Redesigned for Additive Manufacturing: Serial production of a new fuel swirler for Siemens gas turbine

Whilst the principles of Design for Additive Manufacturing (DfAM) may suggest ‘clean-sheet’ components are the best way to reap the benefits of AM technology, many examples of redesigns have brought significant performance and economic benefits. In this article, Ray Huff and Terry Wohlers report on further success at Siemens in the use of AM for gas turbine fuel swirlers, highlighting both the development process and the evolving role of digital data in manufacturing. [First published in Metal AM Vol. 5 No. 3, Autumn 2019 | 10 minute read | View on Issuu | Download PDF]

Since purchasing Materials Solutions, Worcester, UK, in 2016, Siemens has been vigorously evaluating conventionally-made parts as candidates for Additive Manufacturing and driving new component design with AM in mind. As early as 2012, Siemens showed work it had done to repair gas turbine burner tips using AM technology. In 2017, the company subsequently redesigned its entire burner for manufacture by AM, yielding a more functional part with fewer manufacturing steps. This application was extensively covered in the article, ‘Siemens: Digitalisation enables the industrialisation of metal Additive Manufacturing at Finspång’, published in the Autumn/Fall 2018 issue of Metal AM magazine.

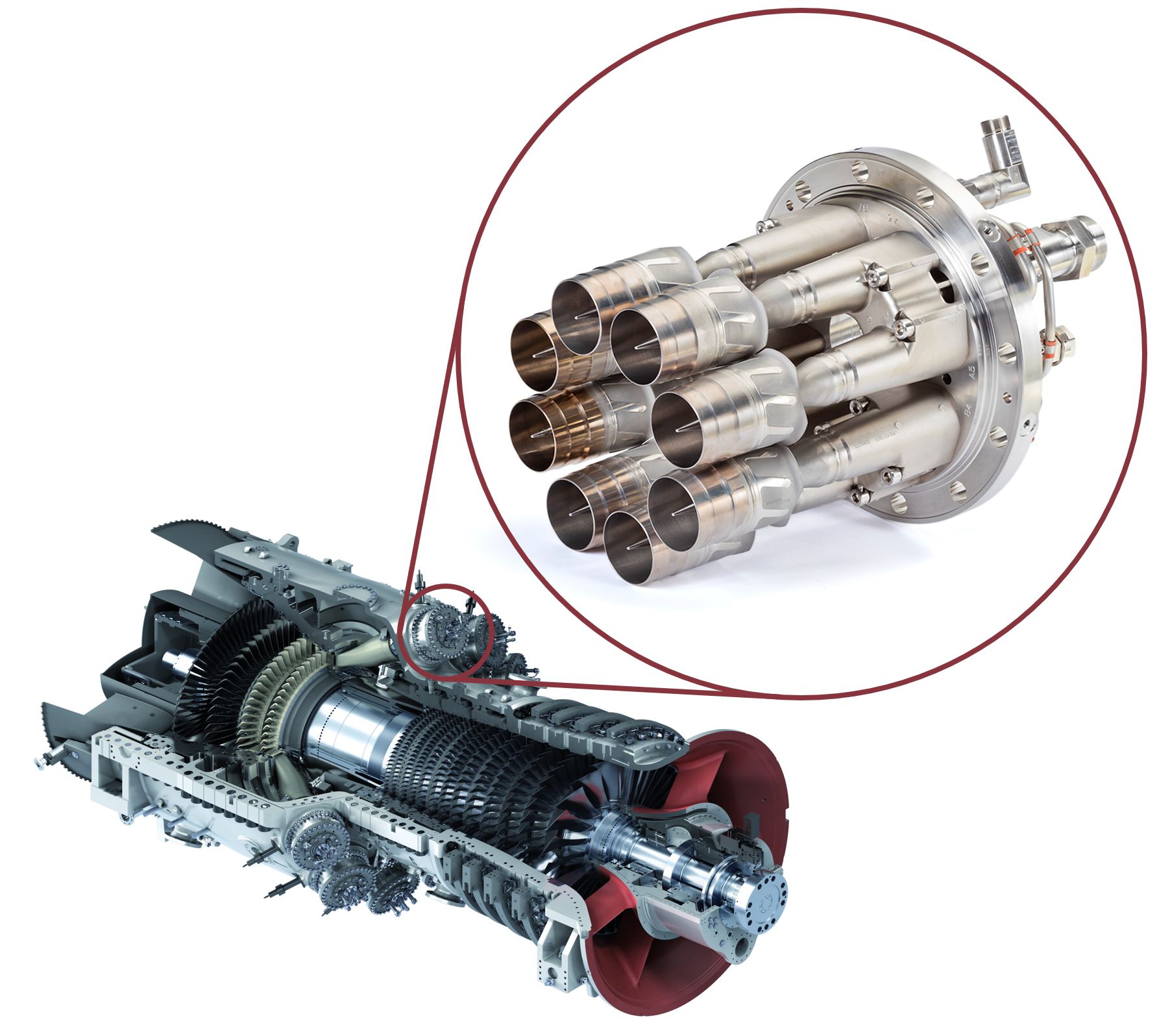

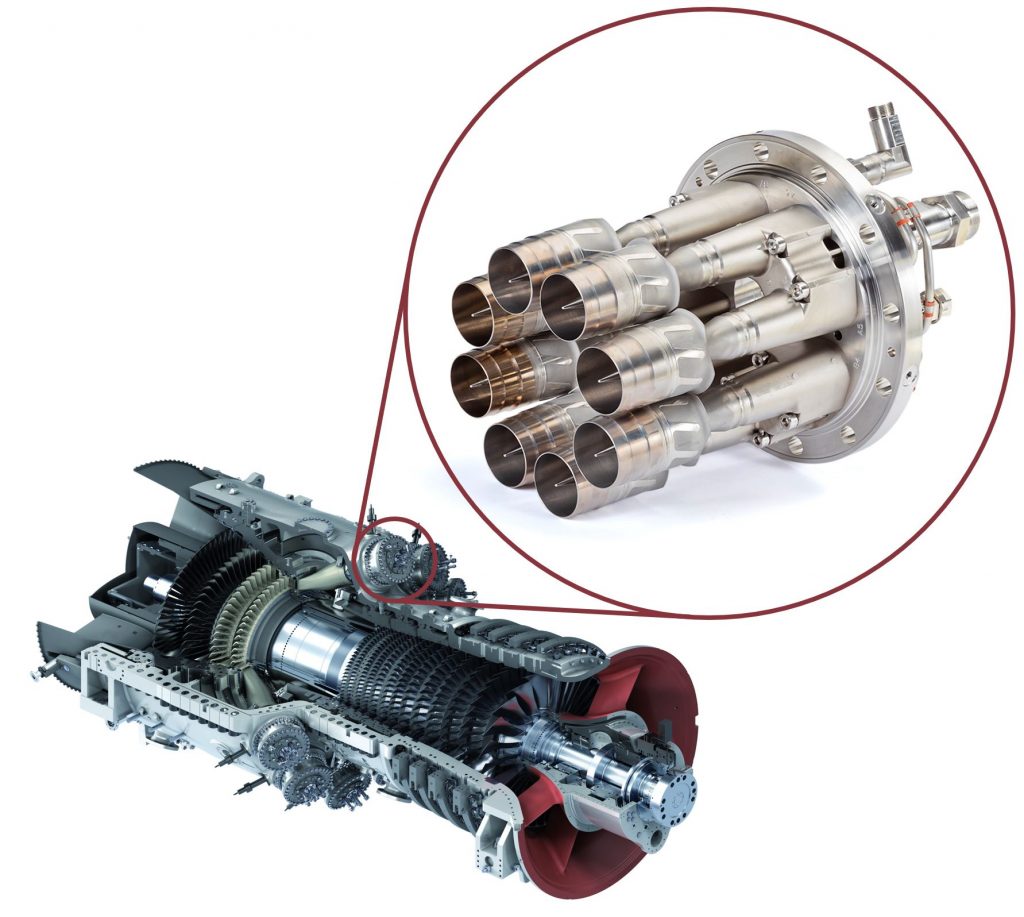

Most recently, Siemens has redesigned another burner component, bringing additive serial production to its large flagship gas turbine product line. The new part, a fuel swirler, fits into the company’s SGT5/6-8000H gas turbine engine. The part followed the now-familiar workflow of redesign for AM, which takes advantage of the benefits of AM quickly, while making a strong business case for the new manufacturing method. Siemens credits AM for enabling higher firing temperatures in its combustion chambers. The swirler is responsible for mixing air and fuel prior to combustion by the burner. Conventionally, the swirler is made up of ten cast and machined parts welded together. The part is an active service component with production demand of more than 1,000 units per year.

