Link3D’s ‘Additive Manufacturing Maturity Model’: Developing an agile and resilient supply chain

As the metal Additive Manufacturing industry matures at a rapid rate, organisations are now faced with the challenge of scaling their AM operations. Based on a study of 253 companies in a number of sectors, US-based AM software specialist Link3D has developed an ‘Additive Manufacturing Maturity Model’. This simple model can be used as a tool to understand an organisation’s AM maturity whilst also helping them navigate the steps to developing an agile and resilient AM supply chain. Shane Fox, CEO and co-founder of Link3D, explains. [First published in Metal AM Vol. 6 No. 2, Summer 2020 | 10 minute read | View on Issuu | Download PDF]

The Additive Manufacturing industry has started to fulfil its promise and many of the world’s largest economies are taking notice. The 21.2% growth of the overall industry in 2019 (estimated to be worth $11.867 billion) is foundational proof of its momentum [1]. However, investing in new technologies is always risky, and Additive Manufacturing is no exception to the rule.

Over the last two years, Link3D has conducted a study of 253 companies across the aerospace, automotive, consumer, defence, medical and other industrial sectors to better understand the risks of scaling up industrial AM production environments. Headquartered in Boulder, Colorado, USA, Link3D’s Additive MES workflow software is designed to help organisations scale their digital manufacturing strategy and applies modern technologies, such as the Internet of Things (IoT), workflow automation and machine learning, to enable manufacturers to unlock the benefits of Industry 4.0.

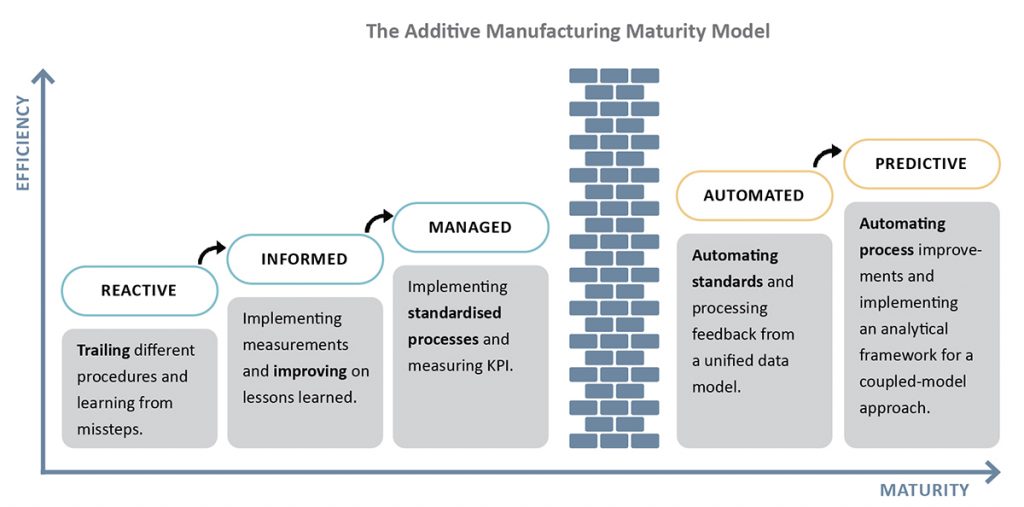

Using the results of a two-year study, we have developed a framework known as the ‘Additive Manufacturing Maturity Model’. Within this model, as organisations mature their processes, production efficiencies are expected as they transition through defined stages; these being named reactive, informed, managed, automated and predictive. They can choose various paths to mature their processes, including incremental growth, leapfrogging or starting from zero. It is important for businesses to navigate the risks that all change poses and manage them to ensure success by minimising overhead costs, eliminating poor data management and gaining leadership and employee buy-in.

In this article, we will consider how Fortune 500 organisations, contract manufacturers and service bureaux can overcome risks to enable a sustainable business model and ensure business continuity.

