Arcast: Applying advanced melting and atomisation expertise to the production of a new generation of metal powders

Arcast Inc., based in Oxford, Maine, USA, is today emerging as a leader in advanced melting and metal powder atomisation technologies, with a diverse international customer base. As Metal AM magazine reports, the company provides processing solutions for some of the most challenging alloys, as well as offering through its new venture, Arcast Materials, a range of commercially-produced metal powders. [First published in Metal AM Vol. 4 No. 4, Winter 2018 | 10 minute read | View on Issuu | Download PDF]

In 2005 in the US state of Maine, Rayland O’Neal established O’Neal’s Manufacturing, a machine shop specialising in components and fabrications for the radio frequency broadcast equipment industry. After some years of initial success, it became apparent that this sector had fully matured and orders were becoming harder to come by. It was around this time that O’Neal had a conversation with his old school friend, Sasha Long, who had been working in the UK in the field of specialist vacuum furnaces and melting systems. Long had identified this as a field of burgeoning interest and activity, and persuaded O’Neal that this was an area of manufacturing that was worthy of further investigation.

It quickly became apparent that the capabilities and machining skills acquired in the RF equipment business could be transferred to the manufacture of certain kinds of metallurgical process equipment. As a result, Arcast Inc. was incorporated in 2010 by O’Neal, and Long followed shortly after in partnership as its two principals.

Early success in specialist melting systems

Initially, the company strove to establish and develop a niche range of products focused on specialist metal melting furnaces. It was fortunate to win some small but important early contracts for custom metallurgical equipment from a number of prestigious customers that included NASA and Los Alamos National Laboratory. It was this business, plus valuable development grants from the National Science Foundation and some remaining work for its RF customers, that provided initial cashflow and allowed the company to survive.

In 2009, Arcast sold its first Arc 200 cold-crucible arc melting system. The company had identified a need for such systems from various research establishments and universities investigating and developing new metal alloys. Whilst there were a few existing systems available at that time, Arcast sought to provide equipment with greater versatility and adaptability, introducing several innovative features that were not available from other manufacturers. Since then, the Arc 200, the smaller Arc 50 and, more recently, the larger Arc 500 have proven very popular with a number of high-profile customers around the world. Arcast is now firmly established as a leading manufacturer of this kind of arc melting equipment.

In addition to arc melters, Arcast has also designed and supplied melt spinners and splat cooling devices to both research and industrial users interested in bulk metallic glasses.

Gas atomisation technology

While reaping the rewards of its growing sales of arc melting systems, Arcast had its sights set firmly on an even greater prize: the development of gas atomisation systems for the production of metal powders. Even before its incorporation, Arcast’s management team had significant experience in the design and manufacture of metal atomisation systems and were therefore fully aware of the growing interest in metal/alloy powders for manufacturing processes such as Metal Injection Moulding, Hot Isostatic Pressing and, more recently, Additive Manufacturing.

The company states that designing and developing its own technology and systems in-house has been key to its success in creating equipment that can accommodate a wide range of feedstocks. It is also claimed that Arcast’s proprietary technology and designs deliver higher operating efficiencies than competing systems.

Arcast supplies gas atomisers that are based on both conventional, ceramic-contained melting and ‘clean’, contactless melting regimes. During 2015 and 2016 the company supplied three industrial scale atomisers, one for Uddeholm, Sweden, the world’s oldest steelmaker in continuous production; the other two for a US metallurgical conglomerate.

Long told Metal AM magazine, “Along with the conventional ceramic-lined close-coupled and induction drip melt rod feed [EIGA type], we offer a range of cold crucible and ‘contact free’ melting and atomising methods using plasma/arc and induction techniques. One of these methods is what the company calls a tube feed plasma/arc melting system. This allows a wide range of feedstocks to be directly melted and atomised without contamination and in an inert atmosphere.”

Tony Deacon, Arcast’s Contracts Manager, stated, “Arcast spent years developing its gas die/jet designs – close-coupled, free-fall and others – to give the most efficient and effective powder production. We continue to improve these designs to increase robustness and efficiencies. Combined with our gas heater and chamber designs we produce very high-quality powder that is low in satellites and with good particle size distributions.”

