FasTech and University of North Dakota explore DED Additive Manufacturing for space

March 7, 2023

The University of North Dakota (UND), Grand Forks, North Dakota, USA, has been awarded a grant funded by NASA to investigate the potential of metal Additive Manufacturing to produce aluminium components for future lunar exploration. This comes as part of NASA’s initiative of supporting space exploration via partnerships with small businesses and universities to develop metal AM capabilities for the International Space Station (ISS) and future missions.

Dr Sougata Roy, who leads this effort at UND and has selected FasTech, Danville, Virginia, to produce the parts using Wire Arc Additive Manufacturing, referred to by the company as Arc-Directed Energy Deposition (DED-Arc). FasTech offers AM, conventional manufacturing, and inspection systems as part of its service.

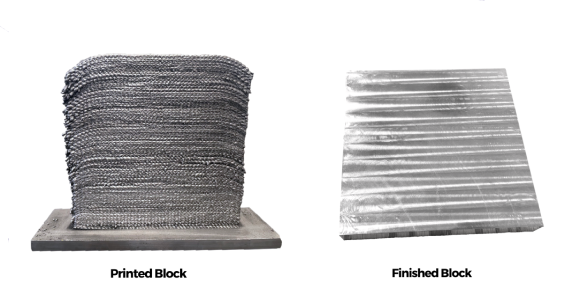

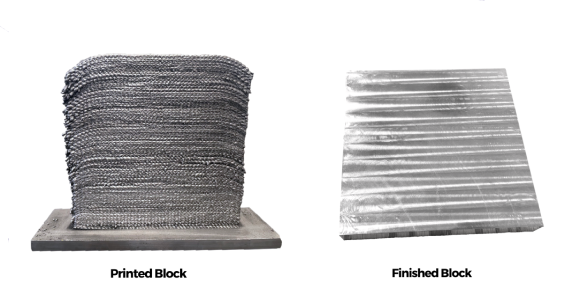

Aluminium 6061 was selected as the starting material for this project, due to its high strength-to-weight ratio and its compatibility with heat treatment. Fastech additively manufactured a block from the chosen material enabling Dr Roy’s research team to extract coupons for testing and evaluation.

The block was additively manufactured at a deposition rate of 1.5 kg/h, including the inter-layer cooling time. In parallel, samples from Al 6061 powder were additively manufactured utilising laser-based DED (DED-LB) at UND. The lunar dust tolerance of parts via different Additive Manufacturing techniques will be subsequently tested.

FasTech and UND plan to apply this technology and expand their partnership to manufacture aluminium alloys for different engineering sectors.

Download Metal AM magazine