Poly-Shape: Metal Additive Manufacturing for the high-performance motorsport industry

In a little over ten years, France’s Poly-Shape has grown into one of Europe’s leading manufacturers of AM components. With more than thirty metal AM systems installed across four plants, the company is a key supplier to top-tier motorsports, from Formula 1 and IndyCar to World Rallycross and the Pikes Peak International Hill Climb. In the following article, the company presents a series of case studies highlighting the use of metal AM in this sector, and reveals its approach to the technology and plans for the future. [First published in Metal AM Vol. 4 No. 2, Summer 2018 | 20 minute read | View on Issuu | Download PDF]

In terms of the metal Additive Manufacturing industry, Poly-Shape, at more than ten years old, is one of the more experienced companies operating within the sector. Founded in 2007 near Paris, France, by its CEO Dr Stéphane Abed, the company offers a depth and breadth of experience in metal AM to international customers in a range of high-tech industries, including aerospace, energy, industrial and motorsports, and is involved in both the prototyping and series production of parts.

As well as offering a high level of expertise in powder bed Additive Manufacturing for the production of geometrically complex parts, the company also uses Directed Energy Deposition systems for the production of simpler components from both powder and wire feedstock. Currently, it operates more than thirty metal AM production systems across its four European plants, aided by in-house capabilities covering the full component life-cycle, from conception through design to eventual manufacture.

A heritage in high-performance motorsport

Poly-Shape’s motor racing roots date back to the establishment of its original facility, situated close to Renault Sport’s Formula 1 engine development site in Viry-Châtillon, France, where initial collaboration between the companies quickly identified a range of applications for metal AM within the automotive industry. Continued growth in this and other areas soon saw Poly-Shape launch its first R&D facility in Salon-de-Provence, close to one of Formula 1’s most famous circuits, the Circuit Automobile Paul Ricard at Le Castellet. It was out of this facility that the company produced its first parts for the motor racing industry.

In 2011, the company began a research programme in collaboration with Renault F1 to explore the use of hot exhaust gases directed upwards to help ‘suck’ its R31 vehicle to the track. The following year Team Lotus – then the F1 team of English sports car manufacturer Lotus Cars – engaged Poly-Shape as it investigated the use of the Coanda effect to augment the effectiveness of the rear wing on its E20 car (Fig. 1). The Coanda effect is a phenomenon in which a jet flow attaches itself to a nearby surface and remains attached even when the surface curves away from the initial jet direction. Both parts required a complex three-dimensional geometry and very thin walls for weight-saving, making them impossible to produce by conventional manufacturing methods and thus ideal candidates for metal AM.

Around the same time, a number of teams began to turn to metal AM to manufacture multiple iterations of components for use in dynamometer (dyno) and wind tunnel testing. As confidence in the technology grew through the testing process, an increasing number of parts were designed and manufactured specifically for race conditions. Poly-Shape has since seen revenue from the F1 industry grow dramatically and states that it has manufactured parts for engines, chassis, suspension, exhaust systems and accessories for the majority of teams active in the sport. Today, four engine manufacturers across eight F1 teams have used metal AM parts produced by Poly-Shape, including complex components such as roll hoops, cooling plates, hydraulic blocks, pump housings, cooling pipes, wing support structures, turbine and compressor casings and other areas in which strength and temperature resistance may be critical.

Expertise in converting components to AM

One of the key strengths which Poly-Shape believes has helped it to achieve such success in the high-performance motorsport industry is its ability to take existing, traditionally manufactured components and apply the principles of Design for Additive Manufacturing (DfAM) to optimise their weight, functionality and suitability for metal AM. A vital part of DfAM is topological optimisation – a mathematical iterative method able to calculate the very minimum mass required in a component based on a material’s mechanical properties within the volumetric constraints of the part. This enables the designer to build a part with the right amount of the right material at the right place for the right reason.

Using this expertise, the company now co-designs and produces parts not just for F1 cars but for a range of performance racing vehicles for hill climbing, open wheel racing, rallycross and more. In 2016, it launched Poly-Shape Italia, a new facility dedicated to the manufacture of components for motorsports vehicles in Carpi, Modena, Italy.

