High-performance nickel-base alloys for Additive Manufacturing: A review of their limitations and potential

Nickel-base superalloys are an important material group for components used in the gas turbine, aerospace and chemical processing industries. Many of the well-established superalloys available today do not, however, adapt well to processing by Additive Manufacturing. In this article, Dr Tatiana Hentrich and Dr Christina Schmidt, VDM Metals International GmbH, present an overview of nickel-base alloys with a focus on strengthening effects, mechanical properties and weldability, comparing production challenges by conventional production routes and Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing. [First published in Metal AM Vol. 6 No. 3, Autumn/Fall 2020 | 20 minute read | View on Issuu | Download PDF]

Conventionally produced wet corrosion, high-temperature (heat resistant) and special purpose nickel-base superalloys such as Alloy 59, Alloy 625, Alloy 718, Waspaloy, Alloy 939, Alloy 738 and Alloy 247 have been in existence for decades. They are widely used in demanding industries such as gas turbine production, aerospace and the chemical processing industries, and belong to the most studied of alloy systems. While the focus for the development of most wrought Ni-base alloys has generally been on post-processing properties such as weldability, the development of superalloys has primarily concentrated on end-part performance. Furthermore, the weldability of superalloys was sacrificed for the increase in strength as related to the volume of strengthening phases. Consequently, many superalloys are available as castings.

To date, research into Additive Manufacturing using Ni-base powders has led to some interesting results. However, for a successful transfer to the commercial series production of components by processes such as Powder Bed Fusion (PBF) and Directed Energy Deposition (DED), material performance remains a critical factor.

Unfortunately, the use of established nickel-base alloys designed for casting is not viable because of their specific thermodynamic properties, such as phase precipitation kinetics and crack susceptibility, unless the processing side of AM, including post-processing, progresses significantly.

This article presents an overview of nickel-base alloys with a focus on strengthening effects and mechanical properties in relation to conventional production routes and weldability, including the related opportunities and limitations for Additive Manufacturing. Moreover, we will discuss the newly-developed alloys VDM Alloy 699 XA and VDM Alloy 780, designed for high-temperature usage in chemical processing and aircraft applications by VDM Metals Group, a specialist in high-temperature nickel alloys, cobalt and zirconium alloys and high-alloyed special steels, headquartered in Werdohl, Germany.

The motivation for this paper arose from discussions with customers and partners from different projects on aspects of material selection, for example, for part design and prediction of total life to failure. This article is not intended to replace scientific work and/or publications in AM. However, it should help to build an overview and guide a successful implementation of Ni-base materials processed by AM.

The motivation for an Additive Manufacturing business case

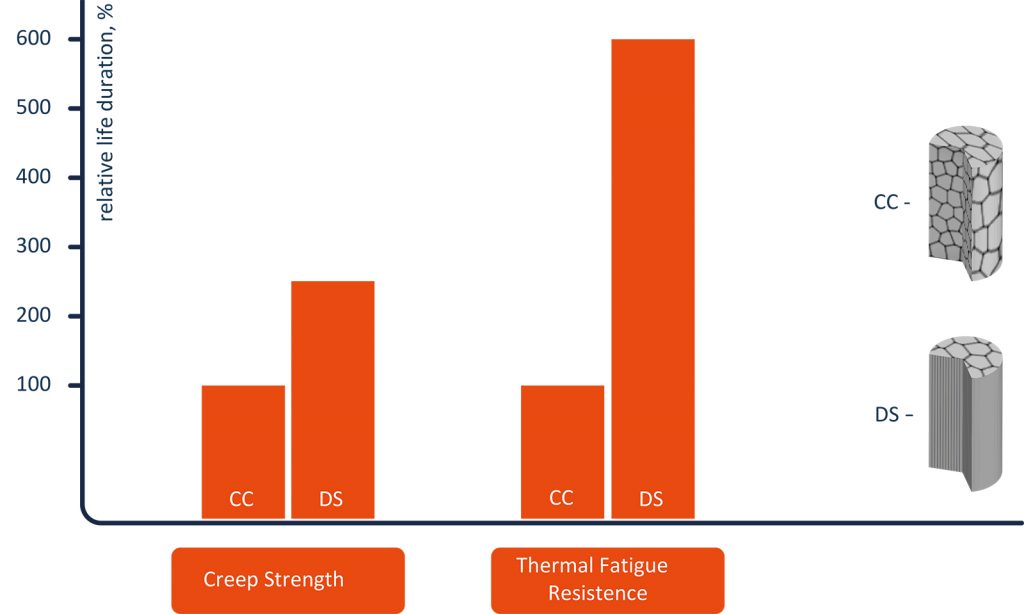

Additive Manufacturing, as a comparatively new group of manufacturing processes, has made rapid progress in recent years. AM best fulfils industrial niches which require a low production volume of parts, and complex designs that formative or subtractive manufacturing methods are unable to produce due to high costs, logistics or long delivery times. In the process of selecting components suitable for developing a business case for AM, some further aspects should be considered:

- Material production costs, including virgin metals and alloy production costs

- Customisation degree, usually combined with the opportunity for improvement of performance efficiency

