GROB releases Liquid Metal Printing machine

July 7, 2022

GROB Systems, headquartered in Mindelheim, Germany, has released its new GMP300 Additive Manufacturing machine, which utilises Liquid Metal Printing (LMP) technology in a 300 x 300 x 300 mm build chamber. The machine features 3-axis kinematics.

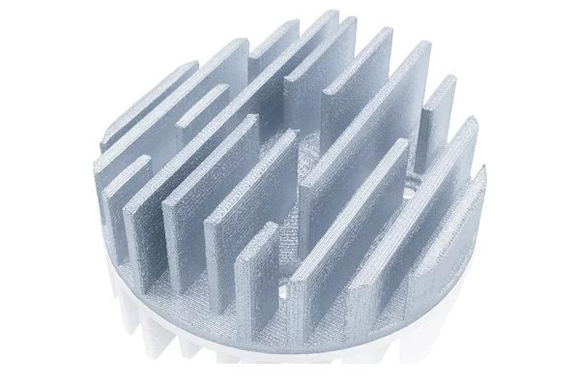

The GMP300 is currently designed to process aluminium alloy wire feedstock, and as a powder-free machine, is intended to act as a safe, fast option for the metal Additive Manufacturing of near-net shape components. GROB’s LMP process is believed to fall broadly into the ISO/ASTM 52900:2015 category of Material Jetting.

According to GROB, its LMP process creates a homogeneous part microstructure with yield points that are the same as – or sometimes even higher than – the values of the starting material. The process’ flexibility is achieved through the ability to perform quick changes of material without intensive cleaning efforts, made possible by the high variability of the droplet diameter and the fact that the print head and nozzle can be changed during the build-up process.

The productivity rate of the process is primarily made possible by the high build rates that can be achieved using liquid metal, the reduced post-processing effort and the fact that the component costs scale only slightly over the fill level of the building board.

GROB has highlighted the machine’s suitability for the manufacture of parts such as heat sinks, holders, clamping rings, distributors and spindle covers.