Rapid qualification of new alloys for Additive Manufacturing through a holistic process chain

The limited number of alloys currently commercially available for metal Additive Manufacturing is regarded as a key factor hindering the growth of the industry. In this article, Rosswag GmbH’s Daniel Beckers reports on a high-speed qualification process that the company has developed for new alloys, and that spans the complete AM process chain – from alloy atomisation to L-PBF process parameters, heat-treatment and mechanical testing. [First published in Metal AM Vol. 5 No. 2, Summer 2019 | 15 minute read | View on Issuu | Download PDF]

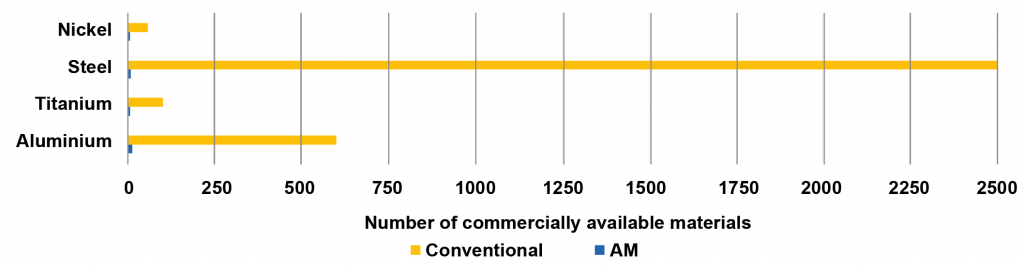

With Additive Manufacturing on the rise when it comes to its market share in the manufacturing industries, and with the development of more sophisticated tools for the design of parts specifically for AM, customers and producers alike are shifting their focus increasingly toward the materials that are commercially available for the technology. This brings to the fore one of the most crucial barriers for the widespread adoption of AM; namely, the low number of alloys usable as standard materials for AM parts. A comparison between the number of commercially available alloys available for conventional manufacturing and Additive Manufacturing is shown in Fig. 1.

Compared to conventional manufacturing processes, where up to 2,500 steel alloy compositions are available for their respective fields of usability, only about two dozen different alloys are available for metal AM. This material gap slows down development speed, due to the time and costs involved in developing and qualifying new materials, and as a result the procurement of the necessary powders can take months for customised alloy compositions. To bridge this gap, a new high-speed material qualification route has been developed by Rosswag GmbH which is centred on the process needs to optimise material qualification with a focus on time and availability, from powder production to the first solid technical data.

Rosswag GmbH is a family-owned company, founded in 1911, with over a hundred years of experience in open-die forging with over four hundred different raw material alloys, from steels, nickel-base alloys and aluminium to titanium materials, all available from stock. The company employs a staff of two hundred and is regarded as one of the world’s leading suppliers of open-die forged products up to 4.5 tons, which are manufactured in-house in a holistic process chain. Its in-depth knowledge of the manufacturing and testing processes is reflected in the high quality of its end products, which are used in the aerospace industry or in energy engineering. Rosswag also holds a number of industry certifications, such as ISO 9001 and ISO 9100 for aerospace.

To further increase its potential for innovation, Rosswag founded its Engineering division in 2014 after seeing the potential of Laser Powder Bed Fusion (L-PBF) technology and possible synergies between the forging division and the new capabilities offered by Additive Manufacturing. The incorporation of the Additive Manufacturing process enables the production of functionally optimised metal components in addition to forged products. In 2017, the Additive Manufacturing production operation was supplemented with in-house metal powder production facilities for material development.

To complete the already comprehensive production chain, in 2018 a new material analytics laboratory was installed. This enables Rosswag to analyse and quantify material properties such as alloy composition, microstructure and porosity. Furthermore, a complete examination of produced powders is possible to assess particle size distribution and relative humidity, as well as the flow characteristics of the powder. These properties are crucial to ensuring powder usability for Additive Manufacturing. By combining all of its experience and equipment, Rosswag was able to develop the following material qualification route, and became the first AM powder producer to be certified by TÜV SÜD Industry Service GmbH.