- Part size

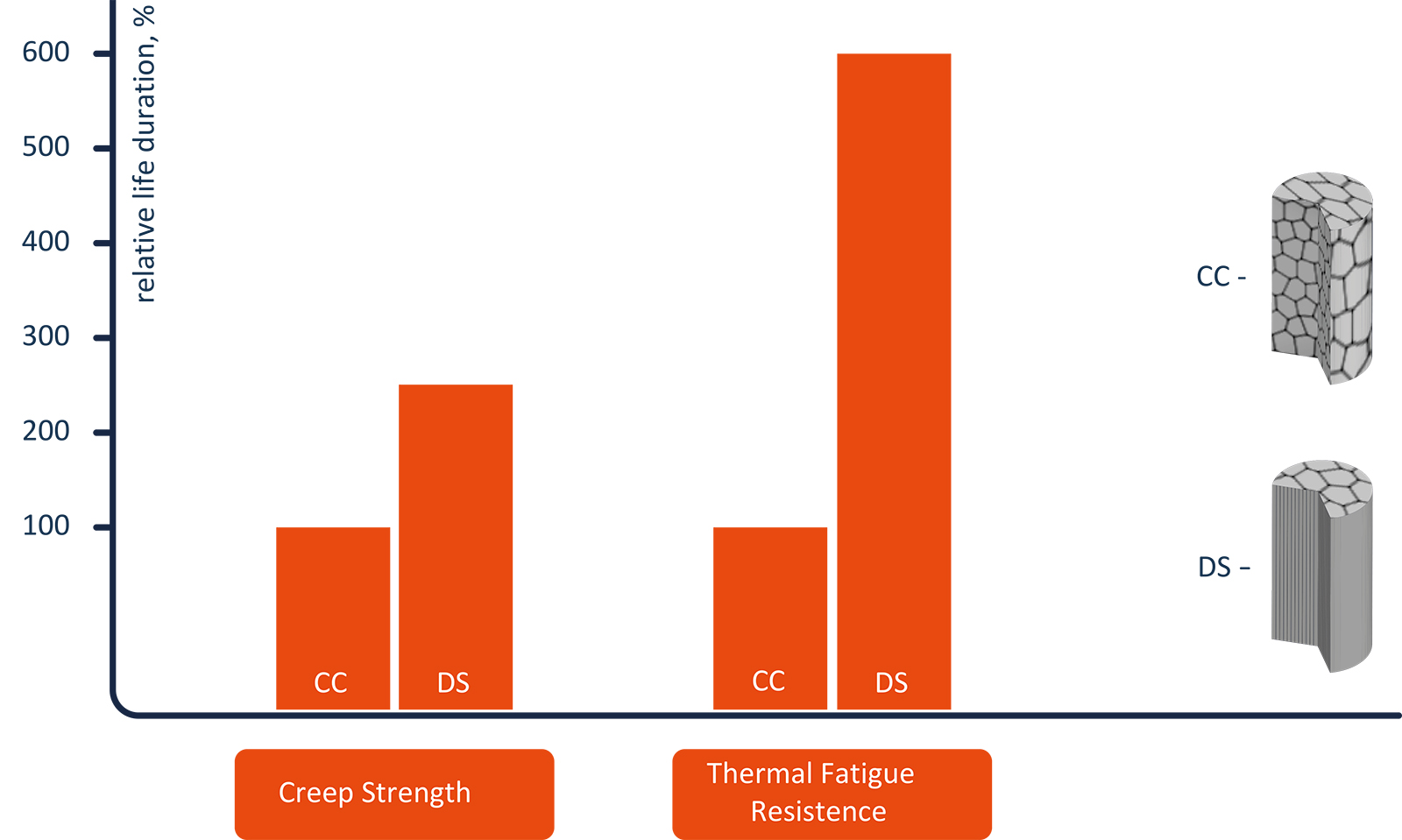

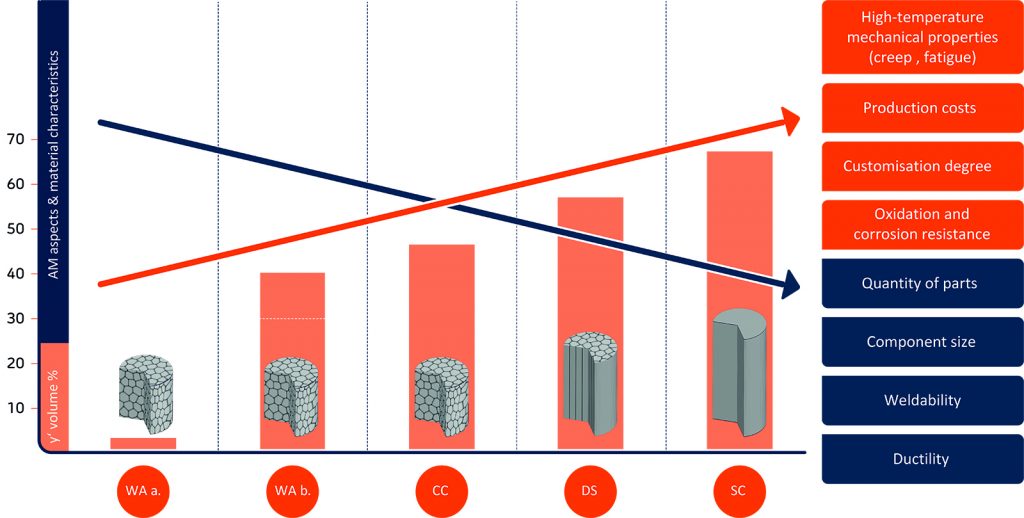

In many industries, AM is seen as a performance enabler, rather than a cost-reduction enabler. What needs to be accounted for is the benefit derived versus euros spent. In this case, material performance becomes a key factor. The casting process for turbine blades using conventional production technologies can be used as an example here: switching from the conventional cast (CC) process to the conventional directional solidification (DS) process results not only in a change of microstructure from polycrystalline to columnar-crystalline, but also in an increase in the creep strength of the material by 150%, and thermal fatigue resistance by 600% (Fig. 1) [1].

The major difference in the material in this case is in its microstructure, in particular the much lower number of grain boundaries and their orientations. This means that not only the previously highlighted motivations for using AM should be considered when making a business case, but the material performance of the conventional part must be compared with the AM part.

In this paper, we will discuss current industry standards and the requirements, opportunities and limitations of the existing alloys and available industrial machines for Laser Beam Powder Bed Fusion (PBF-LB). Also discussed are material characteristics, which are important to consider in successfully implementing high-performance alloys in AM.

Fig. 2 summarises aspects of the selection process for AM parts, as discussed above. The first potential problem that can be seen in this figure arises if DS alloys are considered. Small quantities of parts, relatively small part sizes, high levels of mechanical properties (creep, fatigue, oxidation and corrosion behaviour) and high production costs can all be readily identified in the selection process for potential AM part substitution. In addition, the high potential for customisation and increase in a component’s efficiency achievable with specific AM opportunities make parts produced with the DS technique very promising for the AM community. However, the currently-available AM processes produce polycrystalline structures (and so the expected properties decrease automatically on the left side of Fig. 2); secondly, conventional DS alloys are very difficult to weld, and achieving some complex geometries with the AM process may be problematic.

Generally, the main challenge to the successful application of high-performance Ni-base superalloys to be addressed is weldability. Another challenge relates to microstructural considerations: during AM processing, inherently small grain sizes are produced, elongated in the build direction, resulting in anisotropic material behaviour. This may cause a significant variation between a component’s expected and actual performance.