“Thanks to our training sessions and through our motorsport-dedicated designers, who are going to customers’ design offices to work side-by-side with engineers, more and more of the components we are producing are now designed for AM,” states Frédéric Impellizzeri, Business Unit Manager Motorsport/ Ground Vehicles at Poly-Shape. “The most important step to reach for our customers is for them to accept that, once a part has been redesigned for AM, they will not be able to return to a conventional manufacturing method, and this acceptance is only possible once the customer feels very comfortable with the technology in terms of reliability and consistency.”

As an approach to AM, Impellizzeri suggests, “Forget all that you learnt about process limitations, focus on the function of the system you are designing and open the box to give freedom to your mindset.”

The following case studies demonstrate some of the ways in which the motorsport industry, supported by Poly-Shape’s designers, is embracing new approaches to redesigning and optimising critical components for a range of performance vehicles.

Norma Auto Concept and Romain Dumas: Pikes Peak International Hill Climb

In 2017, Poly-Shape was approached by Norma Auto Concept for design and manufacturing input on its Norma MXX RD Limited vehicle, intended to be driven by Romain Dumas in the annual Pikes Peak International Hill Climb, Colorado, USA (Fig. 2). Known as the ‘Race to the Clouds’, this is said to be the third oldest official automobile race still active in the USA, having begun in 1916. The course consists of 156 corners over 12.42 miles, with an average gradient of 7.2%, finishing at an elevation of 14,110 ft.

