United Technologies: Pioneering new possibilities for Additive Manufacturing in aerospace

United Technologies Corp (UTC), through its Pratt & Whitney and Collins Aerospace businesses, has a long history of innovation in aerospace engineering. As Venkat Vedula, Executive Director of UTC’s Additive Manufacturing Center of Expertise (AMCoE), and Vijay Jagdale, the centre’s Principal Engineer, explain, this tradition is today being continued through the corporation’s cutting-edge Additive Manufacturing activities. This report highlights, with the support of an in-depth case study, the centre’s core areas of activity and UTC’s vision for the future of AM. [First published in Metal AM Vol. 5 No. 2, Summer 2019 | 20 minute read | View on Issuu | Download PDF]

From the propeller that powered Amelia Earhart’s non-stop flight across the Atlantic, to the space suits worn by generations of US astronauts and the communications equipment that captured the footage of the first step on the moon, United Technologies Corp (UTC) and its businesses have over decades helped to define the aerospace and defence industries. Today, with more than 110,000 aerospace employees stationed globally at over three-hundred sites, UTC continues to drive innovation in commercial and business aviation, intelligent defence solutions, helicopter systems and spacecraft design and production. The company’s portfolio also powers communications, navigation and surveillance technology for the world’s leading aircraft companies.

As part of United Technologies, Pratt & Whitney and Collins Aerospace Systems represent the enterprise’s deep commitment to aerospace innovation. Both businesses have a long history of manufacturing ingenuity, and each played a critical role in building the modern air transportation network. Now, as new technologies fuel rapid advances in the aerospace industry, UTC is building on its legacy of innovation with cutting-edge Additive Manufacturing initiatives. For over three decades, UTC and its business units have been using AM to prototype polymer and non-metallic parts. But more recently, recognising the vast potential of metal AM, the company has ramped up its efforts through the creation of UTC’s Additive Manufacturing Center of Expertise (AMCoE) in East Hartford, Connecticut, USA (Figs. 1-2).

“UTC companies helped build the second industrial revolution in the early decades of the 20th century,” said John-Paul Clarke, Vice President of strategic technology at UTC. “As we build the next industrial revolution, additive could be a game changer in manufacturing. Our AMCoE is a mechanism for driving a critical mass capability across the enterprise.”

Accelerating the adoption of Additive Manufacturing across the enterprise

While each business unit under the UTC umbrella has its own path on the UTC AM roadmap, the AMCoE is a cross-divisional organisation that aims to bring the creative minds in materials science, mechanical design, diagnostics and machine learning together to solve the toughest challenges. Launched two years ago, the AMCoE is responsible for accelerating the adoption of AM across UTC’s engineering and manufacturing organisations. The initiative is focused on three key goals: achieving process certification for key AM processes, deploying a design-for-additive toolchain and training UTC’s engineering and operations teams on both AM design and manufacturing. Together with ongoing efforts at individual UTC business units, the initiative will demonstrate new engineering and operations capabilities to produce cost-competitive additively manufactured parts across a range of materials and functions. The current focus is on nickel-based superalloys, titanium, aluminium and engineered plastics for brackets, fuel nozzles, complex manifolds and other components.

