Wohlers releases report on post-processing of AM parts

October 15, 2021

Wohlers Associates, Inc, Fort Collins, Colorado, USA, has released a new report titled ‘Post-Processing of AM and 3D-Printed Parts’ discussing the many time consuming and often expensive steps in post-processing parts made by Additive Manufacturing, including support material removal, the finishing of surfaces, colouring & coating, and heat treatment.

Organisations involved with AM have vast amounts of post-processing knowledge and experience, yet little systematic documentation is available, explains Wohlers Associates. This has led to companies ‘reinventing the wheel’ and spending time and money unnecessarily to complete jobs. The company states that the methods and techniques described in this report can reduce the trial-and-error that so many organisations use.

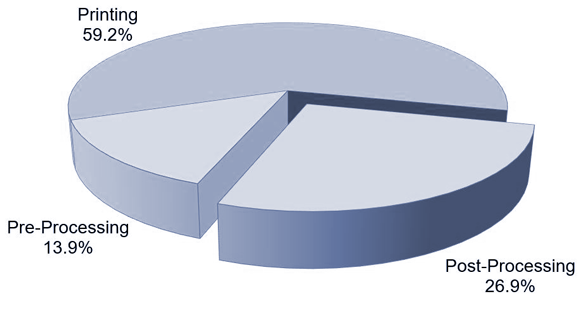

Post-processing is one of three major phases of producing AM parts and, according to research conducted for Wohlers Report 2021, it accounts for nearly 27% of the cost of production. The study involved input from 124 service providers in twenty-seven countries. The following chart presents the cost segmentation between pre-processing, printing, and post-processing among companies that offer both metal and polymer AM.

When calculating the cost of post-processing, it is critical to consider the entire end-to-end workflow, explains Wohlers Associates. Bottlenecks are a challenge, especially when scaling into production quantities. The post-processing steps for metal Powder Bed Fusion (PBF) include the removal of powder, thermal stress relief and the separation of parts and support material from the build plate. They also include the removal of supports from parts, media blasting, and machining and grinding. Some parts may require Hot Isostatic Pressing (HIP), additional heat treatment, anodising, and inspection. If post-processing is not scaled and streamlined accordingly, bottlenecks will occur, especially with large quantities.

Design for AM is key to reducing time and costs associated with post-processing, states the report. For example, metal PBF parts can be oriented sop that the faces to be machined are pointing down – these downward surfaces will be rough due to the support material and can be used to one’s advantage.

More information on the report and its purchase is available through the Wohlers Associates website.