AMPM2017: Understanding the impact of powder reuse in metal Additive Manufacturing

An issue of significant current interest to the AM world, which can potentially impact both the quality and cost-effectiveness of built parts, is whether there is a limit on the number of times that metal powders can be cycled around an AM process. In this article, Dr David Whittaker reviews three presentations on the topic from AMPM2017, the fourth annual Additive Manufacturing with Powder Metallurgy Conference, held in Las Vegas, USA, June 13-15, 2017. [First published in Metal AM Vol. 3 No. 3, Autumn 2017 | 20 minute read | View on Issuu | Download PDF]

Understanding the effects of metal powder reuse in laser Powder Bed Fusion

The first reviewed presentation on this subject was given by Lucy Grainger (Renishaw plc, UK) and further supported by reference to a relevant Renishaw White Paper on the subject. The presentation began by underlining that the properties of the powder, and the machine parameters that are used to process it, are closely related. The chemical and physical properties of the powder are therefore critical.

Only a small proportion of the powder that is laid down in a build process is actually melted into a component, with most being left unmelted and therefore available for reuse. If unmelted powder was to be considered as contaminated and, therefore, unfit for reuse, then the cost of additively manufactured parts would likely be prohibitive for the vast majority of applications.

Renishaw AM systems use an inert argon atmosphere, which is generated by first creating a vacuum and then backfilling with the inert gas. Builds generally start at a low oxygen content of <1000 ppm, with the possibility of a starting atmosphere of <100 ppm if required. The oxygen content in the chamber drops to approximately <10 ppm after the first few layers. For the main reported study, builds began at <1000 ppm oxygen content. For titanium powder, it is important to have a low oxygen (and nitrogen) atmosphere due to the material’s propensity to absorb these gases. The question therefore arises as to whether, if reused many times, the cumulative effect might cause the powders to become out of specification in terms of these elements.

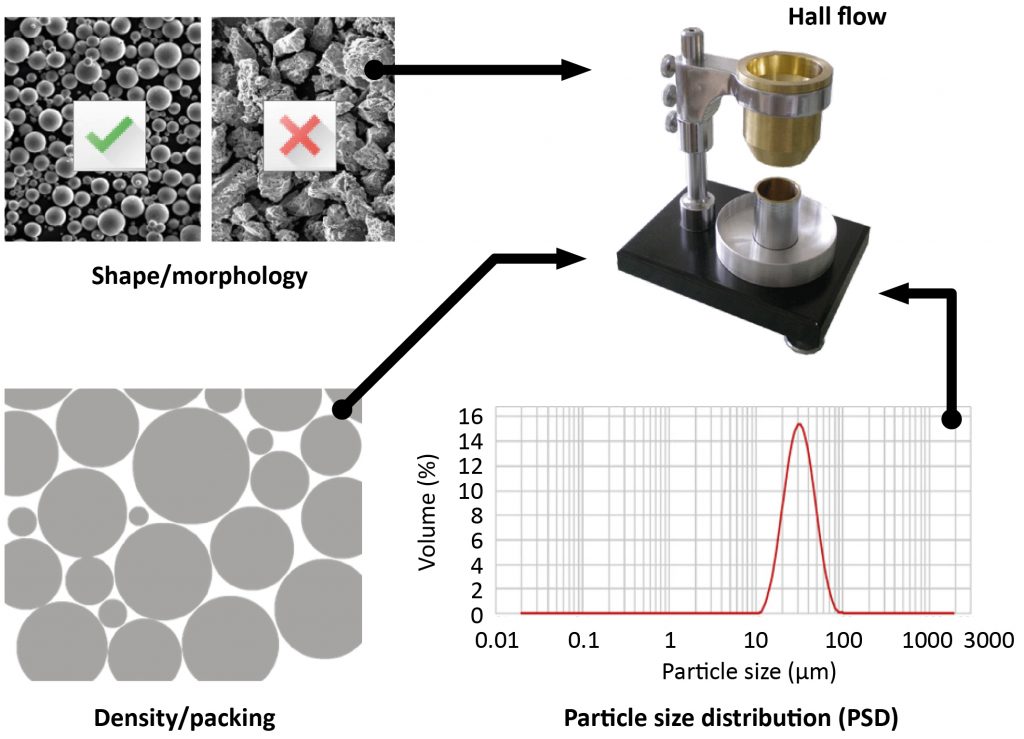

In terms of physical characteristics, the powder can be affected in a variety of ways, with the majority of effects due to powder particles being either near the weld pool or being ejected from the weld pool. Physical properties which will have an effect on the way a metal powder behaves within the AM system include:

- Shape; a spherical morphology is preferable compared to angular or spongy

- Packing/density

- Particle size distribution (PSD)

- Flow

Powder flow is very important when dosing from the silo and for creating consistent layers across the bed and this is directly affected by shape, density/packing and PSD. If PSD is too wide or bimodal, the smaller particles will sit in the spaces between the larger particles, increasing packing and inhibiting flow. If the PSD is too narrow, this could lead to insufficient packing and pores in the melted part (Fig. 1). In the study, powder flow was measured using the Hall funnel method.

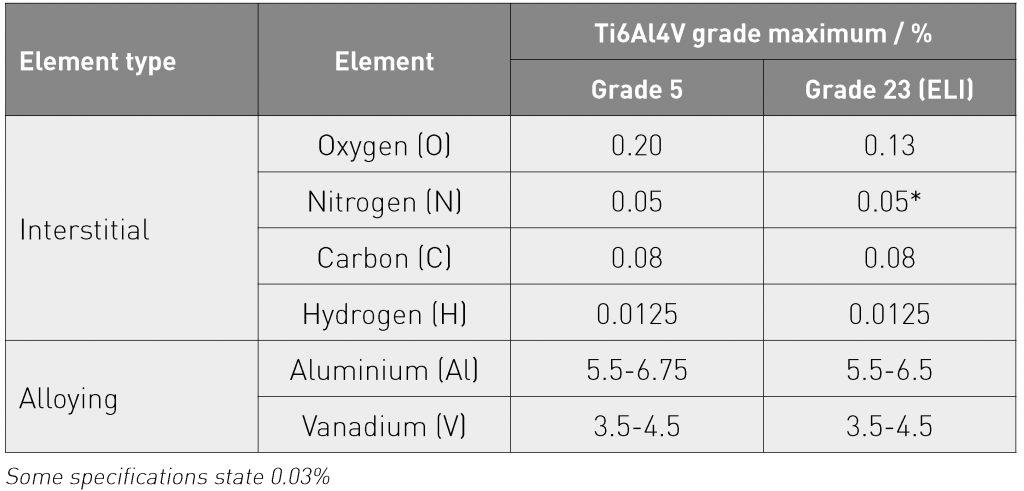

The reported study focused solely on the reuse/recycling of a titanium alloy, Ti6Al4V, which is specified in two main grades; 23, also known as ELI or extra low interstitial, and 5. Maximum allowable levels of some elements are highlighted in Table 1.

