AM’s industrial impact celebrated as Sweden hosts ASMET’s fourth Metal Additive Manufacturing Conference

The fourth Metal Additive Manufacturing Conference (MAMC 2019), organised by the Austrian Society for Metallurgy and Materials (ASMET), took place in Örebro, Sweden, from November 25–27, 2019. The event, which attracted an international audience, covered a broad range of metal AM technologies and considered the technical challenges that need to be overcome to make the industry more economically competitive with conventional manufacturing. Prof Dr Jürgen Stampfl, Prof Nader Asnafi, Dr Bruno Hribernik, and Dr Gerhard Hackl review the event for Metal AM magazine. [First published in Metal AM Vol. 6 No. 1, Spring 2020 | 15 minute read | View on Issuu | Download PDF]

MAMC 2019 was the fourth in the Metal Additive Manufacturing Conference series organised by the Austrian Society for Metallurgy and Metals (ASMET) and attracted over 220 decision-makers, engineers, developers, industry experts, scientists and students from more than twenty countries. For 2019, the event moved from its previous home in Vienna, Austria, to the city of Örebro, 200 km to the west of Stockholm.

Örebro was for many centuries one of the most important ports for the trade of iron from the Bergslagen mining district, and this long metallurgical tradition, in combination with Sweden’s current position as an important player in metal Additive Manufacturing, made the city a natural home for an AM conference that focuses exclusively on the processing of metals.

The conference venue, Örebro’s medieval castle, lies in a picturesque setting on an island in the river Svartån. The name Örebro comes from the word for small stones, called ‘ör’ in Swedish, that are washed down a river, with the second part of the word coming from the bridge (‘bro’) that was built over this ford. This was historically a strategic location, because from here one could control traffic and trade with Sweden’s interior. In 2015, the historic town celebrated its 750th anniversary.

The MAMC 2019 technical programme consisted of more than sixty oral presentations and identified the latest trends and developments along the entire AM process chain, as well as numerous applications that have had a real and positive impact in industry. The opportunities connected with such a dynamic technology are raising interest in both the raw materials and manufacturing equipment industries, and an indication of the relevance of AM to Swedish industry was given in a welcome address by Anna Olofsson, County Director on the Örebro Administrative Board.

