Sauber Motorsport AG and Additive Industries: Formula 1® engineering meets metal AM

As the new Formula 1 season gets underway, Additive Manufacturing will have played a vital role in the development and manufacture of the cars on track. Metal AM magazine’s Nick Williams recently visited Sauber Motorsport AG at its headquarters near Zürich, Switzerland, and discovered how a partnership with Dutch AM technology supplier Additive Industries has supported both the development of in-house AM applications and an expansion of Sauber Motorsport’s AM services for third parties. [First published in Metal AM Vol. 4 No. 1, Spring 2018 | 20 minute read | View on Issuu | Download PDF]

Formula 1 has long been recognised as a hub of technological innovation, so when it comes to Additive Manufacturing (AM) it is no surprise that the sport has been at the forefront of the use of AM technology for many years. In terms of the application of metal AM parts in F1®, in 2015 it was estimated that there were between forty and sixty parts per car [1]. Given the rapid advancement in the speed and capabilities of metal AM processes over the past three years, as well as the increased availability and affordability of AM machines, it is not surprising that applications have continued to increase.

Whilst, a decade ago, the use of AM in F1 would have been shrouded in secrecy, today teams and Additive Manufacturing technology providers are openly publicising their partnerships. In January 2017, Stratasys signed a four-year technology partnership with McLaren Racing as their ‘Official Supplier of 3D Printing Solutions’ and, back in 2015, EOS GmbH entered into a three-year technical partnership with Williams F1.

It was therefore a logical step when, in June 2017, Dutch metal AM technology provider Additive Industries and Switzerland’s Sauber Motorsport AG announced their own three-year partnership. Sauber became the launch customer for Additive Industries’ entry level machine, the MetalFAB1 Process & Application Development Tool, and invested in two of these systems as it built its own in-house metal AM capability.

The story of Sauber

Although Sauber’s involvement in motor racing dates back to the 1970s, Sauber Motorsport began its involvement in Formula 1 in 1993. Founded by Peter Sauber, this private team has launched the careers of some of motorsport’s most famous names, including Michael Schumacher, Kimi Räikkönen, Felipe Massa and Sebastian Vettel. Whilst the team’s fortunes have fluctuated as engine suppliers and partners entered and withdrew from the sport, the team has nevertheless enjoyed numerous successes, including twenty-seven podium finishes and one race win.

Recent management and ownership changes have put Sauber Motorsport on a fresh footing. Swiss investment firm Longbow Finance S.A. became the owner of Sauber in 2016, coinciding with Peter Sauber’s retirement from the sport. Pascal Picci was appointed as Chairman of Sauber Holding AG and, in Summer 2017, Frédéric Vasseur was appointed Managing Director & CEO of Sauber Motorsport AG, as well as Team Principal of the Formula 1 team.