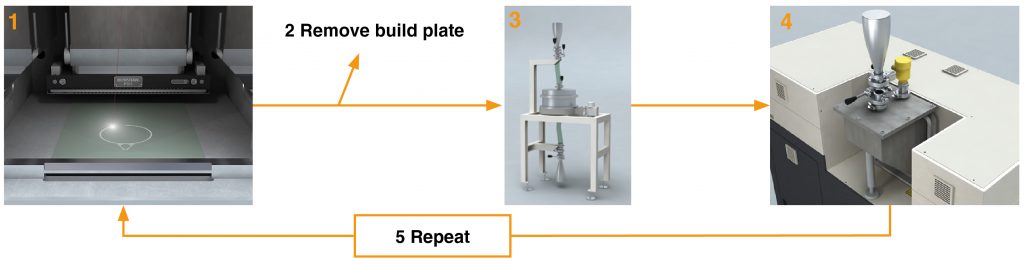

In the Renishaw AM250 machine (Fig. 2) used for the reported trials, the powder silo is located at the top of the machine. The advantages of this arrangement are that sieved powder from a previous build can be placed directly on top of the remaining powder in the silo. It can also be topped up during a build with virgin or used powder, although for this study only used powder was added.

The way that the argon atmosphere is generated is unique to Renishaw systems. Firstly, a vacuum is created in the chamber to remove any air and moisture. The chamber is then backfilled with argon, creating an inert atmosphere for the build with <1000 ppm O2. This process takes approximately 10 min and requires 600 l of argon.

After the build, all unmelted material is directed into overflow bottles, using the integrated glove box located in the door of the build chamber. Overflow bottles are then sealed ready for removal from the system. Overflow bottles filled with unmelted powder from the build are directly connected to the sieve, which is kept under an inert argon atmosphere. An argon-filled overflow bottle catches the powder as it is sieved and is then used to replace the powder directly back into the silo.

The basis of the experimental study was to start with a single batch of virgin powder to fill the silo, to use the same AM250 system throughout, to carry out routine builds reusing the powder until there was not enough left to build to the full test sample height, to not add any virgin or other powder to the batch at any point, to build standard test samples to analyse both powder and tensile properties over the period of reuse and to sieve unmelted powder to remove oversized material from each build before replacing into the silo. In total, thirty-eight AM builds were carried out over a period of three months.

This was an extreme analysis of powder reuse, as usually the silo would be topped up regularly with virgin powder, essentially refreshing the used powder; this study looked at the most extreme case of never refreshing the used powder. After the silo had been filled with virgin metal powder, the following stages (Fig. 3) contributed to a reuse cycle: AM build, removal of the build plate, sieving of the unmelted powder under argon, replacement of the sieved powder into the silo located at the top of the machine and repeating of the cycle

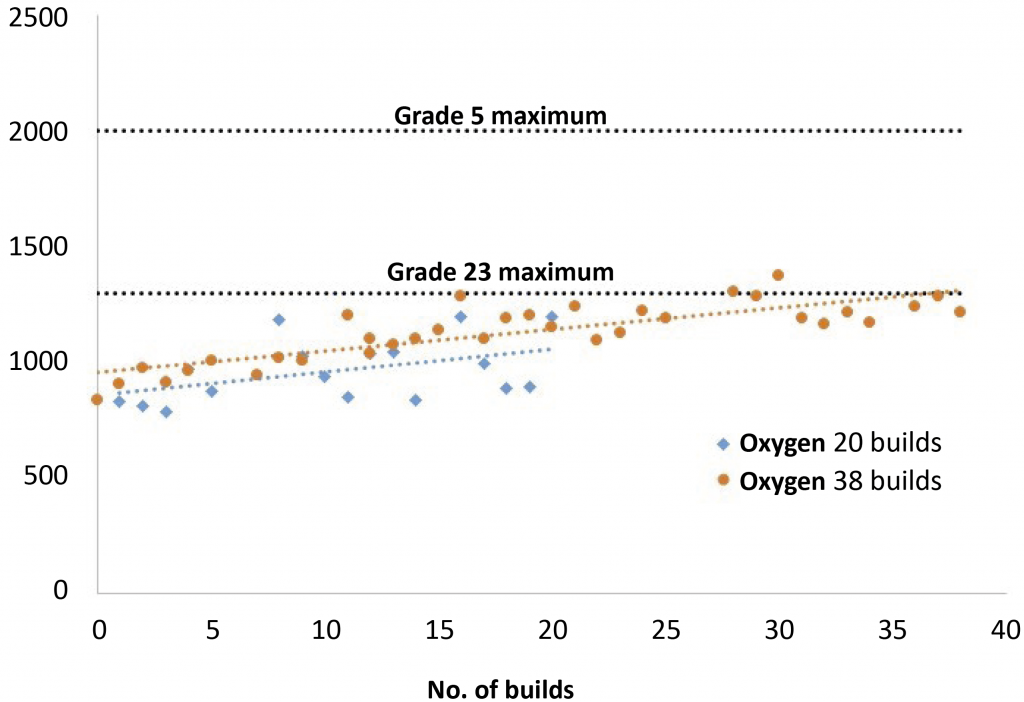

Fig. 4 shows the oxygen content results from this and an earlier study, starting from a slightly lower oxygen level of 800 ppm and comprising twenty builds. Compared to the first study, the oxygen levels from the second study were generally higher, but the oxygen pick-up rate was similar. A few of the builds crept out of the ELI maximum range (builds 15, 25, 26, 27 and 33), but all others were within the boundary of grade 23 ELI and well within the grade 5 boundary. Results from the first study showed all of the powder was within ELI limits for oxygen over 20 builds.

