The science behind a basic consumer product: Bottle openers by metal Additive Manufacturing

Bottle openers manufactured by metal Additive Manufacturing have become a popular promotional gift, with a variety of designs produced by AM technology suppliers. In the first of a new series of design-oriented articles for Metal Additive Manufacturing magazine, Olaf Diegel and Terry Wohlers reveal how these products effectively demonstrate several key concepts that designers need to understand in the development of parts for production by metal AM. [First published in Metal AM Vol. 3 No. 1, Spring 2017 | 5 minute read | View on Issuu | Download PDF]

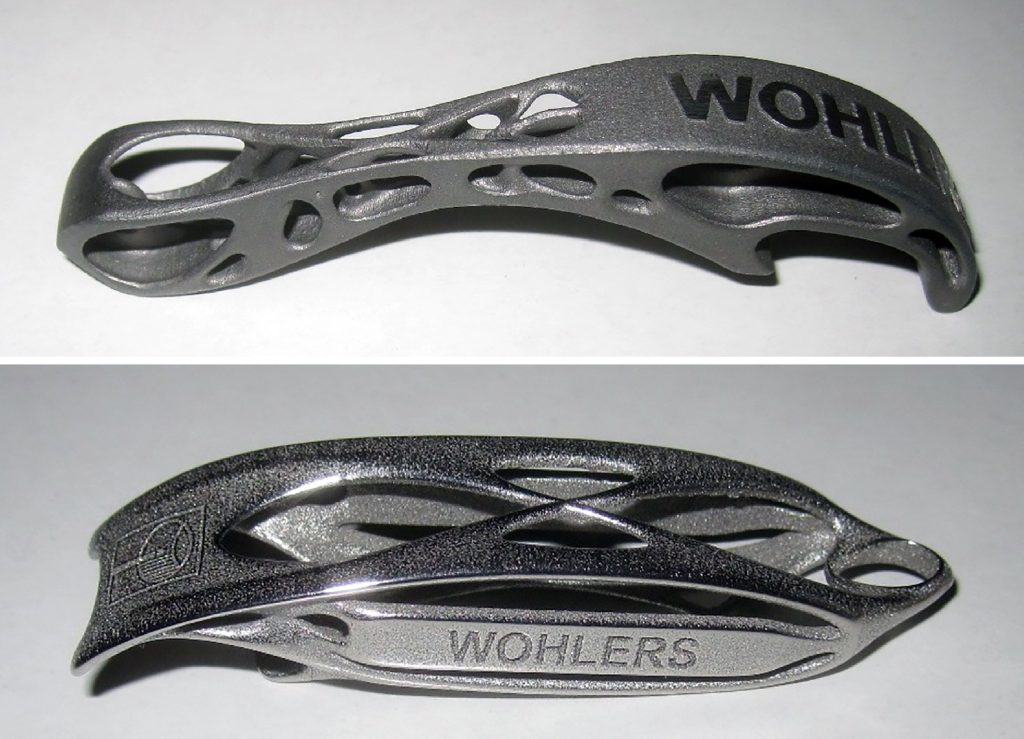

Bottle openers have long demonstrated the benefits of Additive Manufacturing. Methods of topology optimisation and lightweighting, coupled with ‘complexity for free’, clearly show what is possible with metal AM. Also, they make a great gift that people will use and enjoy showing to others when discussing the subject of Additive Manufacturing (Figs. 1, 2). But what do these bottle openers really show and is it possible to quantify some of their benefits to truly grasp the advantages offered by Additive Manufacturing? Are they little more than a trinket or do they really reveal the power and utility of metal AM?

Conventional manufacturing processes are typically sub-optimal in their use of material. This is because the shape of a part is largely driven by the ease of the manufacturing process. A lack of design optimisation reveals itself when a stress analysis is performed. Some regions of a part will be highly stressed, while others have very low stress values, indicating that too much material is present. The geometric freedom offered by AM enables parts to be designed to the same functional specifications as conventional parts but with less material. This is often referred to as lightweighting a part. Approaches to lightweighting can be performed using standard CAD methods, such as reducing the thickness of features in low-stress regions. However, to achieve a high degree of weight savings across an entire part, topology optimisation is required.

Topology optimisation overview

Topology optimisation is letting mathematics decide where to put the material to optimise the strength-to-weight ratio. It seeks to use the least amount of material to sufficiently perform the job. Topology optimisation uses finite element analysis software at its core to make design decisions. The process usually begins with a regularly shaped ‘design space’ for a part. The user then adds forces and constraints that the part will experience while functioning. Several different algorithms can be used to remove material from low-stress regions to arrive at a lightweight conceptual design.

