GKN Sinter Metals: Global Tier 1 automotive supplier anticipates opportunities for Additive Manufacturing

GKN Sinter Metals, with more than 6,000 employees at 30 locations worldwide, is the world’s leading Powder Metallurgy group. The company produces 11 million PM parts per day, with around 80% going into the automotive industry. The company started its metal Additive Manufacturing activities at its Innovation Centre in Radevormwald, Germany, in 2013. Dr Georg Schlieper visited the centre on behalf of Metal AM magazine and reports on the company’s AM activities and ambitions. [First published in Metal AM Vol. 2 No. 2, Summer 2016 | 15 minute read | View on Issuu | Download PDF]

Radevormwald, a small town in the rural hills of the region known as Bergisches Land, is located in the western part of Germany, not far from the cities Cologne and Düsseldorf on the Rhine River and close to the Ruhr region. The town has long-standing connections to Powder Metallurgy through Sintermetallwerk Krebsöge, the predecessor of the current GKN Sinter Metals plant. Powder Metallurgy parts, porous filters and self-lubricating bearings are produced here in extremely high volumes and the plant has an international reputation as a pioneer in the development and early adoption of cutting-edge Powder Metallurgy technologies. These technological developments included powder forging for the production of high-performance components such as connecting rods in the 1980s and Metal Injection Moulding for high volume automotive applications in the 1990s, as well as the development of PM aluminium components.

GKN Sinter Metals Engineering GmbH is responsible for new Powder Metallurgy related process and product developments within the global GKN Sinter Metals Group. The GKN Innovation Centre, constructed in Radevormwald in 2004 and the home of GKN Sinter Metals Advanced Engineering, is an architectural highlight (Fig. 1). With its convex glass front, the building resembles a huge eye overlooking the countryside. The building, which incorporates blue steel beams and expansive windows, communicates clearly that this is the home of advanced technology. When visitors enter the lobby, which extends over the entire height of the three-storey building, a broad curved staircase leads them to the upper floors. From the offices and meeting rooms one has a breathtaking view over the surrounding green hills.

The GKN Innovation Centre provides offices for around forty engineers and scientists as well as conference rooms and a large machine hall with a floor space of 900 m² equipped with modern presses, sintering furnaces and other facilities. Workshops and laboratories are set up for materials investigation, including metallography, tensile and fatigue testing.

GKN’s approach to AM technology

The motivation for focusing on metal Additive Manufacturing is obvious. Considering GKN Sinter Metals’ long tradition and expertise in Powder Metallurgy, it was a natural extension of its existing technologies when the Additive Manufacturing of metals emerged. Furthermore, there are many additional synergies within the GKN Group relating to AM.