Material qualification

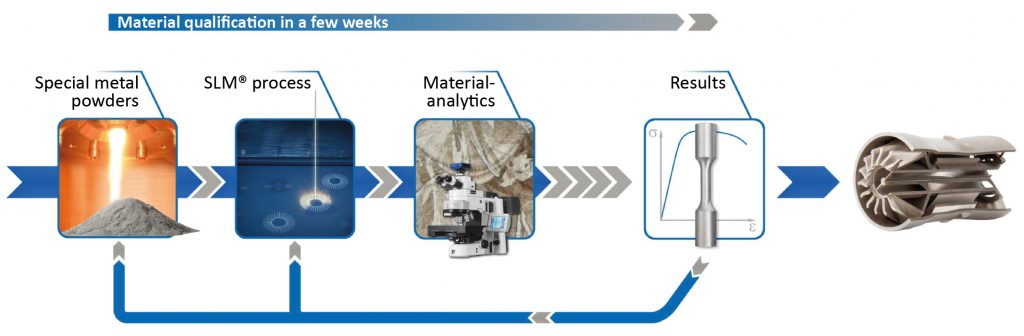

Rosswag’s material qualification process consists of a number of stages which together make up a flexible and fast workflow that is able to develop different material compositions and target the optimisation of process parameters in the L-PBF process. The process chain is shown in Fig. 2.

An important step in the qualification process is the production of the metal powder. Since the procurement of typical amounts of around a few hundred kilograms is time consuming and costly, especially in relation to custom-made powders, the focus here is on small amounts (≤ 20 kg) of self-produced metal powders. For the production of powder for qualification, a BluePower AU3000 atomiser is used (see Fig. 3 left), with an Al2O3 crucible and a volume of 3 litres. This can equate to up to 12 kg of feedstock material.

The system uses an inert gas (in this case, argon) to atomise a melt stream and create the powder (Fig. 3, right). To minimise powder oxidation, the melting and the atomisation take place under an argon atmosphere created by purging the melt and atomisation chamber before the process start. The atomiser is especially designed for particles in the size range between 10–100 µm using a close-coupled nozzle. Here, the melt only travels a few millimetres before coming into contact with a supersonic gas flow field. It is therefore capable of covering the typical AM particle size ranges. The necessary powder can be produced within a matter of days.

After powder production, the material composition is analysed via x-ray diffraction (Bruker S8 Tiger) to ensure that it did not change during the melting process. In the case of a problem, a change in composition by making further additions of alloy elements to the melting crucible before atomisation is possible without significant effort. Afterwards, the powder must be sieved and air classified into the target size range to ensure flowability in the powder layer application (Fig. 4).

During preparation of the powder, the flowability is constantly controlled by a Hall-Flowmeter and a powder coating system developed by Rosswag Engineering (Fig. 5), simulating the coating process used in an SLM Solutions SLM®280 HL Additive Manufacturing system [2].

The coating device creates a defined powder layer on a metal plate. This layer is then analysed via image processing. Typically, around 60% of the atomised material can be used in the AM process. At the end of the powder production process, powder characterisation including particle size and shape measurement, and a humidity check, is performed.

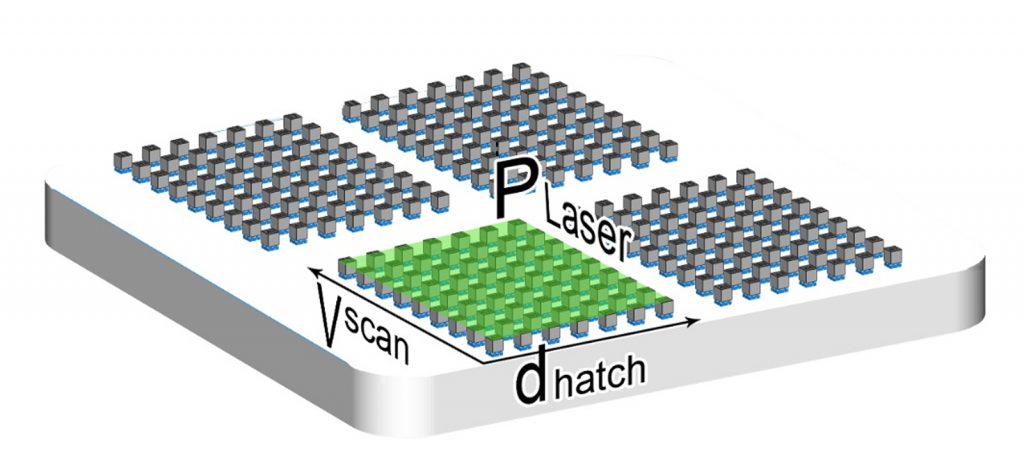

Directly connected to powder preparation is parameter development, with a primary focus on producing a highly dense material with low porosity. For the porosity analysis, a build job with cube samples is processed, as shown in Fig. 6.

