Permanent magnets for electric motors by cold spray Additive Manufacturing

January 26, 2018

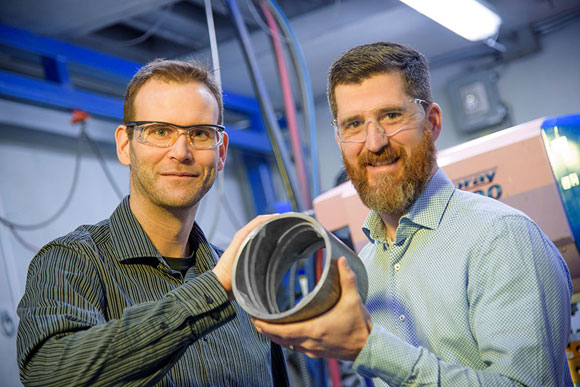

Researchers Jean-Michel Lamarre and Fabrice Bernier prepare a prototype part for an electric motor in the NRC’s cold spray facility (Courtesy NRC)

Researchers at the National Research Council of Canada (NRC), Ottawa, Ontario, Canada, have developed a method to produce permanent magnets by cold spray metal Additive Manufacturing for electric motors. Fabrice Bernier and Jean-Michel Lamarre, the team who developed the new method, state that this technology could make it possible to produce magnets in complex shapes and for complex parts without the need for assembly.

Currently, high-performance magnets used in electric motors are typically made using processes such as powder compaction for sintered magnets or injection moulding for bonded magnets. In these processes, magnets must first be fabricated and then shaped and assembled into a final product. The NRC’s cold spray technology reportedly combines all the steps into one and could lead to significant cost reductions, it also opens up a world of design possibilities not achievable using traditional manufacturing processes.

The NRC also states that its cold sprayed magnets have excellent mechanical and thermal properties. The high velocities used in the deposition of the material and the absence of polymer in the material matrix are said to give the magnet mechanical properties superior to conventional magnets, including increased thermal conductivity, corrosion and oxidation resistance. The adhesion of the magnetic material to the surface of the part is also reportedly exceptional, since neither glue nor assembly is used, and magnets created using cold spray Additive Manufacturing are said to be easy to machine when compared to more brittle sintered magnets.

Lamarre and Bernier reveal a product made using their new magnet manufacturing technology (Courtesy NRC)

Prototype magnets have been constructed using the new material and tested with success, and the NRC’s researchers state that they are already looking into new ways to use cold spray Additive Manufacturing to enhance motor designs. Currently, the team is working on the development of soft magnetic materials to complete the range of available resources.

“This technology will allow the creation of more compact, better performing motors for the future and could pave the way for building entire motors using cold spray technology, offering significant advantages such as cost reduction, better thermal management and more complex geometries and functionalities,” stated Bernier.

As the automotive industry strives to reduce reducing CO2 emissions in the next generation of vehicles, much of the NRC’s recent development efforts have been focused on electric motors. However, additional industries could benefit from the new technology, with key potential applications including magnetic cooling, wind turbines and telecommunication devices.