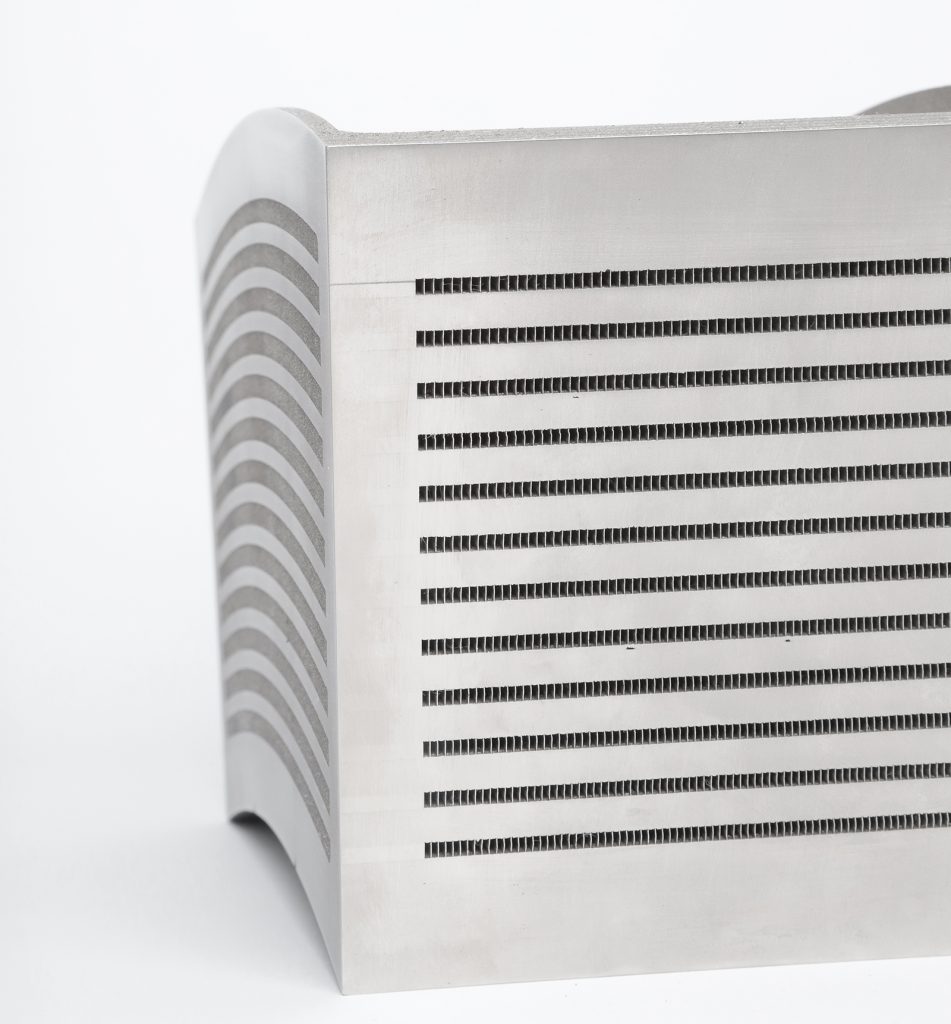

Most recently, UTC broke new ground in its AM efforts through the successful design, full-scale build and testing certification of a conformal heat exchanger, which this article will explore in greater detail. “Until now, manufacturing has been constrained by what’s possible,” stated Venkat Vedula, Executive Director of UTC’s AMCoE. “But with additive, if you can imagine it, you can build it. In partnership with America Makes and the Collins Aerospace additive team, the conformal heat exchanger demonstrated that Additive Manufacturing opens the door to novel designs that allow us to truly optimise for performance.”

Changing thinking, opening new markets

While the AMCoE is a catalyst for scaling AM operations across the enterprise, it’s hardly UTC’s first or only foray into the field. Since the 1980s, Pratt & Whitney has additively manufactured more than 100,000 prototypes, hundreds of which supported the development of its PurePower® Geared Turbofan™ (GTF) engine range. In 2017, the company took the major step of entering additively manufactured parts into production for its PW1500G Geared Turbofan engines, which were used exclusively by Bombardier for its CSeries aircraft family, now branded as the Airbus A220.

“Additive Manufacturing isn’t just driving improvements in performance and quality, it’s changing the way we design and even think about manufacturing challenges,” explained Jesse Boyer, Technical Fellow at Pratt & Whitney. “Each additive project we undertake generates insights and creates opportunities for the ones that come next.” Building on its decades of work in this area, UTC has already begun to realise new market opportunities, thanks to AM. For example, at Collins Aerospace, a fully additively manufactured industrial fuel nozzle (Fig. 3), produced with just four components – compared with the seventeen components necessary for a legacy standard fuel injector (Fig. 4) – opened up new possibilities for the business in the diesel segment. The AM fuel nozzle also yielded notable advantages, such as 75% shorter lead time, 10% weight reduction, 70% fewer operational steps and 80% less raw material.

“Additive Manufacturing gives engineers so much flexibility to solve our customers’ challenges,” commented Paula Hay, Executive Director of Additive Design and Manufacturing at Collins Aerospace. “The fuel nozzle solved a technical problem and enabled us to reach a new customer market the older product couldn’t serve. As we drive toward the future, we’re looking at the next level. How can we really take advantage of additive to create new designs that bring the biggest benefits?”