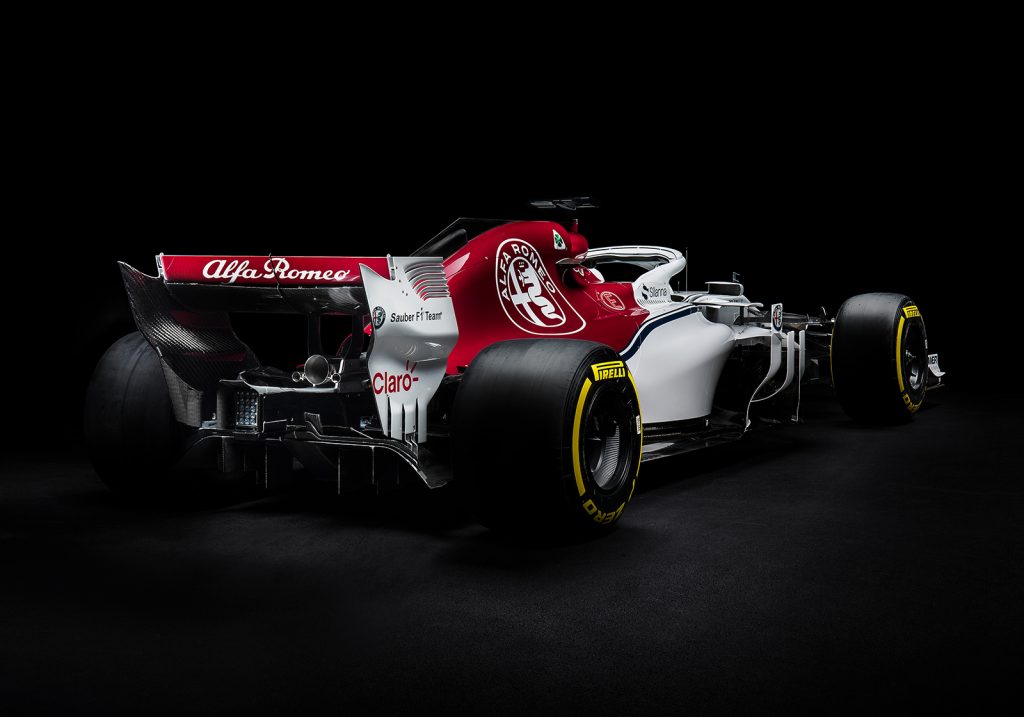

Thanks to an engine deal that gives Sauber use of the latest 2018 Ferrari power unit and an influx of both capital and experience, there are high hopes for the team’s two drivers, Charles Leclerc and Marcus Ericsson. Additionally, a new multi-year technical and commercial partnership with Alfa Romeo has seen the team renamed the Alfa Romeo Sauber F1 Team.

Whilst the use of the current generation of Ferrari engines will certainly bring a performance boost, the team’s ability to improve its cars’ aerodynamic performance is recognised as being of potentially greater significance. It is here that Sauber’s established Additive Manufacturing capabilities, combined with its recent metal AM investments, is playing a vital role.

Additive Manufacturing at Sauber

Sauber is no stranger to Additive Manufacturing and, over a period of more than ten years, the company has developed a high level of expertise and production capacity in plastic AM. Selective Laser Sintering (SLS) and Stereolithography (SLA) are used primarily for the manufacturing of the aero parts required for testing new car designs in Sauber’s state-of-the art wind tunnel. Current regulations require teams to perform all wind tunnel testing on a 60% scale model car, so SLS and SLA systems are used to create the required high-precision scale components.

AM is the perfect technology for this, enabling the production of individual components featuring numerous minor variations of aero surfaces, details and angles to achieve an optimised airflow.

Christoph Hansen, recently appointed as Sauber’s Head of Additive Manufacturing, has worked at the company for more than ten years. With a background in both mechanical and design engineering, his career with the team is firmly embedded in the world of aero development, beginning as an aero designer and progressing to the position of Chief of Wind Tunnel Production in 2014. This path inevitably brought him into contact with the world of AM and he was pivotal in establishing the company’s plastic AM capability.

Today Sauber’s plastic AM ‘machine park’ comprises eleven large volume production machines; six SLS machines and five SLA machines, all supplied by 3D Systems. Hansen told Metal AM magazine, “We spent several years building up our SLS and SLA expertise to the point where we were confident that we could achieve the world class production of components. There is a strong learning curve in AM, whether metals or plastics. We learned a lot from our years of experience to-date, from environmental controls for both production stability and safety to highly optimised material reprocessing.”

Thanks to the diverse skills base within Sauber, Hansen and his colleagues were able to take a very hands-on approach to the optimisation of their plastic AM operation. The laser cooling systems on their SLS machines, for example, were fully customised to deliver optimum performance and the SLS systems’ integrated material recycling stations were also upgraded with a customised tablet interface to monitor and control their operation. The result, stated Hansen, was a dramatic improvement in the quality and efficiency of the facility.

The focus on learning to control all aspects of process and product engineering in-house also encompasses material development. The company’s proprietary HiPAC SLS material is based on a carbon-reinforced polyamide 12. With extremely low water absorption compared to other polyamides, it offers extremely high dimensional stability, with mechanical properties that are barely affected by moisture. As a result, Sauber’s AM HiPAC brake cooling ducts are used on the final F1 cars.