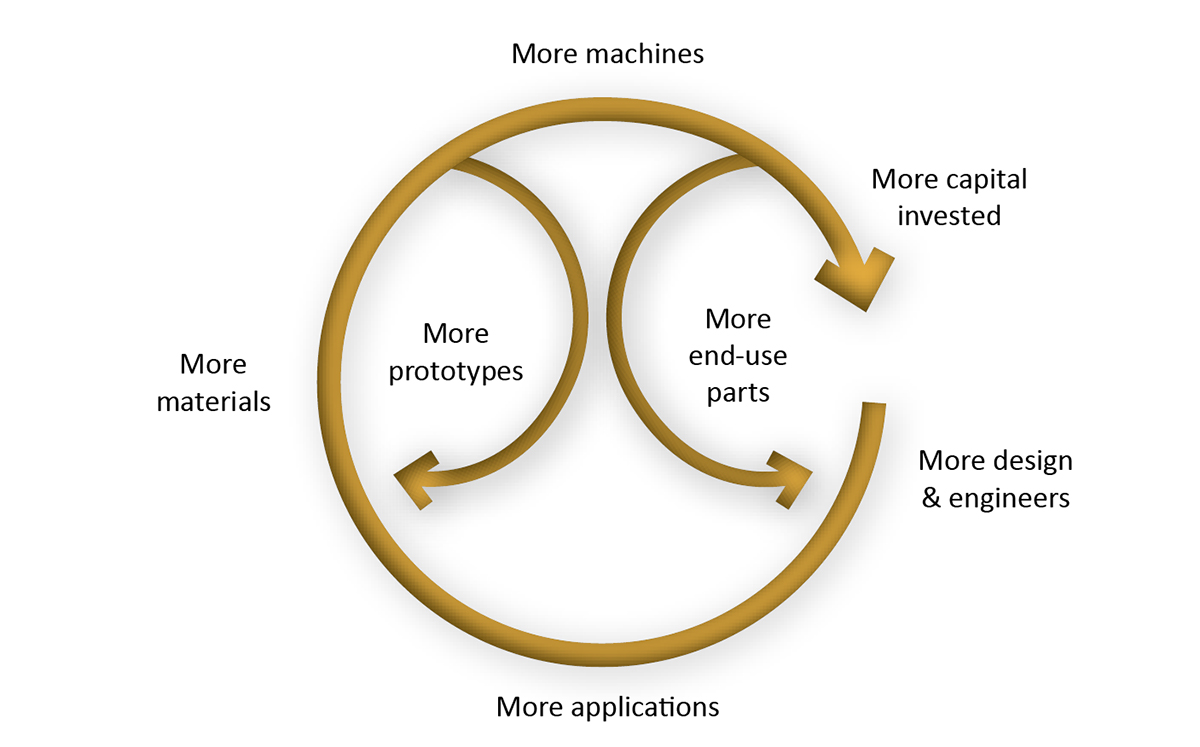

AM is enabling new technologies in a cyclical ‘virtuous cycle’

The Additive Manufacturing industry has now entered the ‘virtuous cycle’, a recurring cycle of events, the result of each one being to increase the beneficial effect of the next – literally, the opposite of a ‘vicious cycle’ (Fig. 1). In the virtuous cycle, the more engineers that design products, the more applications there are. The more applications there are, the broader the AM material selection becomes. Thanks to this cycle, we are starting to see new generations of machines with broader material capabilities, larger build volumes and serial production build times and quality. These advancements are now pushing the downstream technologies into a virtuous cycle to complete the manufacturing process.

This virtuous cycle has meant that Additive Manufacturing technologies have rapidly matured and will only continue to be improved upon in the future, as the loop reinforces itself. In summary, innovation within materials, AM machines and a host of post-processing and downstream technologies showcases the capabilities and processes that are constantly evolving.