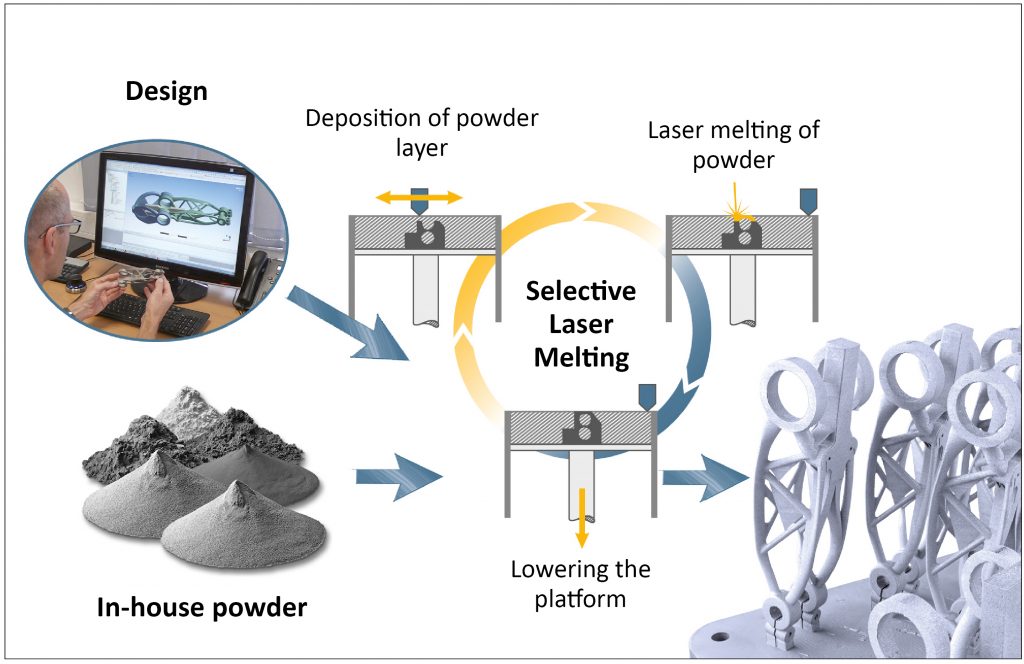

The introduction of metal Additive Manufacturing technology within the GKN Sinter Metals Group is managed by Dr Simon Höges, who granted Metal Additive Manufacturing magazine an exclusive interview. Höges looks back on ten years of experience in Additive Manufacturing, having received a diploma in physics from RWTH Aachen, one of the most distinguished technical universities in Germany. His PhD thesis was focussed on AM technology and he worked on Selective Laser Melting (SLM) technology at the Fraunhofer Institute for Laser Technology (ILT) in Aachen. After a further four years of practical experience in the R&D department of a supplier of customised dental crowns, bridges and implants in Bremen, a sector where SLM is already a well established technology, he joined GKN Sinter Metals in 2014 as Manager Additive Manufacturing.

GKN as a group has, of course, a much longer history in metal Additive Manufacturing than that of the Sinter Metals division. One such example is GKN Aerospace in Bristol, UK, which primarily uses Electron Beam Melting (EBM) technology to produce components for the aerospace sector. EBM is advantageous for larger parts and is highly suited to the processing of titanium and nickel base alloys. The build rates are relatively high and the build space is larger than in most SLM machines. A truly unique feature with EBM is that it is a hot process in which the powder bed is pre-heated before melting each layer, offering several important advantages. Firstly, residual stresses are reduced which means that large and reasonably bulky components can be built very efficiently and without the risk of distortion. Secondly, it also means that titanium parts, for example, do not need to be heat treated after the build.

Höges told Metal AM magazine that besides the plant in Bristol, where the focus is on powder bed based processes, GKN Aerospace’s plants in Trollhättan, Sweden, and St. Louis, USA, use metal deposition processes to manufacture very large aircraft components. These processes do not use powder bed systems and as such have far higher build rates. They are, however, much less accurate than SLM systems. GKN Sinter Metals therefore ruled them out as unsuitable for smaller, high precision components.

