Cheaper powders, faster build speeds and no thermal stresses? How AM is going supersonic at SPEE3D

In recent years, Australia’s SPEE3D has made waves in the AM industry with its Cold Spray-based metal Additive Manufacturing systems. Following successful projects with the US and Australian military, and multiple installations at one of Europe’s most experienced metal AM parts manufacturers, the world is starting to take note. Alex Kingsbury visited the company at its Melbourne base for Metal AM magazine and spoke with its founders and newly expanded management team about its technology and international expansion. [First published in Metal AM Vol. 6 No. 1, Spring 2020 | 20 minute read | View on Issuu | Download PDF]

SPEE3D co-founders Byron Kennedy and Steven Camilleri are no strangers to commercialising deep tech innovations. It was during their time working together on the Charles Darwin University World Solar Car Challenge team that they developed a revolutionary high-efficiency motor for their car, the ‘Desert Rose’. The Desert Rose was awarded the world speed record for solar cars in 2000; and in 2001, Kennedy and Camilleri established In Motion Technologies to commercialise their electric motor. A successful sale of the company in 2006 to NYSE-listed manufacturer Regal Beloit made the motor technology one of the most successful spin-offs from solar car racing, and the motors are now widely used in many commonplace applications such as pool pumps and air conditioners.

The sale to Regal gave the co-founders the opportunity to oversee commercial production of their electric motors around the world, and the pair embraced the new knowledge and learning that came with commercial production. “We’re electrical engineers that come from research backgrounds,” explains SPEE3D CTO and co-founder Steven Camilleri. “Regal helped us understand how manufacturing worked. You don’t normally have academic people that worry about cost, lead time, or customer experience.” Through exposure to international metal supply chains and products, the pair found sourcing quality metal components to be a very painful experience. In 2010, they began investigating alternative manufacturing methods and were excited by the promise of Additive Manufacturing, but the excitement faded quickly when confronted with the price tag. Calling on their manufacturing training, they knew this was due to the slow speed of the machines. “We set our minds to solve the scaling issue that Laser Powder Bed Fusion (L-PBF) faces, but ultimately we realised that there was no way forward due to the laws of physics,” says Camilleri. Knowing heat was the limiting factor, they looked at technologies that could densify material without heat. During a visit to the CSIRO laboratories (the Commonwealth Scientific and Industrial Research Organisation), they witnessed Cold Spray technology and saw the potential immediately. In 2015, Kennedy and Camilleri decided to pursue commercialisation of this technology full time, and SPEE3D was born.

What is Cold Spray?