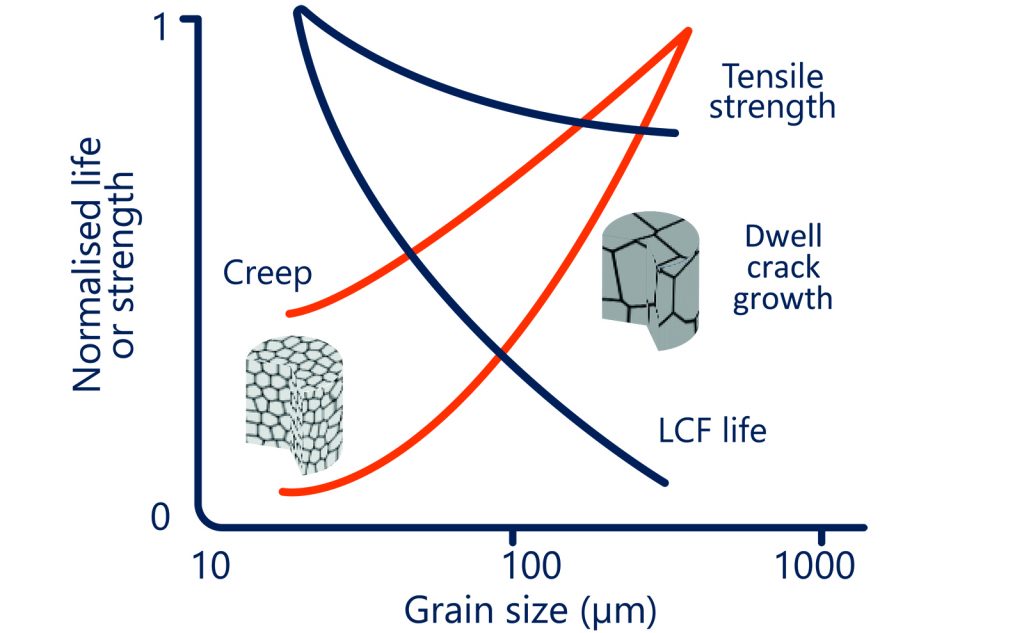

Properties such as creep strength, fatigue resistance and stress-rupture properties for AM parts can be degraded, compared with conventionally produced parts, if dimensional adjustments are not made. If the grain sizes of CC materials are around 1 mm and the grain size of DS materials is about 10 mm in the load direction, the grain size of AM materials is significantly smaller than 1 mm. This reduces the expected creep properties of AM parts, even in comparison with CC components.

The classification of Ni-base alloys according to application, conventional production methods and volume of strengthening phase

Ni-base alloys are widely used because of their unique characteristics – nickel does not change its crystal structure, in contrast to iron (Fe) or cobalt (Co), with a similar high melting temperature, and reveals good corrosion and oxidation resistance. Due to the Face Centred Cubic (FCC) structure, these alloys have a low diffusion rate at high temperatures. Ni can dissolve many alloying elements – up to around 50 wt.% – and many modern Ni-base alloys contain more than ten alloying elements. Alloying with Cr, Mo and Al is responsible for significantly improving corrosion and oxidation resistance. Al triggers another important effect in Ni-base alloys, as it is responsible for the precipitation of the strengthening γ’-phase.

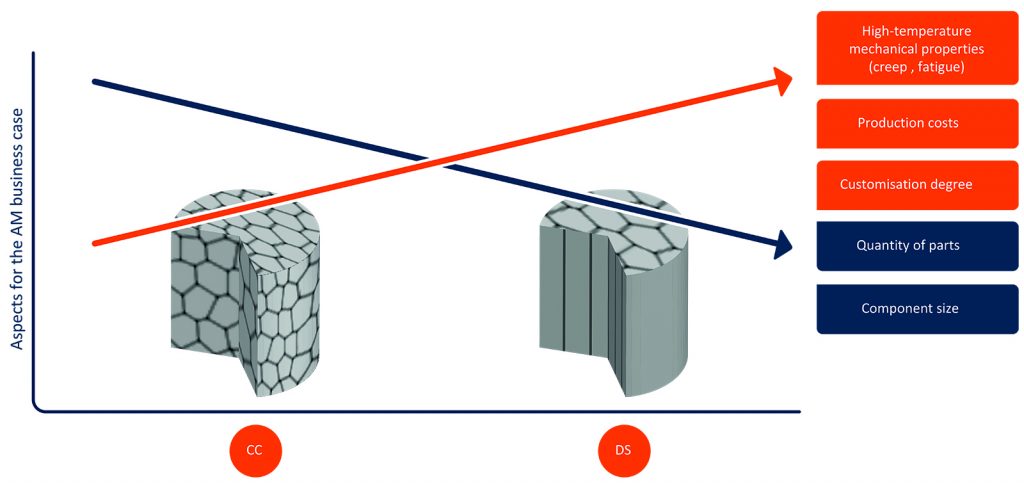

Generally, Ni-base alloys can be divided into three classes: wet corrosion alloys, high-temperature alloys and special alloys, as shown in Fig. 3.

High-temperature alloys can be further split into two groups: heat-resistant alloys and superalloys. The major difference between these groups is the main strengthening mechanism: superalloys are strengthened by γ’-phase, which will be considered later.

On the basis of market size, most Ni-base wet corrosion, heat-resistant and special alloys are wrought alloys. They have found a wide range of application in the chemical processing, oil & gas, automotive and power generation sectors. Because of their chemical composition and specific production route, the following strengthening techniques can be used:

- Solid solution hardening

- Precipitation (carbides) hardening

- Fine grain or cold-forming hardening, depending on application temperature

γ’-phase can precipitate in these alloys, particularly in the case of Al additions; however, this generally only occurs in small amounts. Thus, alloys such as Alloy 59, Alloy 625 Grade I or Alloy 699 XA show an excellent combination of corrosion resistance and mechanical properties at moderate temperature levels. Moreover, due to design and application requirements, many efforts have been made during alloy development with regard to the weldability of these materials [2]. These alloys have not typically been represented in the AM community, but should be considered ‘ready-to-use’ for AM. Luckily, they are slowly attracting more attention.

The aerospace and energy sectors can be considered the main drivers of AM, so superalloys have inevitably been a major area of focus for the AM community. In addition, typical target parts for AM are relatively small, use expensive materials, and have a high potential for customisation to leverage AM-specific design opportunities, such as cooling channels. Because of the required strengthening γ’-phase, many of the alloys used are generally cast.

One typical differentiation between wrought and cast alloys is based on the γ’-phase volume: wrought alloys contain less than 40% of γ’-phase, cast alloys above 40% [3]. The development of the casting process allows the production not only of polycrystalline CC and DS alloys, but also single crystal (SC) materials. In this case, the whole part contains only one grain with no grain boundaries (Fig. 4). The casting process for SC turbine blades requires enormous effort and highly specific processes. These components are the leaders in the category ‘processing costs of a material’ and, because of their niche applications, only a small quantity of parts are produced with a high degree of customisation. These alloys contain more than 60% of γ’-phase. Based on their chemical composition, thermodynamic properties, cracking susceptibility and the current state of AM, it is not reasonable to consider the industrial application of SC alloys for AM in the near future.

