VRC Metal Systems to demonstrate Cold Spray AM at US Navy event

August 11, 2022

VRC Metal Systems, Box Elder, South Dakota, USA, announced that it has been selected by the US Navy to take part in the 2022 Navy REPTX to provide solutions for pier-side and shipboard Cold Spray Additive Manufacturing corrosion and damage repair & mitigation.

2022 REPTX allows industrial maintenance solutions to be demonstrated onboard the US Navy’s Self Defense Test Ship in a one-on-one setting between August 22-September 2, 2022. The event will consist of technical demonstrations, field experiments and exercises (both discussion and operations-based).

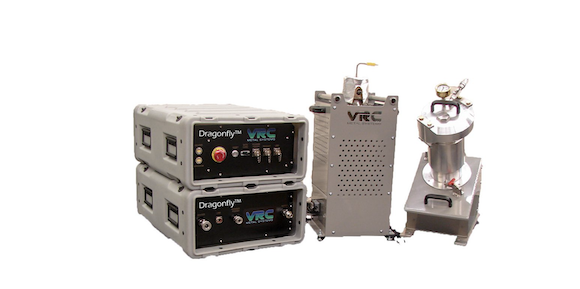

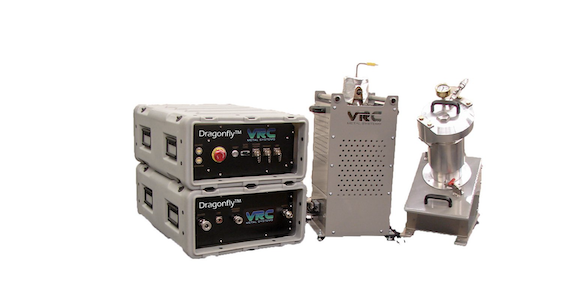

The company has stated that this is a major step in its mission to provide reliable metals disposition technologies, solutions, and components. Also in line with that mission is the recent development of the CAMP Site and VRC Dragonfly, both of which are fieldable Cold Spray Additive Manufacturing machines. CAMP Site is a self-supporting, portable unit intended to repair corrosion and damage, while the Dragonfly is for use aboard ships.

Rob Hrabe, CEO & co-founder, VRC Metal Systems, stated, “Being selected to participate in the Navy’s REPTX programme demonstrates the Navy’s confidence in VRC equipment and expertise.”