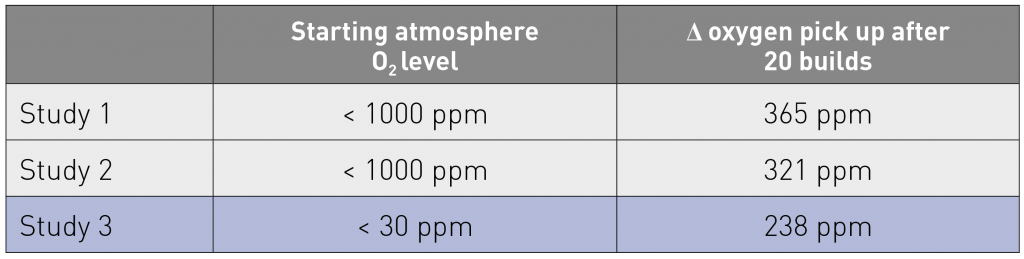

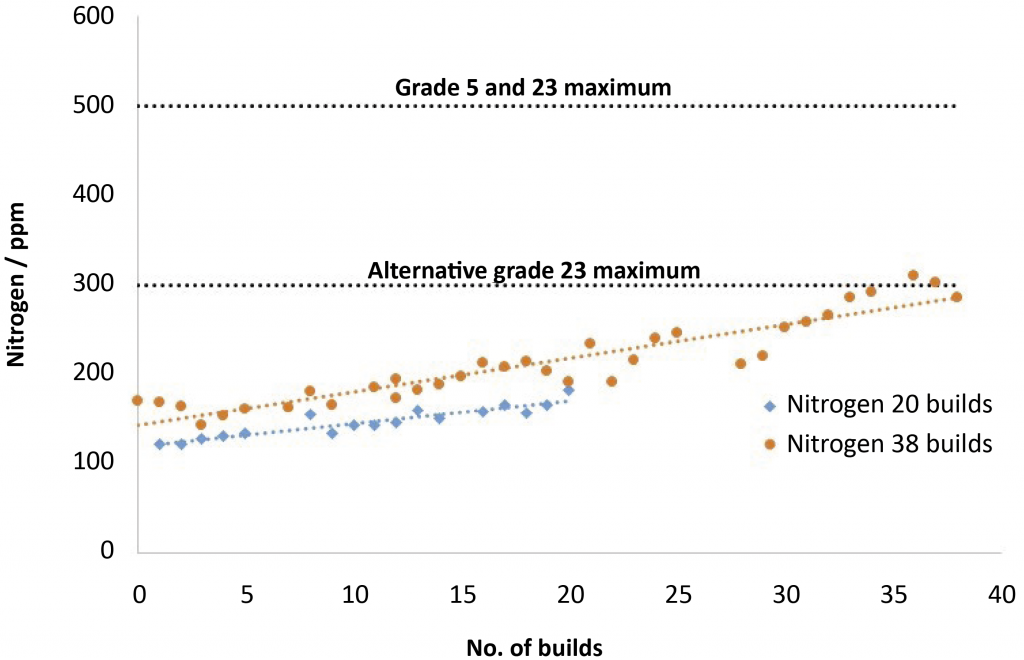

In studies 1 and 2, it was observed that, when starting with <1000 ppm oxygen in the chamber, oxygen pick-up over 20 build cycles was 320-360 ppm. In a third study with zero oxygen in the chamber, there was still an oxygen pick-up of around 230 ppm (Table 2). It seems likely that the source of this oxygen was H2O from moisture in the powder or chamber; this issue is currently under investigation at Renishaw. Nitrogen levels (Fig. 5) also showed a gradual increase, staying well within the 500 ppm maximum specification and coming above the 300 ppm maximum specification within the last few builds.

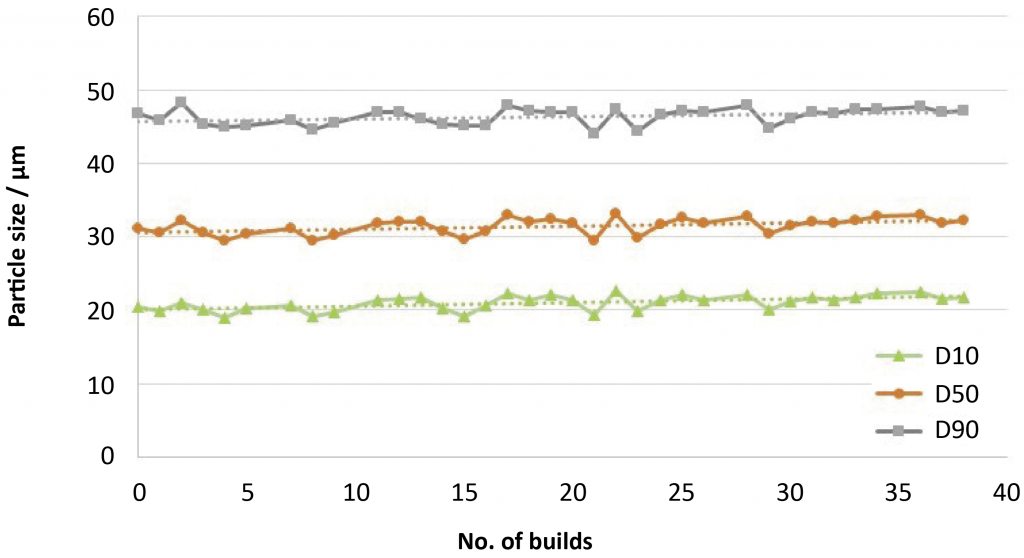

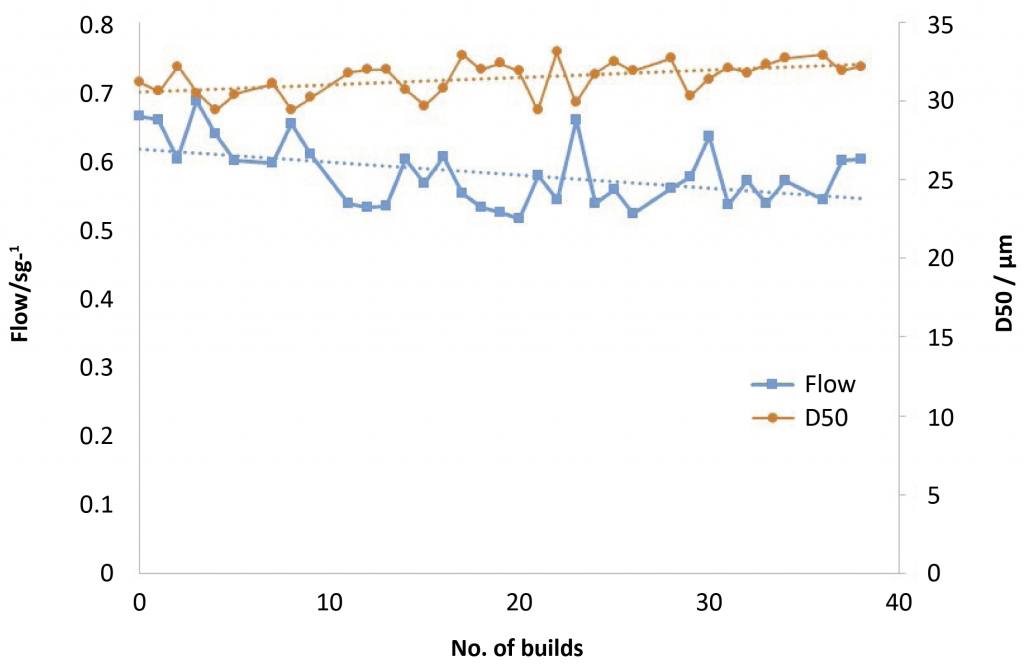

PSD was measured using a wet laser diffraction method. Very little change was observed in the particle size distribution of the powder (Fig. 6). The difference between the 1st virgin and 38th build powder samples was most significant in the D10 value, where a very small change of +1.30 µm was recorded. D50 and D90 values increased by +1.0 µm and + 0.4 µm respectively. There was a general tightening in PSD over the reuse cycles, with smaller particles being slowly removed – probably by sintering to larger particles. This resulted in an increase in the Hall flow of the powder. The virgin powder required a single tap to flow through the Hall funnel, while all subsequent powder samples flowed freely.

There was a general increase in Hall flow speed over the period of the reuse. This was probably due to a reduction in the number of smaller particles. D50 is compared with Hall flow speed in Fig. 7. It is clear that, as D50 increases, so does flow speed, highlighting the relationship between the two powder properties. However, these changes did not appear to be significant in terms of material parameters or layer spreading.

Powder density was measured using a helium pycnometer. There was little change found in the powder from virgin to 38 builds, all values being within 99.397-99.158%.