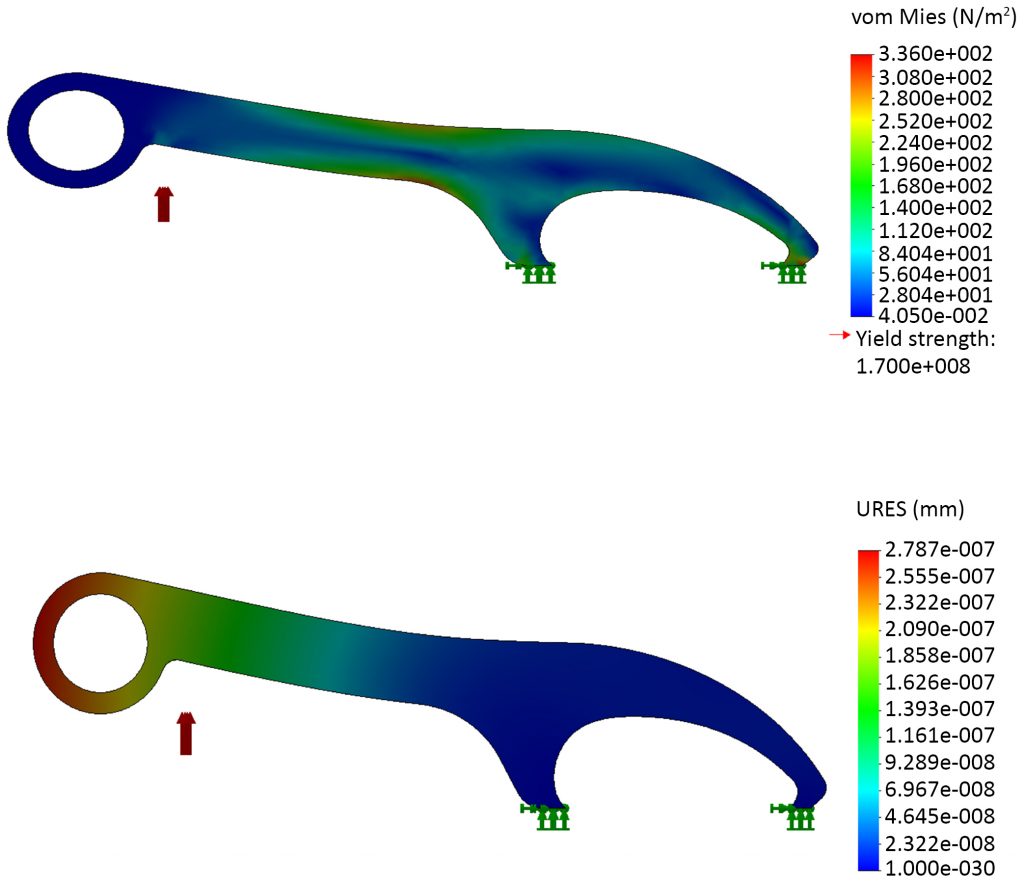

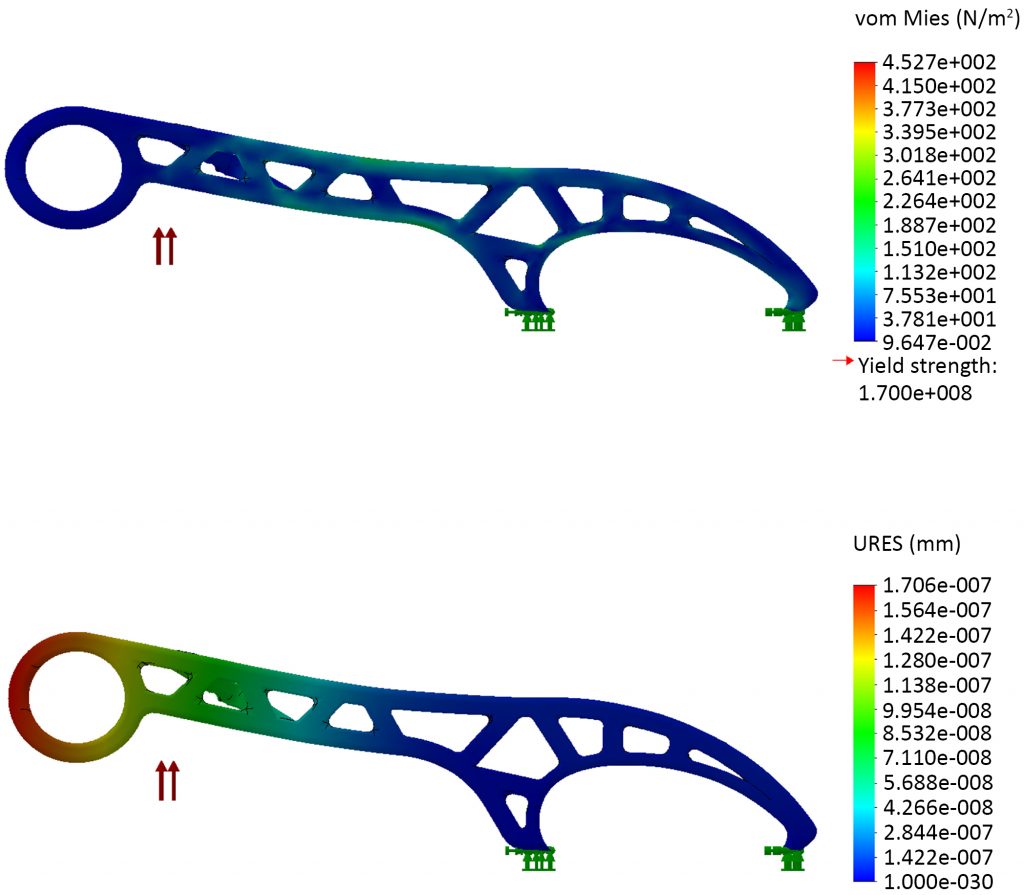

Topology optimisation software produces a design idea that optimises the part only for a particular set of load characteristics. As most products are subjected to a variety of different load cases, it is important to repeat the topology optimisation exercise for each particular load case. The bottle opener, for example, may have a worst-case load scenario in which only an upward force is applied at a point on the bottom of the handle, as used in the analysis in Figs. 4 and 5. It might have another load scenario in which all the force acts downwards on the handle. Each of these cases produces an entirely different design optimisation.

The end result of a complete topology optimisation process is the generation of a number of different design ideas, each optimised to withstand a particular set of forces. These design options can be combined to produce a final design that is optimised for all conditions.

Topology optimisation usually results in shapes that are organic in nature with many limbs and webs. The conceptual design usually needs to be refined using conventional CAD to improve its appearance and feasibility by removing impractically thin webs. It is often followed by shape optimisation to further refine the look and performance of a design. Topology optimisation is highly automated, so it can reduce development time substantially, compared to a conventional iterative design process.

Weight reduction in Additive Manufacturing

When optimising a design such as a bottle opener, the first area of interest is weight reduction. If you were to make a metal bottle opener using traditional manufacturing techniques, you might, for example, machine it out of a solid billet of material such as steel. In the case of the bottle opener shown in Fig. 3, one might start with a solid block of steel, weighing about 40 g (1.41 oz), and mount it into a CNC milling machine. Using a relatively small cutter, the machine would mill away as much material as possible, resulting in a relatively simple bottle opener weighing about 22 g (0.78 oz). The 18 g (0.63 oz) of material that is milled away becomes scrap or is recycled, which requires further cost and energy.