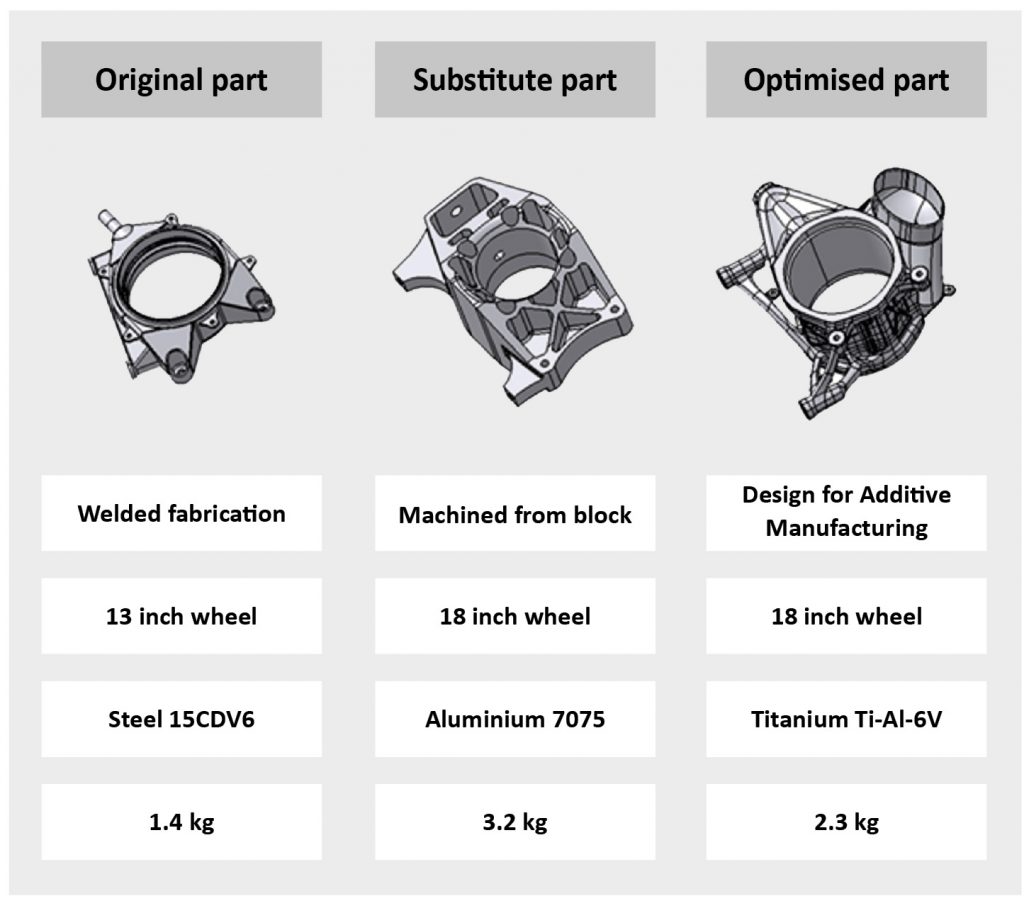

Norma Auto Concept had previously developed the M20 RD Limited prototype, also for Romain Dumas. Equipped with alloy steel 15CDV6 mechanically welded uprights and 13-inch wheels, the car had won the event in 2014 and 2016. In order to challenge for a third win, the company began work on the Norma MXX RD, with a new aerodynamic package and tyres specifically designed for 18-inch wheels.

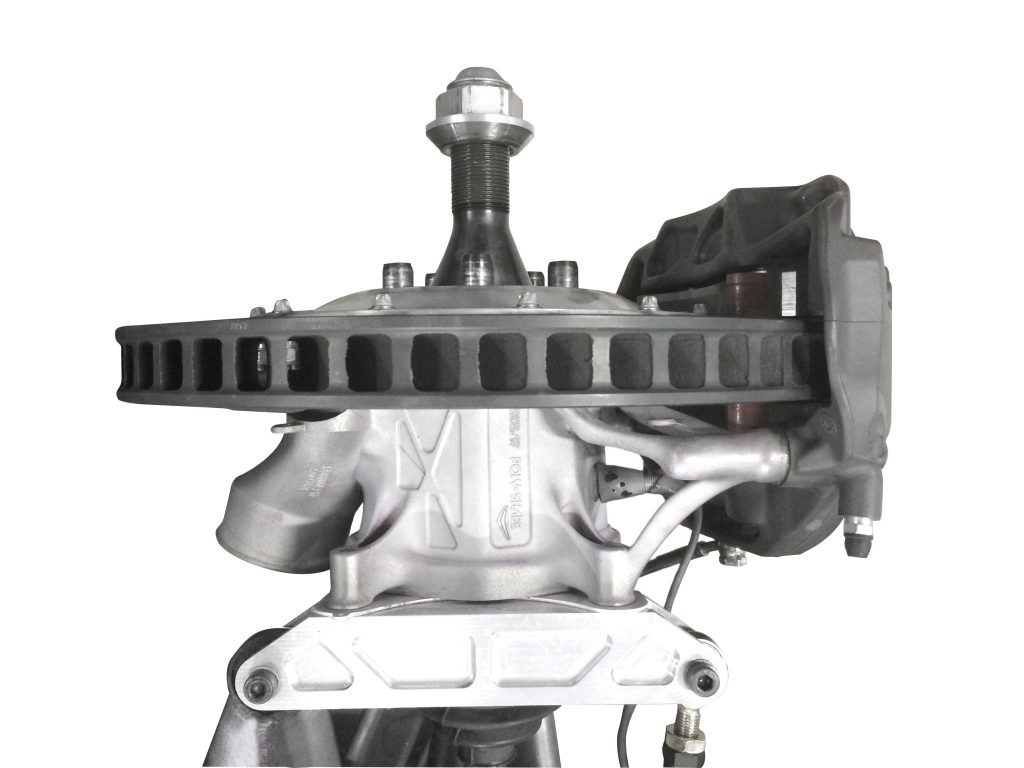

On finding that these modifications created a 30% increase in load, the company identified the need to create new uprights which would be able to withstand the new load while limiting any increase to the vehicle’s mass (Fig. 3). Due to its proven track record in the topological optimisation of automotive components by AM, Poly-Shape was approached for design and manufacturing input.

