Aconity3D and Equispheres enter powder distribution agreement

April 6, 2022

Equispheres, Inc, Ottawa, Ontario, Canada, has partnered with metal Additive Manufacturing equipment manufacturer Aconity3D, Herzogenrath, Germany, to distribute Equispheres’ feedstocks to its customers.

“Our material has proven to work well with Aconity3D equipment,” stated Evan Butler-Jones, vice-president – Product & Strategy. “This non-exclusive agreement allows Aconity3D to provide its customers with a powder qualified on Aconity3D printing equipment, that has been shown to achieve higher build rates than traditional aluminium powders when combined with the precision and power of Aconity3D’s equipment.”

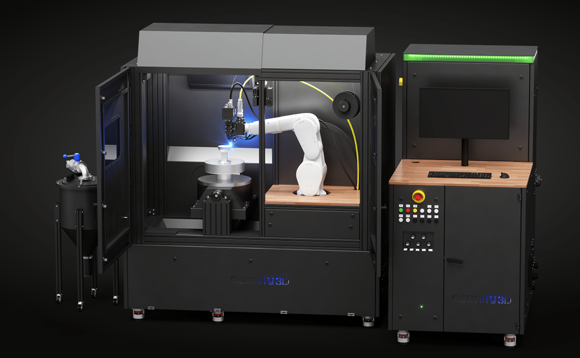

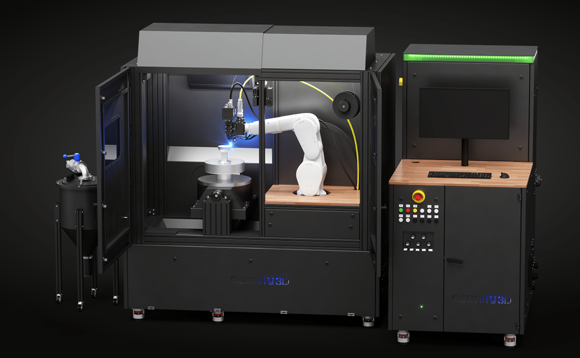

The companies state that they have achieved remarkable production speeds for Additive Manufacturing using the AconityTWO system and Equispheres’ specialised aluminium powders, which have attributes designed specifically for AM. Equispheres powder is used to additively manufacture the AconitySCAN, a key component of the Aconity3D line of Additive Manufacturing machines.

Yves Hagedorn, Managing Director of Aconity3D, commented, “We want our customers to have the best production experience when they utilise our specialised printer equipment. The best way to showcase our devices is to equip them with the best powder.”

According to the companies, the AconitySCAN can be additively manufactured three times faster using Equispheres’ powder (i.e., fifty-three hours reduced to seventeen and a half hours) with no impact on mechanical properties. This dramatic reduction in production time reduces the cost to produce the part by greater than 50%. Such a productivity improvement will reportedly help advance metal Additive Manufacturing in cost-sensitive industries like automotive.

Butler-Jones added, “This is a good example of how a high-precision printer and a high-performance powder can elevate Additive Manufacturing beyond conventional performance. Aconity3D has achieved fantastic results using our Performance line of powders, and now that same manufacturing advantage is available to any company embracing metal 3D printing.”

“Equispheres’ powder can absorb the energy from a powerful one-kilowatt laser without disturbing the stability of the melt pool. This is not attainable with standard aluminium powders, and it becomes more important as the industry embraces newer higher-tech printing equipment.”