In contrast, a bottle opener made by Additive Manufacturing, weighs only about 8 g (0.28 oz). This is less than one-third of the weight of the machined opener and one-fifth of the weight of the block of steel used to make the CNC machined opener. Also, the AM design produces only about 2 g (0.07 oz) of scrap from the support material that is used to anchor the opener to the build platform during the build process.

Mechanical integrity considerations

Weight reduction is desirable, but only if it does not compromise the mechanical integrity of a part. Therefore, it is important to look at the mechanical properties of the topology optimised design and compare it with the conventional design. Most CAD software offers simple finite element analysis that allows one to examine the stresses on a part or the displacement that an applied force can cause. In a bottle opener, the jaw of the opener is normally fixed on the bottle cap while the handle is pulled up. The rigidity of the handle is important because it allows the user to exert the required leverage to remove the bottle cap. In the case of the bottle opener manufactured by CNC machining, a quick analysis (Fig. 4) shows that the displacement, caused by the lack of rigidity of the handle, from a pressure of 100 N/mm2 results in displacement of about 2.7-007 mm. In layman’s terms, this means that if an upwards force of about 10 kg (22 lbs) is applied to the bottom left end of the bottle opener handle, the handle will bend up by an amount of about 0.0000003 mm.

In contrast, the topology optimised design (Fig. 5), under the exact same force conditions, shows greatly reduced stress, and a displacement of only 1.7-007 mm. The result is about half the amount of bending of the solid design. This clearly shows that the optimised design has less displacement than the solid design, and therefore offers a substantial increase in rigidity, which means that it will function better.

Conclusion

On the surface, optimising bottle openers may come across as a frivolous exercise, but it serves as an excellent example of the potential offered by topology optimisation when coupled with Additive Manufacturing. It serves those learning about topology optimisation, lightweighting and AM and demonstrates what is possible. These methods of design can be applied to countless other parts and products at thousands of organisations around the world.

Authors

Olaf Diegel and Terry Wohlers

Wohlers Associates, Inc.

Fort Collins

Colorado 80525

USA