An upright (or knuckle) is a safety-critical component of a car’s suspension, containing the wheel hub or spindle and attaching to the suspension parts. As such, it was of paramount importance that Poly-Shape design a full-scale testing programme involving mechanical tests, metallographic characterisation and other non-destructive control processes, as well as on-track testing in real conditions.

Titanium alloy Ti-Al-6V was selected as the production material for its high strength-to-weight ratio and, following the creation of a number of design iterations using topological optimisation in line with the principles of DfAM, the part was finalised for manufacture using Laser Powder Bed Fusion (LPBF) on an EOS M290 metal Additive Manufacturing system. Once this initial design was structurally validated, a thin wall scoop was integrated for the brake air cooling. Now comprising just one piece, the new design eliminated the need for fastenings and the locally increased wall thicknesses required to hold them, as well as removing the time and risk associated with assembly and eliminating potential failure sites.

At the same time as Poly-Shape was developing its solution, an alternative was created by Norma Auto Concept which could be machined traditionally from a block of aluminium alloy 7075, resulting in a mass of 3.2 kg. As shown in Fig. 4, the additively manufactured approach resulted in a part weighing just 2.3 kg, despite being produced from the denser but stronger titanium alloy. When applied to all four uprights on a vehicle, the total weight saving was almost 4 kg when including an air scoop; a reduction of more than 30% compared to the aluminium alternative. As a result, Norma Auto Concept opted to use the additively manufactured uprights and, after completion of testing, the parts were built, machined and finished by Poly-Shape.

Romain Dumas, who went on to win the 2017 edition of the race in the Norma MXX RD, stated, “With Poly-Shape, it was an amazing meeting. Poly-Shape designed the uprights, manufactured them and improved their stiffness. They represent, I think, more than just a breakthrough for these big 18-inch wheels. For us, they are the most beautiful pieces of the car.”

Dale Coyne Racing: Verizon IndyCar Series 2018

Currently in its 23rd season, the Verizon IndyCar Series is arguably the premier open-wheel racing event in North America. The 2018 series is comprised of seventeen races, beginning in March with the Firestone Grand Prix of St. Petersburg, Florida, and culminating in September with the Grand Prix of Sonoma, California.