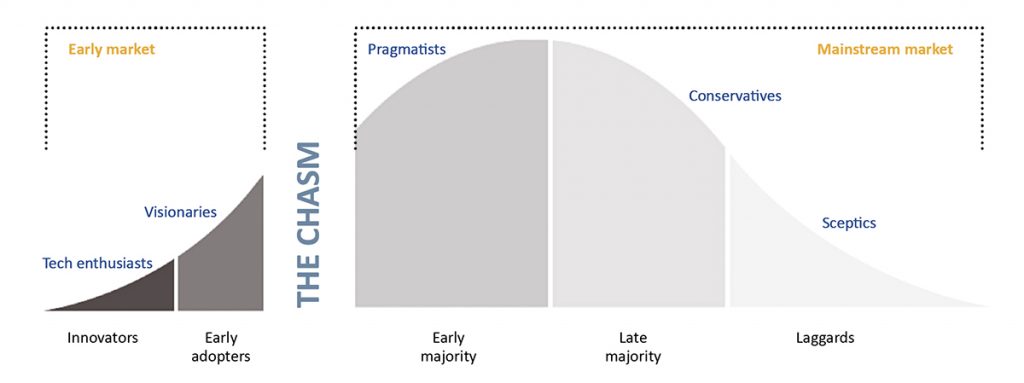

As many of us already know, AM is no longer just for tech enthusiasts and visionaries. Use cases for AM have, in recent years, extended well beyond R&D and prototyping as organisations have begun to utilise the technology for series production with previous success under their belts. The virtuous cycle has pushed the industry beyond the narrow but necessary adoption window in which innovators and early adopters are the target market, through the ‘chasm’ and into the mainstream market (Fig. 2). Innovators set the foundation for AM and now its adoption is becoming mainstream across a variety of industries.

Currently, the majority of organisations are either in the discovery, building or scaling stage of their AM journey. As the demand for AM services such as the production of prototyping, tooling, jigs and fixtures and serial parts, grows, these organisations are naturally under pressure to standardise their workflows to deliver repeatable, timely and consistent results. We see AM continuing on a positive trajectory, as organisations are strategising and creating their five to ten-year digital manufacturing plans and building practical approaches to utilise AM alongside their traditional manufacturing technologies for series production.

The growth of AM leads to added complexity and challenges

Although the progress of AM enables the development of agile supply chains, opportunities for cost reduction, better supply chain resiliency and product advancement, and enables ‘vision to delivery’ on technology that it has not been feasible to manufacture before, these advancements come with challenges and added complexity. Because the Additive Manufacturing industry is in a constantly evolving state, organisations face the challenge of keeping up with an ever-changing technology at the same time as trying to scale up their AM operations to meet demands.

Innovation within AM has historically been focused on machines and the technology within them; machines to produce complex geometries, machines to build faster, machines capable of building in different materials. However, as organisations begin to use AM for on-demand manufacturing, concurrent manufacturing, and series production, the focus has to shift from the hardware to the environment in which these machines operate.

Isn’t the end-goal for AM to achieve repeatable, quality parts that meet standards and regulations and to be a ‘new’ tool within the supply chain? If so, there is a critical need for innovation beyond hardware.

How organisations can mitigate risks within their AM supply chains

While the virtuous cycle and the adoption curve are both tools to assess the progress of the AM industry, the ‘Additive Manufacturing Maturity Model’ developed by Link3D can be applied to its customer base and future prospects to assess each organisation’s AM maturity across its people, process and technology.

A critical component in how organisations grow their Additive Manufacturing operations is discipline – from both a process and financial perspective. Link3D guides organisations through their AM maturity and consolidates data into a single unified data layer, translating information into actionable insights to prove return on investment for AM.

We believe that understanding an organisation’s stage of maturity through the use of the Maturity Model is a necessary discipline in order to enable them to set up a strategy to reach their digital manufacturing vision. This can be used as a benchmark for organisations to visualise the growth of their AM operations and understand how they can mitigate scaling pains associated with risks.