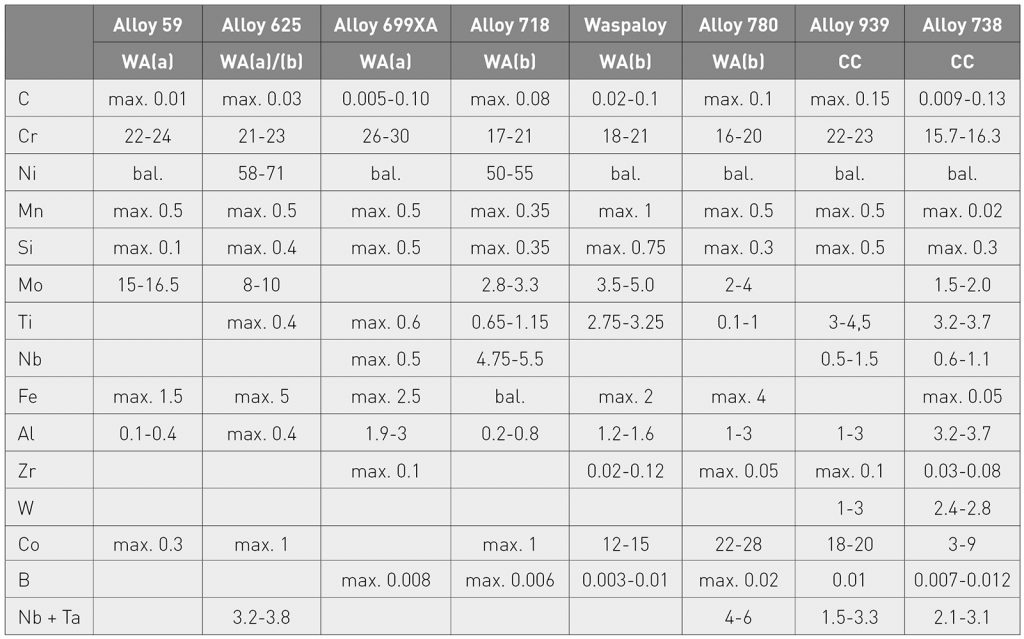

The chemical compositions of Ni-base alloys can be seen, along with a typical production route, in Table 1.

Weldability, a tendency to cracking during production, and the ductility of alloys are necessary considerations which define limitations in the successful application of alloys for AM.

γ’-phase

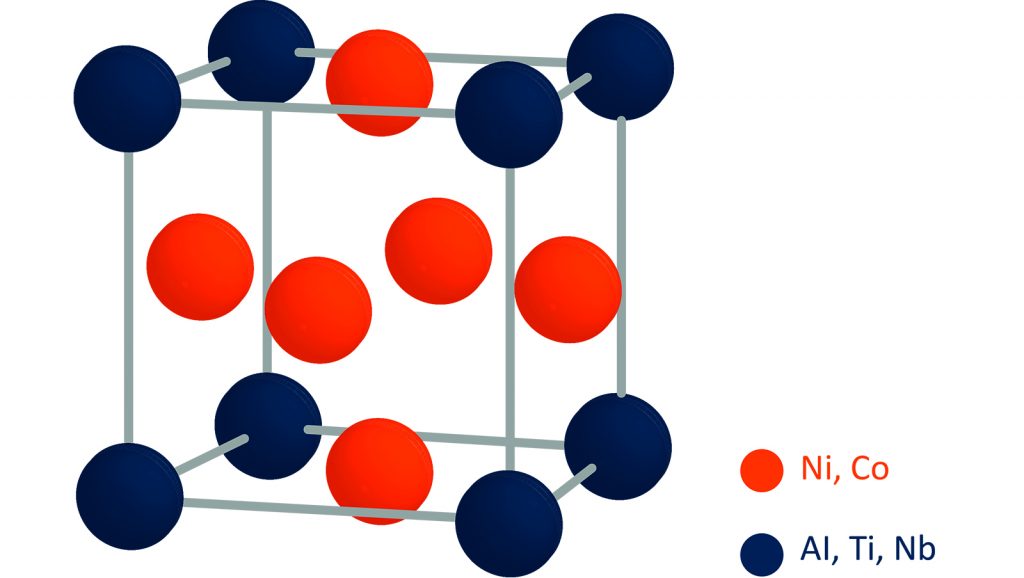

The γ’-phase is the most important phase in Ni-base superalloys. It is a coherent phase, meaning that it has a good lattice fit with the matrix, with stoichiometric composition Ni3Al and a crystallographic FCC structure Cu3Au. Due to its coherence, γ’-phase precipitates homogeneously in the whole material, in particular within grains, and creates a strengthening effect. Moreover, the γ’-phase is stable up to high temperatures and is thus responsible for the superior creep resistance of Ni-base superalloys. Generally, the precipitation of γ’-phase is based on Al. Additionally, Ti, Ta and Nb can be substituted in γ’ in Al lattice positions. Elements such as Co, Fe and Cr can be included in the γ’-phase instead of Ni atoms [3, 4] (Fig. 5).

During wrought processing, γ’-phase should be dissolved. This is beneficial because of its strengthening effect, which causes an increased material flow resistance and reduction in material ductility. With increasing γ’ volume, the stability area of this phase and the solvus temperature shift to higher temperature, with the consequence that wrought processes cannot be conducted.

Another important aspect related to γ’-phase is a ‘misfit’. The misfit is the difference between the lattice parameters of the matrix and of the γ’-phase and can be influenced by the chemical composition of the alloy. Misfit is responsible for morphology (spherical, cubic or plate like), precipitation kinetics, the temperature stability of γ’-phase and the main mechanical properties of an alloy [3, 4]. For example, Ti substitutes for Al in the γ’-phase and causes a strong increase in its precipitation kinetics.

The precipitation kinetics of γ’-phase is an extremely important parameter for technological properties such as forgeability, weldability and, finally, for processability in AM. Alloy 699 XA can be used here as an example for excellent material design and understanding of production and application needs. This alloy was developed for the chemical processing industry for use in extremely aggressive atmospheres at high temperatures. In this case, in addition to Cr, Al is an important alloying element in achieving corrosion resistance. For this reason, Ti and Nb contents were severely limited, in order to slow down precipitation of γ’-phase. Al can be used in VDM Alloy 699 XA as a solid solution strengthening element in the matrix.