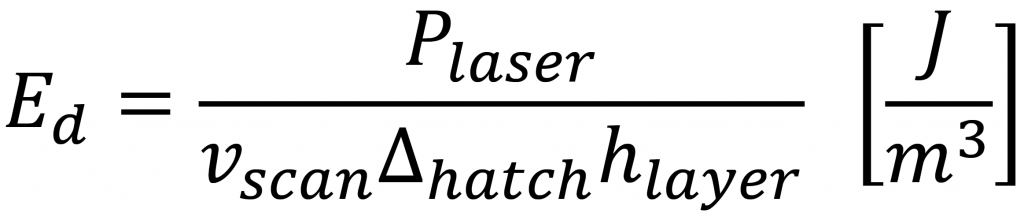

Here, every cube is printed with a different set of process parameters. To increase the amount of data generated, the cubes can be arranged in matrices to vary an additional parameter. Typically, the scan velocity and the hatching distance, as well as the laser power, are varied based on the volume energy density as given in the following equation.

The produced samples are then subjected to grinding and polishing. In the second step, a parameter set based on the first results from a porosity analysis is chosen for the Additive Manufacturing of additional sample geometries. In most cases, these specimens are used for mechanical testing, such as impact or tensile strength testing. The chemical composition of the additively manufactured material is also evaluated to further evolve the alloy composition, if necessary.

All of these steps can be performed within a few weeks, giving customers the opportunity to receive the first solid data about their materials in a short time frame. This helps to evaluate the next steps in their development, by either changing certain parameters or the material, or even giving the possibility to stop the project before either time or costs are beyond reason.

Case study: AISI 4140 & AISI HSS M2

The concept and functionality of Rosswag’s qualification route was evaluated with the qualification of two steel alloys, an AISI 4140 and an AISI HSS M2 tool steel, both of which were achieved within a few weeks, including the production of the necessary powders. AISI HSS M2 is one of the most used cutting steels, because of its extremely high wear resistance. With a carbon content of 0.9 wt.%, weldability is relatively poor; this poses a problem for the L-PBF process, since it is based on micro-welding.

The second material is AISI 4140. This has a high strength and toughness and many different heat treatment procedures for this material are well researched in order to optimise mechanical properties based on an application’s requirements. Because of a carbon content at 0.45 wt.%, a limited weldability was predicted.