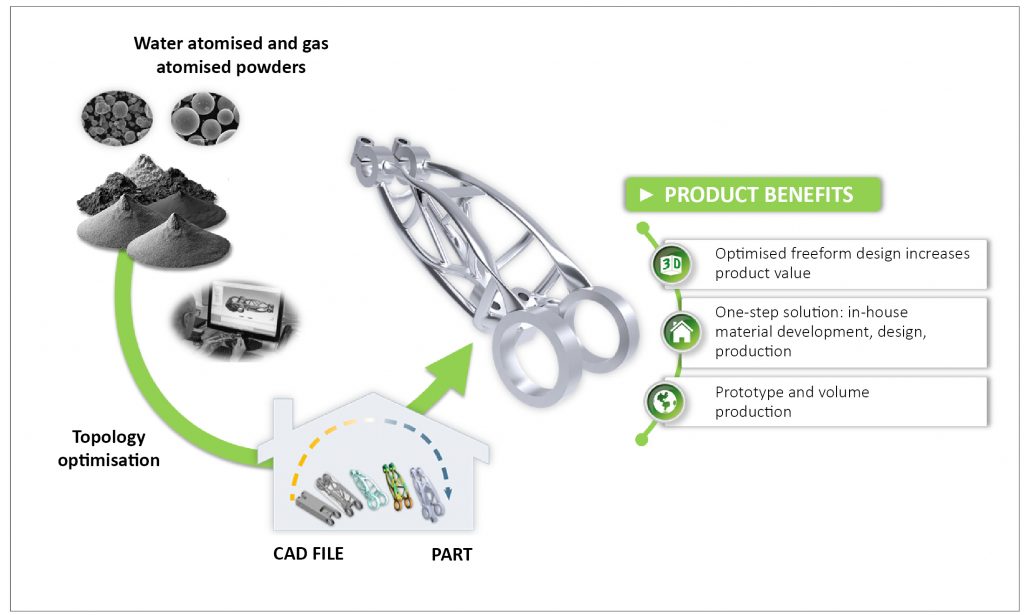

Hoeganaes Corporation, a part of GKN Sinter Metals with its headquarters in Cinnaminson, New Jersey, USA, is one of the world’s leading metal powder producers with an estimated 25% share of the world market for ferrous metal powders. Hoeganaes’ recent activities on gas atomised titanium powders for Additive Manufacturing have already been reported in Metal AM magazine (Vol. 1 No. 3, pp 71-74 ). Hoeganaes is committed to entering the fast growing market for AM metal powders and to develop better and less costly powder grades in close cooperation with its partners in the group. GKN will therefore be in a position to cover the entire AM value chain, from powder production to the finished product.

AM facilities at the GKN Sinter Metals Innovation Centre

The first SLM machine at GKN Sinter Metals, a Renishaw AM 250 with a build space of 250 x 250 x 300 mm, was installed in 2013 (Fig. 3). From the start the company decided to focus on powder bed based technology such as SLM with the highest accuracy and to use ferrous alloys to produce near-net-shape components. According to Höges, SLM offers a higher dimensional accuracy than EBM. “The cost pressure is much higher in the automotive industry than in aerospace”, he stated, “therefore the reduction of manufacturing costs along the whole value chain, besides process consistency and reliability, is our first priority.”

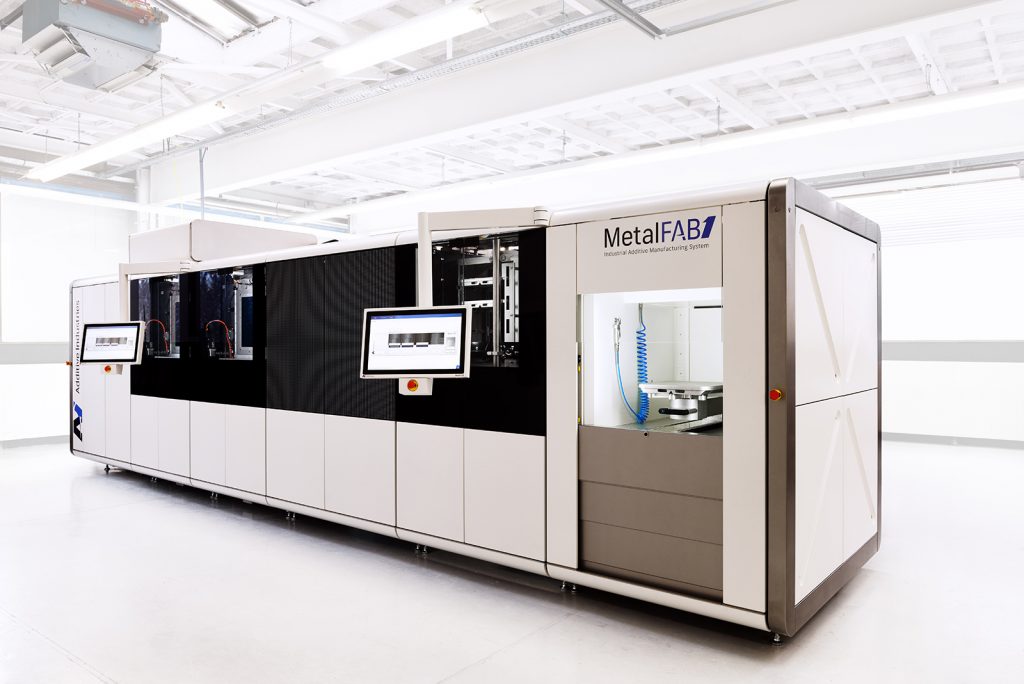

GKN has a broad technological base in metal Additive Manufacturing. Four AM machines are currently installed at the Innovation Centre; two SLM machines from Renishaw, one SLM machine from EOS and one binder jetting machine from ExOne. GKN recently announced that a further SLM machine, the MetalFAB1 from Additive Industries (Fig. 4) will be delivered in 2016. Other GKN Sinter Metals plants in Europe and North America also have Additive Manufacturing machines in operation.