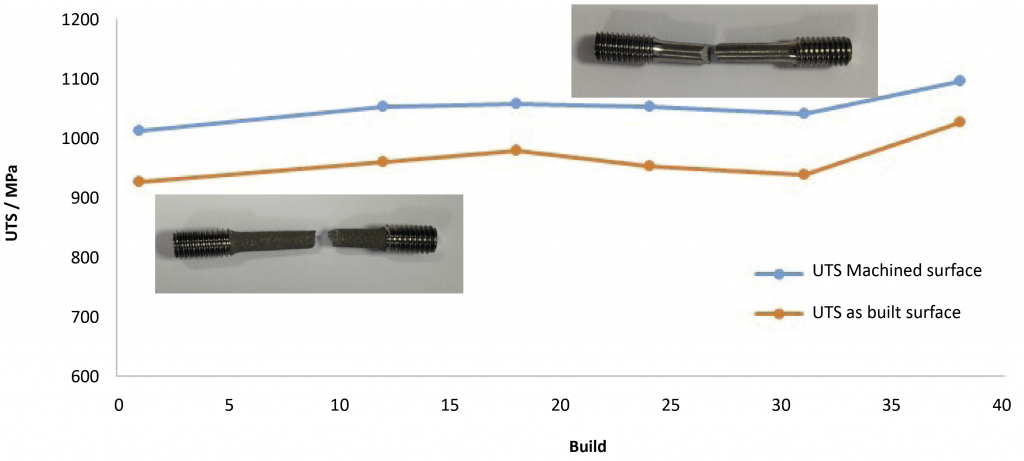

All tensile bars were heat treated in a vacuum furnace. Bars from builds 1, 12, 18, 24, 31 and 38 were tested. In order to investigate as-built surface and machined surface tensile properties, three of the test bars from every build were designed with an extra 1 mm diameter to allow for machining, meaning that all six bars conformed to the E8 ASTM standard diameter of 3 mm.

Ultimate Tensile Strength (UTS) values did not change significantly. An increase in 100 MPa from virgin to build 38 can be attributed to the increase in oxygen and nitrogen levels. A comparison between the ‘as built’ and machined tensile test bars is shown in Fig. 8. The machined bars gave higher UTS values, which can be attributed to their smoother surfaces, with fewer crack initiation points compared to the rougher ‘as built’ samples. However, an alternative explanation could be that the values for the two different surface finishes are a result of measurement error in the cross-sectional area for the rougher surface.

Qualitative analysis of powder morphology was carried out by scanning electron microscopy. The virgin powder was highly spherical, with a moderate level of satellites and small particles. It was clear from the PSD data that smaller particles had been removed over the period of the builds and this was also observed in the SEM analyses. Other than the loss of smaller particles, the powder changed very little, staying spherical, with the occasional misshapen particle, most likely ejected from the melt pool or agglomerated next to the weld pool.

The observations from this study suggest that there is no requirement to dispose of unmelted Ti6Al4V after it has been cycled around the AM250 system a limited number of times. This does, however, depend on the specific requirements of the component material properties, in which case a stringent blending regime may be required for traceability.

The effects of powder reuse may potentially be different for other materials, in terms of physical property effects. However, because titanium has a high propensity to pick up interstitial impurities, the pick-up rates observed can be thought of as a ‘worst case’ for commonly used metal AM powders.

Investigation of the effects of recycling 316L powder on consistency and properties of parts made by Selective Laser Melting

A further reported study also used a Renishaw AM250 system but focused on Type 316L austenitic stainless steel powder. This presentation came from Martin Kearns (Sandvik Osprey, UK) and was co-authored by his Sandvik Osprey colleagues Keith Murray and Mary-Kate Johnston, and Nick Lavery (MACH1 Centre, Swansea University, UK).

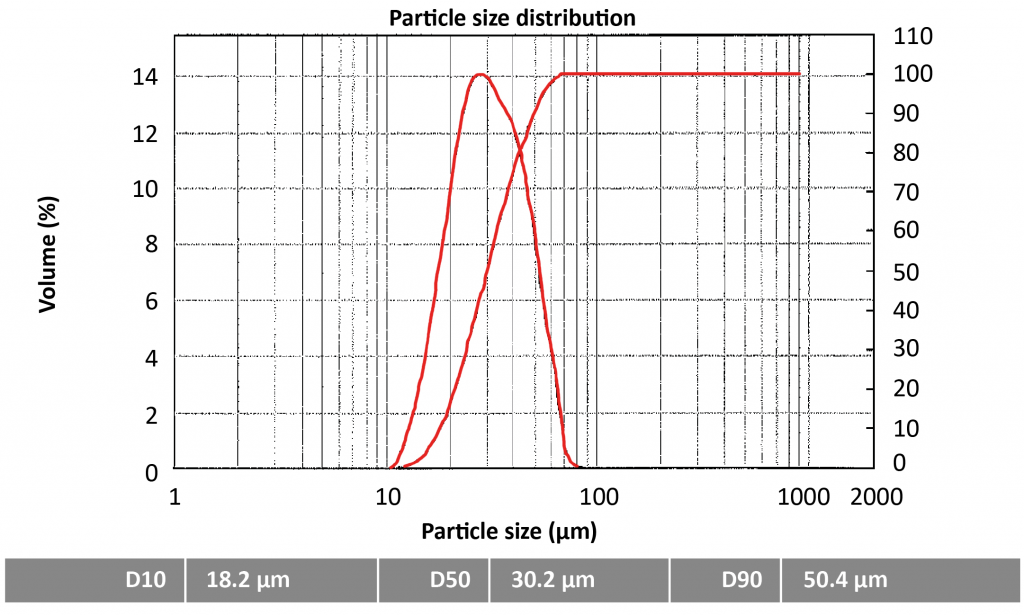

The virgin 316L powder had the composition Fe-16.8%Cr- 12.4%Ni-2.3%Mo-0.7%Si-0.7%Mn-0.02%C-0.02%P-0.01%S and was processed to the -45+15 µm size range by sieving and air classification. Particle size distribution was as shown in Fig. 9.

The powder was processed through over 30 AM test builds, producing a range of density cubes and tensile test pieces for evaluation. After each test build, the remaining powder was sieved using a 63 µm mesh in preparation for the next build. Powder samples were taken after each build for the characterisation of particle size distribution, rheology and chemical analysis.