Next-level manufacturing for next-level aerospace technology

As the next generation of aircraft technology becomes more sophisticated, it seems clear that getting the most out of Additive Manufacturing – with new designs and novel concepts – will become more important than ever. Inspired by that challenge, United Technologies recently partnered with industry accelerator America Makes to develop a heat exchanger produced using Laser Powder Bed Fusion (L-PBF) for the Department of Defense and Air Force Research Laboratory (AFRL) [1]. New head-up displays, onboard electronics and other avionics, as well as engine advances, will create increasingly aggressive cooling requirements for thermal management systems. As a result, heat exchangers will need to meet a more advanced level of performance in the same or more constrained space.

The UTC-led team, which included UTC’s AMCoE, the United Technologies Research Center (UTRC), Collins Aerospace, Pratt & Whitney, Stratonics and 3DSIM, set out to achieve several goals:

- Establish a quantitative link between key product characteristics and the manufacturing process parameters required for repeatable and reliable fabrication

- Address key risks and gaps in AM processes, including in-situ defect detection, non-destructive inspection and thin-fin manufacturing capabilities

- Demonstrate an additively manufactured heat exchanger and value proposition relevant to the Department of Defense and AFRL

“Heat exchangers play a critical role in the thermal management systems that remove heat generated from advanced electronics and more efficient jet engines,” stated Brian St Rock, Project Manager, America Makes / AFRL project, UTRC. “But even though they must handle greater demands, performance improvements have been hindered by the limitations of traditional manufacturing. This project gave us an opportunity to experiment with conformal shapes that let us put performance first.”

The proposed benefits of AM in a heat exchanger application

Traditional heat exchangers are rectilinear, box-like forms created with metal roll sheets that are brazed and welded together in a multi-step process that is often associated with low yield. Because the heat exchanger must fit into constrained, non-rectilinear spaces on aircraft, sometimes wrapped around the engine core, these linear segments are connected using transition headers to make a curved conformal shape. But the addition of these bridge-like components adds volume and weight and can create efficiency losses.

Conformal heat exchangers with curved sides and without the transition headers will improve thermal performance and flow distribution while reducing volume by around 10%. But manufacturing such heat exchangers through traditional methods is economically unfeasible and operationally arduous. Additively manufactured heat exchangers, on the other hand, promise to more effectively use overall volume by eliminating welding lines and distribution headers, thereby unitising the structure and improving yield, as well as reducing lead time for new products. They also improve thermal performance and flow distribution through complex fin topologies and spatially varied geometry. Localised geometry modifications, such as fillets, can also reduce stress concentrations and improve fatigue life.

A preliminary optimisation and benefit assessment conducted by UTC suggested that with an advanced additively manufactured heat exchanger design, a 40% improvement in precooler UA per unit volume (the product of the overall heat transfer coefficient and the heat transfer area) could be achieved. That would correspond to a 29% improvement in cooling capacity or an 11% decrease in the amount of engine bleed needed to drive the thermal management system.