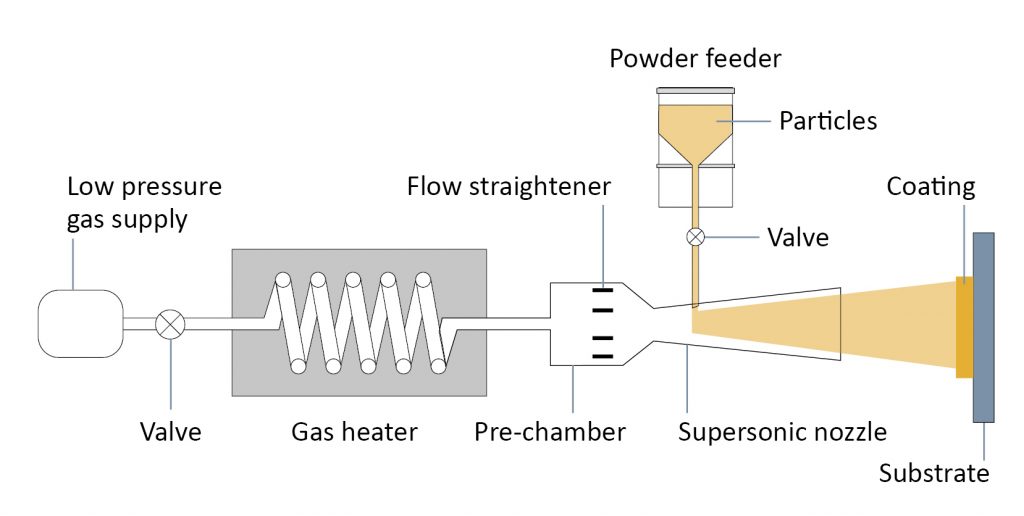

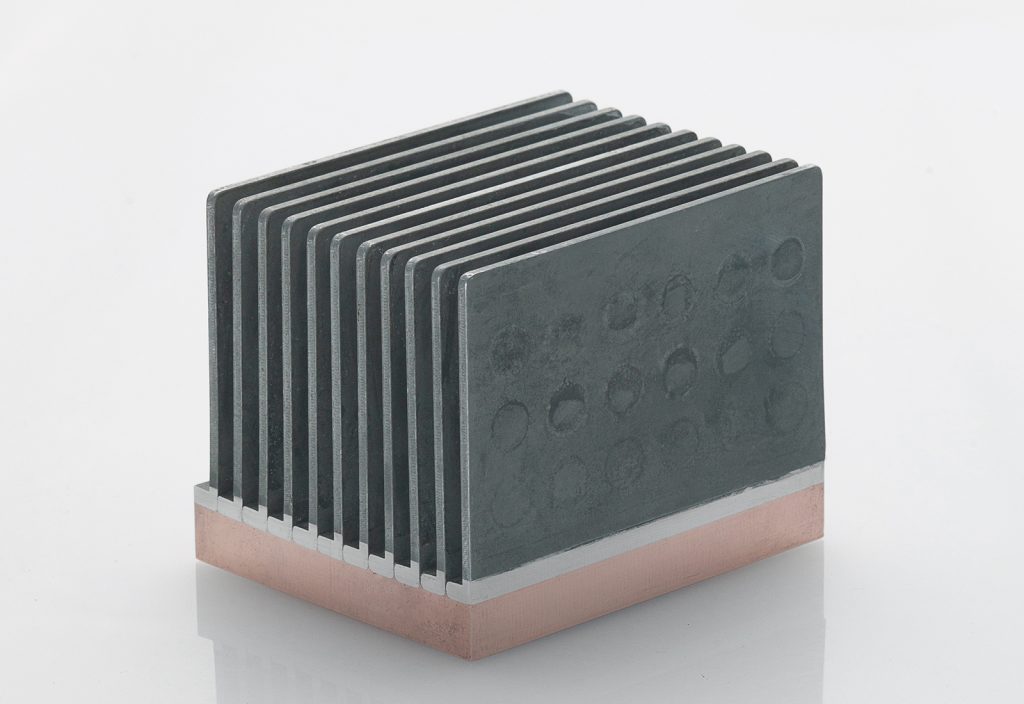

In the Cold Spray process, metal powder of a 5–45 µm size range is deposited onto a substrate by accelerating the particles to supersonic speeds via a carrier gas. This kinetic energy plastically deforms the particles upon impact, forming a ‘particle splat’ on the substrate. The plastic deformation of the particle is shown in a change of shape in the particle and substrate. Some mechanical interlocking occurs, and a small amount of heat is produced; however, the heat is not significant enough to change the microstructure of the particles. In fact, the particles largely retain their original microstructure, with the exception of some peening or cold working effects. Unlike many other AM processes, Cold Spray can process a wide range of particle shapes; spherical, irregular or dendritic morphologies are all cold-sprayable by adjusting spraying parameters.

Like many innovations, Cold Spray’s discovery was one hundred years too early; true commercialisation has only occurred in the last thirty years. The key innovation in the technology is the use of a de Laval nozzle, a convergent-divergent nozzle that allows metal powder to reach supersonic speeds; this method was first patented in the 1960s. In the 1980s, scientists at the Russian Academy of Science experimenting with metal powders in a wind tunnel were able to achieve coatings of a thickness and density that signalled that the technology had potential for commercial use (Fig. 2) [1]. Since the 1990s, it has been successfully used as a coating technology, but its use as an AM technology to create near-net shape structures has only developed in recent years.