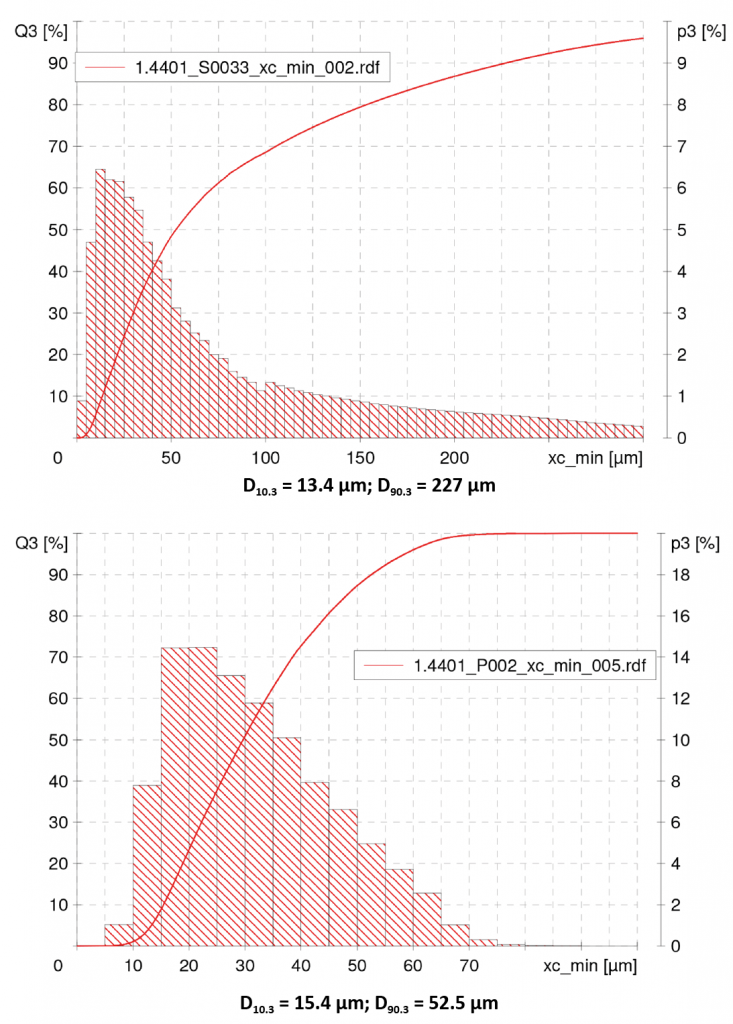

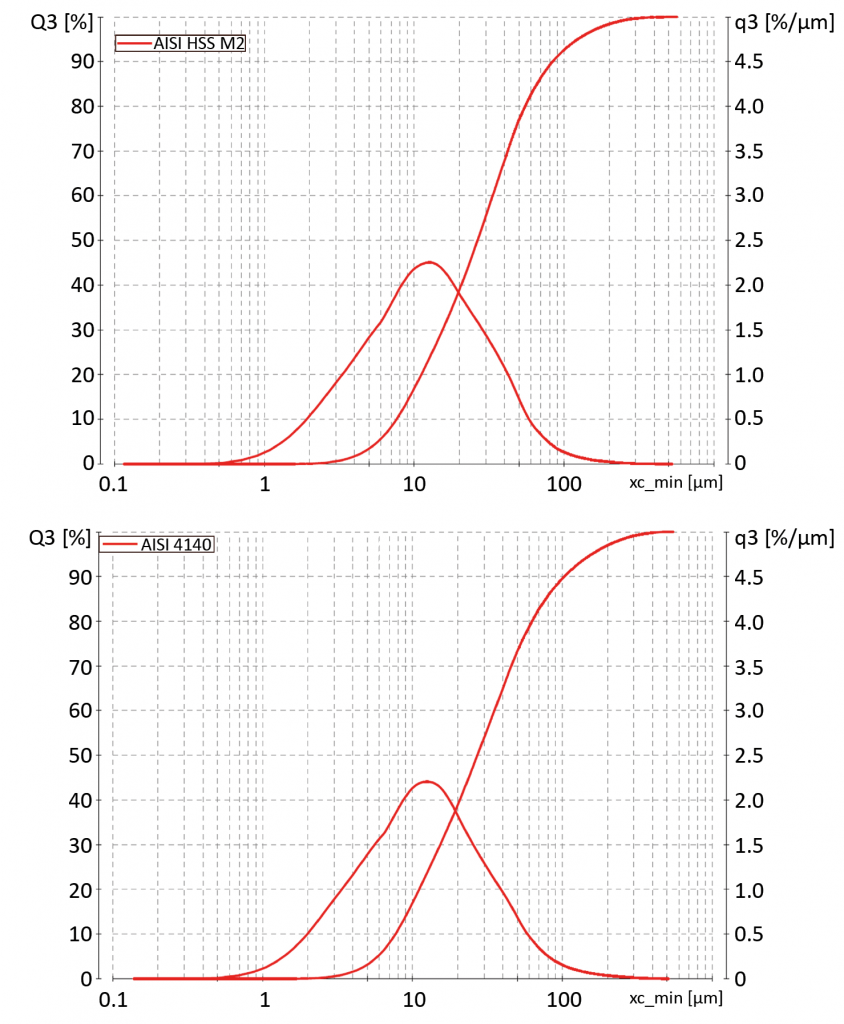

After the atomisation of both alloys, the produced powders were measured in the as-atomised condition to evaluate the atomisation parameters for further optimisation. The resulting particle size distributions are given in Fig. 7.

