Ulrich Medical USA receives FDA clearance for AM interbody device

October 18, 2022

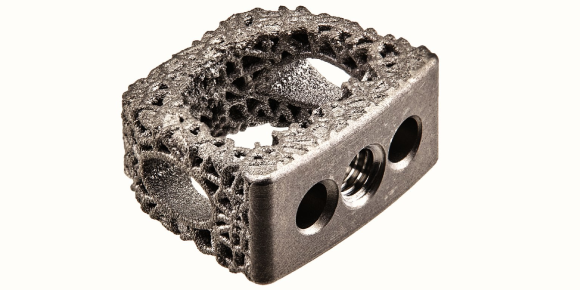

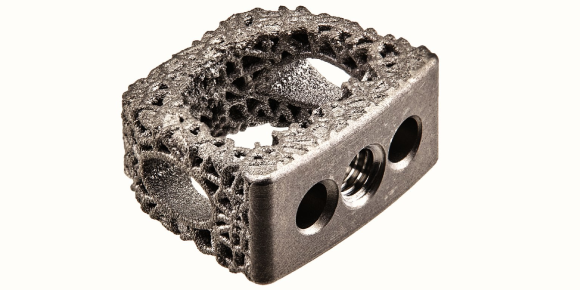

Ulrich Medical USA, St Louis, Missouri, USA, has announced that the US Food and Drug Administration (FDA) has given 510(k) clearance for its additively manufactured porous titanium cervical interbody device: the Flux-C.

“Surgeons have many options for cervical interbodies. The Flux-C porous titanium device offers one of the best in class with superior endplate contact and spaces for generous inter-device bone grafting. It is a welcomed complement to their superior array of expandable cages,” stated Patrick Maloney, MD, a Director of Deformity and member of Ulrich Medical USA’s Surgeon Advisory Board.

Flux-C is manufactured using Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing, designed with a large graft window and a side window to enable improved radiographic imaging. The interbodies are available in multiple parallel and lordotic options at various heights.

Eric Lucas, PhD, Ulrich Medical USA’s Director of Technology, added, “We are continuing to develop procedural solutions for reconstruction of all spinal pathologies in collaboration with our Surgeon Advisory Board. We strive to help our surgeons and distributors achieve New Heights and Beyond with integrity, through excellence in design, manufacturing and craftsmanship.”