What is key to understanding this technology is an awareness is that bonding between materials and particles does not require a thermal source, i.e. there is no melting and cooling cycle; it is a solid-state process. The cold sprayed deposit is therefore very low in oxides and has little thermally-induced residual stress. Unlike thermally processed parts that are built in tensile stress, cold sprayed parts are built in compressive stress, which increases the fatigue properties of built parts. The absence of heat in the process makes it ideal for use with reactive materials such as titanium, aluminium and magnesium. Solid-state processing enables thick coatings to be applied without compromising the dimensional tolerance or underlying metallurgy of a parent part, making Cold Spray ideal for reclamation and repair processes. Cold Spray has, for example, been widely used for the repair of magnesium helicopter gearboxes.

The ductility of the sprayed material is an important consideration; less ductile materials undergo less plastic deformation and the built part can exhibit a brittleness not seen in thermally processed parts. Thermal post-processing such as Hot Isostatic Pressing (HIP) can negate these effects. More ductile materials such as aluminium and copper are less prone to embrittlement and, depending on the end use, do not always require a thermal treatment.

Cold Spray is a ‘line of sight’ technology similar to Directed Energy Deposition (DED) processes and, as such, the Cold Spray nozzle must be perpendicular to the sprayed surface. For this reason, intelligent toolpath strategies need to be employed to create shapes with overhangs, internal, or complex features. In general, the spot size of the nozzle limits the fidelity that Cold Spray can attain, and highly complex features, sharp corners or smooth surfaces are only achievable with post-machining.

Despite these challenges, the most exciting characteristic of Cold Spray is the speed with which it can deposit material. At rates of up to 6 kg per hour for small-scale Cold Spray systems, it is clear that Cold Spray can deposit material an order of magnitude faster than L-PBF systems, which was what drew Kennedy and Camilleri to the technology in the first place.

