industry, some space companies are already using AM to build complex components and achieve significant weight savings. AM is being used, for example, in satellites. The requirements for the production of satellite components have increased enormously in recent years; on the one hand, parts need to be as light as possible, because every kilogram that a launch vehicle carries into space costs the client several hundred thousand euros. At the same time, however, satellites must be robust enough to withstand the tremendous forces experienced during launch.

Trumpf Additive Manufacturing systems make it possible to meet these requirements. As an example, the company has been commissioned by the space company Tesat-Spaceroom GmbH & Co. KG to produce an additively manufactured mounting structure for Germany’s Heinrich Hertz communications satellite, which will be used to test the spaceworthiness of new communication technologies, a mission being carried out by DLR Space Administration on behalf of the Federal Ministry of Economics and Energy and with the participation of the Federal Ministry of Defense.

The mounting structure includes strap-on motors that are used to modulate microwave filters. In collaboration with the company AMendate, Trumpf’s engineers succeeded in optimising the topology of the mounting structure for AM and reducing its weight by 55%. The mount, originally 164 g, now weighs just 75 g. “This is just one example of how we can use additive processes in satellite construction to reduce weight and increase payload capacity,” explains Matthias Müller, Industry Manager Additive Manufacturing for Aerospace and Energy at Trumpf. The team built the redesigned part on Trumpf’s TruPrint 3000, a medium-format machine incorporating industrial part and powder management, a build area that is 300 mm in diameter and 400 mm high, and laser power of up to 500 W. The part’s new geometry could not have been produced using conventional methods. As well as being lighter, the optimised mounting structure is more robust, and it is expected that during the launch of the satellite, it will withstand the same high forces as its predecessor and hold its shape better.

Aerospace repairs by Additive Manufacturing

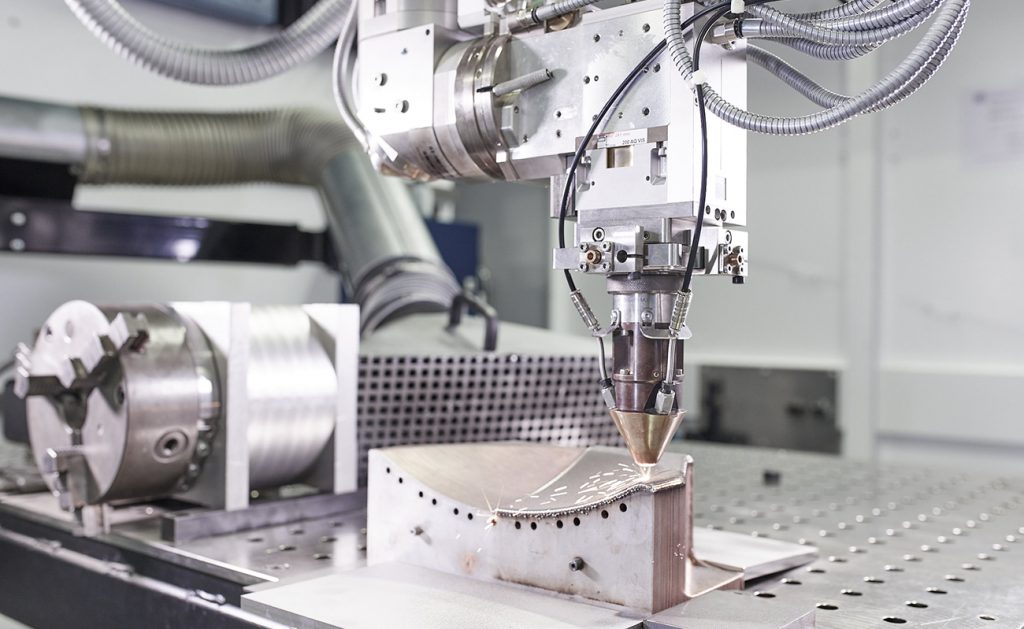

AM can also be used for the repair of aerospace components. Laser Metal Deposition (LMD) technology, which Trumpf also develops, is suitable for this purpose. As a sample application, the Trumpf team repaired a high-pressure compressor blade – also known as a 3D aeroblade – using LMD. These components are used in aircraft engines and must be able to withstand extreme changes in temperature during flight. They are also in constant contact with dust and water, and typically show signs of wear on the edges and tips. Aviation engineers are required to periodically repair the blades to maintain engine efficiency.