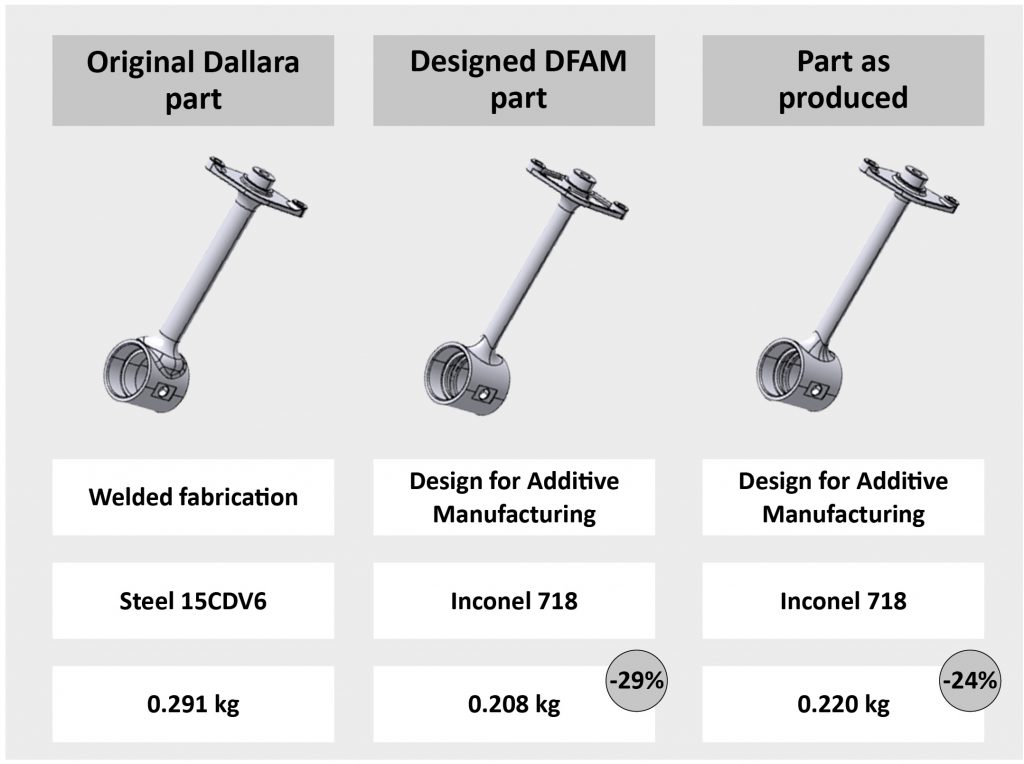

The IndyCar Series originally required all teams to purchase a stock chassis from Dallara. However, from 2017, the series began to allow teams to manufacture certain Dallara designed components in-house to take advantage of any cost savings they could identify. Modifications to some stock Dallara parts were then also allowed, enabling teams to redesign parts to achieve better performance and weight savings. One team to take advantage of these changes to the regulations was Dale Coyne Racing (DCR), which, in 2017, approached Poly-Shape for design guidance on the production of its front and rear anti-roll bar components (Fig. 6) using metal Additive Manufacturing.

An anti-roll bar is a system within a car’s suspension which helps to reduce body roll during fast cornering or when travelling over road irregularities. It connects the opposite (left and right) wheels using short lever arms, which are linked by a torsion spring. The anti-roll bars produced from the existing stock design were stiffer than needed for some tracks. They were also fabricated assemblies, which were welded together by hand, and as such were heavier than necessary. DCR’s goal was to produce parts which were as light as possible and softer in spring rate, while maintaining the strength required to resist the loads and resulting deflections of the car in race conditions.

Poly-Shape worked through numerous iterations with DCR’s engineers, eventually presenting an optimised inconel design to the IndyCar Series for approval. However, the series regulators rejected the redesigned parts due to their lack of visual similarity to the Dallara design. As a result, revised designs were created and manufactured by Poly-Shape on a LPBF Additive Manufacturing system, with production, heat treatment, hand finishing, NDT and dimensional inspection taking around three weeks overall (Fig. 7).

The stipulation that the redesigned parts should look similar to the stock part prevented the company from incorporating the holes, pockets and thickness variations, which enable a part to take full advantage of the possibilities offered by AM, thus limiting the weight savings it could achieve. However, the final design remained considerably lighter than the original, eliminated the assembly and weld steps by consolidating the parts, and offered better dynamic properties (Fig. 8).

Craig Hampson, DCR Race Engineer, stated, “By using Additive Manufacturing, we were able to create parts that were manufactured as a single piece, rather than welded-up fabrications. The parts are both lighter and stronger, and we were able to optimise the material thicknesses to maintain a consistent level of stress. Our original design brief was to create anti-roll bars which were softer in spring rate but would still fit within the confines of the Dallara chassis and IndyCar rules. Poly-Shape was able to help us accomplish that, particularly because of their high-level finite element stress analysis and topology optimisation capability.” The new anti-roll bars will be used depending on the track’s configuration, being either street circuit or oval. Poly-Shape is now working on a magnetic alloy to meet IndyCar’s recent revision of the regulations.

PIPO Moteurs: World Rallycross and World Rally Championship

PIPO Moteurs, Guilherand-Granges, France, specialises in the design, development, manufacture, and maintenance of race engines. Over its forty-five year history, the company has been responsible for the Peugeot 306 Kit Car, 206 & 307 WRC, Ford Focus WRC, Ford Fiesta S2000 WRC, Hyundai i20 WRC, i20 R5 & i30 TCE, Bentley Continental GT3, Ford Fiesta WRX Hoonigan and DS3RX Solberg. Vehicles with engines by PIPO Moteurs have won five World Rally Championships (WRCs) and two World Rallycross (WRX) FIA Championships.