Opening keynotes highlight AM success stories

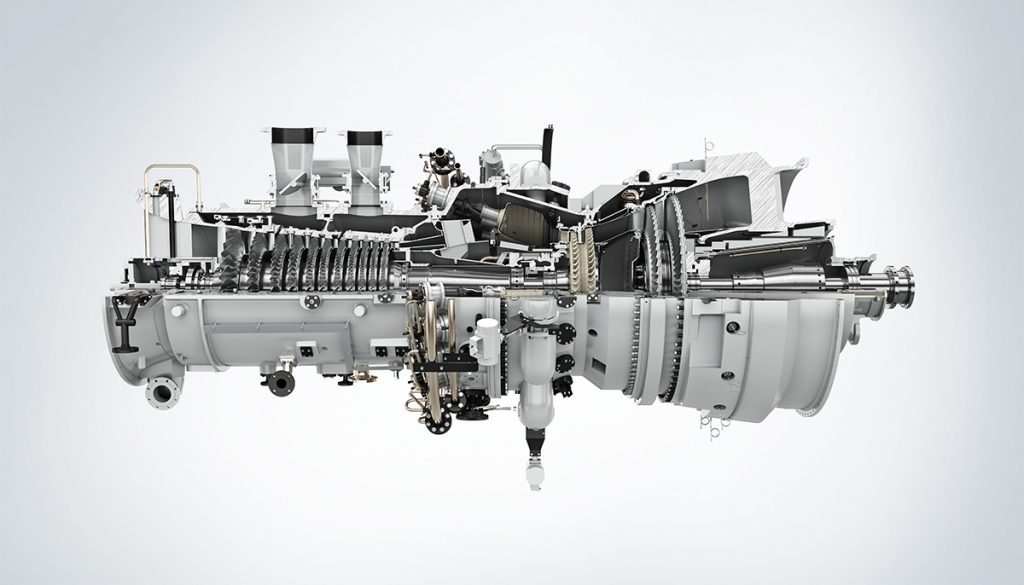

The conference’s opening keynote presentations set the stage for the more detailed discussions on materials, processes and systems for metal Additive Manufacturing that would come later in the programme. Andreas Graichen, of Siemens Turbomachinery, presented ongoing projects and research efforts taking place in Siemens’ energy business unit, which also hosted a guided tour of its Finspång AM facility. Siemens has invested heavily in the development of metal AM since 2006 and, in 2016, used additively manufactured burner heads in its SGT-1000F gas turbines for the first time. Many other ‘mission-critical’ parts have since been added to the company’s growing list of successes, and metal AM is, in the meantime, at the heart of Siemens’ digitalisation strategy (Fig. 2).

Edmar Allitsch, Managing Partner at AM Ventures Holding GmbH and Chairman of the Supervisory Board of EOS Holding AG, Munich, Germany, gave insight into the eco-system surrounding EOS’s metal AM activities. On a technical level, his presentation focused on the suitability of Laser Powder Bed Fusion (L-PBF) in comparison with metal Binder Jetting technologies (BJT). With the advent of a number of new players in both fields, potential users are now seeking to understand which AM technology is best suited for their specific applications. Binder Jetting technology offers an interesting cost structure thanks to the high throughput offered by the process and the use of low-cost components, such as inkjet heads, in comparison with laser-based systems. Nevertheless, the sintering process required to obtain fully-dense metal parts by Binder Jetting limits certain applications, especially for larger parts with non-uniform wall thicknesses.

Highlighting applications in aerospace engineering (Fig. 3), Allitsch pointed out the challenges and achievements of the recent years, resulting in EOS’s leading position in the metal AM market thanks to its installed base of around 3,500 machines.

In his keynote, Jürgen Stampfl, TU Wien, Austria, spoke on the topic of ‘3D Printable Materials: Design principles for strong and tough polymers, ceramics and metals’, describing the common design principles in AM fabricated polymers, metals and ceramics, with a focus on highlighting the importance of fracture mechanics in the development of AM materials.

Later, Tobias Brune, SMS Group, Germany, presented the current status of one of the most advanced metal powder atomisation plants developed by the SMS Group. SMS provides turnkey solutions for the production of metal powders with the highest purity requirements, thanks to in-house expertise that ranges from CFD simulation to decades of experience providing integrated engineering systems to industry.