Cold Spray AM in SPEE3D systems

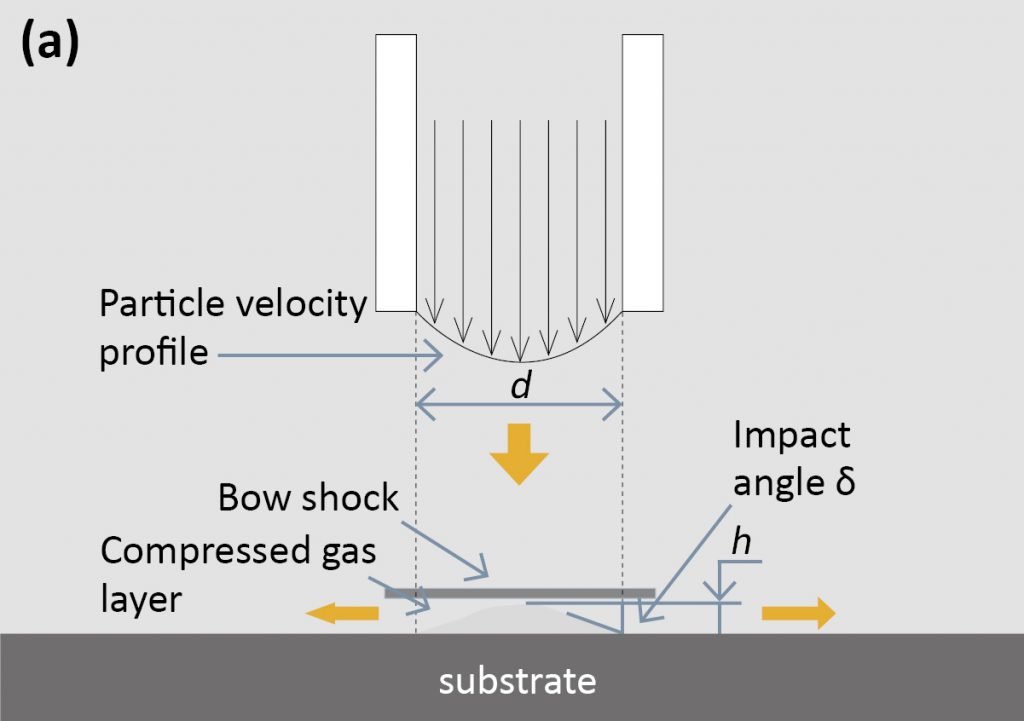

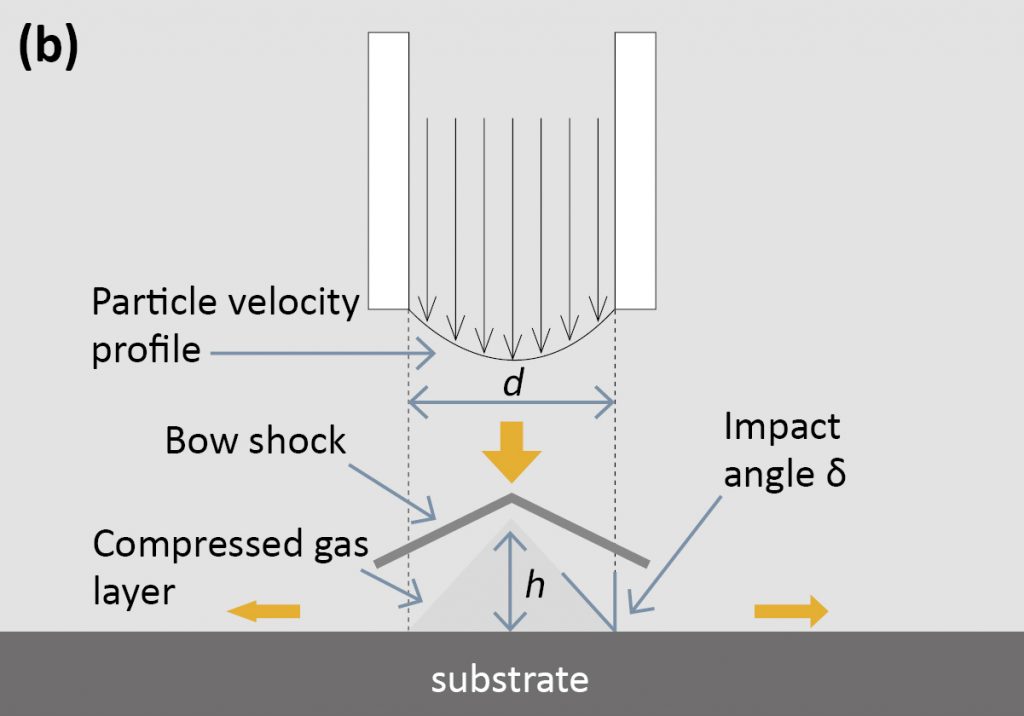

Kennedy and Camilleri’s biggest task was to create a product that could leverage the advantages of Cold Spray while addressing the challenges of taking the technology into the AM realm. The evolution of Cold Spray from coating technology to Additive Manufacturing seems simple, but it is not straightforward. Camilleri explains, “One of the problems with Cold Spray is that shapes saturate; you build a cone and then you cannot continue to build as the cone starts deflecting particles away, so you have to be able to reorient the nozzle.” (Fig. 3) [2].

