In pursuit of perfection: A case study on how Bugatti and APWORKS leverage the full potential of AM

It is far too easy to overuse superlatives when speaking about hypercars or Additive Manufacturing. When the discussion combines both – Bugatti’s new driver-focused Chiron Pur Sport and a high-performance AM component that truly pushes today’s processes to their limits – the result is worthy of a closer look. In the following in-depth case study, Bugatti and APWORKS explain the requirements, development and production of the Chiron Pur Sport’s exhaust finisher and share insight into some of its hidden details, from lattice structures to nature-inspired honeycomb reinforcements. [First published in Metal AM Vol. 6 No. 2, Summer 2020 | 10 minute read | View on Issuu | Download PDF]

France’s Bugatti Automobiles S.A.S., famous for its ultra-high performance hypercars, was one of the early adopters of metal Additive Manufacturing in the automotive sector. The company has developed numerous components using Additive Manufacturing, many in partnership with APWORKS GmbH, Taufkirchen, Germany. One component type that Bugatti has gained significant experience of developing by Additive Manufacturing is the high-performance exhaust finisher. These have been fitted to a number of cars in the Chiron range since 2018, including the Chiron Sport, the La Voiture Noire, the Grand Tourisme and the Centodieci.

Most recently, a metal additively manufactured exhaust finisher was developed and manufactured by APWORKS for the newly developed Bugatti Chiron Pur Sport. With this application, Bugatti has become the first company in the automotive industry to use Additive Manufacturing to produce exposed titanium exhaust finishers for series production that are officially approved for road use. At approximately 22 cm long, 48 cm wide and 13 cm high, the finisher weighs just 1.85 kg including grille and bracket – some 1.2 kg less than the finisher on a standard Chiron.

“Bugatti is all about French-style luxury and exceptional vehicles, but it’s a brand that stands for innovative technology, too,” stated Stephan Winkelmann, President of Bugatti. “In addition to the iconic 8 litre 16-cylinder engine with 1,500 HP, technical innovation is just as much part of our brand essence – such as our components made of titanium or a special alloy that are produced by 3D printing.”

Saving weight through AM where it matters

The impressive 39% weight reduction achieved on the finisher of the Chiron Pur Sport is thanks to an innovative but highly challenging Additive Manufacturing-enabled design. Nils Weimann, Head of Body Development at Bugatti, explained, “The advantage of the 3D printing process lies in the geometric shapes that are possible. It is possible to create very finely wrought, complex forms which would tear if made using other techniques such as forging or forming.” This is an ideal production method for Bugatti: lightweighting can be at the heart of a design, there are no tool costs, production is comparatively fast and individual adjustments to the design are easily possible. Complex organic geometries can also be developed, often inspired by the natural world, as is the case in this application.

In particular, the use of Additive Manufacturing enabled the development of an exhaust finisher with very thin walls; this helped to save weight where it really mattered. The exhaust tailpipe is just one part of the complex rear design of the Chiron Pur Sport, which has a new aerodynamic configuration that generates more downforce, while reduced overall vehicle weight contributes to the car’s increased agility.

“By cutting weight by 50 kg, while simultaneously boosting the downforce and configuring an uncompromising, sporty chassis and suspension setup, the Chiron Pur Sport boasts incredible grip, sensational acceleration and extraordinarily accurate handling. It’s the most uncompromising yet agile Bugatti of recent times,” explained Winkelmann. The reduced mass of the exhaust finisher contributes to the car’s new aerodynamic configuration, which is designed to contribute to both agility and dynamic cornering. Through the use of titanium alloy Ti-6Al-4V, with its high heat resistance and strength, the AM exhaust tailpipe is also highly temperature resistant.

Designing with (almost) no limits

The AM exhaust finisher fits into Bugatti’s strategy of lightweighting to maximise the speed, driving experience and agility of the vehicle. Because the design of the finisher pushes metal Additive Manufacturing to its limits, various optimisations were applied during its development. These go beyond features intended to simply reduce the weight of the part while maintaining or improving on performance, and take into account the requirements of the whole manufacturing process.

The exhaust finisher’s development process was supported by APWORKS’ engineers and the result was a part with extensive high vertical walls and wall thicknesses as low as 0.4 mm in places. The part’s design takes into account many factors, from a safe and stable manufacturing process to the most efficient build time and ease of support structure removal after the build. Whilst designing supports for ease of removal, their function and performance for in-process heat transfer also has to be calculated in order to ensure the highest dimensional accuracy.

