Additive Manufacturing needs you: Why you and your company should get involved in standards development

The development and communication of standards is vital to building customer confidence and trust in Additive Manufacturing, and it is only by building that trust that the industry can advance its adoption across a wider range of markets and applications. In this article, Khalid Rafi, ASTM International, and Shane Collins, Wohlers Associates, highlight the importance of standards, outline the standards development process, and explain why individuals employed within the AM industry should seek to involve themselves in this process. [First published in Metal AM Vol. 8 No. 3, Autumn 2022 | 10 minute read | View on Issuu | Download PDF]

As Additive Manufacturing advances to new and diverse applications across different industry sectors, standardisation is crucial to driving growth. A standard is a vehicle that facilitates a transaction between two parties such that both parties understand exactly what is transacted. As these standards are developed through a consensus process, and the requirements are communicated more clearly, product acceptability can be increased. Developing and communicating standards in this way builds customer confidence and trust; this is particularly important for new and emerging technologies such as Additive Manufacturing.

Standards are used by industry, government, and academia. In industry, they are often used in areas such as testing, inspection, and certification. They can also be used to facilitate specific activities and validate material quality and performance, as well as to qualify new machines and processes. Government agencies use standards as a reference and baseline for policy-making and legislation. This is particularly true in heavily regulated industries such as aerospace and health care, where product safety is of utmost importance. Standards are used in academic research to provide a common set of terminology and test procedures.

Standards are created by standards development organisations (SDOs), which are grouped under international, regional, and national levels. Examples of international SDOs include ISO, ASTM International, AWS, SAE, etc. At the regional level, they include CEN for the member countries of the European Union. National organisations include ANSI (US), DIN (Germany), BSI (UK), and AFNOR (France).

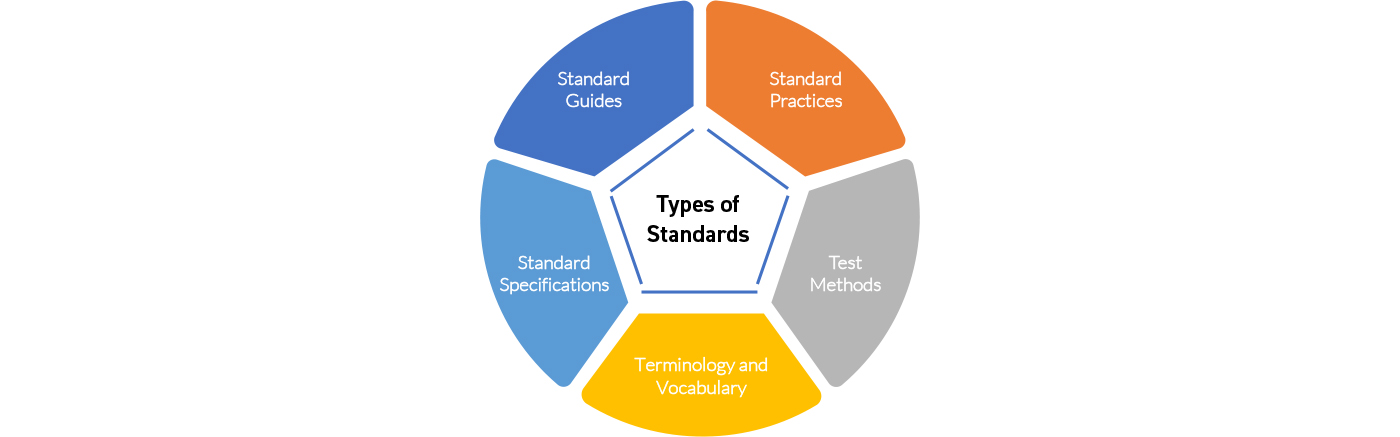

Types of standards

Standards are categorised based on their intended purpose and use. Within ASTM International, there are five common types of standards:

- ‘Standard guides’ are informative and describe a process or technology

- ‘Standard practices’ have normative requirements regarding a process or technology

- ‘Standard specifications’ have strict requirements such as for materials

- ‘Test methods’ establish requirements for a testing protocol

- ‘Terminology’ or ‘vocabulary’ provides accurate communication

These five categories provide user education (informative) about products and services as well as setting upper and lower limits on required content (normative). This approach is extremely important for emerging technologies because many products and services are evolving quickly, making concise transactions troublesome. Additive Manufacturing, as an emerging technology, has significantly benefited from ASTM standardisation efforts.