Limitations of the typical AM approach

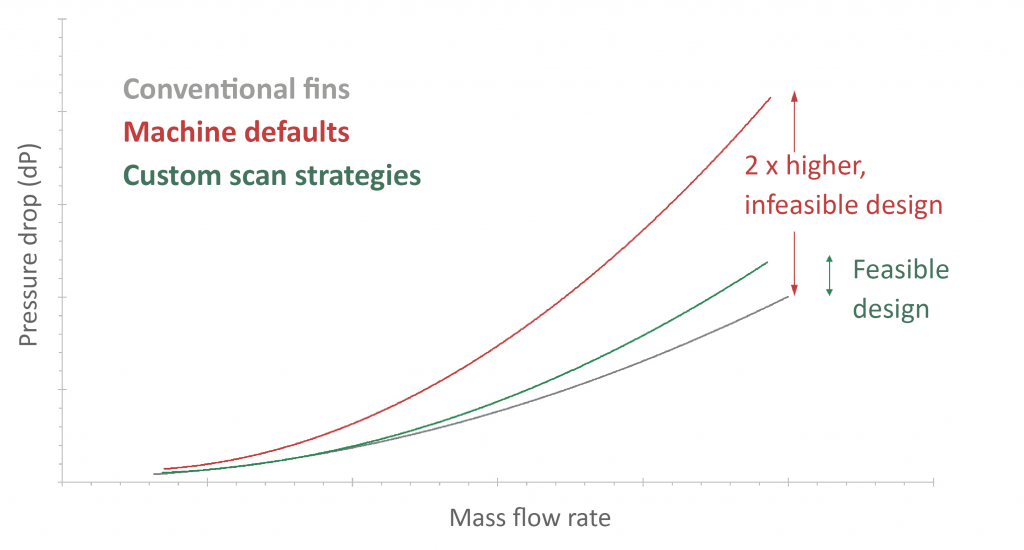

Around 150 different process parameters can influence AM, from power to scan speed to build orientation. In a typical AM process, engineers assign a uniform set of parameters (also called ‘defaults’) to an entire component. But existing AM technology is not without its limitations. When it comes to producing a heat exchanger, merely switching from traditional manufacturing to out-of-the-box AM actually more than doubles the volume of the part, largely because default AM scan strategies generate fins that are 0.25 to 0.4 mm thick with a surface roughness of 7.6 to 25.5 micron, depending on build orientation. That is significantly greater than traditionally manufactured fins, which are 0.1 to 0.15 mm, with a surface roughness of 0.1 to 0.4 micron. When the fins are too thick and rough, the pressure drop exceeds the requirement. Indeed, it can be two-to-ten times higher than with smooth conventional fins.

While roughness can help increase heat transfer, depending on the fluid, its impact on the pressure drop is more significant. This is a highly critical trade-off and, if the roughness issue is not properly addressed, the resulting AM heat exchanger will not perform as needed (Fig. 7).

Cutting a new path

To achieve the aggressive goals of the project, which touched various aspects of the AM value-chain, UTC assembled a multi-disciplinary team of experts with backgrounds in product engineering, design, AM, process modelling, in-process sensing and post-processing. UTC also embraced an approach that was systematic, model-guided, performance-driven and feature-based. This strategy enabled them to drive new Additive Manufacturing build strategies, develop a robust AM process and, as a result, create an effective heat exchanger (Fig. 8).

“This project provided freedom and required creativity, which made it a fascinating undertaking,” commented Vijay Jagdale, Principal Engineer at the UTC AMCoE and lead investigator on the project. “We had to ask, ‘What are the critical features of the heat exchanger that are driving performance? And what is the response needed at the feature level?’ That thought process led us to focus on the fin thickness, its surface roughness and leak-free parting sheets.”

Recognising the constraints of existing AM technology, UTC internally developed a product performance prediction tool to conduct the trade-off analysis between surface roughness and pressure drop and provide the necessary manufacturing targets. “The industry is still developing post-processing techniques to achieve the desired surface finish reliably and repeatably, as well as thermal post-processing to control defects,” Jagdale continued. “Many a time, this can add up to be a significant portion of the additive product cost. We set out to minimise post-processing required to achieve surface roughness targets in the as-built configuration, as well as avoid the Hot Isostatic Pressing (HIP) process. This required taking calculated risks and pushing the limits of the technology through novel build strategies.”

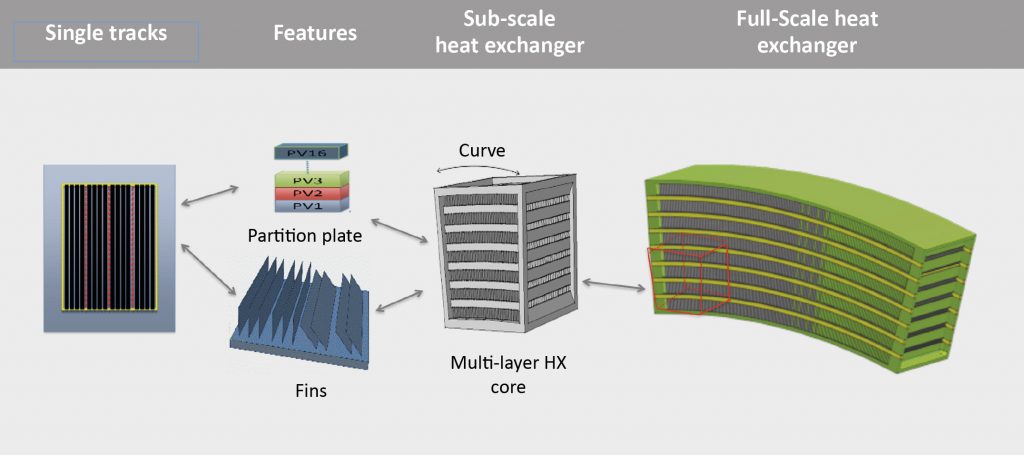

One of the team’s critical innovations was to divide the geometry of the desired heat exchanger into various sections, including fins, parting sheets and headers. From there, they worked together, sample by sample, to use process models, in-situ process monitoring and process-mapping approaches to identify the optimal build strategies and parameters for each specific section (Fig. 9). Given that existing commercial AM toolchains and build set-up programs do not allow for the level of customisation required, UTC developed many new tools and approaches to enable the AM machines to, ultimately, create the desired end product.