Considerations behind the redesign

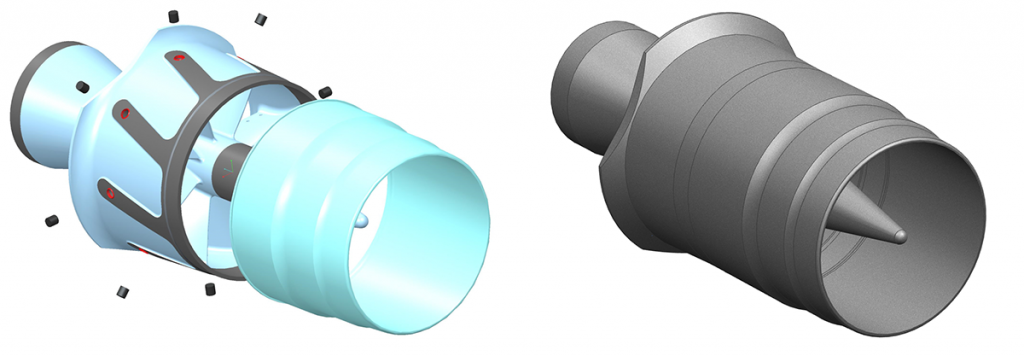

Siemens redesigned the swirler assembly by integrating vanes, a shroud, and mounts into a single AM design, which is about 250 mm (9.8 in) in length. To meet the high-temperature demands of the application, the swirlers are made in a proprietary, solution-strengthened Inconel alloy. The core IP related to the AM redesign is in the integrated control over the entire process chain. Everything from the powder and machine parameters, to the post-processing and heat treatment, has been developed specifically for this engine component.

The conventional swirler design required many machining and welding steps to produce and assemble. This accounted for about six hours of processing time per swirler for the conventional design, not including the time for casting. The AM version, on the other hand, requires only one hour in post-processing. This consists of depowdering, part removal by wire EDM, removal of support structures, and bead blasting. It also requires CNC machining at the base of the part where it is later welded to the larger burner assembly. After printing, each swirler is individually measured and uniquely marked for serialisation.

A focus on key value drivers

Siemens uses time, cost and performance as the value drivers when choosing which parts might be produced by AM. In the case of the swirler, the principle driver was the time savings offered by AM and the fact that the entire manufacturing process could now be done in-house. Time savings were a consideration in each step of production. For example, Materials Solutions has invested in automated depowdering systems from Solukon to shorten hands-on post-processing time. The AM-produced swirler is functionally identical and cost-competitive to its conventionally produced counterpart.

To meet production demand, sixteen swirlers are printed at one time on EOS M 400-4 quad-laser Powder Bed Fusion systems. By adapting build parameters at individual regions of the part, the team reduced the print time by 33% over standard settings. With optimised build settings, a full build takes up to a hundred hours. Siemens is currently running more than forty metal AM machines – all Laser Powder Bed Fusion – across its locations, with twenty-two in operation at Materials Solutions.

The power of software: Enterprise Resource Planning and the digital twin

The company uses an Enterprise Resource Planning (ERP) system in combination with its Real Time Locating System (RTLS) to track parts through the various production steps. The system is connected to a production scheduling system, which is expected to include the facility’s industrial powder management workflow in the future. The Materials Solutions team collaborated with Siemens Digital Industries to capture digital data along the entire process chain, from concept development to serial production. A digital twin of the swirler is available at every stage of development, and continually updates as new data informs design and process changes.

The digital twin, which begins with the CAD model, provides several benefits. For example, it is the basis for the printing process. After printing, parts are scanned, resulting in a second digital twin, which is compared against the original CAD model. If any significant deviations are found between the digital and additively manufactured models, the process has the potential to update the model for a more accurate part if necessary. Each version of the digital twin is stored and later used to generate machining toolpaths for accurate post-build machining.

Part certification

Materials Solutions has also invested in its part certification process. For Siemens industrial gas turbines, parts require ISO certification at minimum. Aerospace customers are served by similar certifications from Materials Solutions. The facility is certified by the National Aerospace and Defense Contractors Accreditation Program (NADCAP). It also has AS9100 and ISO 9001 quality management certifications. The entire process chain, including AM build parameters, is locked down and ‘frozen’, which is required by the certification process. This ensures repeatability over the part’s production life, with the possibility of building spare parts in the future.

The company required about six months to qualify its first two AM machines for swirler production. As of July 2019, these two machines were qualified, with two more in the queue. Gas turbine parts with a less critical function can be certified in as little as ten weeks.

Conclusion

While parts fully designed for AM are often touted as the harbingers of change in manufacturing, parts at many OEMs can benefit from this ‘adapt for AM’ approach. Such production parts will not only save customers money, but also help build confidence in AM. Wohlers Associates expects that in more heavily regulated sectors, such as aerospace, mainstream use of AM for series production is still some years away. Even so, Michael Gorelik of the Federal Aviation Administration (FAA), has expressed his belief that the transition to safety-critical parts will occur sooner than initially expected.

In the meantime, Siemens and its energy business are leveraging design for AM more heavily to turn the rudder of manufacturing with innovative AM production parts. Siemens already has more than thirty parts qualified for AM serial production, with plans to industrialise two hundred parts in the future.

Acknowledgements

The authors thank the team at Siemens for its support of this article.

Authors

Ray Huff and Terry Wohlers

Wohlers Associates, Inc.

Fort Collins

Colorado 80525

USA