AM standards development

Understanding the need for standards in driving the industrialisation of AM, several international and national SDOs are involved in developing AM standards. Out of many SDOs, ASTM and ISO take the lead role in this initiative.

ASTM International Committee F42 on Additive Manufacturing Technologies was the first committee specifically created to develop standards on AM. This committee, in fact, defined the term ‘Additive Manufacturing’ in the first terminology standard, published soon after the committee was formed in 2009. Committee F42 has grown from a handful of industry subject matter experts to more than 1,100 members from forty countries. These members cover multiple industries that impact a significant portion of the AM ecosystem.

As the committee and technical content of the standards evolved over the years, so have the expertise and background of the members. The F42 Committee includes experts in materials, processes, testing methodologies, big data, safety, and many other aspects of AM. A diverse and experienced membership is necessary to approve and publish consensus-based standards. The ASTM requires 100% agreement by the membership that a standard is accurate, relevant, and meets the needs of industry.

A significant amount of effort is involved in the consensus process, particularly for normative standards. To accelerate the standard development process and efficiently use the AM technical expertise, ASTM has signed a partnership agreement with ISO to develop Additive Manufacturing standards jointly. Based on the agreement, ISO/TC 261, the committee for Additive Manufacturing at ISO, joined with ASTM F42 to create robust industry-relevant AM standards.

Getting involved in the standards development process

The stakeholders involved in standards development serve as a microcosm of the broader industry. Being involved in the development of standards for an emerging technology, such as AM, can provide great insight into the maturity of the AM industry. Experts from multiple domains come together to create these standards; this also provides unparalleled access to industry experts for technical advice and networking opportunities. Furthermore, the collaboration between ISO and ASTM opens the door to a broader pool of domain experts to exchange ideas.

Alison Park, Deputy Tech Fellow of Materials, NASA NESC, commented on NASA’s involvement in standards development, “Being involved as an active participant in voluntary consensus standards development organisations (SDO) is important to NASA. We are highly encouraged to facilitate the standard development activities as well as their adaptation for use to meet NASA’s needs. For a short time, I have been involved in SDOs, including ASTM F42. It has been a rewarding experience to lead and contribute to critical AM standards development.”

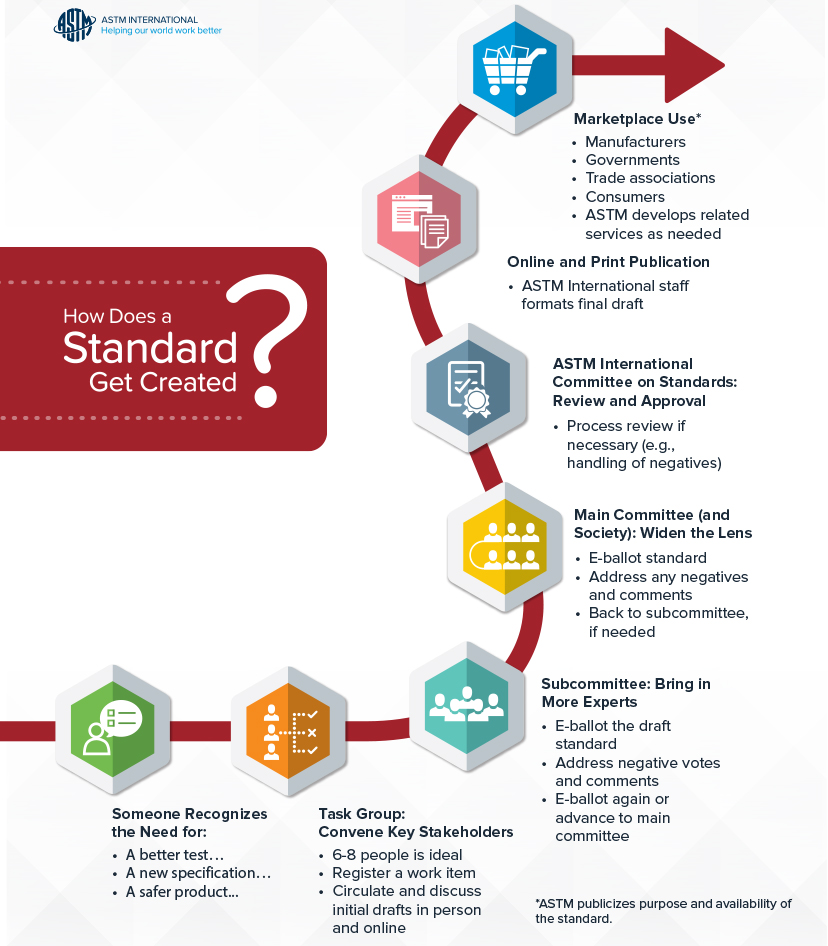

While the underlying principles of the standard development process across different SDOs are essentially the same, subtle differences exist in structure and requirements. Each SDO applies its own rules and methodologies to the standard development process.