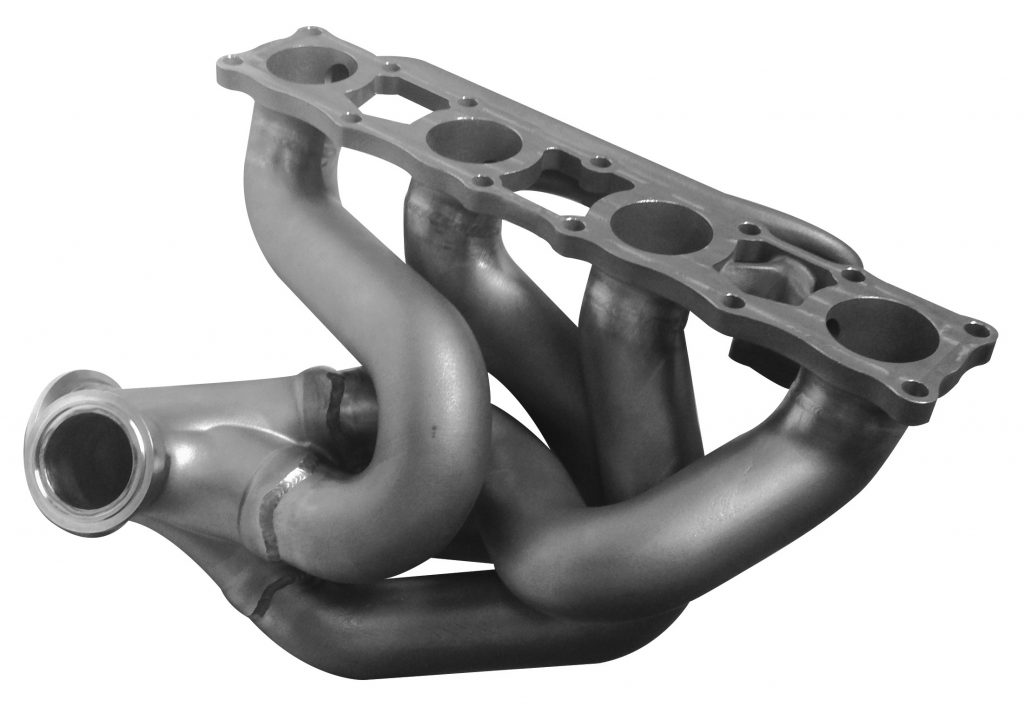

The company recently worked with Poly-Shape to design and additively manufacture the exhaust assembly for its turbocharged 1997cc inline four engine, designed for non-factory private teams competing in World Rallycross and Word Rally championships. The final exhaust assembly consisted of six additively manufactured components:

- A flange, with integrated tubing and fresh air collector

- A 4:1 collector with bypass wastegate

- Four individual primaries

These parts were produced individually from Inconel on a Laser Powder Bed Additive Manufacturing system, before being welded into a complete assembly with the addition of one machined V clamp flange (Fig. 9). With the new design of the fresh air flange and the exhaust plate, the complete exhaust assembly comprises eight parts instead of eighteen, yielding an 18.9% mass saving while reducing assembly and welding failure risks.

Porsche: Aftermarket application

One application area for which the potential of metal Additive Manufacturing is increasingly recognised is in the automotive aftermarket, for the provision of spare and replacement parts for older or collectible vehicles. Some major automotive companies to have recognised this potential are Mercedes-Benz, Audi and Porsche Classic, all of which have recently adopted metal AM for the production of parts for vehicles which are no longer produced, or which were produced in very limited runs.

The production of metal replacement parts has traditionally been dependent on the availability of the blueprint for the original part, the type of tool used in their original manufacture and the original materials, meaning that the cost of obtaining replacement parts for older models can be prohibitively high, especially when the part is required in small batches or as a one-off order.

The use of Additive Manufacturing can allow the original part design to be inputted and reproduced using a single system, thus making production more cost-efficient even at low quantities compared to where the retooling of conventional machinery is required. However, where the original part design is not available, it may be necessary to retro-engineer the design for AM.