MAMC 2019 ‘best paper’ awards

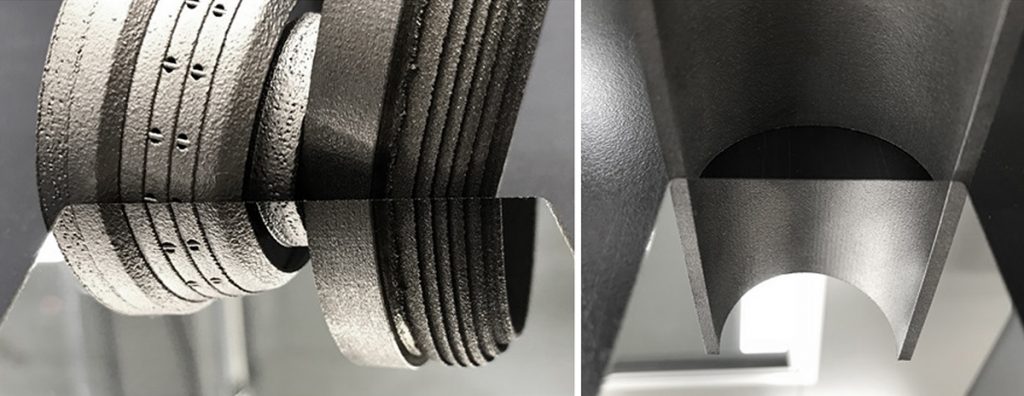

A highlight of the conference were three presentations given by the recipients of the MAMC 2019 ‘best paper’ awards. In a paper titled ‘Automotive stamping tools, dies and injection moulds made by L-PBF AM’, Nader Asnafi and colleagues from Örebro University focused on automotive stamping tools, dies and injection moulds made by Laser Powder Bed Fusion. Following the procedures of Volvo Cars, he and his co-workers certified solid and topologically optimised tools additively manufactured in maraging steel 1.2709 for the forming and trimming/blanking/cutting of 2 mm thick hot-dip galvanised DP600 sheet steel. Asnafi also showed an additively manufactured punch from a production tool that was designed both conventionally and using topology optimisation. This was produced using the same maraging steel and used for the stamping of 1 mm-thick hot-dip galvanized DP600 sheet.

The conventionally designed punch was first additively manufactured with a hollow honeycomb inner structure, before a variant was topologically optimised using two different software packages, LS-TaSC (LS-Dyna) and Siemens NX12. The purpose of the topology optimisation using LS-TaSC was to obtain reasonable maximum displacement during loading. The topology optimisation using Siemens NX12 then aimed at reducing the tool’s weight by 70% and to study how large the maximum displacement was during loading. All versions of the same punch are shown in Fig. 4.

The team showed also a core used in the injection moulding of a medical container. This core was first optimised through simulations and then additively manufactured using a voestalpine material. Improved cooling and reduced cycle time were the targets of this optimisation (Fig. 5). In production testing of this core, cooling was improved by 15% and cycle time was reduced by 8%.

![Fig. 5. Core for the injection moulding of a medical container: Cooling performance was improved by 15% and cycle time was reduced by 8%. After optimisation, the core was additively manufactured in a voestalpine material [Courtesy Anton Alveflo]](http://www.metal-am.com/wp-content/uploads/sites/4/2022/07/05-1024x673.png)

In their presentation, ‘Low-defect AM of high strength aluminium alloy by Direct Energy Deposition’, Anika Langebeck and co-authors from BIAS Bremen, Germany, presented results on the Directed Energy Deposition (DED) of 7075 aluminium alloy, a material which can be used in applications such as roller bearings designed for lightweight applications. The alloy is sensitive to residual porosity when it is processed using DED; however, by developing a dedicated setup featuring multiple nozzles and an additional gas shroud for shielding gas (Fig. 6), the team was able to gain a detailed understanding of its processing and material properties.

The setup that was developed was designed in such a way that it can be operated without an inert gas chamber, enabling the manufacturing of large components. The challenges presented by the omission of a process chamber are mostly related to a difficult-to-control deposition atmosphere within the process zone. An additional gas shroud, which protects the multi-nozzle head from the surrounding atmosphere, is one of the key elements to reduce contamination with oxygen. Further measures to better control and monitor the process conditions helped to achieve a stable and reproducible deposition state, leading to alloys with 220 MPa Ultimate Tensile Strength.

Finally, Mihaela Albu and colleagues from Graz Centre of Electron Microscopy, Austria, presented their paper ‘Ex- and in-situ microstructure investigations of powders and AM parts’, in which they used Scanning Electron Microscopy (SEM) and Scanning Transmission Electron Microscopy (STEM) to investigate in-situ and ex-situ how the microstructure of Al-alloys and N700 steel powders evolve during a heat treatment procedure that matches the processes that occur within a Laser Powder Bed Fusion system.

STEM images made by high angular annular dark field experiments and differential phase contrast images, and Electron Energy Loss Spectrometry (EELS) spectrum images, were used to localise and identify the elements and their stable and metastable phases. In-situ STEM observations were used to gather information regarding the crystallisation of amorphous phases and the development of metallic microstructures at different temperatures.

Success for AM tooling applications

Production tooling made by AM processes has today reached a high manufacturing readiness level and tooling is becoming a competitive market for the AM industry. This was reflected in a number of related presentations at MAMC 2019. In addition to the previously highlighted presentation by Nader Asnafi, Petter Damm and Anton Alveflo focused on why, how and where to use Additive Manufacturing in tooling.