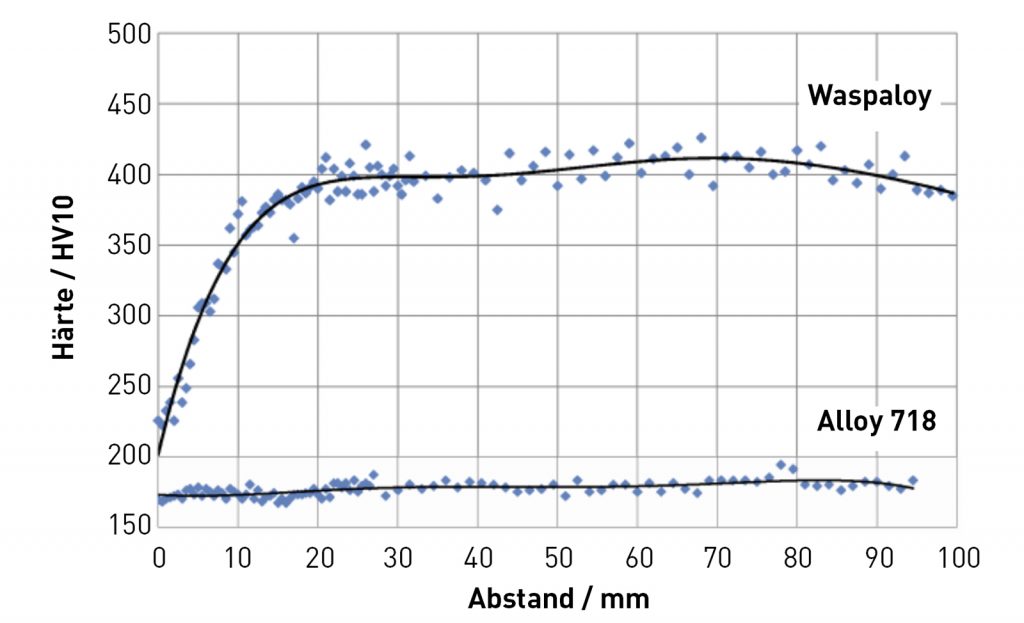

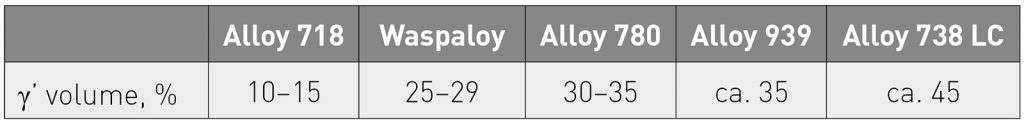

Alloys 718 and Waspaloy can be considered as another example. Fig. 6 shows the difference between γ’-phase precipitation kinetics and the consequent influence on hardness in the two alloys. Alloy 718 shows about 10%, Waspaloy about 29% γ’-phase (Table 2).

Because of very slow γ’ precipitation kinetics in Alloy 718, this alloy is much easier to process than Waspaloy. To demonstrate these differences, Jominy end quench tests can be used, according to DIN EN ISO 642. In a study, samples were heat treated before quenching at 980°C/1 h and 1080°C/1 h for Alloy 718 and Waspaloy, respectively, ensuring complete dissolution of the strengthening phases. After water quenching of one circular end, the hardness was measured as a function of the distance from this end. The results are plotted in Fig. 6. Clearly, the differences are drastic. In the case of Waspaloy, the hardness increases immediately with the distance from the quenched end, demonstrating that γ’-precipitation takes place even close to the quenched end. For AM processes, this means that Waspaloy has a higher cracking susceptibility during building and post-processing, because fast strengthening in the material causes not only a reduction of ductility but also additional stress in additively manufactured components.

