Latest Altair HyperWorks 2019 release offers expanded solutions for design and engineering

June 13, 2019

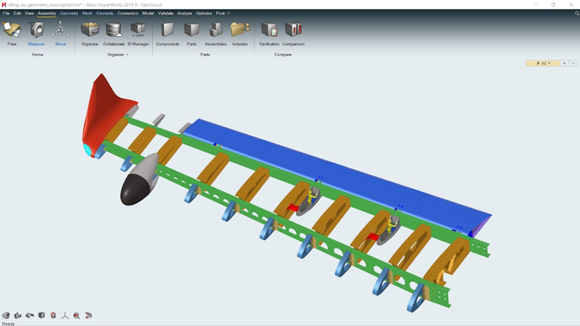

Altair releases the latest version of its HyperWorks 2019 software (Courtesy Altair)

Altair, a provider of software and cloud solutions for product development, headquartered in Troy, Michigan, USA, has released the latest version of its simulation and AI driven product development platform, Altair HyperWorks™ 2019. The new version reportedly expands on the number of solutions available for designers and engineers under a single, open-architecture platform with the aim of streamlining decision making and time-to-market.

“We want to help our customers explore more ideas, better understand their designs, and improve profitability,” stated James Scapa, Altair’s Chief Executive Officer and Founder. “To achieve this, our development focus for HyperWorks 2019 was to increase solve speed and functionality across our solutions for every stage of product development with optimisation and multi-physics workflows for all manufacturing methods.”

According to Altair, the latest version of its HyperWorks 2019 includes the following highlights, applicable to a range of manufacturing methods, including Additive Manufacturing:

- Fast simulation of complex assemblies

- Easy-to-learn fatigue life prediction

- Efficient workflows for multi-physics

- Superior high-fidelity modeling

- Enhanced user experience for fast concept modeling

- Expanded non-linear solver functionality

- Continued generative design leadership

Scapa added, “HyperWorks 2019 enhances the user experience for both experts and part-time analysts. This release includes a new set of workflows for our flagship Altair HyperMesh product, making advanced analysis capabilities more accessible. In addition, the new Altair HyperLife product enables test engineers to perform fatigue simulations with minimal training.”