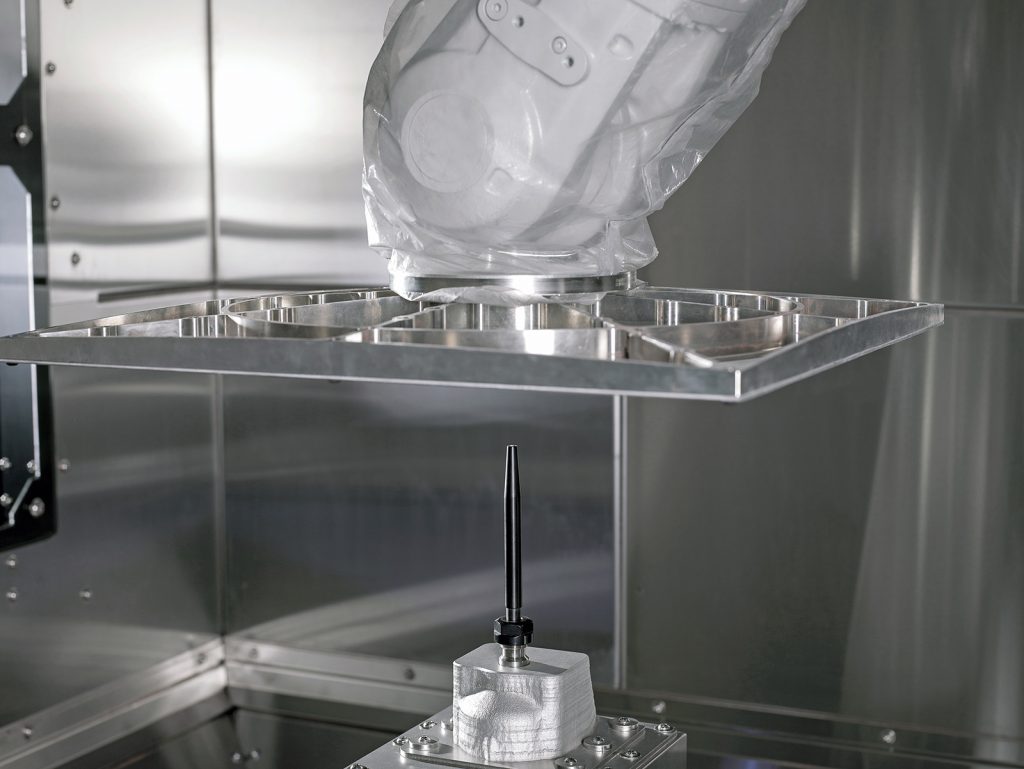

To most Cold Spray users, the SPEE3D machine design appears counter-intuitive. The nozzle is fixed at the base of the machine and a six-axis robot controls, rotates and orientates the build platform (Fig. 4). In fact, a moveable build platform means that the Cold Spray machinery is stationary within the machine, reducing operational complexity. With this key piece of architecture confirmed, Kennedy and Camilleri then commenced the arduous task of developing the Cold Spray Additive Manufacturing (CSAM) design rules and build strategies that underpin SPEE3D’s TwinSPEE3D software and, ultimately, the key value proposition of their offering.

The LightSPEE3D was the company’s first machine release; with a build volume of 350 mm diameter by 300 mm, this is the company’s smallest format machine. The larger WarpSPEE3D was released in 2019 and has a build volume of 1 m diameter by 0.7 m. Both machines have a similar design and layout, and were built with a view to the robustness of a manufacturing floor. “Our mission was always to make manufacturing easier, it informs everything we do at SPEE3D,” explains Kennedy. “We are solving the issues that we faced when commercialising our electric motor.” The company’s latest offering, the SPEE3Dcell, was also designed with this mission in mind. The ‘cell’ integrates Cold Spray, heat treatment and machining operations in one product offering. “We have cut out the supply chain headaches. We aren’t going for the fun stuff, we are doing the hard work to attack the volume market,” stated Kennedy. To that end, SPEE3D’s machines are capable of additively manufacturing thirty tonnes of copper per year.

This manufacturing mindset, combined with a strong commercialisation track record and deep foundations in innovation and R&D, makes Kennedy and Camilleri a rare and formidable combination. From the outset, they have had a razor-sharp focus on their value proposition. Where traditional Cold Spray utilises inert gases such as argon or the even more costly helium, SPEE3D systems use only compressed air. Likewise, rather than focus on exotic materials, SPEE3D’s focus has been on the larger markets of aluminium and copper. Furthermore, metal powder from conventional Powder Metallurgy supply chains can be used with Cold Spray, dramatically lowering the material cost when compared with L-PBF technologies. Kennedy and Camilleri have always seen casting as their competitor technology and, throughout their product development, have continued to benchmark against more conventional manufacturing technologies to ensure cost-competitiveness.