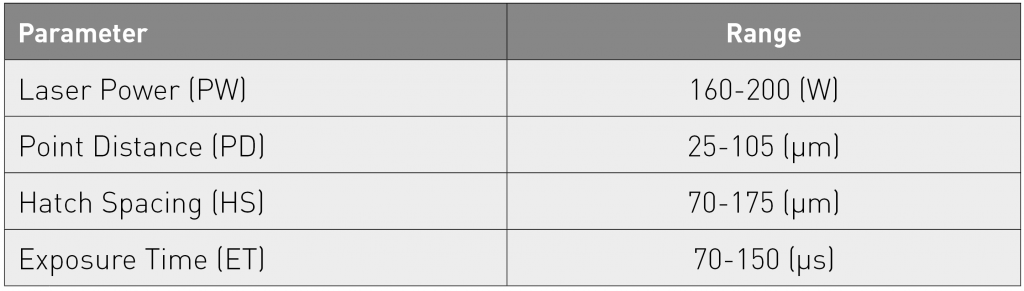

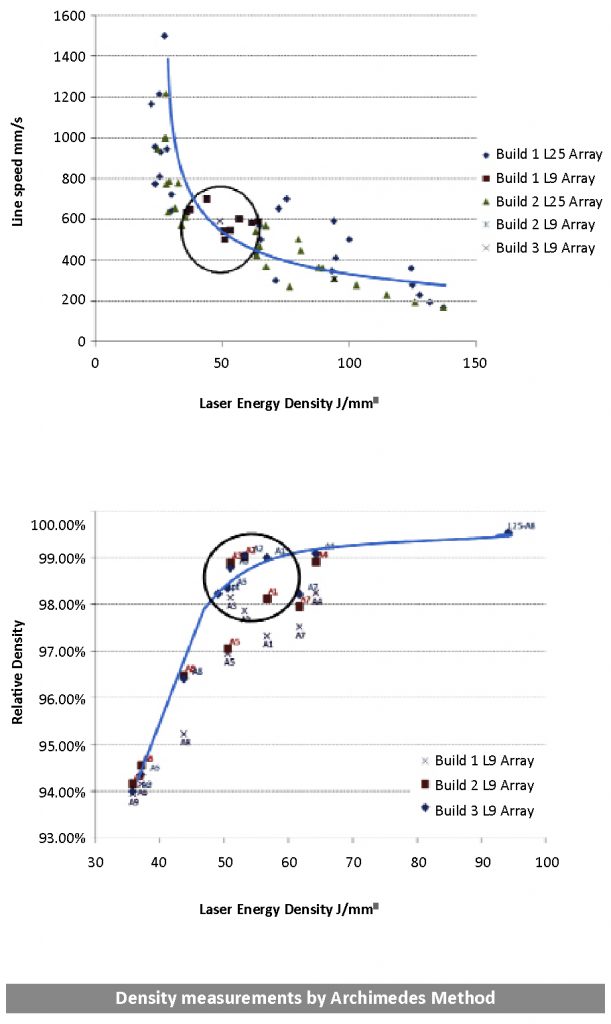

In builds 1-3, L25 and L9 arrays were designed to determine the influence of AM machine parameters on build densities and to identify the optimum settings. The investigated machine parameters are shown in Table 3. In Fig. 10, the circle on the lower graph shows an inflection, where the plateau high density achieved in the L9 array corresponded to a laser energy density of 56-60 J/ mm3. This was selected as the set of conditions to be run repeatedly as a reference to monitor the effects of recycling on density in the array.

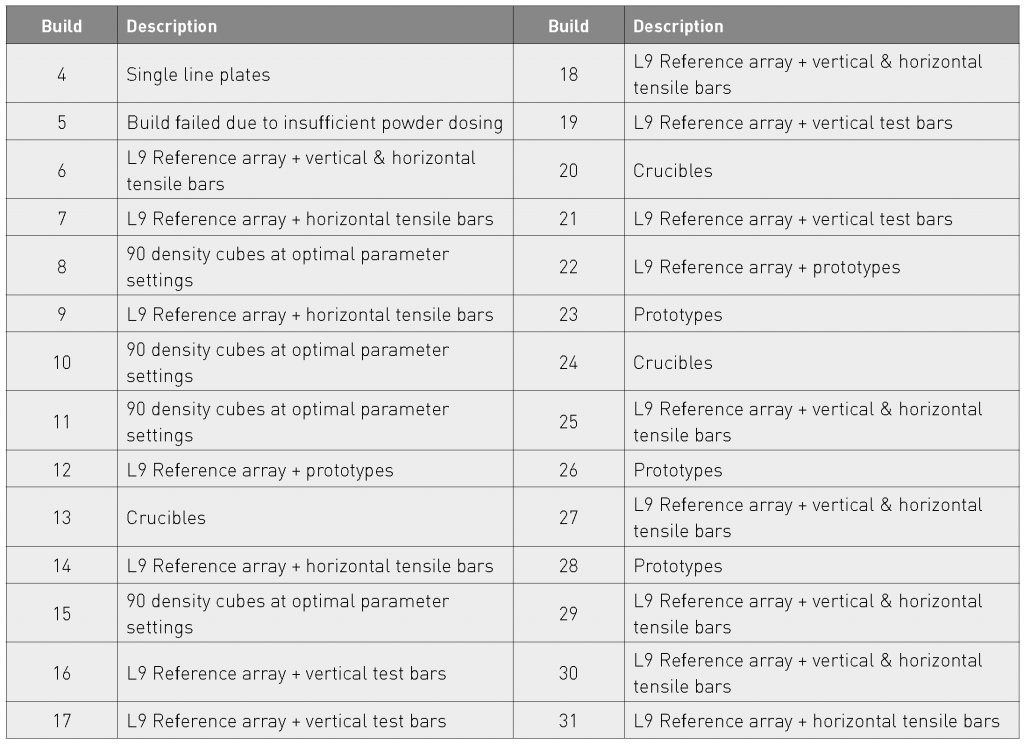

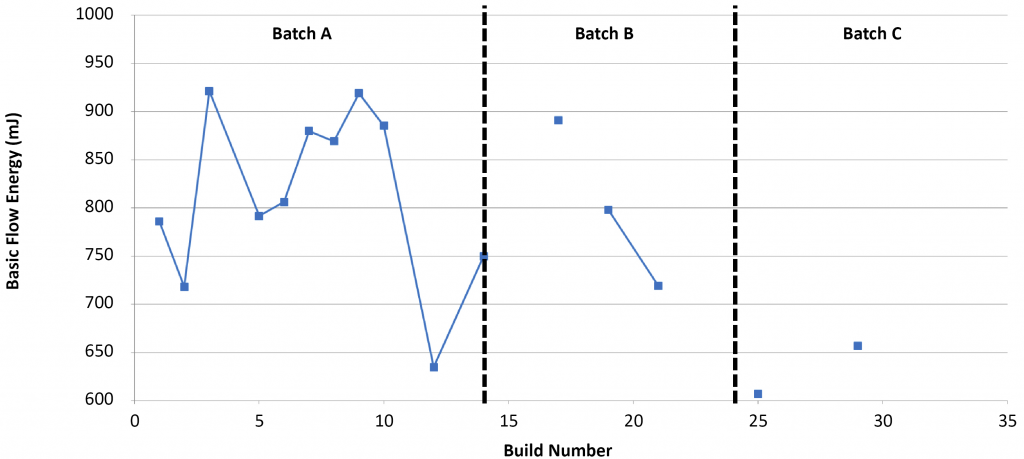

For builds 4-31, the schedule of samples built was as defined in Table 4. For builds 1-14, the powder used was that remaining from the initial virgin batch (Batch A). For builds 15-24, the remaining powder was supplemented with an addition of 66.7% fresh powder from the original virgin batch (Batch B). For builds 25-31, the remaining used material was supplemented with an addition of 31% fresh powder from the original virgin batch (Batch C).