With this in mind, some of the biggest challenges faced by the design team when reducing wall thicknesses to such a low value were heat transfer, dimensional deviations, and in-process instability. The solution that APWORKS’ engineers turned to in order to overcome these challenges was generative design.

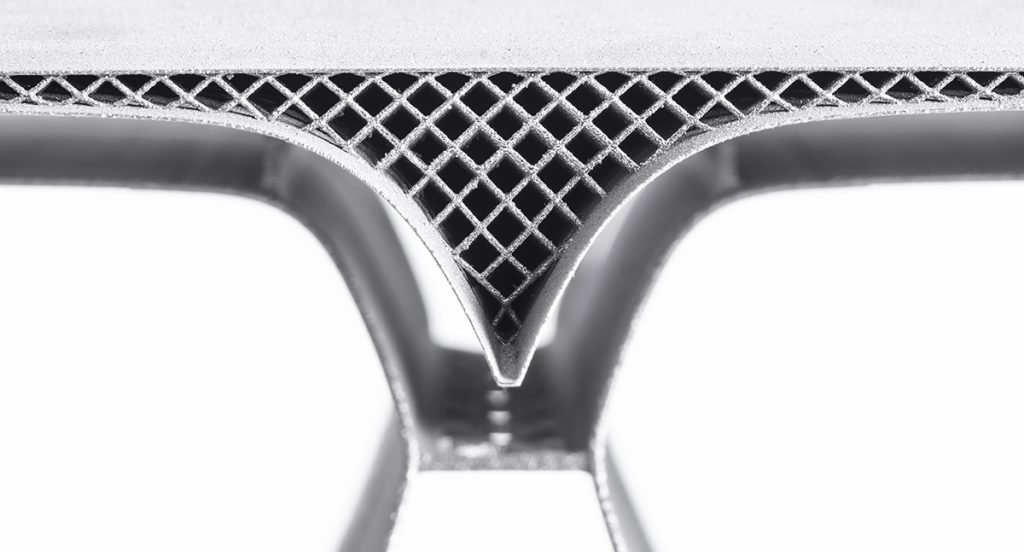

Lattice structures

Lattice structures are very well known in the world of AM. To achieve this design feature, an initial volume is converted into a generative design model by replicating a small representative unit – the unit cell – over the whole designated geometry. This design feature offers many advantages; foremost, it reinforces two thin walls by connecting them, guaranteeing dimensional accuracy, and enabling minimal use of material.

“Wherever possible, we designed the exhaust finisher for the Chiron Pur Sport with a single layer so as to further reduce weight,” explained Weimann. “The minimal material thickness in multi-layer areas is made possible by its lattice structure – where the cavity is filled with numerous filigree struts. In this way, the walls provide stable support for each other during the construction process – enabling minimal use of material.” Through this process, volumetric mass was decreased by 70% (Fig. 3).

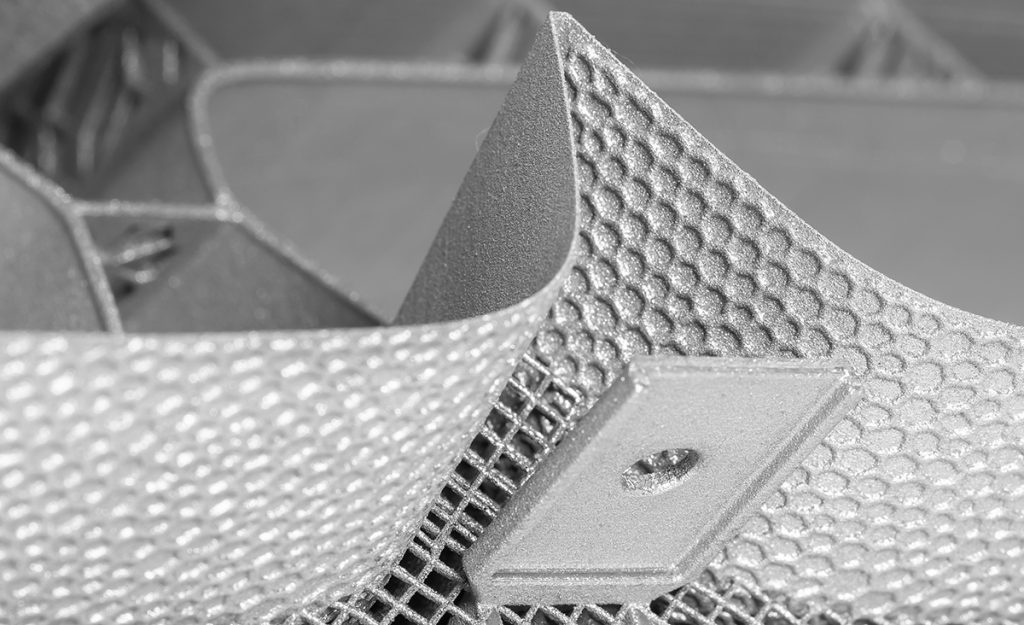

Honeycomb patterns

Another design feature which is made possible by AM and widely used in the lightweighting of components is the application of a honeycomb pattern onto a designated surface. Inspired by nature, this geometry acts as a stabilising feature for the thin walls. In this application, the pattern enables the highest possible dimensional accuracy for the thin walls by distributing tension all over the affected surfaces and increasing stiffness.

