C.A.M.P. Site portable Cold Spray Additive Manufacturing system from VRC Metal Systems

August 1, 2022

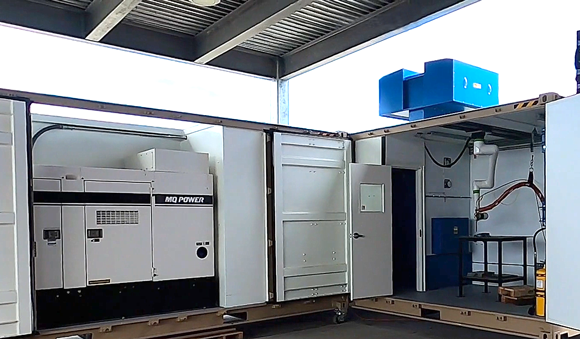

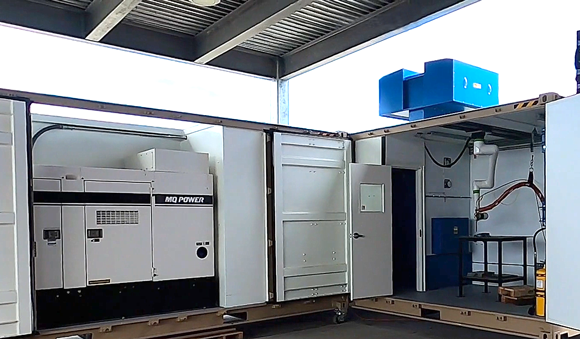

VRC Metal Systems, a Cold Spray Additive Manufacturing Specialists based in South Dakota, USA, has released its portable C.A.M.P Site™ Cold Spray system. The Cold Spray Advanced Manufacturing Portable Site (C.A.M.P. Site) is said to be the company’s most powerful and relatively portable unit to date, housed within a standard shipping container.

The C.A.M.P. Site system is designed to be self-supporting for all operations, without the need for additional services other than a water connection for the dust collector part of the unit. The system includes a generator that supports the entire unit’s power requirements, including the cold spray system, compressor, dust collector, robotic system and all the lights and electrical equipment.

The other major key factor for the C.A.M.P Site being self-supporting is the compressor system that supplies a working pressure of 4,500 psi. Behind the compressor itself there are twenty-four bottles of compressed gas, each capable of 4,500 psi. This gives the unit enough gas on hand, depending on the recipe being used, to spray continuously for up to eight hours.

Included inside the container is a heater/AC unit, that maintains the working environment, with a small laboratory furnace capable of temperatures of 1,200°C that can be used for PBI nozzle drying, powder drying, powder processing and adhesion test glue setting. Next to this utility cell room is the cold spray cell that includes a hoist capable of extending out of a container to bring any larger parts, up to 227 kg, into the spray booth.

All of the operations that occur within the spray booth are aided by a CRX10 collaborative robot that sits along the roof’s linear rail system for mobility. A further feature of the spray booth is a pass-through door that allows users to perform hand spray operations outside the booth. To achieve this, the gas and power lines are routed outside to the heater and powder feeder.