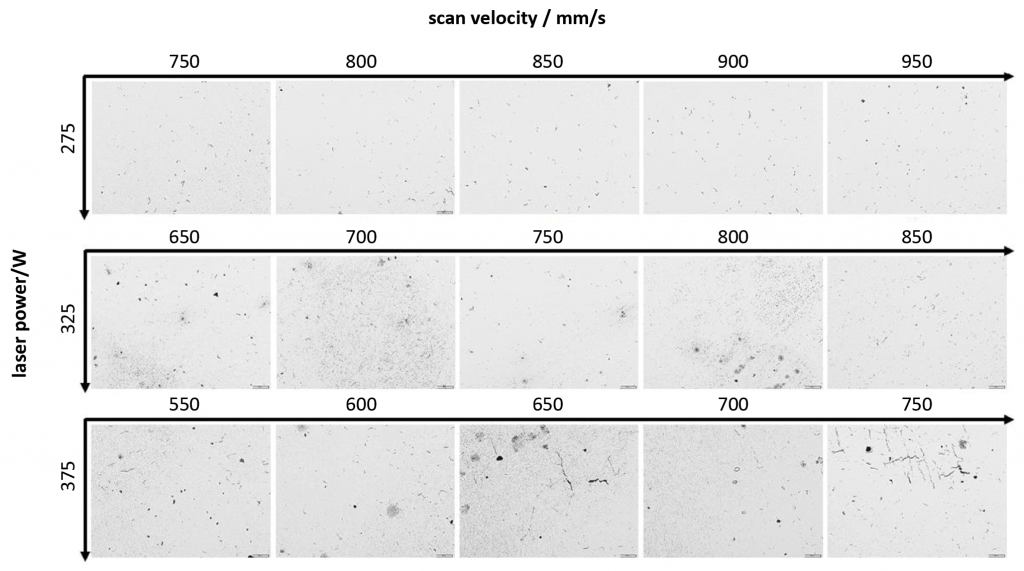

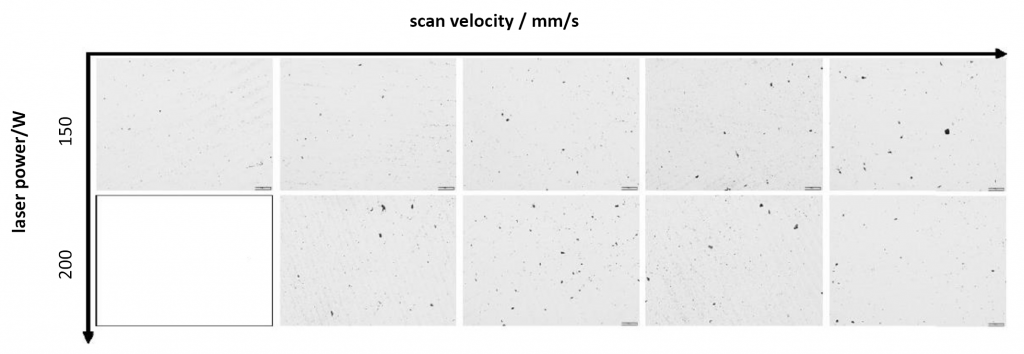

Both powders show a typical distribution for steel alloys atomised in the plant. After conditioning the powder for flowability and usability in the AM process, the samples for parameter analysis were produced as defined above. Sample production took place on an SLM 280 HL. Laser power, hatch distance and scan velocity were varied. For both materials, 30 µm layer thickness was used. After grinding, polishing and etching the samples, the microstructure was analysed with a Scanning Electron Microscope (SEM) and a light microscope. Results for the AISI 4140 porosity analysis are shown in Fig. 8.