SLM is the technology that is most widely used in the GKN Sinter Metals Group today because it is the most advanced and mature AM process for metals. With the MetalFAB1, GKN Sinter Metals will take part in the beta test program of Additive Industries, whose explicit strategy is to improve the productivity of metal AM by moving towards automation and integration. The MetalFAB1 is a first step that opens the door to the series production of AM components for GKN’s core markets.

Out of the wide spectrum of materials that are available for AM today, GKN Sinter Metals is currently focusing on two ferrous alloys, the austenitic stainless steel 316L with excellent corrosion resistance and high ductility and, for high strength applications, the maraging tool steel 1.2709 which can attain a hardness of 54 HRC after ageing. Restricting development activities to ferrous alloys is down to the fact that, for cost reasons, the automotive industry has little interest in employing titanium or superalloy components. Ferrous alloys have thus absolute priority at GKN Sinter Metals and the development of further steels is on the agenda, with 20MnCr5 for gear prototyping given as an example.

Besides the production equipment, the design software is a key factor behind the success of AM. Once a CAD file of a part has been completed it can be used immediately to print the part anywhere in the world. There is no need for additional re-programming of machine parameters. The requirements on operating personnel are therefore lower than in machining or other Powder Metallurgy processes. This, it was stated, is another key advantage of AM.

Developing cost-effective powders for AM

The development and qualification of cost effective ferrous powders for AM is regarded as an important step towards overall cost reduction in metal AM and work on this is undertaken in close cooperation with Hoeganaes Corporation.

Currently, the majority of powders used in AM are produced by gas atomisation, a costly process that generates spherical particle shapes and the desired excellent flowability of the powder. GKN Hoeganaes has committed itself to enter the fast growing market for AM powders with new powder grades including gas atomised titanium and water atomised specialty powders for AM. The company has also modified its water atomising processes for ferrous alloys to increase the proportion of spherical or near spherical particles. Water atomised powders will then partly or entirely replace the gas atomised grades, especially for Ni- and Fe-based materials. GKN Sinter Metals is testing these powders at its various AM facilities and is helping to develop powder specifications for AM processes.

Quality assurance

The design software for metal AM is based on Finite Element Analysis (FEA), which requires input of material characteristics, in particular the fatigue properties. GKN uses the facilities at its Innovation Centre to continuously determine tensile and fatigue characteristics of its AM materials. Materials testing is also used as a quality assurance method. Tensile test pieces are produced with each machine run and analysed to ensure the consistency of the material properties and consequently the reliability of the process.

The densities of SLM parts are typically above 99% of full density. However, the residual porosity is only an issue for components that operate under high fatigue loading. Nevertheless, Höges has concerns about porosity. “Residual porosity is our greatest concern when it comes to quality assurance,” he stated. “The technology is just not yet capable of consistently delivering densities above 99.5%. Our hope is that in the future machine manufacturers will develop systems that automatically detect process irregularities and have a feedback system that corrects them immediately while the machine is operating.”

Rapid prototyping

The initial approach to the commercialisation of metal AM by GKN Sinter Metals is rapid prototyping. The ability to supply prototypes of PM and forged components is, in the short term, regarded as a competitive advantage. In many cases, optimising the design of an assembly of new products can be achieved with AM even though the material properties of additive manufactured parts are not the same as, and usually far better than, those of pressed and sintered parts.

GKN Sinter Metals is working hard to get its AM processes certified according to the ISO/TS 16949 standard. With this strategy, GKN’s AM technology is seeking to distinguish itself from prototype manufacturers who do not have a specific focus on automotive components and are therefore unable to be accepted by automotive OEMs as regular parts suppliers.