Arcast’s latest research or pilot atomiser, the VersaMelt, can accommodate four kinds of interchangeable melting capability within a single system package. The first of these was supplied to the Catholic University of Louvain, Belgium, in 2018.

A move to materials supply and collaboration with Cristal Metals

In 2018, Arcast took the decision to form a separate company, Arcast Materials, that commercially produces metals and alloys in both powder and other product forms. Arcast Materials focuses on specialty and niche alloys and toll work for customers. Deacon told Metal AM magazine, “In recent years, we have been assisting customers in refining materials like hafnium and titanium sponge. In particular, we have been working closely with Cristal Metals [Ottawa, Illinois, USA] to take its pre-alloyed titanium material and turn this directly into high-quality spherical powder, with very little increase in oxygen or nitrogen, typically ≤ 200-400 ppm O and < 10-40 ppm N when using standard industrial argon supplies. In fact, our process reduces undesirable elements such as hydrogen and sodium by more than 99%.”

“Through its own process, Cristal Metals can create a wide range of titanium alloys directly. This ensures that there is a homogeneous alloy in the resulting material. By combining the capabilities of both companies, we have a direct route to creating high-quality custom alloys to supply the fast-growing requirements of downstream Powder Metallurgy processes. There is now no longer a need to create multi-ton ingots with multiple VAR stages and then draw this down to rod or wire to create custom titanium or similar alloy powders,” stated Long.

The direct atomisation of materials such as this offers the most efficient and the cleanest method to produce spherical powder in bulk quantities. The flexibility of alloys using the Cristal Metals process and the additional flexibility of the Arcast process gives, it is claimed, an unprecedented range of economically viable spherical alloy powders. “With our continued work with Cristal Metals we can offer high quality customised alloy powder with the most direct processing route in the industry. Because we can also process scrap directly, we can drive the cost down on standard composition powders,” explained Deacon.