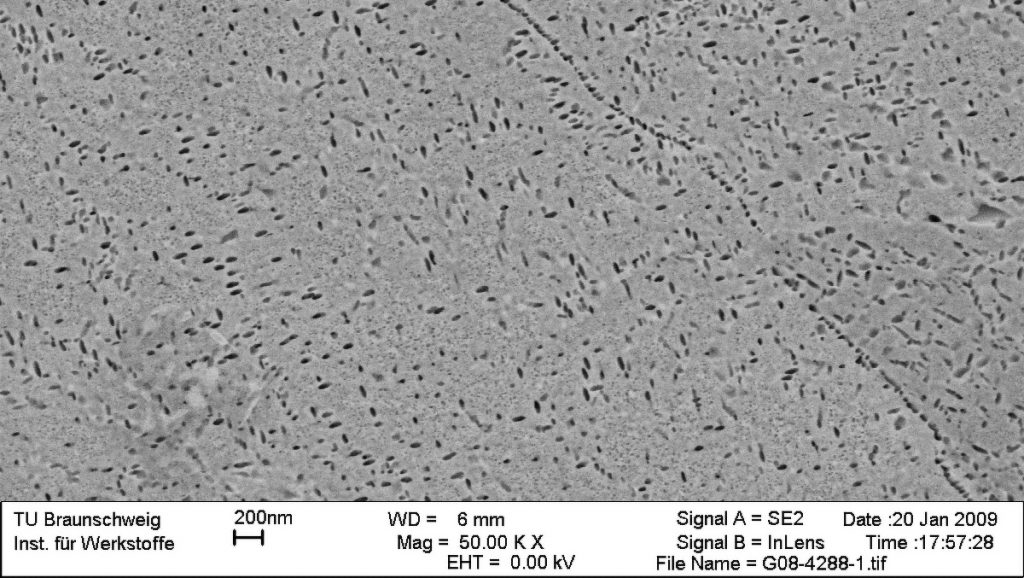

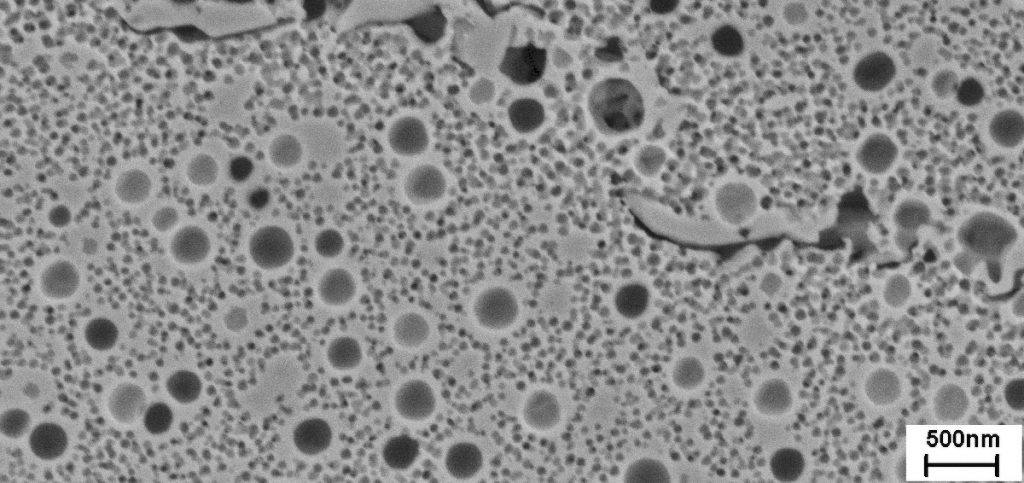

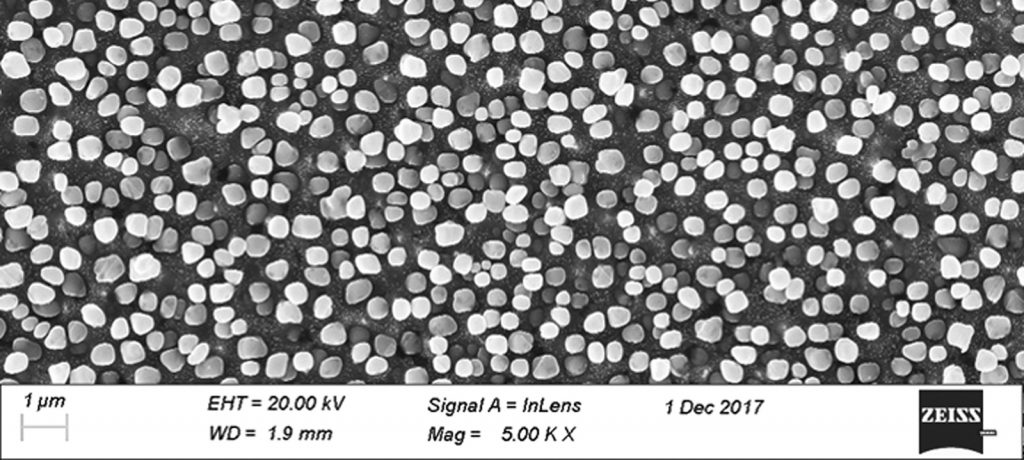

Furthermore, the difference in γ’ in the two alloys can be seen in their microstructures. Fig. 7 shows the microstructures of Alloy 718, Waspaloy and Alloy 939. γ’-phase size and morphology can be influenced by the chemical composition and heat treatment. Because of the γ’-phase’s coherency, its size, morphology and distribution behaviour can be obtained equally in conventional and AM-produced alloys after adjustment of heat treatments.

In Table 2, the approximate amount (this can be influenced by heat treatments) of γ’-phase volume can be seen. Alloy 939 and Alloy 738 LC, which belong to the CC group and are promising for the AM community due to their high-temperature mechanical properties, are also shown. These alloys contain higher γ’-phase volumes and reveal advanced thermomechanical properties in comparison with Alloy 718 and Waspaloy, but also a higher crack susceptibility.

Depending on component geometry and complexity, it can be difficult to achieve a crack-free microstructure in these alloys using AM. In some cases, the additional process step of Hot Isostatic Pressing (HIP) is necessary. HIP processing can be used for both crack healing and homogenisation heat treatment in a single treatment.

Table 2 also shows VDM Alloy 780. This alloy is a wrought alloy and was developed with the aim of providing a material superior to Alloy 718. Its long-term operating temperature is at least 50°C higher than Alloy 718. During development work, much effort was applied to ensuring a good workability of this material. The good workability of superalloys is related, amongst other issues, to slow precipitation kinetics of the γ’-phase. VDM Alloy 780 has about 35% γ’-phase, but, because of its relatively large misfit, it shows slow precipitation kinetics. As a result, it can be processed in the AM process window of Alloy 718 without any crack formation.

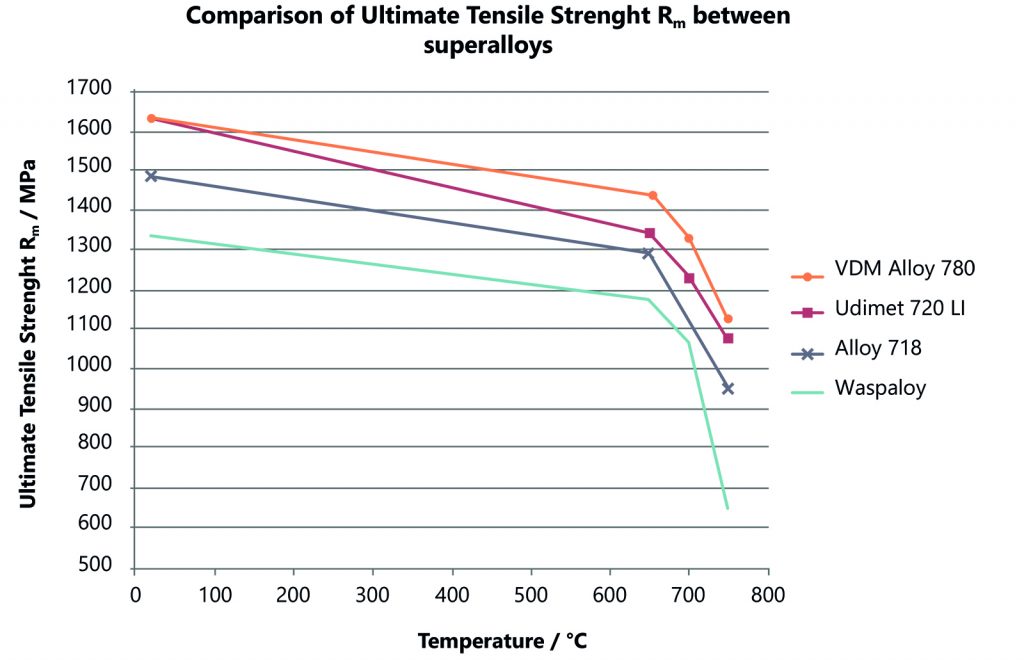

Based on improved thermomechanical properties (Fig. 8), good microstructure stability at 800°C, combined with user-friendly weldability, makes this alloy a strong potential candidate as a new alloy for AM industrialisation.

Production route and technological properties vs chemical composition

Achieving advanced material properties is only possible with the careful development of production routes. In recent decades, improvements in production capabilities have led to enormous advances. From the use of extremely clean virgin material to vacuum melting and remelting technologies, the processing of Ni materials requires knowledge and allows for certification to stringent requirements. For example, Alloy 718 requires either a double-melt (melting and one remelting process) or triple-melt process (melting and two remelting processes) in order to achieve extremely homogeneous elemental distribution and the lowest level of trace elements such as S. A homogeneous elemental distribution helps in the avoidance of phase segregation behaviour. Narrow control of minor elements, such as B, C and trace elements, can greatly improve high-temperature properties.

Based on more than ninety years of experience in material production and an understanding of customer-specific needs, VDM Metals offers products and services to support AM. VDM Metals has the opportunity to use the same pre-material from conventional production as the feedstock for powder production in order to achieve the highest requirements with regard to the chemical composition of powder.

Another important aspect to understand is the correlation between chemical composition and technological features such as the mechanical properties of alloys. Taking Alloy 718 as an example, it was found that the positive effect of B on grain boundary cohesion and high-temperature properties could be improved by alloying with P. 40 ppm B and 80 ppm P increased the stress-rupture life at 200 h in comparison with the standard Alloy 718. By further increasing the B and P contents to 110 ppm and 220 ppm, respectively, the stress-rupture life can be improved by 300%. Complete research work was done with a C content of 50 ppm [7], but these results were performed on wrought components. In AM, weldability also needs to be considered: the influence of B, C and P should be considered not only with reference to the resultant material performance, but also to weldability and crack susceptibility. So, it was reported that the similar B (100 ppm), P (220 ppm) and C (60 ppm) content caused a catastrophic effect on alloy weldability, with crack susceptibility being increased [8].

For this reason, VDM Metals produces modifications of this alloy, in particular for welding products. These chemical modifications also offer an advantage for AM applications.