As stated in the introduction to this article, as organisations mature their AM processes, greater production efficiencies are expected as they transition from the reactive to the informed, managed, automated and predictive stages (Fig. 3). Whether they mature their processes through a path of incremental growth, leapfrogging or starting from zero, businesses must manage the risks which all change generates and work to ensure success by minimising overhead costs, eliminating poor data management and gaining leadership and employee buy-in.

Reactive stage

Organisations in the reactive stage are just beginning to dabble in AM. Typically, they are evaluating the host of technology options available and comparing them to opportunities they have identified for best fit. Organisations within the reactive stage tend to be focused on R&D, and possibly low-volume production, and are starting to envision new possibilities based on their successes.

When organisations are in the reactive stage, they are just beginning their journey and there tend to be fewer strategic decisions inclusive of capacity, facilities, verticals and technology integration. Ultimately, the risk of living in the reactive stage is the inability to create strategic vision around the potential future, as organisations are acting in response to rather than creating or controlling situations. This becomes a limiting factor for organisations as they find strategic opportunities to leverage the technology through their R&D efforts.

Informed stage

Through lessons learned in the reactive stage, organisations in the informed stage have begun identifying strategic uses for AM within their business model. They may have started identifying ways to include AM in their operational and financial plans, but are usually struggling with the growing complexity driven by the manual work and volume of data AM involves.

As the AM industry is complex, fast-paced and constantly evolving, organisations at the informed stage risk remaining stagnant, as they may miss new market opportunities and become obsolete.

Managed stage

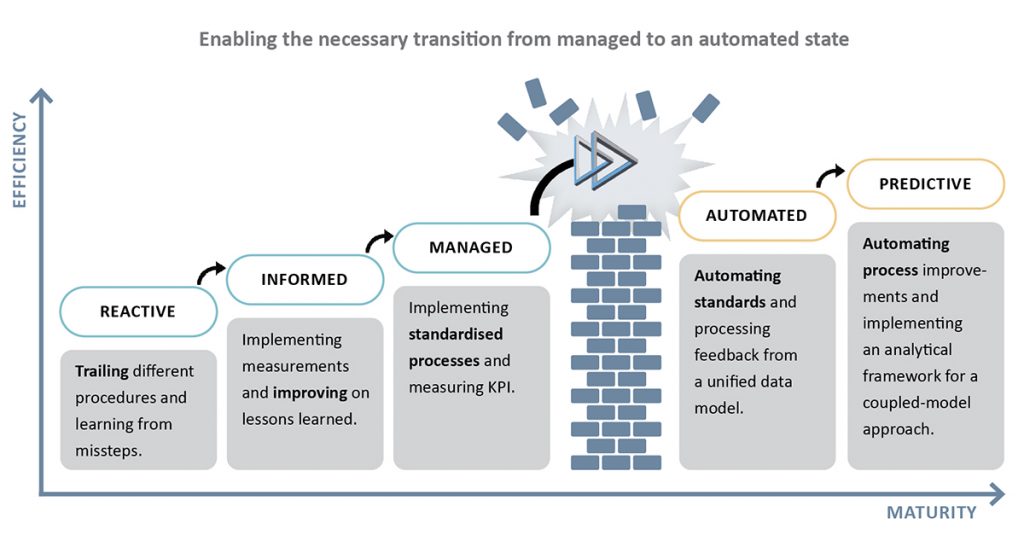

When organisations operate in the managed stage, they tend to have high human capital with manual workflows. As demand has increased, new or previously adopted siloed solutions present additional risks as systems are disconnected, leaving room for human error, loss of data and challenges to meet stringent customer quality requirements. By remaining in the managed stage, organisations’ future growth and profitability is limited.

We have observed that organisations in the managed stage tend to be past the point of no return, with a sizeable investment having been made in the infrastructure, people and technology required for AM adoption. However, they are stuck at a ‘brick wall’ with analogue and point solutions. This wall inherently limits a unified data layer and ultimately blocks the ability to move into an automated stage (Fig. 4).