LMD is the perfect repair solution for this job. On some sections of the blades, the material to be repaired is just 0.2 mm thick. Conventional methods quickly reach their limits in these kinds of applications, but using LMD technology, the laser can be positioned with an accuracy of approximately one hundredth of a millimeter before applying a precisely calculated dose of energy. At the same time, the system feeds in material of identical composition as the part itself.

Depending on the application, this process typically takes just a few minutes, and makes it easy to repair blades multiple times, significantly reducing cost per part in each engine overhaul. “Laser Metal Depisition delivers a low dose of energy – and that makes it perfect for aerospace applications,” explains Oliver Müllerschön, Head of Industry Management Laser Production Technologies at Trumpf. “We can use it not only to repair and coat parts, but also to build up three-dimensional structures. That’s simply not possible with conventional welding methods.”

Helping customers achieve aerospace certification

In 2018, Trumpf assisted MBFZ toolcraft GmbH, Georgensgmünd, Germany, as it worked to become one of the first metal Additive Manufacturing companies to achieve Nadcap (National Aerospace and Defense Contractors Accreditation Program) certification for aerospace. Nadcap is an industry-driven programme whereby highly qualified individuals with experience in the aerospace industry conduct the process audits of manufacturers, using criteria specific to an actual process, and can give successfully audited companies a competitive edge over their rivals.

Toolcraft manufactures precision components and automation solutions for a number of industries, including aviation and aerospace, using metal Additive Manufacturing alongside a number of other production technologies. The company regularly undergoes certification for aviation and aerospace; a requirement in order to be allowed to manufacture components for applications in these industries. The process of Nadcap accreditation involves comprehensive certification of the entire production environment; for L-PBF manufacturing, this meant documenting and ensuring transparency over the numerous process steps which take place before, during and after the L-PBF process.

Complete verification of the metal powder used was carried out, as well as the inspection of component quality through optical and tactile measurement and non-destructive surface testing. Special attention was also paid to the L-PBF process within the company’s TruPrint 3000 machine. In addition to monitoring oxygen levels and air humidity in the process chamber, it was important that it be verifiable that the laser power and shape of the laser beam within the machine were coordinated in such a way that every part in a build was exposed in precisely the same way.

Trumpf proactively supported toolcraft prior to the audit with ideas, solutions and suggestions in order to furnish the quality assurance proof throughout the entire process – before, during and after the build. To do this, Trumpf employees examined the Nadcap question catalogue intensively, and developed testing procedures such as path precision analysis and laser power measurement. The actual TruPrint machine was also part of the audit, and here toolcraft states that it was able to rely on Trumpf as a laser and mechanical engineering specialist, guaranteeing quality and process stability for the beam source and all of its individual components.

Aiding toolcraft as it prepared for the Nadcap audit were its own on-site facilities, including a laboratory with extensive equipment to verify powder and component quality, meeting the powder management and quality control requirements of Nadcap. The company also has its own tensile and fatigue strength testing facilities, and manufactures a specific different material on each of its TruPrint machines, using an entirely separate room for powder and parts handling and unpacking. The maintenance and upkeep of the TruPrint 3000 by Trumpf’s Technical Service department, and inbuilt intelligent monitoring solutions, also played a key part in the audit.

Thanks to Trumpf’s assistance and its own comprehensive preparations, toolcraft passed the audit with zero errors. Christoph Hauck, Managing Director of toolcraft, stated following certification, “From the start of the process, Trumpf enthusiastically supported us in finding solutions for the Nadcap question catalogue. I believe that the zero errors found during the audit say everything there is to say about our successful partnership.”

Conclusion

This article highlights the multifaceted ways in which Trumpf, and Additive Manufacturing technology as a whole, can support the aerospace industry. Although the hurdles posed by strict qualification procedures may prove challenging to overcome, Trumpf has demonstrated on multiple occasions that it can support customers in these areas, whether by aiding the development and production of parts fit for certification, as in the case of Ramem’s metal AM rake, or by providing the expertise and technology to enable companies such as toolcraft to achieve aerospace certification for their AM workflows.

Contact

Ramona Hönl

Media Relations, Spokesperson Additive Manufacturing

Trumpf GmbH + Co. KG,

Johann-Maus-Strasse 2,

71254 Ditzingen

Germany

+49 7156 303-31251

[email protected]