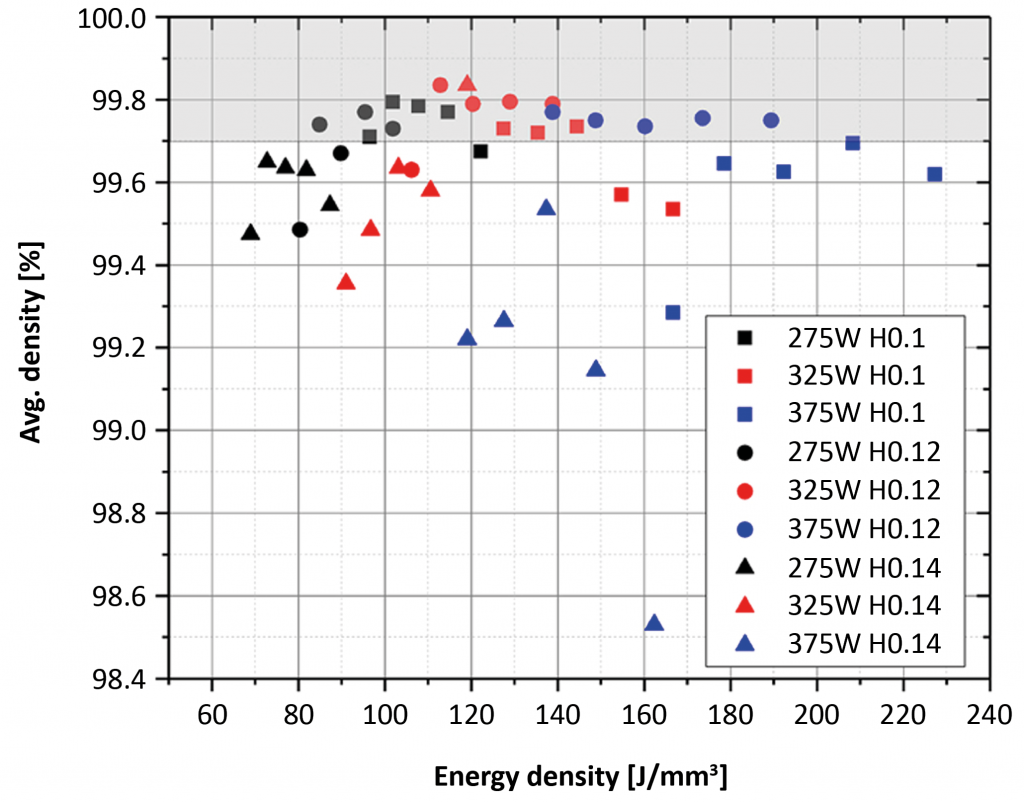

The image shows results for different laser powers and scan velocities and gives an impression of the influence of the different parameters on the development of pores with changing volume energy. A full overview over the achieved densities is given in Fig. 9.

The diagram shows the average material density plotted versus the energy density. The different shaped markers indicate different hatch distances and the colouring refers to the laser power. The results show that neither a high nor a low energy density performs best in the case of average material density. Choosing a certain set of parameters is also always choosing between a dense material and build rate, since both criteria are often in conflict with one another. The final set of parameters here was chosen with a hatch distance of 120 µm, 275 W laser power and a scan velocity of 900 mm/s.