A focused approach to facility development

Competing in Formula 1 requires a huge amount of engineering capability. Sauber’s extensive facility at Hinwil, near Zürich, is a modern complex which today consists of three sections, built in stages over a period of nearly fifteen years yet connected seamlessly. Totalling more than 15,000 m2 of offices and production space, the layout of the facility is guided by minimising the travel distances between related operations and optimisation of workflows. Whilst the scale and capability of the carbon-fibre and machining departments is impressive, it is the company’s wind-tunnel, opened in 2004, that provides one of the facility’s most striking features.

Sauber’s closed-circuit wind tunnel is capable of reaching wind speeds of up to 300 kph and the same velocity is achieved by the steel belt of the rolling road, simulating the relative motion between the car and the track surface. Advanced simulation of cornering or side-slip conditions can also be achieved.

Whilst the wind tunnel was manufactured and installed by an external contractor, the approach that Sauber takes to managing and staffing it also offers an insight into how the company is approaching its new metal AM facility. “What we learned from the wind tunnel and from the plastics side of our AM operation is the importance of developing knowledge in-house, and then ensuring that this knowledge is effectively distributed within our operation,” Hansen explained. “An F1 team cannot afford downtime – when the pressure is on, we cannot afford for a system to fail on a Friday evening and then wait until Monday morning for support.”

Major repairs of the wind tunnel facility are undertaken by the specialists of Sauber’s wind tunnel group, but the company’s engineers and operators also have a deep understanding of all systems and have the ability to notice any issues at an early stage, investigate and take remedial action. “To wait until a system has failed and then face a situation where it is out of operation for a week would be disastrous for an F1 team, where the constant pressure to progress is felt much more keenly than in other industry sectors.” This approach has been echoed in the development of Sauber’s new metal AM operation.

The move into metal AM

Sauber’s first experience of metal AM component development was through the use of external service bureaux. The push to replace some SLA nano-composite epoxy resin aero testing components with metal parts has, however, resulted in a significant increase in the volume of components required, making the case for investing in the technology more attractive. Hansen explained, “For some of our wind tunnel tests, SLA parts did not always offer the rigidity to achieve repeatability, resulting in unreliable test data. We therefore started using metal AM aero test parts to overcome this problem.”

Armed with the knowledge that had been built up from the development of the existing plastics operation, Hansen started evaluating the major suppliers of laser Powder Bed Fusion systems in 2016. Initially he was frustrated at the responsiveness of some AM production technology providers, which cast doubt over the level of support that he might expect to receive as a customer. “The AM industry has been growing at a phenomenal rate and, perhaps as a result of this, we had some frustrating customer service experiences. Such teething problems may be inevitable when firms grow at such a fast pace, but for us it was the motivation to look further afield.”

Hansen’s ‘shopping list’ was guided in part by his experience of AM health and safety considerations, particularly in relation to the working environment, so systems that he believed sufficiently addressed the issues of powder contamination and safe powder handling were targeted. This, combined with the requirement for a multi-laser machine with a large build area of at least 400 x 400 x 400 mm, prompted him to open a dialogue with Additive Industries.

“Following our initial discussions, I immediately got the sense that we were not just another number. There is a particular way of thinking at Additive Industries that chimed with Sauber. Their responsiveness and enthusiasm gave us confidence that they could be a company that we could collaborate with.” The discussions resulted in the announcement of a partnership between the two companies at the Rapid.Tech conference and exhibition in Erfurt, Germany, in June 2017. By November 2017 the first Additive Industries system had been installed in the new metal AM facility at Sauber’s Hinwil base. The second machine was installed in February this year.

The metal AM facility

Sauber’s two MetalFAB1 Process and Application Development Tool systems are housed in a bright, open hall which also houses a Nabertherm heat treatment furnace. New gas infrastructure supplies high-purity gases and, based on the lessons learned in Sauber’s plastic AM facility, the ancillary laser cooling systems have been upgraded and backup power supplies installed to protect against process interruption.