Damm addressed metal AM powder made for tooling and described the benefits of AM in three different tooling application areas: plastic injection moulding, hot work applications and cold work applications. Conformally cooled and additively manufactured cores and inserts for the injection moulding of plastic components reduce cycle times and improve the part quality through both direct improvements and by reducing scrap rate. Part quality is highly related to mould quality, which in turn is determined by several factors, of which the polishability of the mould material is one. The high polishability of AM Corrax is shown in Fig. 7, where the surface roughness is presented both directly after AM and after AM plus polishing.

Tools for hot stamping (or press hardening) and High Pressure Die Casting (HPDC) are two important hot work applications. As far as HPDC is concerned, Damm addressed downtime, maintenance and scrap rate reduction as well as product quality improvement. He described how soldering and erosion constitute challenges in HPDC, particularly regarding part quality and die life. To improve die performance from these perspectives, he stated that the following was of greatest importance:

- A die material with high temper back resistance, high hot hardness and low affinity to Al

- The ability to avoid hot spots and control shrinkage through conformal cooling specifically where it was required.

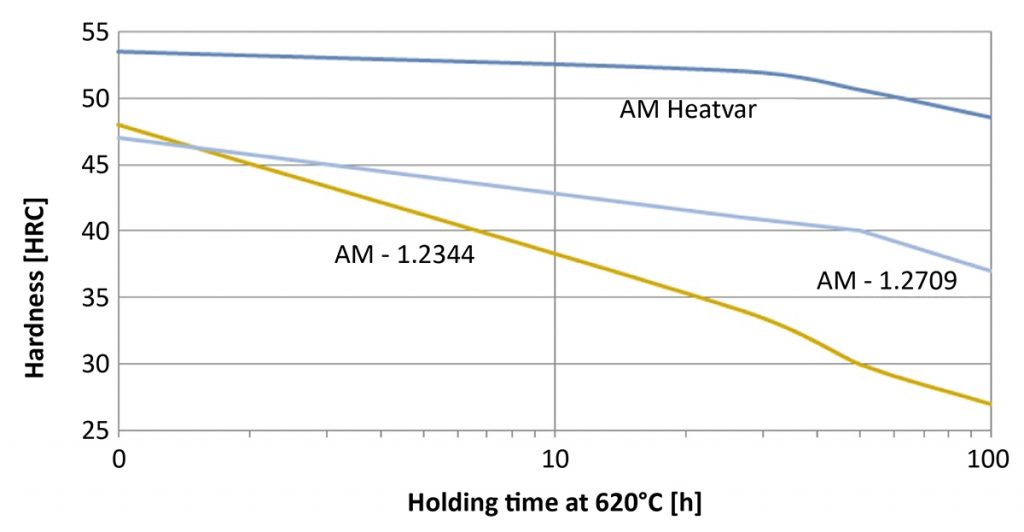

Fig. 8 shows the temper back resistance at 620°C for three different AM tooling materials, Uddeholm AM Heatvar, maraging steel 1.2709 and DIN 1.2344 / H13 tool steel. In relation to cold-work applications, Damm highlighted AM’s benefits as avoiding the need to stock bar material, integrating advanced lubrication and venting, and superior process control through integrated sensor.