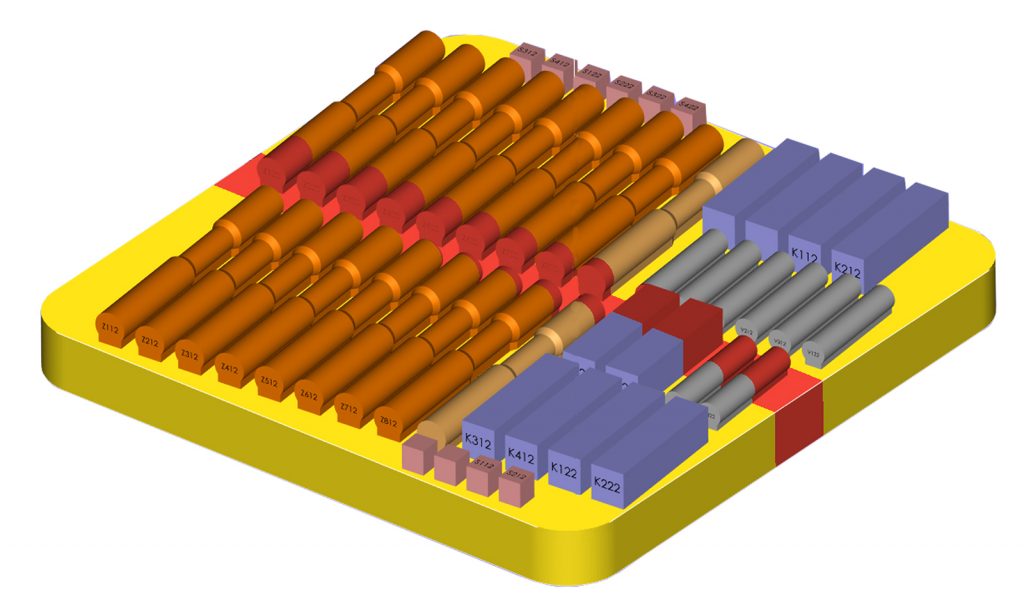

With the given parameters, a second build job with different sample geometries for impact and tensile strength measurements was carried out according to Fig. 10. The plate shows that, even with a very small build job, in terms of height, a large number of samples can already be created. After the build, some of the AISI 4140 samples were hardened for 20 min at 850°C and quenched in oil. Afterwards, a tempering process took place at 450°C for two hours followed by cooling at room temperature under ambient conditions.

The samples were mechanically machined to achieve a sample geometry in accordance with DIN 50125. Some parts were heat treated afterwards. This consisted of soft annealing and hardening followed by tempering. The tensile strength testing was conducted in accordance with existing ISO standards. The sample was tested at room temperature and at 400°C.

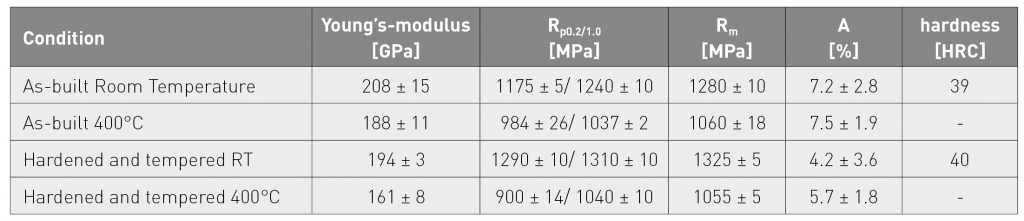

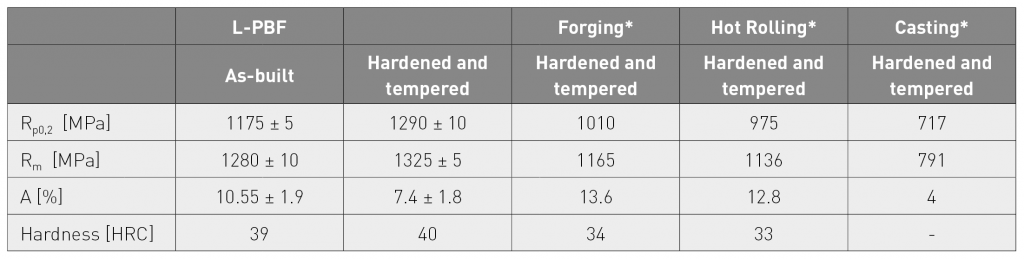

Further tests were carried out, such as the Charpy impact test. Here, standardised samples with a v-shaped groove are broken by a drop hammer. The energy the hammer transfers to the sample is a measure of the toughness. Hardness was measured with Rockwell and a diamond cone with an angle of 120°. Table 1 shows the results of mechanical testing for the AISI 4140.

The data show that the mechanical characteristics at 400°C are below the values measured at room temperature. This is because of the easier movement of dislocations in the material. The difference between the heat-treated samples and the as-printed samples are small compared to the temperature influence. In general, the as-built samples have a 16% lower tensile strength than the tempered ones.

In Table 2, a comparison between the additively produced samples and conventionally produced samples is shown, to further evaluate the performance of the L-PBF process. The comparison shows that the L-PBF process performs in the same range of magnitude as the conventional samples. Depending on the manufacturing route, it can even outperform conventional production processes for the given characteristic values.

Results for AISI M2

AISI M2 was prepared in the same manner as the 4140 steel, beginning with a parameter development evaluation by printing cube samples and analysing the achieved material density. Some results are given as an example in Fig. 11.