Automated stage

Moving into the automated stage is the foundational first step organisations must take in order to start their true digital manufacturing journey. This transition is only possible with the adoption of a unified data model powering a true end-to-end solution. Organisational alignment across key stakeholders regarding a digital manufacturing strategy enables best-in-class integration into a central operating system.

Any internal misalignment of change management presents risks, as an organisation may attempt to build a solution in-house without viable long-term expertise, or adopt an unfit solution, leading to failure.

Predictive stage

Forward-thinking organisations in the predictive stage are taking AM a step further by incorporating data analytics into their processes. At this predictive stage of AM adoption, teams are performing the same functions as they did during the automated stage (mitigating friction points and delivering design optimisation insights), but are doing so in ways that both enable and drive their profitable expansion of Additive Manufacturing. Moreover, data-centric teams have the power to deliver insights when and where they are likely to be most impactful.

Establishing the foundation of your AM strategy is inherently important, as this is the foundation that the digital thread is built upon. If the correct data model was not established in previous stages, the predictive outcomes that are guiding your organisation’s key decisions can be misleading.

Sustainable paths to scale

Incremental growth

Organisations lacking financial and human resources often opt for incremental growth to mature their processes. When it is no longer sustainable to continue operating effectively, standardising processes and introducing small-scale technologies can incrementally improve operations from one stage of AM maturity to the next.

However, such organisations are often challenged by a lack of human resources. As operations are lean, dedicating employees to discover, evaluate and implement new technologies becomes difficult. Hiring consultants or relying on a vendor’s customer service programme can be a solution to alleviate risk for implementing continuous improvement programmes and driving business objectives.

Zero to one

Additive Manufacturing has been around for over thirty years and organisations that have been watching the industry closely have seen success and failure. More often than not, they hire AM experts to launch larger programmes within their organisation to support their business divisions.

Instead of introducing lean practices for validating new technologies with manual workflows, organisations following the ‘zero to one’ path will often develop a holistic business plan that takes into account facility requirements, headcount, AM technologies (machines, materials, auxiliary equipment) and software (CAD, build prep software, workflow automation software). By prioritising the implementation of an end-to-end digital manufacturing solution, they can lay an infrastructure foundation which is able to scale as AM plant operations and supply chains mature.

Leapfrog

Not all organisations have the opportunity to jump from zero to one; however, they can ‘leapfrog’ towards the automated or predictive stage. During the reactive and informed stage, they are not inundated with order requests and so, at this time, can allocate time and resources to introduce the scalable workflow automation software that can enable them to scale their AM production.

Conclusion

Trends for AM growth across organisations include an increased number of developed applications for AM and increased AM literacy, driving production and reduced design cycle times with tech-enabled CAD design software for digitising parts at scale. With the increase in AM demand, organisations will experience growth challenges at every stage of their AM journey, but the AM Maturity Model is designed to help them to reflect and plan how they want to mature their processes and what level of efficiency they would like to achieve.

Link3D is dedicated to helping businesses scale their Additive Manufacturing operations for industrialisation and mitigate the associated risks. Our experience and studies have shown that organisations must consider their digital manufacturing strategy earlier in the AM journey to ensure sustainable business growth as they expand their AM capabilities.

The digital revolution is still in its early stages, but is clearly starting to take shape. This year, the strain put on global supply chains by the coronavirus (COVID-19) has offered yet another example of why organisations must prioritise agility and resilience when it comes to their supply chains. Digital connectivity among designers, engineers, managers, technicians and physical industrial assets will unlock enormous value and has the potential to change the manufacturing landscape forever.

Contact

Shane Fox

CEO

Link3D

2765 Dagny Way Suite #200

Lafayette

Boulder

Colorado 80026

USA

[email protected]

www.link3d.co

References

[1] ‘Additive Manufacturing Industry Grows To Almost $12 Billion In 2019’, May 8, 2020, Forbes www.forbes.com/sites/tjmccue/2020/05/08/additive-manufacturing-industry-grows-to-almost-12-billion-in-2019/#1fcecf1b5678