“We took on more risk than some of our team members were accustomed to,” Jagdale stated, “but we were comfortable, because our hypothesis was supported by physics-based models and a rigorous experimentally-validated scale-up approach.”

Fuelling innovation through physics-based modelling

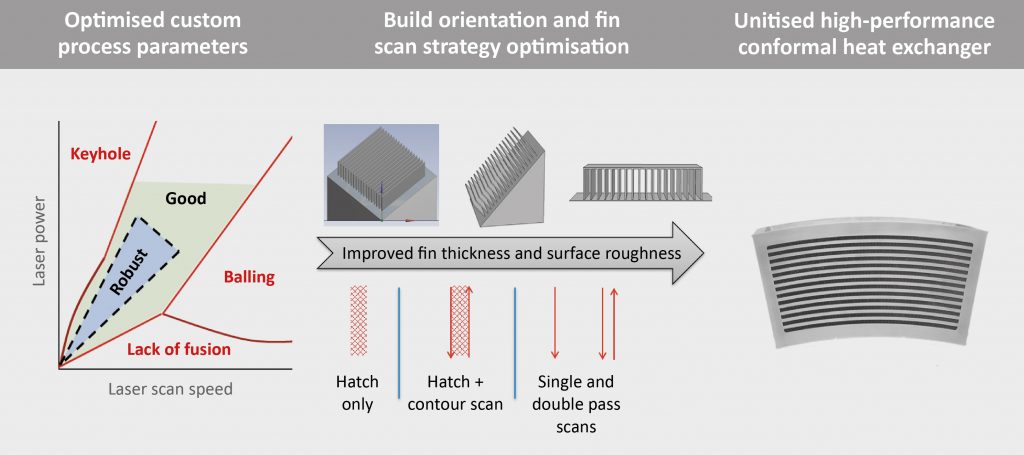

UTC’s physics-based model takes important process inputs into account, including key powder feedstock characteristics, machine and laser level characteristics, thermo-physical material properties and key scan strategies, and then predicts a feasible process space in terms of laser power (P) and scan speed (V). It can also help classify process zones according to how defect-prone they may be, from predicting lack-of-fusion defects and balling to identifying conduction-dominated ‘good’ zones and keyhole regions of higher energy intensity (Fig. 10).

Once the model identifies ‘good’ zones, it is possible to then superimpose other variables, such as feature resolution, residual stress, distortion, microstructure and surface roughness, to narrow down the process parameter selection as a function of a particular feature and its performance needs. This physics-based model enabled the UTC-led team to rapidly develop a feasible process space, use select experiments to validate the process map and use these feature-based parameters for heat exchanger development.

This approach to modelling also helped empower the team to abandon the traditional linear waterfall approach to manufacturing, in which product engineers hand over directions to designers, who in turn deliver digital CAD files of 3D models to manufacturing operators, stated Jagdale: “Usually designers, product leads and manufacturing teams work in siloes, barely speaking to each other. For this project, we were collaborating and iterating continuously.”

A rigorous, repeatable approach for AM heat exchanger manufacturing

The team’s willingness to test new boundaries and ways of working ultimately paid off. When the programme comes to a close this summer, they will have not only developed a high-performance conformal heat exchanger, but a systematic, repeatable methodology for manufacturing it. Compared to one produced conventionally, UTC’s heat exchanger achieves about a 20% increase in heat exchanger effectiveness for the same volume. As the team continues to refine its proprietary parameters and scan strategies, as well as incorporate advanced heat exchanger topologies, it expects to move even closer to the over 30% reduction in volume suggested by its initial analysis.

So far, this approach has reportedly been demonstrated successfully on machines provided by three different OEMs. While this first project focused on the Inconel 625 alloy, the UTC team is also developing aluminium alloy heat exchangers internally. The machine and material-agnostic build strategies approach was assembled with material-specific parameters to enable an orders-of-magnitude reduction in product scale-up time.

Along with establishing a prescriptive methodology for the additively manufactured heat exchanger, the team also developed a comprehensive set of process data that enabled valuable links to be made – from acceptance test anamolies to indications identified in a CT scan, to the appearance of that indication on the in-situ process sensor during the build. These data-driven connections have the potential to support a digital thread for the entire Additive Manufacturing process and ensure the appropriate parameters are guiding its development.