Fig. 2 shows a typical standard development process at ASTM International. The standard development process includes multiple stages before a new standard is created. Different levels of involvement are needed during the drafting stages of the standard.

Because it takes about two years to progress from work item registration to an approved standard, the relationships within task groups can become quite close. Working together for a common goal creates bonds that can last for quite some time, and task group mates can become new customers. Being involved with customers on standards development can offer you the chance to demonstrate your technical expertise and credibility in marketing efforts.

The state of AM standards

A review of ASTM standards paints a broad picture of the state of the industry. As of the date of this article, six AM test methods, eight design guides, and eighteen standards for materials and processes have been published. Also available are four standards for AM applications, one on data, and one on terminology. New standards are approved on a regular basis, and staying current requires involvement in the Committee and regular meeting attendance. Being engaged in F42 is, therefore, a useful way of staying up to date on the developing markets for AM.

ASTM F42’s committee membership has grown rapidly in the past years, with strong representation from all relevant stakeholders. The members of the committee fall into three general categories:

- Members who sign up for all of the subcommittees to monitor the standards development process

- Members who actively participate in task groups of interest as they are formed

- Members who specifically join F42 to publish a standard they believe will help their company prosper

The first two types of member are important. The third type, however, has the most drive and willingness to work overtime and deal with multiple interests to create a new standard. The expertise provided by more than 1,100 members is extensive, and the opportunity to interact and exchange ideas with so many experts is invaluable.

“Participating in the development of AM standards has allowed me to use my experience and know-how in the automotive manufacturing industry in a way that can help advance the use of AM more broadly across all manufacturing sectors,” stated Ellen Lee, Technical Leader AM Research, Ford Motor Company. “Since joining, I have enjoyed expanding my network and having discussions with fascinating people and thought leaders.”

The most relevant standards to an individual are those that affect their company. The same is true when there is no standard available; customer disputes can often become the basis for registering a work item with ASTM. Consider a case where the customer expectations did not align with the deliverable. This is likely due to a lack of explicit instructions, which would have been agreed upon in a standard, and offers a good opportunity for the customer or vendor to register a work item with ASTM that will prevent future misunderstandings.

Another unique situation involves the combination of outcomes from several research projects to support standardisation. With development being a consensus-based process, it often takes two or more years to publish a standard. This is primarily because of the lack of historical data to define certain requirements.

To reduce time-to-market, ASTM introduced the concept of research-to-standards through its Additive Manufacturing Center of Excellence (AM CoE). The CoE helps generate data to form the basis for registering a work item that eventually becomes a standard. This targeted research for standards is based on ideas from committee members, performed at partner organisations, and funded by ASTM. As a committee member, sharing ideas becomes key in shaping AM standards and a significant contribution to the AM community.

Of course, involvement in standards development activities also looks good on a resume, and can distinguish one applicant from the crowd. This demonstrates not only the technical experience gained from being on a task group, but also shows that the candidate is willing to give back to the AM community in their own time. In many cases, an individual involved in standards development activities works outside of typical business hours in order to participate in conference calls and in-person meetings.

Therefore, getting involved in the standards development process brings both tangible and intangible benefits. Being part of a team that is developing industry-relevant and globally recognised standard documents offers a sense of accomplishment. Working on a standard for many months and finally seeing it published results in pride, exhilaration, and optimism.

Getting involved in ASTM standards development is easy. In fact, membership in ASTM is not required to get involved, unless you wish to vote on balloted standards. In order to vote, you can join as an individual member or as an organisation. After joining ASTM, sign up for F42 and select the subcommittee(s) of interest. ASTM will provide proper guidance on navigating the standards development process through on-demand complimentary webinars. Good luck, and thank you for your hard work to advance our industry!

Authors

Khalid Rafi

ASTM International

Shane Collins,

Wohlers Associates