Similar effects of minor elements can also be seen in cast alloys. Elements such as B, C and Zr are widely used for grain boundary strengthening [1]. All these examples show that, during the component dimensioning process for AM-produced components, it is extremely important to consider not only the expected part performance level in order to replace conventionally produced components, but also the need to obtain production route and chemical composition restrictions.

Considerations of microstructure

A material’s microstructure has a strong influence on both a component’s properties and service life expectations. The existence and distribution of precipitates, phase stability, the amount and morphology of grain boundaries, grain size and homogeneity define a material’s performance, amongst other factors.

Generally, the goal of a material producer is to process a homogeneous material independent of an application’s form and size. Homogeneous distribution of precipitates such as carbides, the avoidance of local precipitation of detrimental phases and homogeneous grain size are important characteristics in defining a material’s quality.

Different grain sizes are beneficial, depending on an application’s requirements. The correlation between grain size and expected properties is plotted in Fig. 9. For example, because of its complex structure and high Nb content, Alloy 718 can be wrought to a small grain size microstructure of about 10–15 µm and achieves the necessary Low Cycle Fatigue (LCF) and dwell crack growth properties. This is possible due to Delta-phase (Ni3Nb). Delta-phase precipitates at the grain boundaries pin the grains and thus avoid grain growth.

In order to achieve this fine grain size, the Nb content should be increased to the technically maximum level (about 5.4 wt.%) within the alloy specification (max. 5.5 wt.%). However, distributing Nb homogeneously is very challenging due to its segregation behaviour. This is one of the reasons why Alloy 718 should be produced by a double- or triple-melt production route.

AM processing produces a fine-grained microstructure. In fact, little Delta-phase is needed for the pinning of grain boundaries because wrought processing is no longer part of the production chain. For this reason, VDM Metals tries to discuss with its aerospace customers whether the use of a modification of Alloy 718– Alloy 718 CTP is appropriate. Originally, Alloy 718 CTP was a modification of Alloy 718 for the oil & gas industry; its chemical composition is still within the specification of Alloy 718, but it has a slightly lower Nb and C content. As a result, processability improvements (especially for very complex and large components) can be achieved by reducing crack susceptibility while retaining similar mechanical properties.

Microstructural considerations for Waspaloy can demonstrate a correlation between grain size and stress-rupture test results. Material with a grain size of about 30 µm shows an average time to rupture of about 25 h. The increase of grain sizes to 210–230 µm can improve the time to rupture to about 80 h and higher.

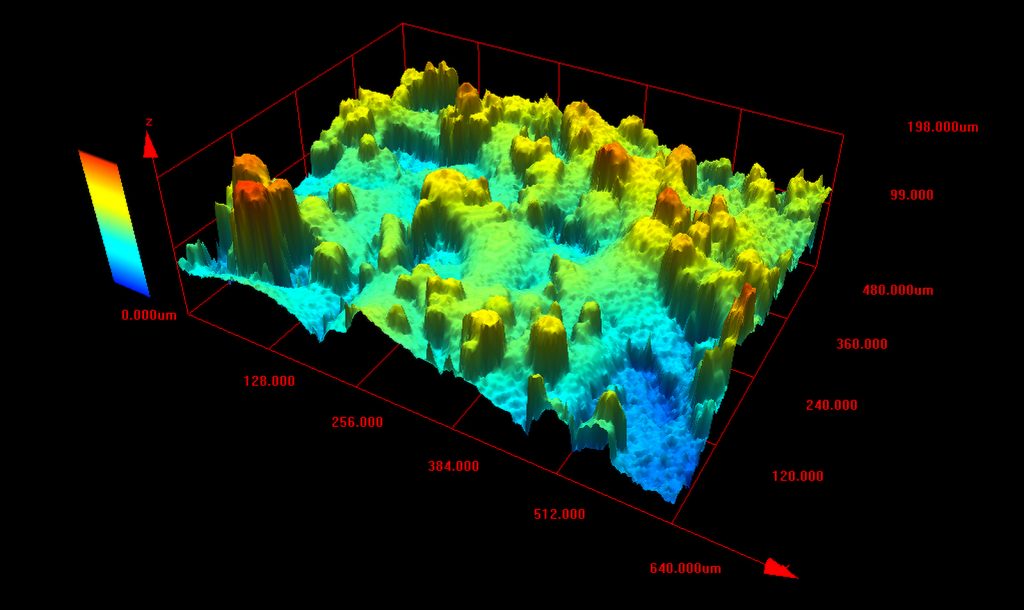

Additionally, an important aspect not considered yet should be highlighted – surface characteristics and their impact on the part’s lifespan, especially if a component is to operate under fatigue load. Surface defects can have a strong detrimental notch effect and, consequently, dramatically reduce time to failure. This aspect has begun receiving attention recently and is now being addressed in the AM community. Fraunhofer Institute for Surface Engineering and Thin Films (IST) has been working on a standardisation routine for the surface qualification of AM components. In Fig. 10, the surface of an AM-produced part with non-optimised process parameters can be seen. Usually, overhanging surfaces provide the worst surface quality. Hence, internal channels with an overhanging surface that cannot be smoothened provide an issue for component fatigue life. The probable surface defects and their influence on fatigue properties should be investigated before new component implementation in the field. Knowledge of microstructural considerations helps VDM Metals to customise both the chemical composition of materials and the production route to achieve the best possible performance required by the customer.