New applications for conformal techniques

While the new heat exchanger itself is a valuable outcome of the project, the team’s new ability to successfully build a conformal component is expected to open the door to a broader range of opportunities for Additive Manufacturing at UTC. “The fact that we were able to do things conformally is a huge piece of the puzzle,” stated Hay. “That really creates new possibilities for us.” For example, now that the team has demonstrated that it can additively manufacture parts robustly and utilise feature-based scan strategies, UTC can advance novel concepts in designing flow passages that improve efficiency in thermal management systems.

And further, Hay said it brings UTC closer to unlocking the true value of Additive Manufacturing. Replacing existing, traditionally manufactured parts with AM parts can deliver some advantages. But, she emphasised, the real potential is leveraging the design freedom offered by AM.

Ready for takeoff

The motivating factor in all of UTC’s work in AM is the enterprise’s planned shift from development into production. The company has built up a strong base of materials knowledge and process-related best practices through years of prototypes and proof-of-concept projects. Now, it is focused on working through the certification and regulatory agencies that will help scale production. Part of that focus requires enhancing internal knowledge of its AM processes to enable it to overcome machine-to-machine variations and truly standardise part production. Another part of that means working with external partners so that the industry is aligned with itself and the regulatory bodies responsible for certification and approvals.

Hay noted that the heat exchanger project, conducted with America Makes and other partners across the industry, is a good example of the kind of collaboration the industry needs in order to move forward. Given that so many groups, from peer companies to academic institutions to AM associations, are working toward similar goals, she said it only makes sense for everyone to work together. “We’re driving toward the adoption of additive,” said Hay. “But we can’t do it alone. Additive is ready for takeoff. There’s no stopping what it can do.”

On the horizon

In the coming years, UTC’s AM initiatives, including the AMCoE and the United Technologies Research Center, will continue to explore new developments in materials, design, and data analytics. In addition to sharpening its understanding of materials systems commonly used today, the company is working to identify future materials that could advance industrial manufacturing. Controlled microstructures and custom alloys, for example, are expected to play bigger roles as the field pushes technology to new limits.

Building end-to-end design tools for AM that capture the entire value-chain, from mechanical design to analysis to post-processing, is another key priority for the enterprise. New technologies and new ways of working mean engineers need better tools for guiding decisions, managing workflow, validating cost assessment methodology and, in general, making ‘smarter’ choices with the new platforms.

“One of our key challenges is that we don’t have design tools that offer end-to-end toolchains,” commented Vedula. “The industry needs tools that can optimise the process from concept and design all the way through to production.” Applying cutting-edge data analytics insights to Additive Manufacturing is also a critical target. For example, UTC is developing an automated, robust data-harvesting process that will establish a data path from initial part material feedstock to final characterisation. The goal is to assimilate unstructured and pre-aggregated data into a database environment that facilitates trend generation and reporting. It is also using machine learning methods to enhance the build quality of additively manufactured parts and develop a deeper understanding of the AM process.

Furthermore, the team is currently looking at the development of ‘smart’ parts, developed by embedding sensors in additively manufactured components. While industry peers are also pursuing Additive Manufacturing solutions, UTC believes that it is carving its own approach to accelerating AM development and deployment. With more than ninety years of manufacturing experience and over 430 unique patent families in AM technologies, the company is uniquely qualified to integrate AM technology into the design process. Its combination of physics-based models and in-process monitoring is unlocking an in-depth understanding of the process’s capabilities and limitations, which will advance adoption through the certification of material and machine combinations. In short, this heat exchanger project demonstrates how UTC’s holistic approach to AM balances the drive to get AM parts to production quickly, while achieving or exceeding aerospace quality standards.

Authors

Venkat Vedula

Executive Director, Additive Manufacturing Center of Expertise, United Technologies Corporation

Vijay Jagdale

Principal Engineer, Additive Manufacturing Center of Expertise

United Technologies Corporation

www.utc.com

References / notes

[1] This material is based on research sponsored by Air Force Research Laboratory under agreement number FA8650-16-2-7230. The U.S. Government is authorised to reproduce and distribute reprints for Governmental purposes notwithstanding any copyright notation thereon.

The views and conclusions contained herein are those of the authors and should not be interpreted as necessarily representing the official policies or endorsements, either expressed or implied, of Air Force Research Laboratory or the U.S. Government.