Rooms off the main hall are used as offices and for the removal of builds from the MetalFAB’s build chambers, or ‘AM cores’. Climate management in the facility uses an over pressure system to ensure that, in the event of metal powder dust being accidentally released from a powder removal chamber, it does not contaminate other parts of the facility.

Following powder removal, build plate removal and the removal of support structures takes place within Sauber’s extensive machining facility, which is equipped with a range of equipment including a large CNC portal milling machine, wire EDM systems and precision milling centres. As one would expect for an F1 team, the quality testing of AM components takes place in an equally well-equipped quality control department.

When commissioning was completed on the first of Sauber’s MetalFAB systems, the team was aware of the much talked about ‘learning period’ for metal AM systems. “We were told that when we started using an AM machine we should ‘go-easy’ with some simple shapes but, driven partly by enthusiasm and partly by pressure to get components ready for testing, we started immediately with some impressive parts and were very quickly up and running. The tolerances that we were able to achieve when producing relatively large aero components were quite impressive.”

The ease with which Hansen and his team made progress with their metal AM operation should of course be considered in the context of the team’s significant experience in SLA and SLS. However, they also credit the stability and usability of the Additive Industries system, along with the support received from the company.

Metal AM components for car development and on-track use

The production of aero components for wind tunnel testing accounts for the greatest use of the metal AM systems at Sauber, with a variety of shapes that make the most of the full build volume of the MetalFAB1 system. “We manufacture a large number of aero components for the front wing, in particular, that offer a significantly higher level of wind-tunnel performance. The beauty of AM is of course that we can build numerous variations of angles and shapes for testing before the final component is manufactured in carbon fibre.” Where necessary, metal AM aero parts are joined together to enable the manufacture of much larger structures.

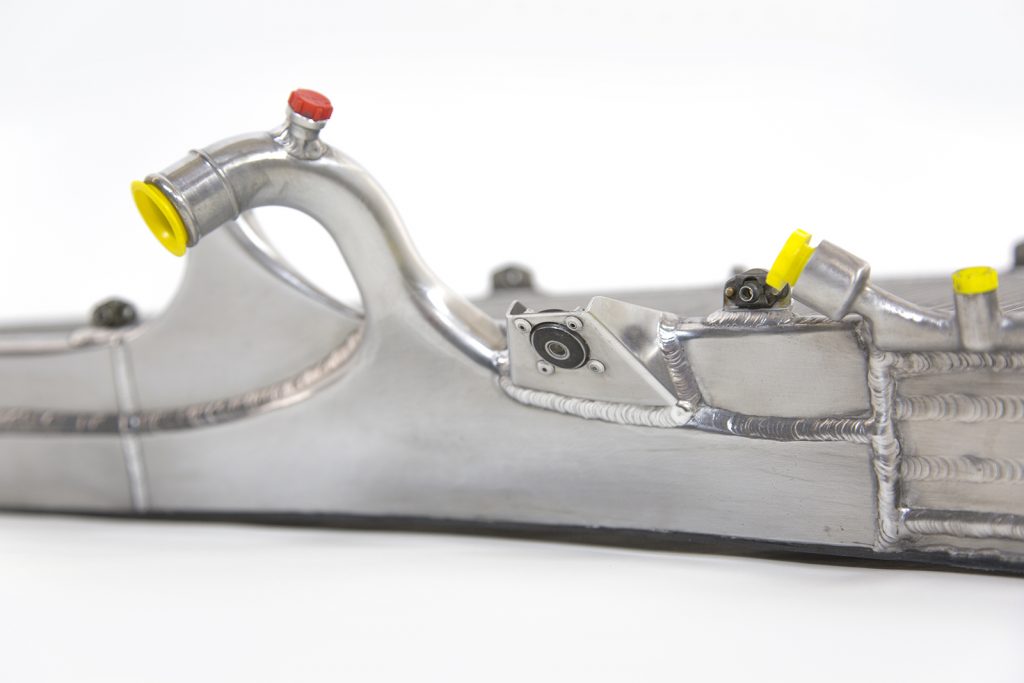

Metal AM components designed by Sauber for use on the final cars include exhaust components (Fig. 10), the Scalmalloy® roll hoop, with complex internal structures, which protects the driver in the case of the car inverting (Fig. 11), and radiator inlets and outlets (Figs. 12 and 13). As Sauber receives its engines and gearboxes from Ferrari, it has no involvement in the development of metal AM parts for these systems. In the case of radiator inlets and outlets, several sets of these are used on each car, with each having a unique design.

