BEAMIT Group develops AM process for nickel-base superalloy René 80

October 27, 2021

The BEAMIT Group, Fornovo di Taro, Italy, reports that it has developed an Additive Manufacturing process for nickel-base superalloy René 80 RAM1, as a result of the group’s efforts to identify new alloys for use in the energy industry.

In recent years, AM has become a trusted technology in the energy industry due to its ability to produce components, such as combustor gas turbines, which offer better combustion efficiency and reduce the environmental impact of energy production, explains BEAMIT.

René 80 has a high melting point and excellent oxidation resistance at high temperatures, making it particularly suited to applications in the energy industry for turbines and valves, and for the aerospace industry. Additionally, when processed with AM technologies rather than conventional technologies, René 80 is reported to be one of the highest performing alloys at ambient temperature.

The first step in developing the AM process for René 80 was processing the alloy: the chemical composition of nickel superalloy powder is very complex, and a few critical issues often arise during the Additive Manufacturing phase. The powder was modified by Elementum 3D, Erie, Colorado, USA, using its patented RAM technology.

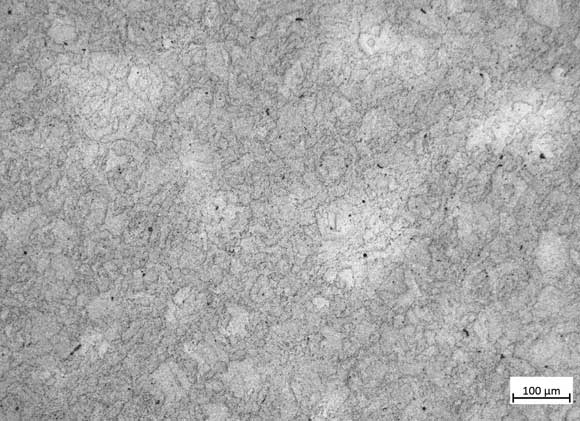

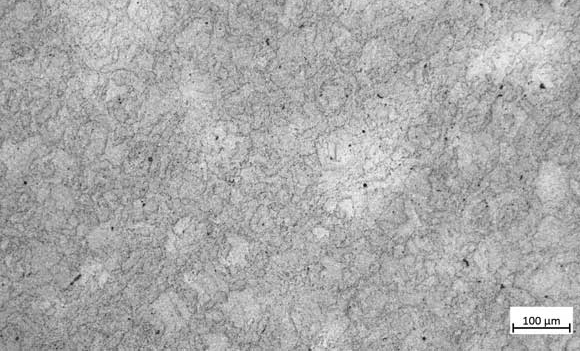

Once the alloy’s chemical composition had been modified, BEAMIT technicians developed and optimised the Laser Beam Powder Bed Fusion (PBF-LB) process to achieve good density and a crack-free microstructure.

BEAMIT explained that heat treatments are a key part of ensuring excellent performance in this case. Thorough research was conducted to identify the most suitable treatment, and also to eliminate any cracks in the components.

“René 80 is proving that our one-stop-shop strategy succeeds throughout the entire value chain, including when researching and developing new materials. Integrating special processes enables us to devise an otherwise unattainable solution with extraordinary results,” stated Andrea Scanavini, BEAMIT Group General Manager.

“The tougher the technological challenges, the more process integration and the innovation of post-processing, made available to highly skilled metallurgists, not only make the difference but become the only way forward,” he continued. “René 80 is one of our first demonstrations of this concept. And we are not done yet because other new advances are already in the developmental phase.”

The parameters for René 80 RAM1 treated with Hot Isostatic Pressing (HIP) and HIP quenching were characterised and compared with as-built René 80. With the optimised HIP-Q cycle, BEAMIT recorded a 20% increase in the mechanical properties compared with the aged condition of René 80 produced with conventional technologies. Furthermore, elongation up to 8% was achieved with a 37% increase compared to casting

The group states that the advantage of the process parameterised lies in the HIP-Q phase. The treatment can be performed with Quintus technology and enables HIPing to be followed by rapid quenching in argon to produce a high-performance material with just a one-step heat treatment and ensure a shorter lead-time than treatments using conventional methods.

Finally, tests were conducted at high temperatures and to gauge cracking resistance which confirmed a yield strength of 750 MPa at around 900°C.

Jacopo Sisti, BEAMIT Group Materials and Special Processes Manager, concluded, “It was a challenge to actually print an alloy that performs so well at high temperatures, but we fine-tuned the AM process and succeeded – plus we achieved high density. The turning point came with the innovative HIP-quenching heat treatment: we avoided the formation of cracks in the material which meant that we delivered better static mechanical properties than the alloy produced with conventional technologies.”