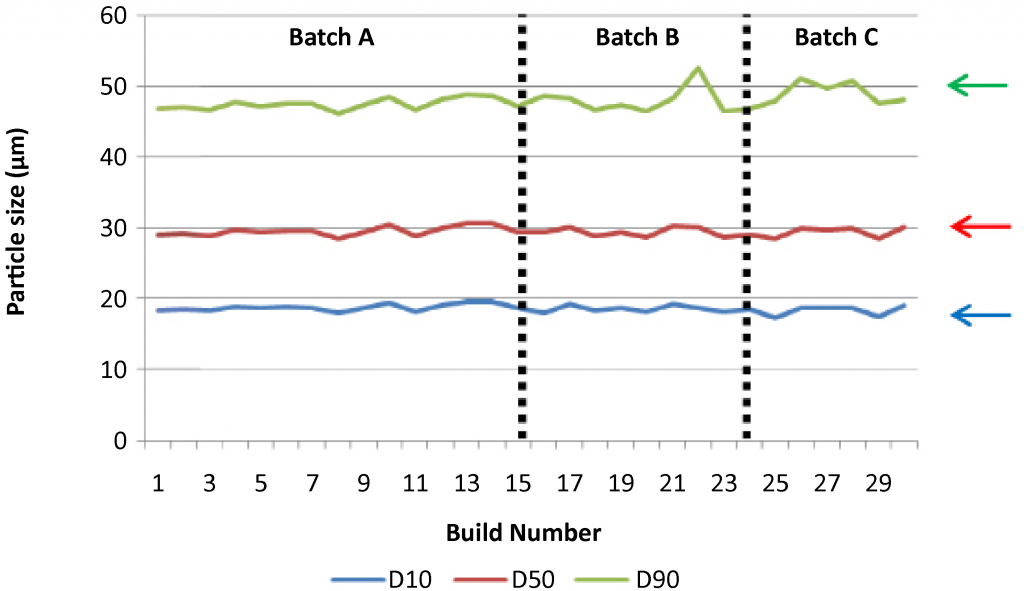

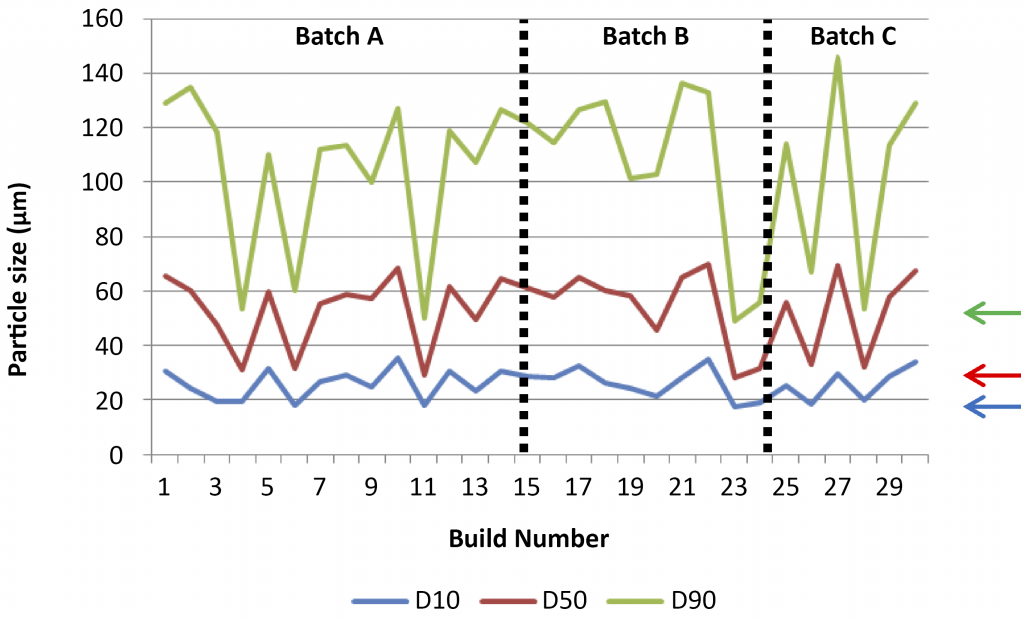

Powder sampling was carried out at various machine locations, including from the freshly dosed powder prior to the build, in front of the overflow after the build, at the argon gas outlet after the build and from the machine’s sieve after the build. Fig. 11 shows the particle size distribution data measured on the powder prior to each build and Fig. 12 the data for the samples taken from the overflow after each build. Fig. 12 shows more variability in the D90 values, reflecting the presence of small amounts of splats formed under the laser actions, but these splats were removed each time by the sieving to restore effectively a standard starting PSD. No systematic trends to a coarser or finer distribution were observed.

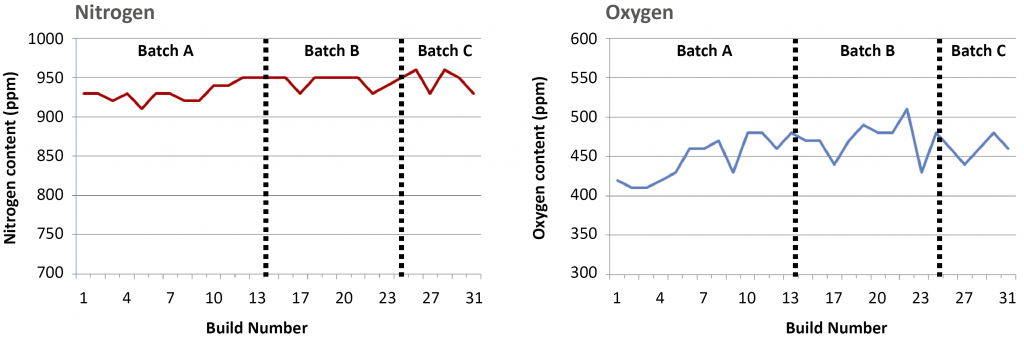

Fig. 13 indicates a very gradual increase in nitrogen and oxygen levels throughout the build series. However, the levels of all major alloying elements were reported as being consistent throughout the build series. Fig. 14 shows results of assessing powder rheology of samples taken from the freshly doped powder prior to a number of builds, in terms of the basic flow energy (BFE) parameter from tests using a Freeman FT4 Torque Rheometer. Received wisdom would suggest that this parameter should tend to rise after powder reuse, as flow is compromised. Although the presented dataset is incomplete, it does not support this view and in fact shows a wide range of values that is difficult to interpret.

Initial evaluations of spatial variations in the density of built parts were in tests where the laser focus was not optimised. However, once this focusing issue was addressed, a much more uniform and higher density was achieved.