Sauber’s previous experience in designing for AM has put it in a strong position to adapt existing components for Additive Manufacturing. Hansen stated, “For functional components redesigned for metal AM, we believe that we are able to push these to a very high level of optimisation.” Support structures and build plate orientation are processed using Materialise Magics software. “Whilst Magics generates an initial set of support structures, we always manually adapt or enhance these to our own requirements,” added Hansen.

The appeal of the Additive Industries system

Additive Industries is a relative newcomer to the world of Laser Powder Bed Fusion (LPBF) systems. Founded in Eindhoven, the Netherlands, in 2012 by Jonas Wintermanns and Daan Kersten, the company designed its system ‘from the ground up’ specifically for the industrial production of metal AM components. This has been achieved through the combination of a modular, expandable design for maximum flexibility, the integration of proven technology from third party sources where appropriate, and a focus on a system design which minimises the risk to operators through metal powder exposure.

In 2016, Additive Industries announced that Airbus’ APWorks division would be the first beta customer for its full-size MetalFAB1 system, followed by the Dutch bakery systems developer Kaak Group and global Powder Metallurgy specialist GKN Sinter Metals.

The AM systems installed at Sauber, called the Process & Application Development Tool, incorporate the modular architecture of the full size MetalFAB1 system family but are aimed at lower initial production runs and do not feature the automation technology of the larger systems. Their modular design does, however, allow users to upgrade to a larger system at a later date. The technology and build volume of 420 x 420 x 400 mm are identical to the larger systems designed for series production. In the case of Sauber’s installation, both feature the quad-laser ‘exposure module’ and have already been expanded with automated build plate and product handling.

AM cores provide production flexibility

“For us, the modularity of the Additive Industries system is a big plus,” explained Hansen. “It enables a wider material mix and equates to a much lower investment when, for example, you want to process four different materials. An AM system needs to run 24/7 in order to recoup the necessary investment and if a machine has to be out of service for an extended period for cleaning, then this has a serious impact on our production capacity and schedules.” Thanks to swappable build modules, or ‘AM cores’, each machine offers a high level of production flexibility. Sauber has ordered two AM cores for each machine, meaning that it will have the capability to process four different materials if required without the need to strip and clean the machine.

Speaking to Metal AM magazine, Additive Industries’ Daan Kersten explained how further materials could be added to a customer’s operation. “In the case that Sauber wanted to process a fifth material, they have three options. They can either send one of their cores back to us for cleaning, rent an additional core for a fixed period, or purchase an additional core. In the case of returning a core to us for cleaning, the process can take a few weeks as this involves the disassembly of sub-systems. If required, a replacement core can of course be sent when collecting the core to be cleaned, making what you could describe as a ‘hot-swap’.”

Design influenced by safety

The risks posed by metal powders are well known in the wider metal powder processing industries, whether through the danger posed by the inhalation of fine metal dust, particularly when considering the carcinogenic nature of materials such as cobalt, or the danger of fire and explosion, which is of particular concern with fine metal powders and reactive metals such as titanium.

Kersten explained, “In our system there is no direct contact between a machine operator and the powder. In 2012, we bought two Laser Powder Bed Fusion systems from our competitors and were astonished how people were working with open powder. We were, of course, fully aware of how dangerous fine metal powder can be and immediately took steps to protect the operator. Whilst it is possible to provide operators with protective masks and clothing, these machines are intended to be used in a busy industrial environment where there is a risk that such precautions may end up being overlooked. Our philosophy is, therefore, to simply avoid the risk of exposing the operator to powder altogether. The safety of the operator is of the utmost importance.”

“With our system, the only time that powder is exposed to air is during machine maintenance and cleaning. This not only has safety advantages, but of course also helps maintain powder specification by avoiding contamination and oxidisation.”