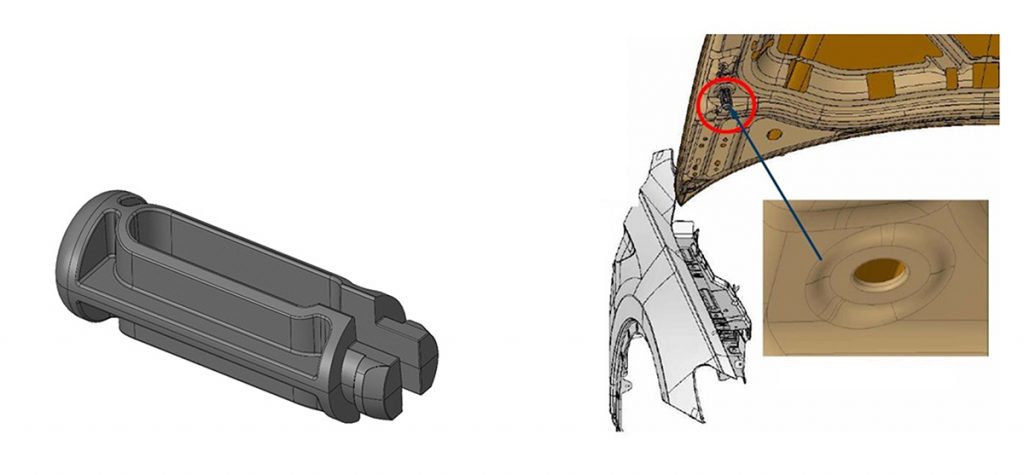

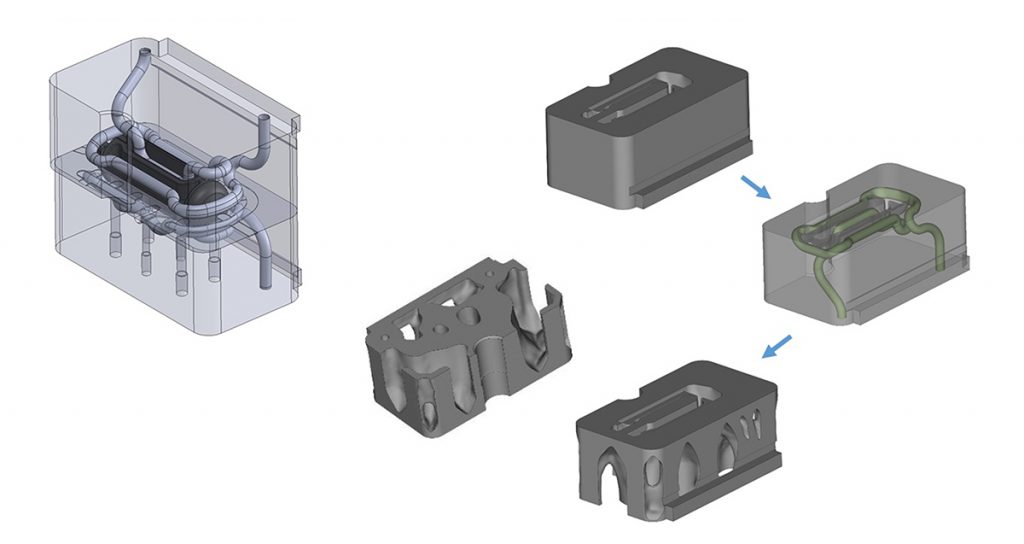

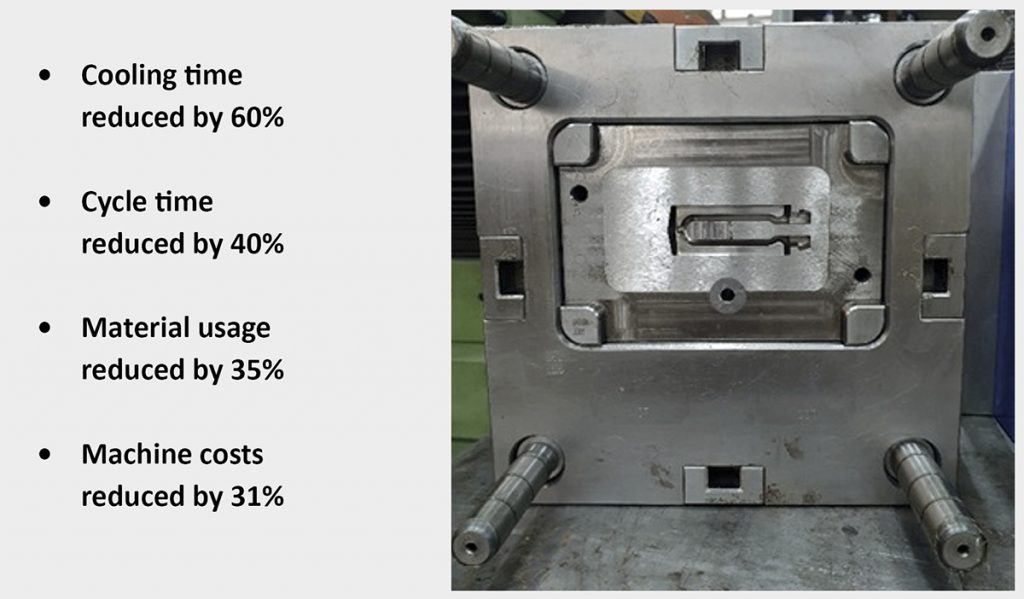

Anton Alveflo described the AM approach and solutions provided by voestalpine along the value chain for powders and parts. voestalpine carries out material development and powder production, design optimisation and component production. Besides Inconel L718, L625, 17-4PH and W722, Böhler and Uddeholm, as divisions of voestalpine, are providing proprietary materials such as E185, W360, M789, Corrax and Heatvar for AM applications. Alveflo showed industrial tooling cases from HPDC and plastic injection moulding, with the tooling for the plastic injection moulding of a Polyamide 66 component for a car body application being one of these cases (Fig. 9). To reduce cooling time, warpage and component weight, conformal cooling and topology optimisation were conducted (Fig. 10). After these optimisations, the tool was additively manufactured using the Corrax material. With this tool, cooling time was reduced by 60%, cycle time by 40%, material usage by 35% and machine cost by 31% (Fig. 11).

Drivers of AM innovation

Several contributions covered the further development of advanced systems and processes for metal AM. Presentations made by Franz Haas (TU Graz, Austria), Sebastian Dirks (RWTH Aachen, Germany) and Ulf Ackelid (Freemelt AB, Sweden) highlighted opportunities and barriers in the context of process innovations for the further development of the field. This topic is also closely connected with the advances achieved in the field of software and simulation tools, as outlined in the contributions of Andreas Markström (Thermo-Calc Software AB, Sweden), Johannes Zielinski (RWTH Aaachen), and Tobias Ronneberg (Imperial College London, UK). These presentations highlighted how crucial software’s role in the evolution of AM is, from enabling the optimisation of AM parts to meltpool simulations and the in-situ imaging of microstructures.

To further enhance the economic and technical benefits of metal AM, innovative and AM-targeted materials, especially powders, are a critical issue. This was reflected by the large number of contributions covering powder production and characterisation, a topic with a very strong tradition in Sweden. Presentations given by, among others, speakers from Fraunhofer ILT, RWTH Aachen, KTH Stockholm, Uddeholm AB, Luleå University of Technology and Mimete Srl can be seen as proof of the vibrant European metal powder production scene.

Demanding and promising applications, where features offered by AM enhance the economic or engineering value, are still the key drivers for AM. In order to guarantee the reliability necessary for such applications, quality assurance and process monitoring are instrumental. Several sessions therefore covered these topics, giving a broad insight. The importance of further developing this field is also indicated by the presentation of one of the three ‘best paper awards’ to a paper on this topic.

Finally, since surface quality and defect control are both critical in powder-based metal AM, post-processing and final quality inspection are key elements of the whole process chain. Post-processing approaches based on both electrochemical and mechanical routes were showcased in a number of presentations, including those from Hirtenberger Engineered Surfaces, Sandvik Additive Manufacturing, the University of Trento and DTU, reflecting the increasing levels of activity in this field.