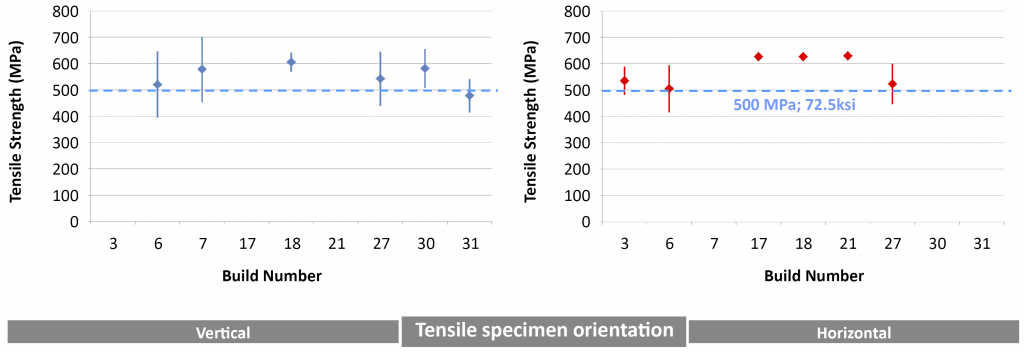

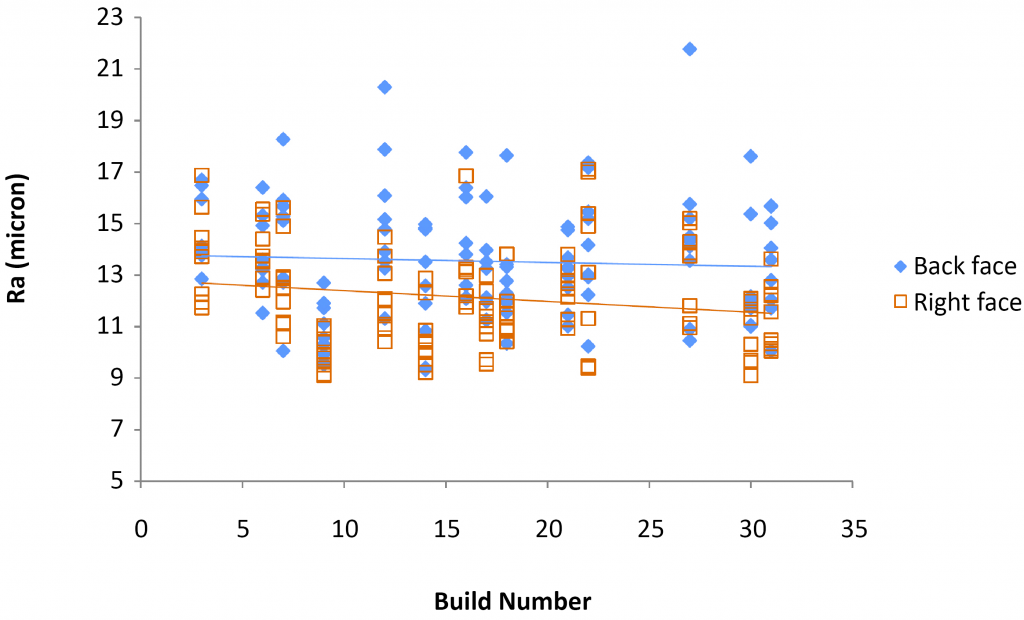

The tensile strength data from samples built with an optimal laser power input of 60-70 J/mm3, shown in Fig. 15, indicate very consistent strength levels throughout the build series. The built sample surface roughness data (Fig. 16) shows a significant scatter, but the regressed trend lines show no systematic trend over the 31 build cycles. The roughness values were similar to those seen in other studies. The authors drew the following overall conclusions:

- 316L stainless steel gas atomised powders can be used effectively in Additive Manufacturing to produce parts with densities exceeding 99%

- Multiple powder reuse (in up to 30 builds) with periodic rejuvenation of the powder does not appear to have a significant effect on powder characteristics, machine performance and the quality of built parts

- There is some evidence of a gradual increase in O and N levels

- Sieving after each build appears effective in reconditioning the powders to remove processing artefacts.

Comparing powder characterisation, mechanical properties and microstructures of virgin and highly recycled 304L for the EOS M280

Finally, a presentation from Robin Pacheco (Los Alamos National Laboratory, USA) focused on an alternative austenitic stainless steel, Type 304L, this time processed in an EOS M280 system.

As an alternative to the use of a relatively expensive powder reconditioning technology such as plasma spheroidisation, this study was aimed at determining the number of reuse cycles that are feasible until powder characteristics and composition, built part mechanical properties and overall functionality are compromised. In this context, the highly recycled (HR) powder had been in use for around two years.

The virgin 304L powder used was sieved and classified to the -44+16 µm size range. The AM process used a build temperature of 100°C, a nitrogen atmosphere, a layer height of 40 µm with a 67° rotation between layers, a contour speed of 1400 mm/s, a contour power of 140 W and a total build time of 85 hours.

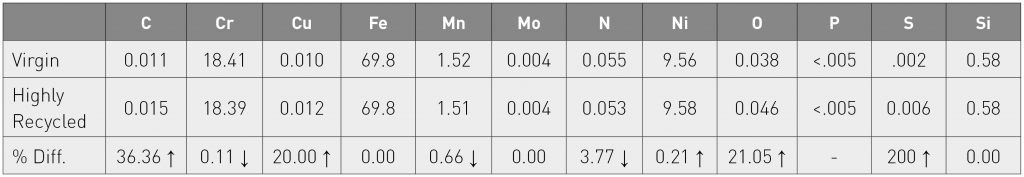

Chemical analyses of the virgin and highly recycled powder are given in Table 5. The increases in C and O in the highly recycled powder suggest that more oxides are present in the deposited layers. The increase in O should cause an increase in oxide layer thickness and a consequent increase in absorptivity of the laser during building. On the basis of the measured low P and S contents, solidification cracking would not be expected.

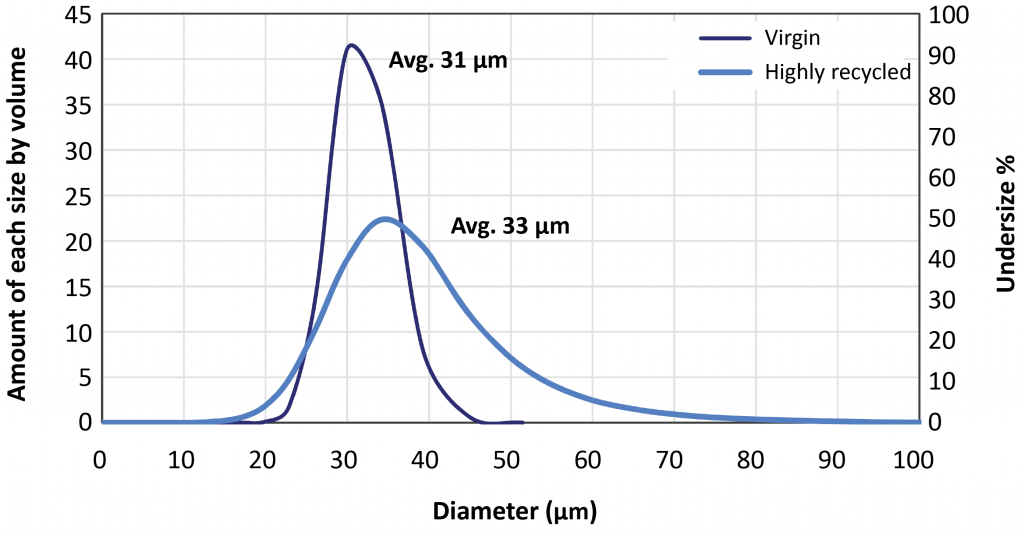

The PSD of the virgin and HR powder samples, taken from storage containers, are compared in Fig. 17. The HR powder had a wider PSD, possibly caused by agglomerated powders in previous builds being broken by the recoater blade. This seemed a very likely hypothesis, as the HR powder had a smoother exterior than the virgin powder. Pores within the powder particles were observed in both virgin and HR powders.