Partnering on R&D and process development

As already highlighted, Sauber’s philosophy is to build internal expertise for all critical processes and facilities and to ensure that this knowledge is shared within teams. This remains the case with the metal AM facility and the partnership that has been formed with Additive Industries will enable in-depth knowledge of the system to be achieved.

Kersten explained to Metal AM, “Our system is designed to be very open and customers have a great deal of freedom to influence system settings and the ways that processes are managed. The technology partnership with Sauber allows us to work with them on improving our technology; with their high-performance applications and high throughput, they are able to ‘stress-test’ our systems for very specific types of applications. We are constantly in close dialogue with them and together with their engineering expertise, we get vital feedback which helps us to continuously improve our systems.”

The partnership will also help support materials development by the team at Sauber. “Without doubt, this technology partnership will add value to both parties,” stated Kersten. “From our initial beta customers to this technology partnership with Sauber, all improvement suggestions from our customers are taken seriously.”

In addition to the strategic long-term development of the MetalFAB1 system’s capabilities, Additive Industries believes that it offers industry-leading customer support for more immediate operational issues. “We want to be the benchmark when it comes to customer service in the Additive Manufacturing industry,” Kersten stated. “A technology supplier needs to be able to guarantee uptime. Our philosophy is therefore to grow our service team in anticipation of sales growth, rather than after sales have been made. We also encourage ‘smart service’, through which we can give remote support to our customers in order to get them up and running again as quickly as possible. Our ‘remote coach’ system consists of an earpiece, camera and microphone that a customer’s engineer can wear in order to be guided through a repair or maintenance procedure, all with the aim of avoiding the production delays that can result from an engineer callout. Time is further saved by having a service engineer dedicated to each customer, so there is an established understanding of a customer’s processes and equipment in advance of a support call.”

Training facility for Additive Industries’ customers

A further aspect of the partnership between Sauber and Additive Industries sees the new AM facility being used as a training venue for Additive Industries customers. Kersten stated, “Sauber has built a world class facility, fitted out to a very high standard and benefits from the ability to offer all process steps in-house, from design and engineering to post-processing and testing. As such, it is the perfect training facility for our customers’ engineers and machine operators. We run biannual training sessions that cover software upgrades and any processing enhancements that have become available.”

The future of metal AM at Sauber

Sauber has for a number of years manufactured end-use SLS and SLA components and prototypes for third parties, making use of spare capacity in its operations. As a natural expansion to this, the company is now also offering this service for metal components. Hansen stated, “Making some of our capacity available to third parties is now part of a growth strategy for us. We can be considered as a service bureau for metal and plastic Additive Manufacturing, but with the ‘USP’ that we are an operation founded on a rigorous and advanced approach to product engineering.”

“As an F1 team we have more than 400 employees who are the best in their field of speciality, be it component design, lightweight structures, testing and analysis or aero engineering. As such, we consider ourselves to be a total solutions provider. Our priority to-date has been internal process and application development, but we are also committed to offering specialist AM application development services to third party customers.”

The investment in metal AM at Sauber not only highlights the importance of the technology to the niche world of high-performance motorsport, but also the rapidly growing business opportunities in the area of third party AM services. These services will be even more attractive where a company can not only offer the entire AM process chain in-house, but the accompanying experience of more than thirty years heritage in engineering at the highest level.

Author

Nick Williams

Managing Editor

Metal Additive Manufacturing magazine

Email: [email protected]

References

[1] Print and be damned?, C Scarborough, Race Tech Magazine, Issue 175, June 2015

Contacts

Christoph Hansen

Head of Additive Manufacturing

Sauber Motorsport AG

Wildbachstrasse 9

8340 Hinwil

Switzerland

Tel: +41 44 937 90 00

Email: [email protected]

www.sauber-motorsport.com

Irina Schatorjé

Marketing Manager

Additive Industries

Leidingstraat 27

NL 5617 AJ Eindhoven

The Netherlands

Tel: +31 6 46280407

Email: [email protected]