Infinite Flex releases pure copper powder for laser-based Additive Manufacturing

January 17, 2022

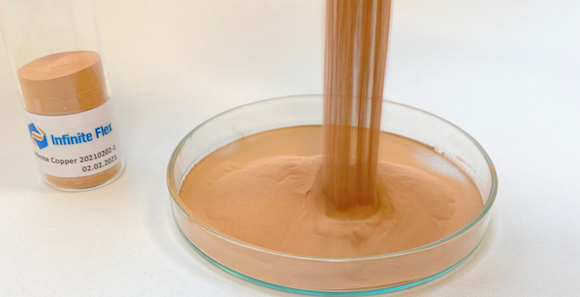

Smart materials company Infinite Flex, with operations in Neu-Isenburg, Germany, and Taicang, China, has introduced its new Infinite Powder Cu 01, a pure copper powder suitable for use with Laser Beam Powder Bed Fusion (PBF-LB) machines. To date, the powder has been successfully tested on the EOS M290 and the TruPrint 1000 from Trumpf.

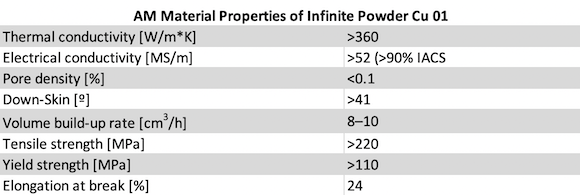

Pure copper is a popular metal in almost all branches of industry, thanks to its good electrical and thermal conductivity. Laser-based Additive Manufacturing has, however, traditionally struggled with adopting the element due to its refractory characteristics. Copper alloys such as CuCrZr and CuNiSiCr have been used in pure copper’s place, but the conductivity of these alloys has only reached 70% and 40%, respectively, of pure copper’s electrical conductivity.

By releasing Infinite Powder Cu 01, Infinite Flex hopes to enable the wider production of additively manufactured components with the high connectivity characteristics of pure copper, such as heat exchangers, induction coils and electronic components, on standard PBF-LB machines.

Infinite Powder Cu 01 is now commercially available.