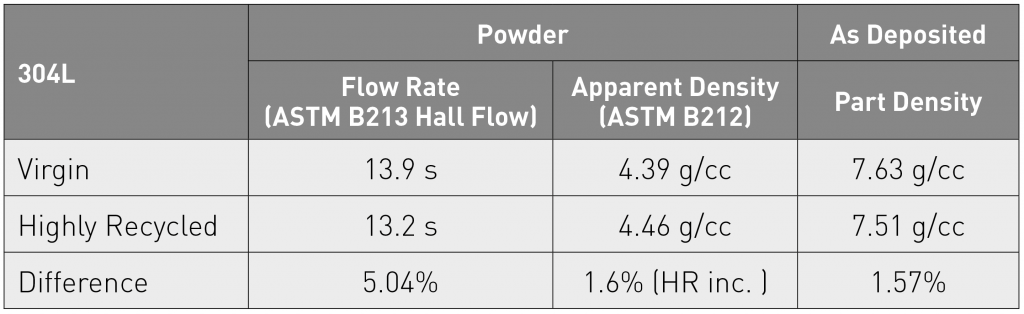

The comparative flow rates and apparent densities of the powder types and the as-built part densities are shown in Table 6. Particle layer packing could be more efficient for the HR powder due to the smaller, broken-off particles, yet the agglomerated particles can impede flow and increase inter-particle friction during recoating.

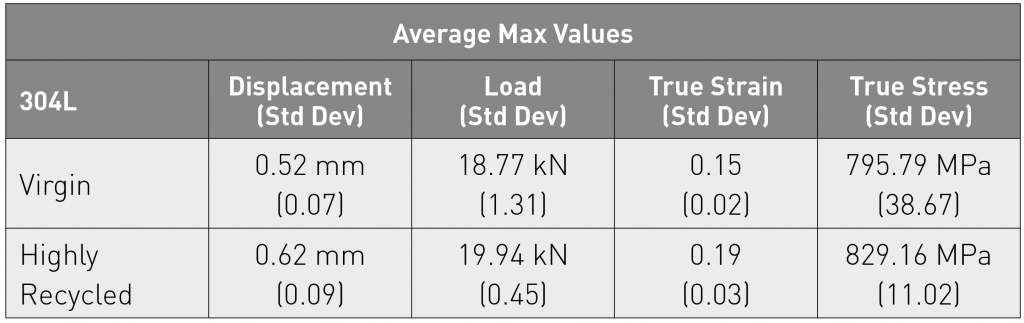

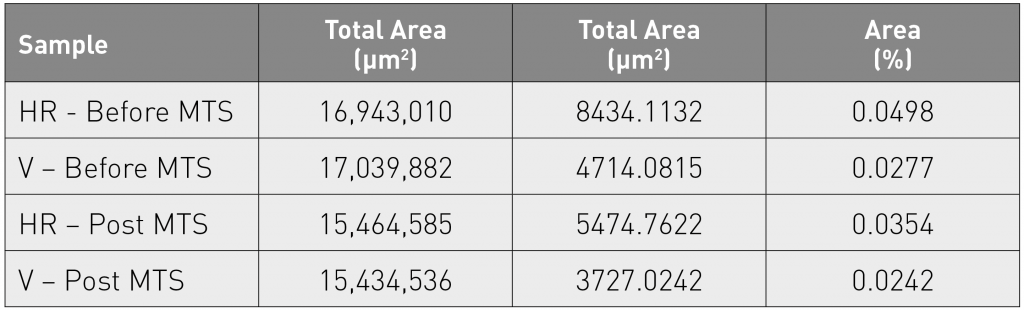

Mechanical properties in compression for parts built from the two powder types are given in Table 7. Oxides, pores and oxides in pores are seen in both powder types, with a typical size of 5 to 10 µm. These oxides seemed to be composed mainly of Si, Al, Ca and O, with their numbers being slightly higher in the HR samples (Table 8). However, there was less than 0.1% oxide/pore area in both powder types, with almost no oxides/pores being observable in both virgin and HR builds.

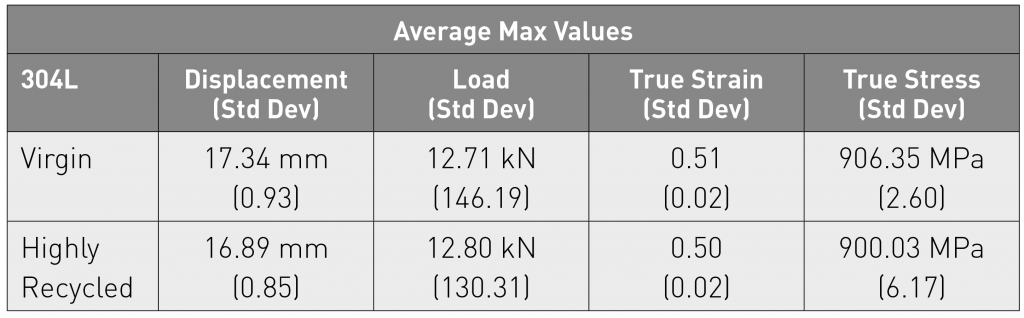

In tensile testing, the parts built from virgin and HR powders, tested to failure, showed virtually identical results (Table 9). Dimpling, oxides, pores and unfused particles were seen in the fracture faces of both virgin and HR builds.

Very similar microstructures were observed in virgin and HR builds, with a ‘fish scale’ dual primary solidification mode (ferrite growing along the austenite). EBSD showed that the grains were not strongly textured.

In conclusion, the differences observed between HR and virgin powders and built samples were as follows:

- Particle size and distribution due to partial fusion, agglomerate formation and the breaking of satellites by the recoater blade

- A slightly higher number of oxides, pores and oxygen/silicon inclusions in deposited HR

- A higher oxygen content in the HR powder.

On the other hand, there were no significant differences in the two powder types, in terms of:

- Microstructures

- Particle morphology – the virgin and HR surface roughness difference was only 1 to 2 µm

- Mechanical properties, with similar average maximum stress and strain to failures, in both compression and tension.

Based on the reported results, it was proposed that highly recycled powder can be used over the range of two years without compromising the AM product.

References

[1] Understanding the effects of metal powder reuse in laser Powder Bed Fusion, Granger, L. As presented at the AMPM2017, the Fourth Annual Additive Manufacturing with Powder Metallurgy Conference, Las Vegas, USA, June 13-16, 2017, and published in the Conference Presentations PDF by the Metal Powder Industries Federation (MPIF).

[2] Investigation of the effects of recycling 316L powder on consistency and properties of parts made by Selective Laser Melting, Kearns, M et al. As presented at the AMPM2017, the Fourth Annual Additive Manufacturing with Powder Metallurgy Conference, Las Vegas, USA, June 13-16, 2017, and published in the Conference Presentations PDF by the Metal Powder Industries Federation (MPIF).

[3] Comparing powder characterisation, mechanical properties, and microstructures of virgin and highly recycled 304L for the EOS M280, Pacheco, R. As presented at the AMPM2017, the Fourth Annual Additive Manufacturing with Powder Metallurgy Conference, Las Vegas, USA, June 13-16, 2017, and published in the Conference Presentations PDF by the Metal Powder Industries Federation (MPIF).

Author

Dr David Whittaker

231 Coalway Road

Wolverhampton

WV3 7NG, UK

Tel: +44 1902 338498

Email: [email protected]

AMPM2017 Conference Presentations

A PDF compilation of presentations from AMPM2017, the fourth annual conference focused on Additive Manufacturing with Powder Metallurgy is available from the MPIF. The PDF features 59 technical presentations and 12 technical manuscripts presented by worldwide industry experts. It is available for $150 (MPIF members $120).

AMPM2018

Additive Manufacturing with Powder Metallurgy – AMPM2018 – will take place in San Antonio, Texas, USA, from June 17–20, 2018. A Call for Papers & Posters has been issued.