“We use a bionic honeycomb structure in the single-layer area to increase the surface rigidity of the walls. Even large components gain a high degree of surface stiffness,” stated Weimann (Fig. 4). Thanks to the use of an outer wall which is double-layered for thermal insulation, the filigree cover is still able to withstand temperatures of over 650°C. In this way, the cover protects surrounding components from excessive heat under full engine load. At the same time, fresh air around the cover cools the component.

AM machine selection

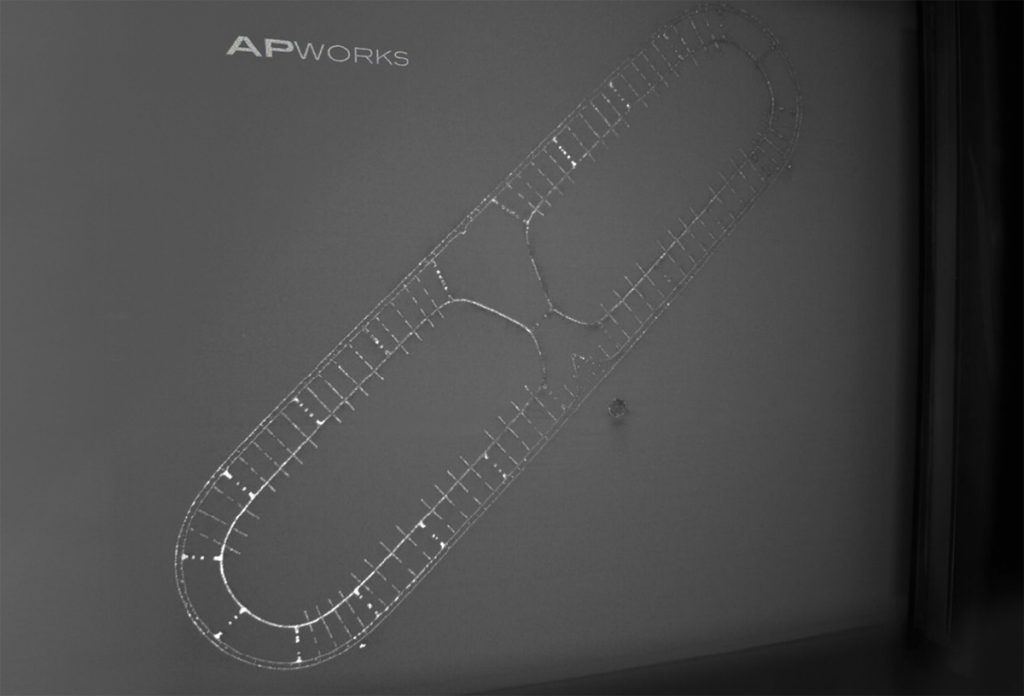

High-end Additive Manufacturing, the related post-processing solutions and software are evolving at a fast pace. When considering the most suitable AM systems for a project with complex requirements such as the exhaust finisher, system build size and speed are crucial. In this case, production takes place on an EOS M 400-4, a four laser Powder Bed Fusion (PBF-LB) system that offers a high level of productivity.

The twin challenges of qualification and homologation

This application is a rather unique example of a fully optimised high-performance part enabled by Additive Manufacturing that fulfills both the highest quality standards for road use, as well as homologation – the approval process a vehicle is required to go through for certification to race in a given league or series.

For this to be achieved, before entering serial production a major quality management process had to be undertaken in the form of qualification. In undergoing qualification, a supplier proves that every defined requirement is not only met, but also validated through testing, and certified by independent testing institutions where necessary. Qualifications such as these usually cover areas such as whether a part meets dimensional tolerances, and requirements like heat resistance, corrosion resistance and insensitivity against abrasion. In this case, the surface and heat resistance properties of the part needed to be tested and confirmed by independent certified testing laboratories working within Volkswagen Group standards.