The prototyping of steel parts by AM is already widely practised in the automotive industry. “Most OEMs have their own AM facilities for prototypes, but for us as a parts supplier it is an advantage to be able to deliver AM prototypes that are planned to be produced as volume components by us later,” stated Höges. “We already cooperate with our customers in the design phase, integrating more functions into a component and adapting the design for our processes. Rapid prototyping is definitely an opportunity to participate in the design phase with our customers. As a global parts supplier with local sites all over the world, GKN is in a position to serve our customers at first hand.”

Noise reduction with AM design

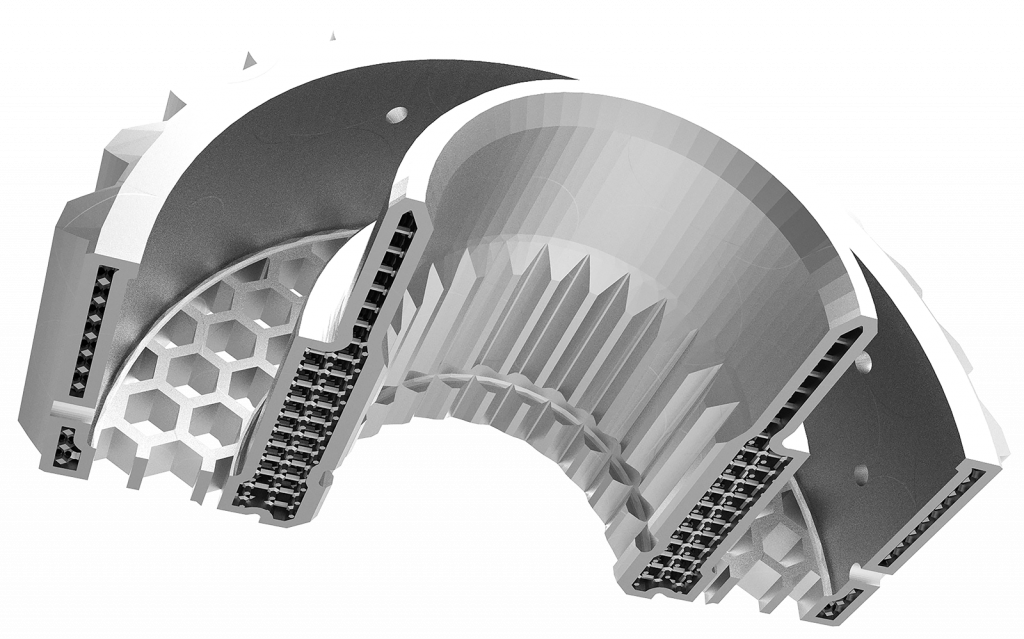

The strategy pursued by GKN Sinter Metals for new AM products in the automotive sector can be seen in the design study shown in Fig. 7. Together with GKN Driveline, a conventional pulley was re-developed for AM with a honeycomb structure between the hub and the outer gear ring and cavities inside the hub and gear. These features not only reduce the mass of the component but, more importantly, offer a significant noise reduction.

Designing for noise reduction follows the principle of acoustically uncoupling the source of the noise from the noise transducing components. In the case of the pulley, the noise is generated by the gear teeth when the tooth flanks meet the teeth of matching gear or drive belt. The internal hollow structure minimises the noise transfer to the hub and shaft. AM technology produces a near-net shape preform of the pulley and only the functional inner and outer surfaces that need high precision are finish machined at affordable cost. With this approach it is possible to develop noise reducing lightweight components for applications where these properties are so valuable that the extra cost of AM processing is acceptable.

Further design options

In addition to conventionally shaped technical components such as the pulley in Fig. 7, bionic design is also applied by GKN. An example is the rocker component shown in Fig. 8. The component is part of a fatigue test rig and was selected to highlight the options that bionic design presents for weight saving. The design process is largely automatic, with only the fixtures and loading conditions entered into the software. When supplied with the material characteristics, the design software generates a lightweight structure that can further be optimised to accommodate other requirements such as aesthetic or functional features. “AM offers an enormous amount of design freedom that allows us to optimise for function without having to compromise with respect to the manufacturing process,” explained Höges.