A business model that works for mid-size firms

SPEE3D’s key markets are defence, transport, and marine, and it has so far placed systems in the key geographic markets of the US and Germany. The company’s business model has recently moved to a subscription basis, allowing customers the ability to access equipment and services for a monthly rate. Kennedy explains, “We are selling capacity. People don’t want printers; they want to be able to build parts easily.” As the customers that SPEE3D is targeting are primarily mid-size manufacturing businesses, the subscription model is proving to be a popular option.

Indeed, with the groundwork having been done on the robust hardware, software with algorithmic design rules, and intuitive user-interface, SPEE3D machines are designed to be run by an apprentice with minimal training. The robust equipment design means that most of the support and upgrades come via the software. As Kennedy explains, “Fortunately the hardware is very robust; most of the support requirement is for the software, which we can do from anywhere.” This suits the Australian-headquartered business well. The machines themselves have an envelope which makes it possible for them to fit into a small shipping container or Conex box, allowing for ease of deployability in and out of locations.

Success in the defence sector

Deployability is something that the defence sector prizes highly, and SPEE3D’s technology has attracted interest from defence forces in Australia at the highest level. In late 2019, an AU$1.5 million investment in a two year pilot for the Royal Australian Navy was announced. For Captain Chris Eggleton, Patrol Boat System Program Office Director, the opportunity to trial building parts on demand using SPEE3D technology provided unparalleled operational flexibility and accessibility. “We extend the lives of our boats for as long as we can,” he stated, “and when spare parts are no longer stocked or hard to source, that affects the availability of our fleet.”

While the ability to reverse engineer spare parts provides operational flexibility at base, the ultimate aim is to have Additive Manufacturing capability at sea. Having a machine in the field and an inventory of digital files has been a long-held dream of the AM industry and, with SPEE3D technology, this may prove viable in the very near future. The savings to an operation at sea are immense: “It saves logistics headaches, inventory management issues, and very costly delays,” says Eggleton. The robust design of SPEE3D’s systems makes them potentially perfect for expeditionary use – that is, use on the front line.

To that end, researchers in the US have found that battlefield scrap, when reclaimed and atomised via a ‘mobile foundry’, can be successfully cold sprayed to repair parts, or build spare parts at a forward operating base [3]. For Eggleton and the Australian Navy, the vision is to have Cold Spray capability at an ‘organisational’ level. This means deploying a SPEE3D machine onto a large platform, such as a landing helicopter deck, to support a task group operational deployment at sea.

New appointments support international expansion

While success on home soil provides some validation, Kennedy is clear that the key markets for SPEE3D are the US and Europe. Being Australian-based and located at some distance from these markets requires a level of flexibility in business structure. Subsidiaries have been established in both the US and Germany, and key appointments have been made in each region. “We need feet on the ground to support customers in those regions,” says Kennedy. “We are confident that we have hired the best people and now we need to build their teams up so we have a full complement of service and support in both regions.”

The first appointment was Bruce Colter, who officially joined the team in June 2019 as Vice-President of the North American operation. Having come from a background in growing and building technology companies, the attraction to SPEE3D was the challenge of establishing a new AM technology in an unproven market. Colter was also drawn to working for SPEE3D by its strong management team, solid financial backing, and clear strategy, but what particularly impressed him was that SPEE3D had a differentiated and very competitive technology. “I wanted a Moore’s Law for AM and I saw that Byron and Steve were really bending the cost curve,” explains Colter. “With our build speeds we can compete with traditional manufacturing and have the advantage of being able to easily do multiple product iterations.” As someone with an eye on software, it is SPEE3D’s digital offering that he believes really differentiates the company from other providers in the marketplace. As to the culture of the company, Colter says the team at SPEE3D are “the smartest and hardest working team I’ve worked with, but without the ego, which is really refreshing.”

The defence market in the US is the focus for Colter; a market that has been made more accessible through SPEE3D’s alliance with Phillips Corporation, Federal Division, a machine supplier to US federal government departments. Phillips Corporation’s new $1.5 million Additive Manufacturing centre in Baltimore, Maryland, will feature SPEE3D equipment and can supply to defence forces such as the Army, Navy, Marines, Air Force, and Coast Guard. A recent workshop with the US Army uncovered battery terminals as a perfect application for Cold Spray technology, as terminals corrode easily and require frequent replacement in the field. Together with Larry Holmes at the University of Delaware, the team manufactured fit-for-purpose battery terminals in ten minutes. Successful testing demonstrated just how useful Cold Spray technology can be on the frontline.