As part of the serial production qualifications within an automotive OEM environment, a special process named ‘sampling’, similar to FAI or PPAP, was executed. In this procedure, new or changed parts need to be inspected with regards to all requirements communicated either by the technical drawing or valid OEM-specific standards. These inspections were conducted with a sample part prior to beginning actual serial production to represent the later certified status of a final part.

Once qualified, it was time to take the part to serial production. Joachim Zettler, Managing Director of APWORKS, stated, “We are proud to be part of this impressive new hypercar development by Bugatti. It is the first visible 3D printed part out of titanium receiving road homologation. We could only realise this innovative tailpipe by pushing Additive Manufacturing technology to the limit. Smallest wall thickness of below 0.5 mm enable the extremely lightweight design.”

The serial Additive Manufacturing workflow

The exhaust finisher’s design truly tested the limits of what is possible using AM, and in particular what parts it is possible to serially produce. To manufacture a high-quality part requires several software- and hardware-based tools, as well as for the production steps to be planned and executed so that they fit together perfectly in an effective workflow.

After the part’s design was released by Bugatti, APWORKS’ engineers commenced the work to prepare it for production by Additive Manufacturing through the use of various digital tools. These supported not only AM production related considerations, but also cost and failure mode analysis – all of which are covered under the concept of Design for AM (DfAM).

Once the geometry was fixed and the design could be released to APWORKS, AM data preparation began. This process includes positioning and aligning the part on the build platform, generating support structures, and optimising the design process by developing suitable build process parameters, etc. Machine parameters such as laser power and scanning speed must be optimised for the exacting requirements of highly-loaded parts, and need to be expertly adapted to achieve thin wall and lattice features such as those utilised in the exhaust finisher. This process ends at the point of the machine interface, where the part data is finally transferred from design software to Additive Manufacturing machine.

Post-processing

After each successful build, various post-processing steps are applied to achieve the required mechanical properties and component performance. Heat treatment in an inert atmosphere at over 700°C is used to relieve the high internal stresses generated within titanium parts during PBF-LB Additive Manufacturing. Following cooldown, parts can be handled safely in different manual and automated metal processing steps in order to remove support structures, smooth surfaces and increase dimensional accuracy.

The mechanically finished parts are subsequently coated with a highly temperature resistant matt black layer consisting of small ceramic particles, capable of withstanding temperatures of up to 1100°C, while both insulating the part and creating a smooth surface.

The whole process is controlled using various quality assurance measures. These are primarily split into quality management system control steps according to DIN EN 9100 and dimensional testing, which includes processes such as 3D scanning and manual testing.

The latest in a series of AM exhaust components for a record breaking car

The Chiron Pur Sport exhaust finisher is not the only part of this type produced for Bugatti by APWORKS. In 2019 the company manufactured a metal AM exhaust finisher for the Bugatti Chiron Super Sport 300+ (Fig. 8). This Bugatti Chiron derivative was the first hypercar to break the 300 mph barrier (482.80 km/h), a record that was set at the beginning of August 2019 in Germany.

The innovative AM exhaust finishers applied in this car were also produced in titanium. In this case, the exhaust finishers are part of a modified longer tail section and are designed to push exhaust emissions further from the rear end of the car to reduce turbulence and improve steering behaviour at high speeds. The design freedom offered by AM enabled optimised exhaust aerodynamics, resulting in increased downforce and enhanced high-speed handling of the car.

In addition to the aerodynamic benefits, the low mass of the parts contributed to the vehicle’s exceptional acceleration. Titanium was the material best suited to this application due to its combination of high strength, heat resistance and low weight. This is a prime example of an optimised high-performance part enabled by AM.

Conclusion

With a legacy of ground breaking innovation, Bugatti considers itself to be continuing a long-standing tradition of innovation and unique vehicle development with the use of additively manufactured components. Company founder Ettore Bugatti himself developed unique vehicles using ground breaking technologies, from lightweight aluminium wheels to a hollow front axle. As Ettore Bugatti once stated, “An automobile component must be technically perfect. But it must be elegant and beautiful, too.”

Today, this spirit remains. The use of Additive Manufacturing has allowed the designers of these exhaust components to incorporate harmonious contours and features that are more elegant and striking than is possible with conventional technologies – all while delivering extreme performance. All of this is in keeping with the Bugatti legacy; a history of combining technical functionality, aesthetics and elegance.

Contact

Angela Grünewald

Marketing & Technical Sales Manager

APWORKS GmbH

Willy-Messerschmitt-Str. 1

82024 Taufkirchen

Germany

Tel: +49 89 954738751

[email protected]

www.apworks.de