A unique AM design that cannot be produced by any other method is shown in Fig. 9. It is a planetary gearbox with a diameter of approximately 30 mm which has been produced in one piece. The outer ring holds seven moving planetary gears surrounding a central gear. The whole assembly consists of nine individual parts that cannot be separated without destroying the gearbox. This demonstrator was developed to highlight the unique possibilities of AM; monolithic and bionic design, internal structures for tailored material properties and noise reduction, as well as part assembly integration.

Commercialisation

“Our market research has identified that chances for a successful business case are best for small and complex parts whose weight is as low as possible because the processing cost of Additive Manufacturing is mainly determined by the mass of the part,” Höges told Metal AM magazine. “Each gram in the product means powder cost and energy required for melting the powder.”

The search for new Additive Manufacturing applications is fully integrated into the global sales network of GKN Sinter Metals. Selected sales representatives have received sets of demonstration parts as inspiration for their customer contacts and feedback on this activity has been very positive. Currently, sales initiatives are primarily directed at prototyping, however potential is seen in the market for small to medium volume luxury cars. When this market becomes a reality, GKN’s ambition is to be recognised as the leading supplier and a special sales force for additively manufactured products is planned.

The sales teams at GKN Sinter Metals are to a large extent focused on the automotive sector. The company therefore anticipates that it can build on its many existing relationships and as a result the best chances to identify new AM applications are expected here. However, there is also interest from other industries. Höges told Metal Additive Manufacturing magazine that specific application developments are under way with Otto Bock, a manufacturer of prostheses for the disabled.

A further step will be to supply customised spare parts for classic cars and specially designed components for motorsport that can be produced in small volumes. Looking beyond custom parts, the company is working towards equipping a whole series of new luxury class with exclusive components that can be produced in quantities of a thousand or more per year.

Further expectations for AM

The development of AM machinery is still in progress and it is likely that, besides further integration of existing systems, entirely new concepts for metal AM will emerge in the future. GKN Sinter Metals is actively involved in research projects on metal AM and, in close cooperation with its equipment suppliers, feedback is shared about the use of their machinery along with proposals to help them improve their products. Höges anticipates that there will be a substantial gain in productivity in the future due to faster processing and, in the long term, price reductions on raw materials and machinery for AM.

“The build space of our machines is sufficient in most cases,” stated Höges, “because we rarely have very large products. The next machine that we will receive, however, has a build space of 420 x 420 x 400 mm. The higher capacity of this machine is a step forward towards the economic series production of automotive parts in small to medium numbers, because more parts can be built in each production run.” Precision, in contrast, is much more important for small functional metal parts and an important economic factor. “A component that needs a lot of machining after AM processing will seldom be competitive,” stated Höges. “We are dedicated to improving the productivity of our AM processes by intelligent use of the design advantages of AM and by reducing the necessary secondary operations as far as possible.”

Particular attention is given at GKN Sinter Metals to the secondary operations that are required on AM parts. “For the technical function and the aesthetic appearance of AM products it is usually necessary to smooth the surface. We look for the most efficient secondary processes that allow for a high level of automation and try to organise our processes to be as lean as possible,” stated Höges.

Beyond SLM, GKN is now also investigating the potential of ExOne’s binder jetting technology. Whilst still in the early development phase within GKN, the higher productivity and similarity to Metal Injection Moulding makes this process interesting to GKN Sinter Metals.

Outlook

The future of AM in the GKN Sinter Metals Group offers several options. “We see AM as a new, independent manufacturing technology of the family of PM processes,” concluded Höges. “It’s not competing with our established press and sinter, powder forging and MIM processes. AM can support these technologies with prototypes, but it will also find its own market segments independent from our other PM products.”

Contact

GKN Sinter Metals Engineering GmbH

Dr Simon Höges

Dahlienstrasse 43

D-42477 Radevormwald

Germany

Tel: +49 2195 609 940

Email: [email protected]

Author

Dr Georg Schlieper

Alleestr. 101

D-42853 Remscheid

Germany

Tel: +49 2191 6889274

Email: [email protected]