To support US sales, Colter will be establishing a SPEE3D applications centre where customer benchmarking can be performed and spare parts stocked. “The US has a high level of service expectation; it’s important that we can meet those needs,” says Colter. As such, the US team will be growing by two-to-three people in 2020, with the expectation it will double again the following year.

The next key appointment was Stefan Ritt, who joined the team in January this year as Vice-President of Europe, the Middle East and Africa. Ritt has spent over twenty years working in the AM industry at a global scale and has been instrumental in establishing metal AM technology in new geographical markets. It was the potential for AM to become an everyday, industrial manufacturing tool that drew Ritt to SPEE3D. “The reason AM is not picking up exponentially as was predicted is because it’s not fast enough, cheap enough, or simple enough yet,” says Ritt. “SPEE3D’s technology integrates well into existing supply chains. We use known alloys, have more flexibility in the powder feedstock, and integrate well with known post-processing technologies.” Past roles within the AM industry have made Ritt a regular visitor to Australia, and he is excited to finally work for an Australian company. “I am honoured that SPEE3D are entrusting me to be their representative in Germany,” explains Ritt. “This was a business relationship that grew from a friendship”.

SPEE3D has something of a head start in the European market, having sold a LightSPEE3D machine to FIT Additive Manufacturing Group in 2018. Since that time, the German service bureau has been working to understand the capabilities of Cold Spray and now offers the technology as part of its AM portfolio. In 2019, FIT AG upgraded to the larger WarpSPEE3D. The ability to additively manufacture large-sized copper parts is the biggest selling point for FIT AG and its customers.

Ritt believes that the automotive and industrial markets will be a major focus for SPEE3D’s technology in Europe. The ability to process copper is a boon for electric vehicle manufacture, and the ability to build multi-material components has many applications in the electronics industry. To showcase just how Cold Spray can be used in electric vehicles, Camilleri recently cold sprayed copper water cooling channels directly onto a battery pack busbar for an electric vehicle. Using Cold Spray eliminated the need for a separate, complex water-cooling system, while improving cooling performance and reducing weight. The part was built in twelve minutes and was less expensive than the currently used system.

Similar to its efforts in the US, the initial focus for SPEE3D in Europe will be on educating the market on Cold Spray’s capabilities and building trust in the technology. Demonstration parts such as the busbar and battery terminals are important for conveying the end-use applications where Cold Spray technology makes sense. The team will be generating more case studies as part of its increased focus on market outreach.

Governance: Putting together an experienced board

In addition to building out the team internationally, SPEE3D has also made two significant board appointments. As of early 2020, Grant Anderson and Stefan Beyer have joined Chairman Raoul Mortley to form the full board complement. These appointments were strategic additions for SPEE3D and each brings valuable skill sets that will assist the company to scale.

Anderson was previously CEO of ANCA, an Australian-based Tier 1 supplier of CNC tool and cutter grinders. ANCA has successfully achieved exceptional business growth, with 98% of its revenue being export derived. As Kennedy explains, “We are mirroring ourselves on ANCA; they are a machine tool company that successfully scaled their business from an Australian base.” Accessing Anderson’s experience will be key to SPEE3D’s growth in international markets. “Grant brings an approach to business that we need to scale our operations. He will help guide us to put adequate processes and systems in place,” says Kennedy.

Industry veteran Stephan Beyer is co-founder and former CEO of BigRep, a provider of large-scale polymer AM machines. Kennedy and Camilleri had always admired Beyers’ achievements at BigRep, both in marketing an AM product to a broad audience and also in his significant success in fundraising for BigRep. A focus for the team in 2020 will be to increase the market awareness of Cold Spray technology, and to turn SPEE3D into a global brand. “Stephan is crafting our outreach strategy,” says Kennedy. “We will be focusing more on promoting high-profile user case studies.” Like Anderson, Beyer has also overseen the expansion of a business into international territories, having established a BigRep presence in the US and Singapore.

