Kittyhawk partners with Synertech PM to provide build plates for AM

November 18, 2020

Hot Isostatic Pressing (HIP) company, Kittyhawk, headquartered in Garden Grove, California, USA, reports that it has entered a partnership with Synertech PM Inc, a Powder Metallurgy parts manufacturer also based in Garden Grove, to offer a range of build plates for Additive Manufacturing machines.

Build plates are an essential element in providing stability and quality in Additive Manufacturing processes. However, Kittyhawk explains that some of them are not readily available and can be costly. The company states that it can also be difficult to acquire thicker plates when a process requires them, for example. Additionally, the inherent anisotropy of rolled plates can also impact the dimensional precision of the AM process.

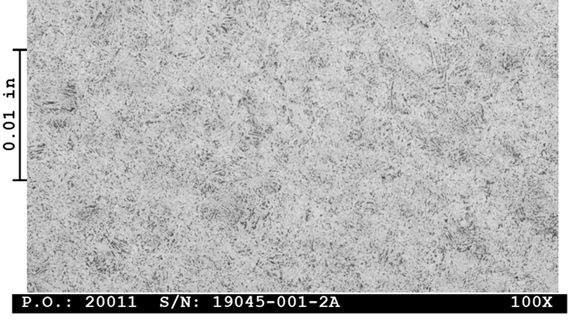

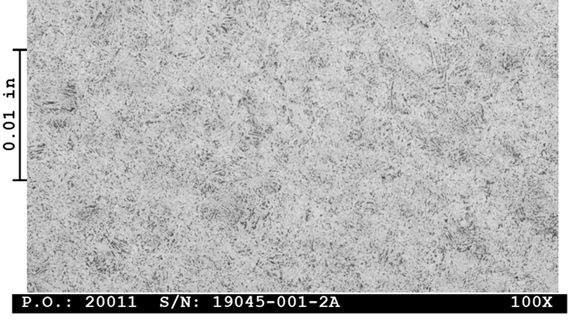

Jointly, the companies will provide uniform and homogenous PM HIPed rectangular blanks, yielding the necessary amount of build plates to the optimal thickness for AM machines. Build plates made by Powder Metallurgy and HIPed are 100% dense with fine-grain micro-structure, states Kittyhawk, resulting in minimised warping during Additive Manufacturing process and producing fewer restrictions on positioning the built parts on their surface.

Kittyhawk states that its HIP equipment and canning technology enables the production of blanks with the cross-section from 25 x 25 cm up to 76 x 127 cm. Lead time for the blanks are four-five weeks and the materials that are readily available include Ti 6-4 Grade 5, Ti 6-4 Grade 23, Ti Grade 2, IN 718 and IN 625.