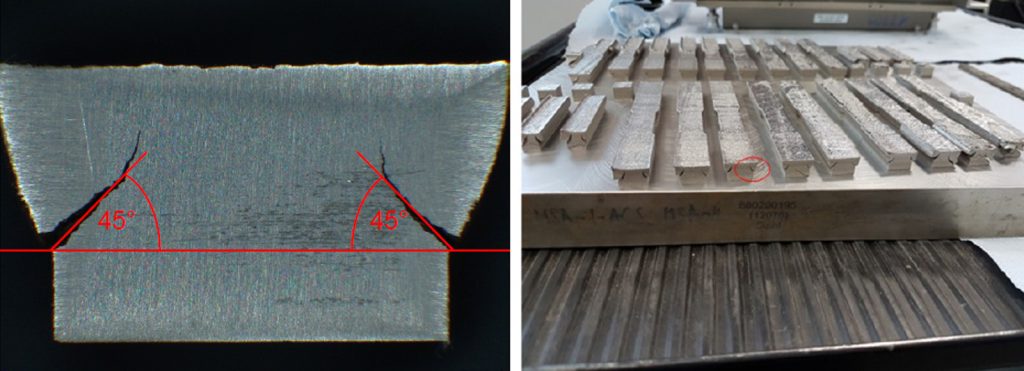

This figure shows that it is generally possible to achieve a good first material structure, in terms of overall material density. After using the results to validate a first set of process parameters, a sample build job was produced comparable to the build job shown in Fig. 10. Despite the fact that a sufficient material density can be achieved, the production of AISI M2 samples was aborted due to major defects during the recoating process as a result of part distortion and cracking (Fig. 12). The fractures result from a brittle carbide network and internal stresses due to the high cooling rates within the L-PBF process.

Although experiments to assess the mechanical properties of AISI M2 were not possible, this alloy should perform in the tempered state much better in terms of wear behaviour in contrast to the untreated part thanks to the precipitation of carbides. These should also lead to an increase in tensile strength, because of the blocked dislocation movement.

Conclusion

Within the scope of the works of R Koch 2018 [3] and J Damon 2019 [4], together with Rosswag Engineering, the material qualification process for AISI M2 and an AISI 4140 was performed. The process was covered from powder production up to the production and testing of characteristic mechanical values, including a preceding parameter study for the L-PBF process.

Both materials show a sufficient material density when an appropriate set of process parameters is selected. In the case of AISI 4140, a build job with additional samples was realised and the mechanical data achieved, due to impact and tensile strength testing, as well as hardness testing, was compared considering different heat treatments and different sample manufacturing routes (i.e. casting, hot rolling and forging). The data show that, for the given static mechanical results, the AM samples are compatible and, in some cases, even outperform the conventional samples (here produced by casting and hot rolling).

In contrast to these results, AISI M2 poses a good example regarding the importance and essence of time frame within the qualification process. Due to the short and fast iteration cycles in the proposed qualification process at Rosswag, the problems with the M2 could be identified in an early project state, and a fast decision about the further development was possible without losing more time or money than needed for initial tests.

Author

Daniel Beckers

Project Engineer

Rosswag GmbH

August Rosswag Straße 1

76327 Pfinztal

Germany

Tel: +497240 9410 614

[email protected]

www.rosswag-engineering.de

References

[1] D. Schwenck, N. Ellendt, J. Fischer-Bühner, P. Hofmann und V. Uhlenwinkel, “A novel convergent–divergent annular nozzle design for close-coupled atomisation,“ Powder Metallurgy, pp. 198-207, February 2017.

[2] P. Schwarz, Entwicklung und Validierung einer Prüfvorrichtung zur Untersuchung der Fließfähigkeit von AM-Metallpulver, Hochschule Aalen, 2018.

[3] R. Koch, Development and investigation of different alloying concepts for the processing of tool steels by using additive manufacturing, Karlsruhe: Karlsruher Institut für Technologie / Institut für angewandte Materialien, 2018.

[4] J. D. e. Al., „Process development and impact of intrinsic heat treatment on the mechanical performance of selective laser melted AISI 4140,“ Additive Manufacturing, pp. 275-284, 28 August 2019.

[5] M. Sanij, S. Banadkouki, A. Mashreghi and M. Moshrefifar, “The effect of single and double quenching and tempering heat treatments on the microstructure and mechanical properties of AISI 4140 steel.,” Materials and Design , 2012.

[6] A. Miklin, Entwicklung einer Fertigungstechnologie für dünnwandigen Stahlguss., Technischen Universität Bergakademie Freiberg, 2010.