It is clear from these appointments, both at the board and senior management level, that SPEE3D’s focus into the future is on strong business growth via expansion. Certainly, there is a quiet optimism and confidence that abounds in the SPEE3D Melbourne offices, and anticipation is building for a very promising few years.

Future plans

SPEE3D has already made a few waves in the media, with its latest efforts at Formnext in November 2019 catching the attention of many show goers. The team was keen to impress upon the audience the speed and functionality of Cold Spray technology. This was done by holding a live demonstration in which the SPEE3Dcell was used to produce a 1.012 kg copper sledgehammer in just ten minutes and two seconds, breaking the world record for the fastest ‘live print’ of a metal part. In a great display of showmanship and spectacle, the hammer head was then attached to a handle and a Thor look-alike smashed a record, literally. For the duration of the show, the team additively manufactured sparkless copper hammer heads in just over six minutes apiece, to showcase the scalable capabilities of the SPEE3DCell.

“We printed hundreds of kilos of copper at Formnext. No other exhibitors could say the same for any material,” says Kennedy. SPEE3D will continue to exhibit at AM shows such as Formnext and RAPID, but will also look to move into larger manufacturing shows such as EMO and IMTS in 2020, to access more conventional industry businesses.

While sales and marketing efforts will be ramping up at breakneck pace, that doesn’t mean the company won’t continue to push technical boundaries with its technology. The team is busy working through a programme of getting stainless steel ready for release to SPEE3D customers, adding to its materials suite of aluminium and copper. Customers are driving many other materials development programmes such as an aluminium bronze, and differing high-performance copper alloys. Applications will also drive powder sourcing. “We will be offering a range of powders with varying qualities for different applications,” explains Kennedy. “For example, we will offer a copper material for thermal and electrical applications, and another copper material for mechanical applications.”

Given the importance of the defence and aerospace markets, SPEE3D will also work with customers and suppliers to ensure full traceability through supply chains. It will continue to make its machines as easy to operate as possible, increasing robustness and continuing to remove the manual handling touch points of the operation. With increased digital capability comes the need for data storage and analysis, aiding the traceability that is critical for many customers.

Wrapping up

The foundations for SPEE3D are now truly in place. With solid governance and an experienced and knowledgeable team situated in strategic locations around the globe, 2020 presents a clear runway for business growth. The task ahead is not being underestimated by anyone, least of all Kennedy and Camilleri; however, the duo remain undaunted by the task ahead. The co-founders are confident that their product solves problems that they faced as manufacturers and that many others continue to experience on a daily basis. Their solution may have roots in a hundred-year-old technology, but if anyone can navigate that valley of death, it’s the SPEE3D co-founders, serial entrepreneurs and innovators, Byron Kennedy and Steve Camilleri.

Author

Alex Kingsbury

[email protected]

www.rmit.edu.au

Contact

SPEE3D

5 Wayne Court

Dandenong

Melbourne, Victoria 3175

Australia

[email protected]

Tel: +61 (03) 8759 1464

www.spee3d.com

References

[1] Singh, Harminder & Sidhu, T.S. & Kalsi, Sukhminderbir & Karthikeyan, J.. (2013). Development of Cold Spray from innovation to emerging future coating technology. Journal of the Brazilian Society of Mechanical Sciences and Engineering. 35. 10.1007/s40430-013-0030-1.

[2] Kotoban, D, Grigoriev, S, Okunkova A, Sova, A. (2016). Influence of a shape of single track on deposition efficiency of 316L stainless steel powder in Cold Spray. Surface & Coatings Technology 309 (2017) 951–958

[3] Pepi, M, Zander, N, Gillan, M. (2017). Enabling Expeditionary Battlefield Manufacturing Using Recycled, Reclaimed, and/or Indigenous Materials. RAPID + TCT 2017 Proceedings; 2017 May 8–11; Pittsburgh, PA. p. 1–23.