Weldability of Ni-base alloys

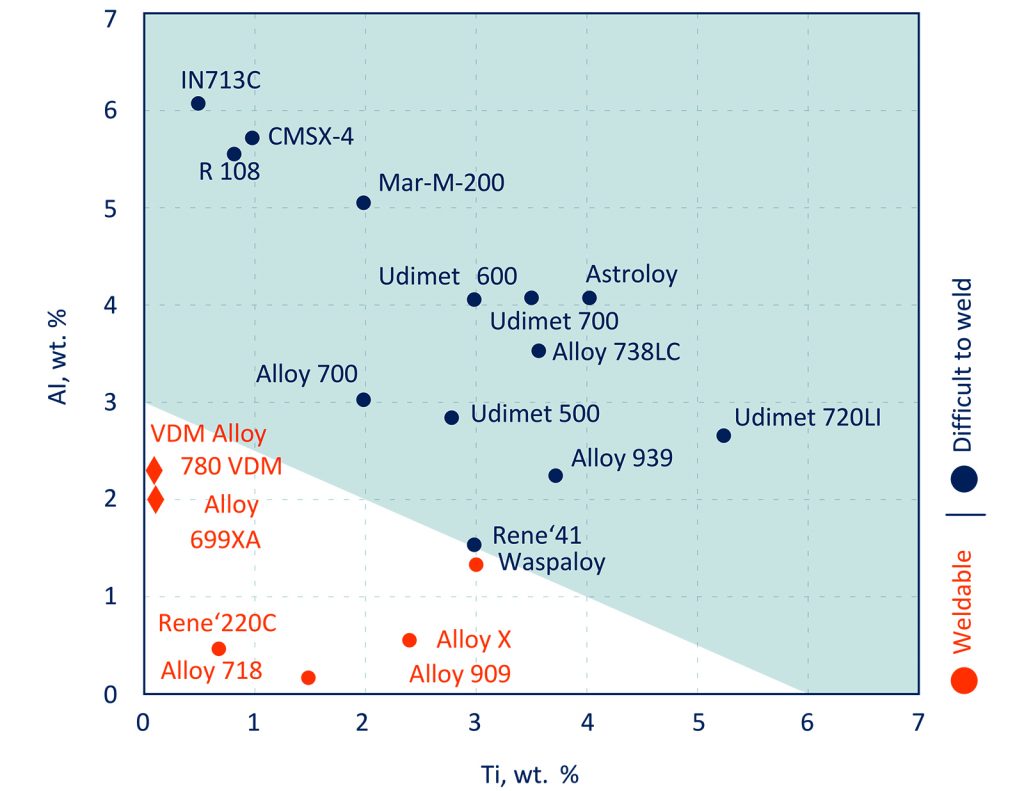

A lot of research and industrial work has been conducted in the area of weldability of Ni-base alloys. Wrought alloys (especially WAa and some WAb) were developed with the attention on weldability. Cast alloys are more challenging, in respect to their weld characteristics. Fig. 11 summarises the relationship between alloy chemistry and crack susceptibility, based on the γ’-phase amount that can be correlated to Al and Ti. Elements such as Nb and Ta are also substituted in y’-phase. However, they do not influence precipitation kinetics as strongly as Ti. The susceptibility of the alloys to strain-ageing and ductility deep cracking grows with increases in the volume fraction of γ’-phase. Fig. 11 cannot indicate the influences of detrimental elements such as S and grain boundary strengthening elements such as B, C, Zr and P and also does not show other cracking mechanisms (liquation or solidification cracking). Both of these cracking mechanisms can be related to the chemical composition and to process conditions.

Alloy 699 XA deserves special attention in relation to weld characteristics. The alloy contains a relatively high amount of Al (2 wt.% – similar to Waspaloy) and limited amounts of Ti and Nb. It was possible to reduce the stability area of γ’-phase and its precipitation kinetics. This alloy shows excellent creep properties, in combination with user-friendly technological properties, including weldability.

The AM process has many similarities with a conventional welding process. Simply put, the AM process can be described as a multi-layer micro-welding process. Because the AM process is usually carried out under well-controlled conditions, such as the use of protective/shielding gas, a minimised size of the molten pool and a maximised cooling rate, AM can have an advantage over conventional welding. However, there can be many hidden risks when choosing AM-relevant components. Fig. 11 (and similar graphs from the literature) shows the general weldability of Ni-base superalloys – especially high γ’ containing materials. However, weldability can be a general term and can have different meanings from different sources. In the case of cast alloys, ‘weldability’ means joint welding and/or repair welding [12]. Weldability here does not guarantee that the alloy would be suitable for an AM part with complex geometry and large variations in wall thicknesses.

Limitations and opportunities of Ni-base alloy application in AM

This article has discussed different material characteristics related to chemical compositions and production techniques. Primarily, we have addressed the need to consider the material and its characteristics carefully for successful implementation in the AM process.

The material characteristics summarised in Fig. 4, including weldability, crack susceptibility, microstructure and expected level of component performance are necessary considerations, which define, in some cases, the limitations of successful alloy applications for AM.

The following questions should be considered during this process:

- Is the selected material weldable? Is it possible to produce a crack-free structure with current AM machines?

- Is it possible to expect the same component performance level based on a change to the AM process? If not, can another alloy be applied with an expected lower performance level, but with better processability (weldability)?

- How important is the surface condition for the component’s performance? Does a component design allow a surface treatment?

This article has focused on materials which are already implemented in AM or are expected to be implemented in AM production. In other words, no further alloy development is needed.

AM has changed not only the industrial landscape of manufacturing techniques, but also the daily life of the material producer. In conventional production routes, material producers are usually the breakpoint in the component production chain. All questions regarding homogeneity, product sizes, workability and achievement of microstructural requirements are answered by the material producer for certain alloys.

Now, we are able to produce any powder material, but the question of successful component production is relocated to AM part producers. For this reason, VDM Metals always tries to discuss its partners’ and customers’ goals with them ahead of material production, in order to prevent unnecessary efforts, balance expectations, and meet their requirements.

Authors

Dr Tatiana Hentrich, Application Engineering and Technical Customer Support

Dr Christina Schmidt, Senior Manager Powder Production R&D

Corresponding author

VDM Metals International GmbH

Plettenberger Str. 2

58791 Werdohl

Germany

www.vdm-metals.com

Acknowledgments

Institut für Werstoffe (IfW) Technical University of Braunschweig

Siemens AG

Fraunhofer Institute for Surface Engineering and Thin Films (IST) Braunschweig

References

[1] Gell, M. et al., Advanced Superalloy Airfoils, 1897.

[2] Heubner, U. et al., Nickel alloys and high-alloyed special stainless steels, 2012.

[3] Bürgel, R.: Handbuch Hochtemperaturwerkstofftechnik, 2006.

[4] Sims, C.T. et al., Superalloys II, 1987.

[5] Fedorova (Hentrich), T., Entwicklung einer neuen Ni-basis Superlegierung auf Basis von Alloy 718, 2013.

[6] Rösler, J., Hentrich, T, Gehrmann, B., On the development concept for a new 718-type superalloy with improved temperature capability, 2019.

[7] Horton, J.A., et al., Microstructural charakterization of superalloy 718 with B and P additions, 1997.

[8] Benhadad, S., et al., The influence of minor elements on the weldability of an IN718- typ superalloy, 2002.

[9] Reed, R., The Superalloys, Fundamentals and Applications, 2006.

[10] Floreen, S., et al., The effects of B and Zr on the creep and fatigue crack growth behavior of a Ni-base Superalloy, 1983.

[11] Gam, G., Kocak, M. Progress in joining of advanced materials, 1998

[12] DuPont, J., et al., Welding Metallurgy and Weldability of Ni-base Superalloys, 2009.

Alloy 718: microstructural considerations

Alloy 718 should be considered as an important alloy for all industrial applications besides this discussion due to its complex structure. It has two strengthening phases: γ’ and γ’’. γ’’-phase is a semi-coherent metastable phase with a stoichiometric composition Ni3Nb and an ordered crystallographic structure DO22. The γ’’-phase is responsible for high strength with a good level of ductility at moderate temperature in Alloy 718. The semi-coherence causes not only high strengthening effect and slow precipitation kinetics but also rapid coarsening behaviour. Due to these phase properties, Alloy 718 can be used for critical applications only up to 650°C.