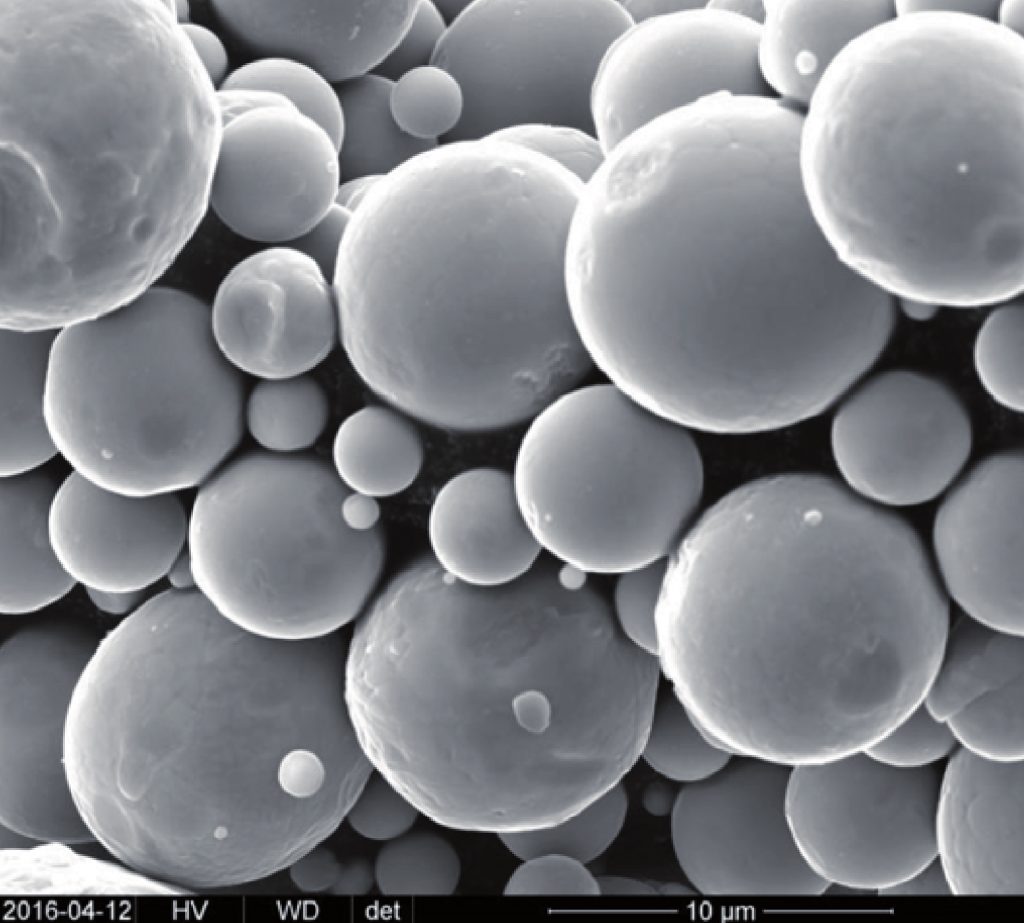

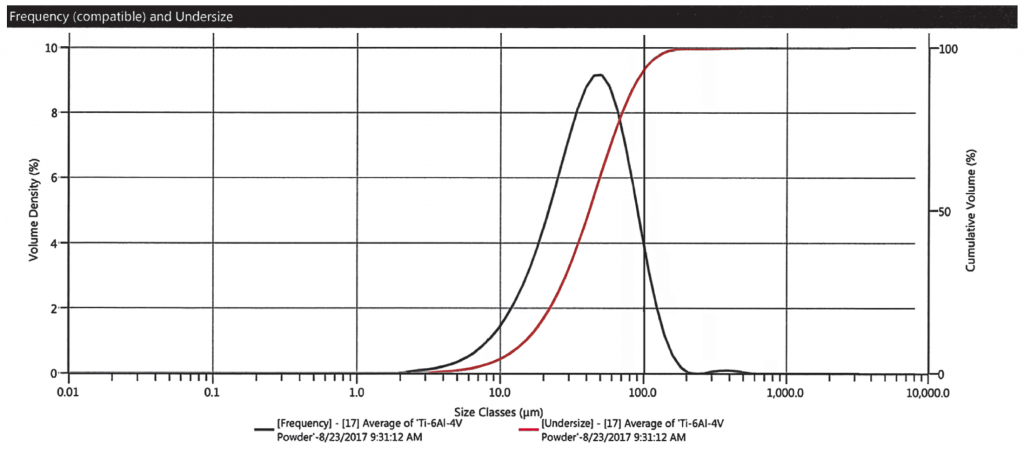

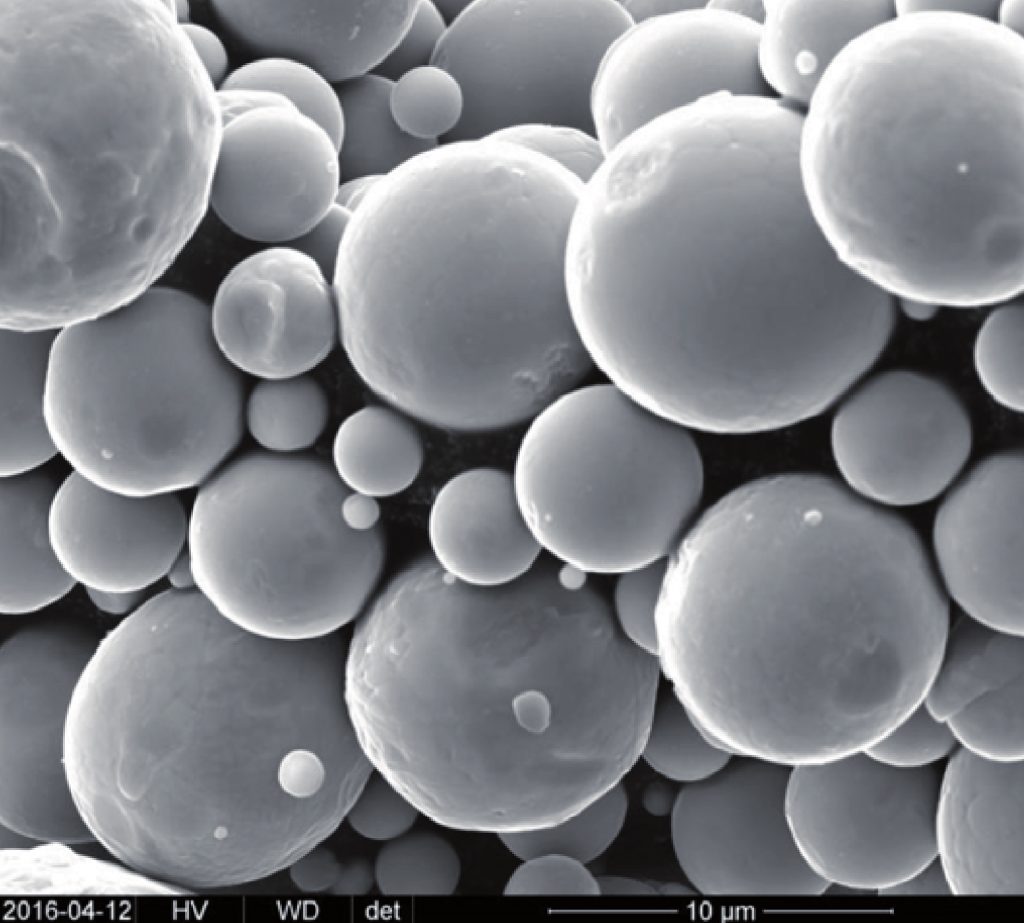

Beyond the work done with Cristal Metals, Arcast has been working with a number of industrial customers and partners to process materials using its atomisation capabilities. Long stated, “Core to the materials business is an atomising process that can receive a wide range of metal feedstock and produce fine powder from reactive alloys such as titanium while avoiding ceramic contamination – all with very low gas usage. This process produces powder equal to or possibly better than that produced from wire plasma atomisation but with a much more flexible feedstock range. This means materials like boron alloys, titanium aluminide, or the direct processing of sponge can be performed. Brittle, or non-ductile materials can be processed because there is no need to pre-cast rod or draw wire. The process typically gives an as atomised D50 of 40 µm and a D90 of 90 µm when processing conventional titanium alloys. The process can be tuned to change these values and certainly with some other difficult to handle materials we have produced finer distributions.” Fig. 6 shows a typical distribution of Ti-6Al-4V produced using Arcast’s technology.

“Often Arcast is speculatively asked if we can process certain challenging materials, for example titanium, tantalum, shape memory alloys and tungsten alloys. With confidence we can say yes. This is usually met with a pause and moment of silence, and then ‘oh, ok, well we have a requirement for x or y…’ and the conversation begins. Although our customers are often surprised, it is a pleasure to be able to address the needs of our customer’s most challenging requirements. This capability helps us grow product lines, along with growing the supply and production of the more conventional metal powder and castings,” explained Long.

Looking ahead

In 2018, Arcast completed the purchase of 10,000 ft2 additional freehold factory space. “This is sufficient to accommodate our near-term expansion plans for both Arcast Inc. and our new materials company, but even now we must seriously contemplate adding more factory space in the near future,” stated Deacon.

“The short-term objective is to have three full-time production atomisers and one experimental atomiser operational to meet current demand. Additionally, a production alloying furnace and small-scale continuous casting furnace will supplement our capability. The new laboratory will have a new Scanning Electron Microscope and equipment for analysing composition, size and morphology. To complement the technical capability we are completing the quality management system and audits to allow ISO9001 and AS9100 certification for this new division.”

“After years of working with different customers and developing novel methods for processing metal and powder we have amassed a comprehensive range of capabilities. If we don’t have an off-the-shelf solution, we can usually create an adaptation that will solve the problem. We believe this will be the strength of a material processing company, being born from a R&D and equipment supply company,” concluded Long.

Contact

Sasha Long

Arcast Inc.

264 Main St.

Oxford ME 04270

Tel: 207-539-9638

[email protected]

www.arcastinc.com