Conclusion

When compared to MAMC 2014, 2016 and 2018, the conference programme at MAMC 2019 demonstrated significant progress regarding materials, the understanding of the Additive Manufacturing process, and the exploitation of new applications. For lightweight applications, such as those in the aerospace and space sectors and complex parts in gas turbines, there is now a clear argument for using metal AM. The final decision between conventional manufacturing processes and AM remains a matter of economics for many applications. Yet, as recent presentations show, there is a significant increase of effort in all fields to implement AM for a rapidly growing range of additional applications.

Authors

Prof Dr Jürgen Stampfl

Jürgen Stampfl is Professor for Materials and Additive Manufacturing at the Institute for Materials Science and Technology at TU Vienna, Austria.

Tel: +43 1 58801 30862

[email protected]

Prof Dr Nader Asnafi

Nader Asnafi is Professor of Mechanical Engineering at Örebro University, Sweden.

Tel: +46 19 30 14 93

[email protected]

DI Dr Bruno Hribernik

Dr Hribernik is Member of the Managing Board at ASMET – The Austrian Society for Metallurgy and Materials, Leoben, Austria

Tel: +43 66411 01010

[email protected]

DI Dr Gerhard Hackl

Dr Hackl is Executive Member of the Managing Board at ASMET – The Austrian Society for Metallurgy and Materials, Leoben, Austria

Tel: +43 3842 402 2294

[email protected]

Proceedings

Details of the presentations can be found in the MAMC 2019 proceedings, which can be ordered from ASMET (please contact [email protected])

MAMC2020

The Metal Additive Manufacturing Conference 2020 will take place at the Wirtschaftskammer Österreich, Vienna, Austria, September 30–October 2, 2020.

Two-day Design for AM tutorial

Directly following MAMC 2019, Nader Asnafi, Professor of Mechanical Engineering, held a two-day course in Design for Metal Additive Manufacturing in collaboration with Jürgen Stampfl, Professor for Materials and Additive Manufacturing Technologies, TU Wien, Austria, and Olaf Diegel, Professor and Head of the Creative Design and Additive Manufacturing Laboratory, the University of Auckland, New Zealand. The course, which was held at Örebro University, attracted participants from Australia, Austria, France, Japan, South Korea and Sweden.

Tours showcase Sweden as a centre of innovation in AM

The morning of November 25 was dedicated to visits to AMEXCI and Lasertech LSH in Karlskoga, a thirty-five minute drive from Örebro Castle. AMEXCI was founded by ABB, Atlas Coco, Electrolux, Husqvarna Group, Höganäs, Saab, Scania, SKF, Stora Enso, and Wärtsiläand FAM on the principle of accelerating the industrial adoption of AM and helping to bring a new generation of innovative engineers and products to the market. AMEXCI has in-house capacity for both metal and polymer AM and strives to be the best partner in applying know-how throughout the product lifecycle in the field of AM. Design for AM, qualification, certification, training and education are some of the focus areas.

Lasertech LSH AB began its operations in 2000 with the aim to become a leading supplier of laser welding services. The company now has nineteen employees and its focus has evolved to encompass other laser processing services such as laser marking, laser hardening, and laser cladding or Laser Metal Deposition (LMD). At the end of 2018 the company invested in an all-new ‘3D factory’ with the ambition of creating a world class AM facility. This began operations in 2019.

The afternoon of November 27 offered a visit to Siemens Industrial Turbomachinery’s AM plant in Finspång, located eighty minutes from Örebro Castle. Siemens is a global engineering powerhouse with a focus on the areas of electrification, automation and digitalisation. In infrastructure and industry solutions, the company plays a pioneering role.

Siemens’ Finspång operation is world-leading in the field of metal Additive Manufacturing and the company has invested in a complete factory with all the necessary physical and digital support systems for series production using L-PBF. More than eighty full-time employees at the facility work on the development, manufacturing and quality assurance of advanced gas turbine components, hybrid repairs, spare parts on demand and other manufacturing activities. Siemens uses single and quad laser L-PBF systems for the AM of primarily nickel-based superalloys for combustion systems, as well as stainless steels. Siemens also develops proprietary special alloys for its most demanding applications.