In this example, Poly-Shape was approached to produce a replacement for a SCART aftermarket ‘three into one’ exhaust collector for a Porsche 911 Turbo 997. The company used data collected from a point cloud using a 3D scanner to generate an electronic model of the part, from which it was able to reverse engineer it into a single component for production on a LPBF system.

The original exhaust collector produced by Porsche would have been in stainless steel and weighed 3.13 kg, while the SCART aftermarket iteration, also in stainless steel, weighed 2.45 kg. By changing the material to Inconel and consolidating the collector into a single component, Poly-Shape was able to reduce the weight to 2.3 kg (Fig. 10). In addition, by eliminating all weld areas, the life span of the part was extended.

Poly-Shape looks to the future

In order to work more closely with its customers and to better accelerate the adoption of Additive Manufacturing for industrial applications, Poly-Shape told Metal AM magazine that it is now developing two additional services which will, firstly, enable clients to better understand and apply Design for AM and, secondly, enhance and ensure the quality of raw materials used in AM and the material properties of the finished part.

With the launch of CREADDITIVE, its new design service, the company is looking to shift the mind-set of its customers from traditional to additive design by offering tools, training sessions, collaborative workshops and further courses. This, it is anticipated, will enable customers not only to accelerate their adoption of AM but to ensure that they take full advantage of the freedom of design which the technology offers.

Beginning with an assessment of the client’s level of DFAM expertise, Poly-Shape adapts each course and its duration specifically to the needs of each customer, with varying goals: from improving an individual’s capacity for creative design and identifying potential AM applications through an investigation of existing parts, to educating multiple departments at a company in AM and identifying the patentability potential of an AM concept.

Beyond a need to grow an understanding of DfAM, Impellizzeri believes that the main factor limiting the adoption of metal Additive Manufacturing is the lack of materials available to manufacturers. “The material choice is currently not at the same level that you can get with traditional processes,” he explained, “but this will be less and less true as more and more materials arrive on the market. Some of them will even be especially developed for AM, bringing new properties you wouldn’t be able to reach with traditional processes.”

Poly-Shape is now placing materials at the forefront of its research and development efforts, having added to its services a new materials analysis laboratory at which it is investigating new materials and processes, as well as ensuring the quality of the raw materials currently used in its Additive Manufacturing processes and the final properties of the parts produced. The new laboratory is fully equipped for inspection of the chemical and mechanical properties of metal powders and the metallurgical compliance of the finished part.

“For each part which is produced, we generate a new metallurgical structure and this is one of the main differences when comparing AM to machining,” states Impellizzeri. “That means we need to validate all of the process parameters, the raw material – which is the powder with its own characteristics – and design, and once the desired outcome is reached in terms of mechanical properties, geometry and surface roughness, we have to freeze them for production. Then, conventional inspection methods can be used on the finished part, especially tomography, which allows both geometrical and metallurgical inspection, whatever the complexity of the part.”

Poly-Shape describes itself as having a ‘mission’ to continue to implement Additive Manufacturing throughout motorsports as well as in other industries, and to increase its awareness as a viable technology for international equipment manufacturers, their sub-tiers and, eventually, across the entire value chain. To that end, the company continues to develop an expertise which covers the entire Additive Manufacturing workflow, supporting its customers through the initial concept and design through CREADDITIVE, up to the manufacture, testing and integration of the part into the final product.

Looking to the next ten years, Impellizzeri highlights one issue he believes will be key to the industry’s success. “We are still in the initial growth phase of this industry and machine manufacturers are still exploring a lot of potential solutions, and do not spend time making sure their machines are totally reliable before they put them on the market,” he states. “At Poly-Shape, some machines have had to be improved or tuned by ourselves in order to make them production ready!”

Over the next decade, he forecasts, “Machines will definitely be more affordable, more productive and more consistent. Young engineers and designers will be better trained to really design for AM, and our customers will consider this technology as a real candidate from the earliest stage of their development projects.”

Contact

Poly-Shape

235, Rue des Canesteu

ZI La Gandonne 13300

Salon de Provence

France

Tel: +33 4 13 22 19 10

[email protected]

www.poly-shape.com